Beruflich Dokumente

Kultur Dokumente

GRV01

Hochgeladen von

rcarlos_810803Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

GRV01

Hochgeladen von

rcarlos_810803Copyright:

Verfügbare Formate

GRV01

Compact Precision Grippers Ideal for Medical,

Electronics, Assembly and Robotics

SERIES GRV

ANGULAR GRIPPERS

GRV

5 Million Cycle Life

Flexible Mounting Capability

2

(800) 624-8511

www.phdinc.com/grv

GRV01

Copyright 2013, by PHD, Inc. All Rights Reserved. Printed in the U.S.A.

ORDERING DATA: SERIES GRV ANGULAR GRIPPERS

INDEX:

Ordering Data

Page 2

Benets

Page 3

Dimensions

Pages 4 and 5

Engineering Data

Pages 6 and 7

Options &

Accessories

Pages 8 to 10

Applications

Page 11

Exploded View &

Parts List

Page 12

99

26

GRV - 5 40

DESIGN NO.

5 - Metric

6

10

16

20

6 - x - L11-UB99

OPTIONS (Omit if not required)

MANIFOLD OPTION

L11-UB99 - Manifold option in location 99

MOUNTING OPTION

GR9 - Mounting flange in location 99

FLUID COMPATIBILITY

V1 - Fluoro-elastomer seals and lubricants

LUBRICATION

Y4 - Cleanroom grade lubricant

PRODUCT

mm inch

6 (.236)

10 (.394)

16 (.630)

20 (.787)

BORE SIZE

PART NO.

JC1STP-2

JC1STP-K

SWITCH DESCRIPTION

PNP (Source), Solid State, 12-30 VDC, 2 meter cable

PNP (Source), Solid State, 12-30 VDC, Quick Connect

Includes one switch and installation directions.

TO ORDER SPECIFY:

Product, Design No., Size, Minimum Total Jaw Opening, and any options required.

Small Profile Precision Jaw

Movement Angular Gripper

NOTES:

1) Design No. indicates metric mountings, dowel pin holes, and ports.

2) -V1 option may reduce gripper life. PHD recommends reducing

tooling inertia to 60% of maximum values for optimal life.

STANDARD PORTS

IN LOCATION 26

SERIES JC1SD MAGNETIC SWITCHES

PART NO.

JC1SDP-5

JC1SDP-K

JC1SDN-5

JC1SDN-K

SWITCH DESCRIPTION

PNP (Source), Solid State, 10-30 VDC, 5 meter cable

PNP (Source), Solid State, 10-30 VDC, Quick Connect

NPN (Sink), Solid State, 10-30 VDC, 5 meter cable

NPN (Sink), Solid State, 10-30 VDC, Quick Connect

Includes one switch and installation directions. Series JC1SD

Switches only function on 16 and 20 mm units. Series 6790 Reed

Switches are not applicable.

SERIES JC1ST 2 POSITION TEACHABLE MAGNETIC SWITCHES

OPTION:

MANIFOLD IN

LOCATION 99

MINIMUM TOTAL JAW OPENING

Total Opening Per Bore Size

degrees

PRODUCT

SIZE

40

40

40

40

MINIMUM

OPEN ANGLE

MINIMUM

CLOSED

ANGLE

MINIMUM JAW TRAVEL = MINIMUM OPEN

ANGLE + MINIMUM CLOSED ANGLE

3

(800) 624-8511

www.phdinc.com/grv

GRV01

SERIES GRV ANGULAR GRIPPERS

Major Benets

Series GRV Grippers compact, fexible design provides large moment

capacities and long tooling lengths.

Robust construction ensures long operating life.

Double acting for use in both internal and external gripping applications.

Manifold porting capability allows for nested gripper installation.

Mounting provided from top (with option GR9), bottom, front, and back

of gripper.

Internal speed control is standard, no external speed control required.

Standard with imperial / metric porting, metric mounting threads and

dowel holes for global appeal.

Supplied switch-ready for easy integration of optional magnetic

position sensing switches.

Magnetic sensing two-teachable position switch available to simplify

set-up and integration.

Standard four working day delivery reduces integration time.

Industry/Process Uses

Medical device manufacturing

Semiconductor manufacturing

Laboratory processing applications

Clamping and fxturing during assembly operations

Incorporation into space restricted processing and

manufacturing equipment

slim design allows stacking of

grippers in a confned area

integrated switch slots require

no additional bracketry

standard mounting provides

fexibility with back, bottom and

front through mounting. GR9

option provides top through

mounting

hardcoated aluminum body with

precision machined jaw slot

delivers robust, wear resistant jaw

support and rod guidance

standard unit includes magnet

for use with two-position teachable

or single position switches

large cross-section seals

provide long-life with low wear

simple mounting of tooling

with two dowel pins and a

single screw per jaw

universal port threads on

sizes 16 & 20 or universal

fttings installed on sizes 6 &

10 simplify installation

manifold capable for

increased mounting fexibility

5 Million Cycle Life in a Robust,

Compact Design

Flexible Mounting Capability

Slim design allows multiple grippers in conned areas.

4

(800) 624-8511

www.phdinc.com/grv

GRV01

DIMENSIONS: SERIES GRV ANGULAR GRIPPERS

2X K6 THD

2X K7 [H9]

DOWEL PIN HOLE

2X K1 THD

2X K2 [H9]

DOWEL PIN HOLE

1

2

3

4

5

6

2X THRU HOLE FOR K12

MOUNTING FASTENER

2X P1 PORT

OPEN PORT CLOSE PORT

2X J1 THD

BARB FITTINGS

SUPPLIED WITH

SIZE 6 & 10.

TUBE ID .125 [3mm]

P7

MAX FITTING

SEE MANIFOLD

OPTION L11-UB99

4X J2 [H9]

DOWEL PIN HOLE

THD TO END

OF TOOLING

J3

J4

P2

P3

P4

P5

B5

J7

J8

J3/2

J5

K8

K9

B2

K11

B3

B1

K5

K3

MOUNTING THDS

K4 DOWEL HOLES

J6

K14

P6

B4

K16

K10

J9 MAX

K15

J10

Y

Y

K17

K18

10

40

K13

SECTION Y-Y

5

(800) 624-8511

www.phdinc.com/grv

GRV01

DIMENSIONS: SERIES GRV ANGULAR GRIPPERS

LETTER DIM

MODEL NUMBER

GRV-5-6 x 40 GRV-5-10 x 40 GRV-5-16 x 40 GRV-5-20 x 40

mm mm mm mm

TOTAL JAW TRAVEL 50 50 50 50

FULL OPEN 40 40 40 40

FULL CLOSED -10 -10 -10 -10

B1 30.0 34.0 43.0 51.0

B2 38.0 46.0

B3 27.9 31.8

B4 36.7 41.9 49.2 55.1

B5 10.0 16.0 22.0 28.0

J1 M1.6 x 0.35 M2.5 x 0.45 M4 x 0.7 M5 x 0.8

J2 1.5 2.0 2.5 3.0

J3 5.00 7.00 10.00 12.00

J4 41.5 49.0 59.2 67.3

J5 3.0 4.5 7.0 8.5

J6 5.0 6.0 6.5 8.0

J7 4.0 6.0 8.0 9.5

J8 45.5 55.0 67.2 76.8

J9 MAX 3.8 5.3 7.1 8.4

J10 8.2 9.6 13.9 15.1

K1 M2.5 x 0.45 x 5 DP M3 x 0.5 x 6 DP M3 x 0.5 x 6.5 DP M4 x 0.7 x 8 DP

K2 2.0 x 3.0 DP 2.0 x 3.0 DP 3.0 x 4.0 DP 4.0 x 4.0 DP

K3 24.0 25.0 32.0 36.0

K4 17.50 25.00 32.00 36.00

K5 4.5 10.0 15.0 19.0

K6 M3 x 0.5 x 6 DP M3 x 0.5 x 6.5 DP M4 x 0.7 x 8 DP M5 x 0.8 x 10 DP

K7 2.0 x 3.0 DP 2.0 x 3.0 DP 3.0 x 4.0 DP 4.0 x 4.0 DP

K8 13.00 14.00 20.00 22.00

K9 24.0 27.0 30.0 36.0

K10 23.5 28.0 37.7 41.3

K11 7.5 8.0 8.0 9.0

K12 M2.5 M2.5 M3 M4

K13 7.3 12.9 18.0 23.5

K14 24.0 27.0 30.0 36.0

K15 31.0 36.0 45.7 50.3

K16 10.5 13.0 13.5 17.0

K17 19.0 22.0 30.0 35.0

K18 16.0 21.0 29.0 33.0

P1 M3 x 0.5 x 3 DP M3 x 0.5 x 3 DP M5 x 0.8 x 4.5 DP M5 x 0.8 x 5 DP

P2 1.5 3.0 4.0 5.0

P3 1.0 .5 3.5 4.0

P4 6.5 6.0 7.5 9.0

P5 16.1 19.2 19.6 24.8

P6 24.7 26.7 N/A N/A

P7 6.5 9.5 13.0 13.0

NOTES:

1) ALL DIMENSIONS ARE REFERENCE ONLY UNLESS SPECIFICALLY TOLERANCED

2) FULL OPEN REFLECTS LEAST POSSIBLE OPEN ANGLE. FULL CLOSED REFLECTS LARGEST POSSIBLE CLOSED ANGLE.

3) CIRCLED NUMBERS INDICATE POSITIONS

4) DESIGNATED IS CENTERLINE OF UNIT

5) DOWEL PINS OR SPRING PINS OF THE SAME DIAMETER ARE RECOMMENDED. THIS PROVIDES A SMALL PRESS TO

SLIGHT SLIP FIT. PHD RECOMMENDS THE USE OF ANTI-SEIZE COMPOUNDS DURING ASSEMBLY.

6

(800) 624-8511

www.phdinc.com/grv

GRV01

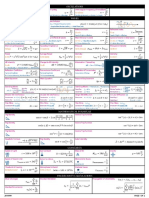

SPECIFICATIONS SERIES GRV ANGULAR GRIPPER

OPERATING AIR PRESSURE 1 bar min. - 8.3 bar max. [15 psi min. - 120 psi max.]

OPERATING TEMPERATURE -28C to +82C [-20F to 180F]

GRIP REPEATABILITY 0.025 mm [ 0.001 inch] of original position

RATED LIFE 5 million cycles

LUBRICATION Factory lubricated for rated life

SIZE

MINIMUM

TOTAL JAW

OPENING

ANGLE

GRIP FORCE FACTOR

INTERNAL AND EXTERNAL

GRIPPER

WEIGHT

DISPLACEMENT

CLOSE OR

OPEN TIME

at 6 bar

[87 psi]

MAXIMUM

TOOLING

LENGTH

MAXIMUM

TOOLING INERTIA

METRIC IMPERIAL kg lb cm

3

in

3

sec mm in kg-mm

2

lb-in

2

6 40 13.7 0.0078 0.034 0.075 0.12 0.008 0.025 30 1.181 22.1 0.0753

10 40 46 0.026 0.070 0.155 0.39 0.024 0.030 40 1.575 66.8 0.228

16 40 179 0.102 0.141 0.311 1.31 0.080 0.040 60 2.362 255 0.870

20 40 320 0.183 0.244 0.538 3.18 0.194 0.050 80 3.150 519 1.770

lb SIZE

6

10

16

20

N

AXIAL FORCE

Fa

MAX. INDIVIDUAL MOMENTS

Nm

0.23

0.9

2.8

5.1

My

in-lb

1.20

5.0

20

30

Nm

0.14

0.6

2.3

3.4

Mz

3

10

20

30

13

44

89

133

in-lb

2.00

8.0

25

45

My

Mz

Fa

My

ENGINEERING DATA: SERIES GRV ANGULAR GRIPPERS

Fa: Total for both jaws

My: Maximum allowable moment per jaw, relative to the pivot pin

Mz: Maximum allowable moment per jaw, relative to the pivot pin

When calculating the value for Fa, include the tooling weight, part

weight, external forces, and accelerations. When calculating values

for My and Mz, include the grip force per jaw, tooling weight, part

weight, external forces, and accelerations as applicable.

RECOMMENDATIONS

Design tooling so that the grip point is as close to the gripper

surfaces as possible. The grip force factor (Gf) values given in the

table above apply at 0 jaw angle only.

The maximum load that grippers can handle will vary based

on: size of the part being picked up, shape of the part, texture of the

part, speed at which the part is transferred, working pressure, shape

of the fngers, etc.

7

(800) 624-8511

www.phdinc.com/grv

GRV01

ENGINEERING DATA: SERIES GRV ANGULAR GRIPPERS

GRIP FORCE

Total gripping force relative to tooling length is shown below

at 6 bar [87 psi] pressure. Grip force per jaw equals the total grip

force divided by two. The graphs also indicate the maximum tooling

length for each gripper size.

GRV 10 GRV 6

GRV 6 & 10 Grip Force at 6 bar [87 psi] with 0 jaw angle

GRV 16 & 20 Grip Force at 6 bar [87 psi] with 0 jaw angle

T

o

t

a

l

G

r

i

p

F

o

r

c

e

,

N

[

l

b

]

T

o

t

a

l

G

r

i

p

F

o

r

c

e

,

N

[

l

b

]

35.00

[7.87]

30.00

[6.74]

25.00

[5.62]

20.00

[4.50]

15.00

[3.37]

10.00

[2.25]

5.00

[1.12]

0.00

160.0

[36.0]

140.0

[31.5]

120.0

[27.0]

100.0

[22.5]

80.0

[18.0]

60.0

[13.5]

40.0

[9.00]

20.0

[4.50]

0

5 10 15 20 25 30 35 40

[0.197] [0.394] [0.591] [0.787] [0.984] [1.181] [1.378] [1.575]

Tooling Length From Pivot Pin, mm [in]

Tooling Length From Pivot Pin, mm [in]

10 20 30 40 50 60 70 80

[0.394] [0.787] [1.181] [1.575] [1.968] [2.362] [2.756] [3.150]

Starts at J10 dimension. Refer to page 4.

GRV 20 GRV 16

Starts at J10 dimension. Refer to page 4.

GRIP FORCE CALCULATION EQUATIONS:

IMPERIAL:

Total Grip Force [lb] =

Pressure (psi) x Gf

Distance from Jaw Pivot (in)

METRIC:

Total Grip Force [N] =

Pressure (bar) x Gf

Distance from Jaw Pivot (mm)

8

(800) 624-8511

www.phdinc.com/grv

GRV01

OPTIONS: SERIES GRV ANGULAR GRIPPERS

L11-UB99

With this option the gripper is confgured for manifold

mounting on the indicated mounting face. The standard ports

are plugged. O-ring seals are provided for mounting between the

gripper and the manifold.

The manifold port option is also available in kit form. See the

Manifold Conversion Kits chart.

MANIFOLD PORTS

CLOSE PORT

OPEN PORT

P9

P10

P8 OPTIONAL

FLANGE

MOUNTING

MANIFOLD PORTING DIMENSIONS

For customer use (dimensions required

on customer mounting surface)

P13 P11

P12

O-RING P4

CUSTOMER

MOUNTING

SURFACE

6

3

Manifold kit includes seals

REPLACEMENT

MANIFOLD SEAL KITS

SIZE

6

10

16

20

KIT NUMBER

82013

82013

82013

82013

LETTER

DIM

P8

P9

P10

P11

P12

P13

P4 O-RING*

mm

5.75

2.5

2.5

1.2

.8

4.0

GRV-5-6x40

2 mm x 1 mm

MODEL NUMBER

GRV-5-10x40

2 mm x 1 mm

mm

7.75

.5

4.5

1.2

.8

4.0

GRV-5-16x40

2 mm x 1 mm

mm

11.5

3.0

3.0

1.2

.8

4.0

GRV-5-20x40

2 mm x 1 mm

mm

14.0

3.5

3.5

1.2

.8

4.0

NOTES:

1) ALL DIMENSIONS ARE REFERENCE ONLY UNLESS SPECIFICALLY TOLERANCED

2) CIRCLED NUMBERS INDICATE POSITIONS

3) *I.D. x CROSS-SECTION

1

3

4 2

MANIFOLD

CONVERSION KITS

SIZE

6

10

16

20

KIT NUMBER

82014-06-5

82014-10-5

82014-16-5

82014-20-5

SERIES GRV

GRIPPER OR

FLANGE

Manifold kit includes seals, port

plugs, and installation directions

GR9

The GR9 option adds a fange with thru holes to the bottom of

the gripper allowing for top mounting. Dowel pin holes in the fange

are clearance to allow dowel pins to install in the body for accurate

mounting. See chart for recommended dowel pin lengths.

The GR9 option is sealed between the body and the fange to

allow use of the L11-UB99 manifold option.

The GR9 fange is also available in kit form. See Flange Mounting

Kit chart.

BOTTOM MOUNTING FLANGE

1

5

4

3

2

CLOSE PORT

OPEN PORT

2X F8 [H9]

DOWEL PIN HOLE

(HOLES IN FLANGE

ARE CLEARANCE)

F2

F4

F1

F5

F7

LETTER

DIM

F1

F2

F3

F4

F5

F6

F7

F8

F9

mm

42.0

10.0

5.0

37.0

4.5

17.5

8.0

MODEL NUMBER

mm

47.0

16.0

5.0

41.0

10.0

25.0

8.0

mm

52.0

22.0

6.0

45.0

15.0

32.0

10.0

mm

63.5

28.0

6.0

55.0

19.0

36.0

10.0

GRV-5-6x40

M2.5

2.0 mm x 3.0 mm DP

GRV-5-10x40

M3

2.0 mm x 3.0 mm DP

GRV-5-16x40

M3

3.0 mm x 4.0 mm DP

GRV-5-20x40

M4

4.0 mm x 4.0 mm DP

2X THRU

HOLE FOR F6

MOUNTING

FASTENER

F9 DOWEL PIN

HOLE DEPTH

(HOLES IN

FLANGE ARE

CLEARANCE)

F3

FLANGE MOUNTING KIT

SIZE

6

10

16

20

KIT NUMBER

81867-06-5

81867-10-5

81867-16-5

81867-20-5

Kit includes: flange,

manifold seals, assembly

fasteners, and installation

directions

NOTES:

1) ALL DIMENSIONS ARE REFERENCE ONLY UNLESS SPECIFICALLY TOLERANCED

2) GR9 OPTION INCLUDES SEALS BETWEEN BODY AND FLANGE

Y4 V1

CLEANROOM GRADE

LUBRICANT

FLUORO-ELASTOMER

SEALS AND LUBRICANTS

Cleanroom grade lubricant replaces all standard lubricants. Fluoro-elastomer seals and lubricants are available to achieve seal

compatibility with certain fuids. Seal compatibility should be checked

with the fuid manufacturer for proper application. PHD recommends

reducing tooling inertia to 60% of maximum values for optimal life.

9

(800) 624-8511

www.phdinc.com/grv

GRV01

ACCESSORIES: SERIES GRV ANGULAR GRIPPERS

This switch provides the ability to identify two separately

programmable jaw positions with a single switch. Programmable

capability means no fne-tuning. With switch properly aligned,

place jaws in desired position and program. Solid-state sensing

technology provides a highly reliable switch. Elliptical housing allows

for easy drop-in installation on sizes 16 and 20 only. Includes LED

indicators for convenient means of positioning and programming.

Available with cable or 8 mm threaded Quick Connect.

SERIES JC1ST TWO POSITION

TEACHABLE MAGNETIC SWITCH

ALIGN SYMBOL ON

SWITCH AND BODY

FOR OPTIMUM

PERFORMANCE

ON SIZE 6, SWITCH

SLOT IS AVAILABLE ON

THIS SIDE ONLY

SW2

SW1

SW3 MIN

(FOR CLEARANCE)

PART NO.

JC1STP-2

JC1STP-K

SWITCH DESCRIPTION

PNP (Source), Solid State, 12-30 VDC, 2 meter cable

PNP (Source), Solid State, 12-30 VDC, Quick Connect

Includes one switch and installation directions

1

5

6

ONE SWITCH FOR 2

POSITION SENSING

(SIZE 6 ALLOWS

ONE SWITCH ONLY)

SW4

3

SIZE 6 AND 10 SWITCHES ARE

INSTALLED AT AN ANGLE AS

SHOWN. OFFSET SWITCH SLOTS

CONTROL THE ROTATION.

SWITCHES SLIDE IN FROM END.

MATCHING CORDSET

PART NO.

81284-1-001

DESCRIPTION

M8, 4 pin, Straight Female Connector, 5 meter cable

INSTALLATION WRENCH

SERIES JC1ST TWO POSITION TEACHABLE

MAGNETIC SWITCHES

HEX WRENCH

SUPPLIED WITH

SENSOR

GRV-5-6x40 GRV-5-10x40 GRV-5-16x40 GRV-5-20x40 LETTER

DIM

SW1

SW2

SW3

SW4

mm

2.5

5.8

4.3

2.2

MODEL NUMBER

mm

6.9

5.4

4.3

mm

9.1

7.7

4.3

mm

12.1

8.0

4.3

NOTE: ALL DIMENSIONS ARE REFERENCE ONLY UNLESS SPECIFICALLY

TOLERANCED

10

(800) 624-8511

www.phdinc.com/grv

GRV01

ACCESSORIES: SERIES GRV ANGULAR GRIPPERS

This switch provides the ability to identify a single jaw position.

Solid-state sensing technology provides a highly reliable switch.

Elliptical housing allows for easy drop-in installation. Includes

LED indicator for convenient means of positioning. Available with

PNP or NPN output. Available with cable or 8 mm threaded Quick

Connect.

NOTE: Series JC1SD Switches only function on 16 and 20 mm

units. Series 6790 Reed Switches are not applicable.

SERIES JC1SD MAGNETIC SWITCH

SERIES JC1SD MAGNETIC SWITCHES

PART NO.

JC1SDP-5

JC1SDP-K

JC1SDN-5

JC1SDN-K

SWITCH DESCRIPTION

PNP (Source), Solid State, 10-30 VDC, 5 meter cable

PNP (Source), Solid State, 10-30 VDC, Quick Connect

NPN (Sink), Solid State, 10-30 VDC, 5 meter cable

NPN (Sink), Solid State, 10-30 VDC, Quick Connect

Includes one switch and installation directions

CLOSED

POSITION

SWITCH

OPEN POSITION

SWITCH

HS2

HS1

HS3 MIN

(FOR CLEARANCE)

HS4

1

3

4 2

5

6

MATCHING CORDSET

PART NO.

63549-02

63549-05

DESCRIPTION

M8, 3 pin, Straight Female Connector, 2 meter cable

M8, 3 pin, Straight Female Connector, 5 meter cable

GRV-5-16x40 GRV-5-20x40 LETTER

DIM

HS1

HS2

HS3

HS4

mm

9.1

7.7

4.3

14.7

MODEL NUMBER

mm

12.1

8.0

4.3

14.2

NOTE: ALL DIMENSIONS ARE REFERENCE

ONLY UNLESS SPECIFICALLY TOLERANCED

11

(800) 624-8511

www.phdinc.com/grv

GRV01

Series GRV Gripper

Series GRV Gripper

Series SFP Slide

Series ESK Slide

Series 160 Escapement

Intermediate part nest

Series 2000-8000

Rotary Actuator

Series SFP

Powered Slide

Series STP Powered Slide

Series 160 Escapement

Series GRV Gripper

APPLICATIONS: SERIES GRV ANGULAR GRIPPERS

A Series GRV gripper along with two

powered slides are used in this multi-

function system. This system automates

the assembly and quality control of syringes

used in medical industry systems.

Two Series GRV grippers, two powered

slides, a rotary actuator, and an escapement

are used to check thread length in this

quality control application. The parts are

escaped from a conveyor, then placed into

a fxture. Once part checking is complete, a

pick-and-place device separates the parts as

either good or bad.

5M-I 4/13 8779

12

GRV01

EXPLODED VIEW & PARTS LIST: SERIES GRV GRIPPERS

1

2

3

4

5

6

7

8

9

10

11

12

13

14

7

15

15

16

20 21

22

19

18

STANDARD

UNIT

L11-UB99

OPTION

GR9 MOUNTING

FLANGE OPTION

KEY DESCRIPTION PART NUMBER

1 Finished Body Full unit description followed by -H2410

2 Rod Seal Part of seal kit -H9000

3 Rod Seal Retainer Part of seal kit -H9000

4 Driver Full unit description followed by -H5610

5 Shock Pad Full unit description followed by -H1800

6 Piston & Rod Assembly Full unit description followed by -H1000

7 Jaw Full unit description followed by -H2600

8 Dowel Pin (Jaw Pivot) Full unit description followed by -H2621

9 Piston Seal Part of seal kit -H9000

10 Bore Plug Full unit description followed by -H3100

11 Bore Plug Seal Part of seal kit -H9000

12 Retaining Ring Full unit description followed by -H7101,

or part of seal kit -H9000

13 Set Screw (Manifold Plug)

14 Jaw Slot Cover

15 Metric Barb Washer Part of ftting kit -H2800

16 Metric Fitting Barb Part of ftting kit -H2800

18 Set Screw (Port Plug) Part of conversion kit -H9091

19 O-Ring Seal (Manifold) Part of conversion kit -H9091,

or part of seal kit -H9090

20 Mounting Flange Part of fange kit -H9055

21 Mounting Flange To Body

SFHCS

Part of fange kit -H9055

22 O-Ring Seal (Mounting Flange) Part of fange kit -H9055,

or part of seal kit -H9090

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Mathematical Reasoning - Writing and Proof Version 2.1Dokument608 SeitenMathematical Reasoning - Writing and Proof Version 2.1gammasync100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Ultimate Bearing Capacity of Foundation On Clays - MeyerhofDokument3 SeitenUltimate Bearing Capacity of Foundation On Clays - Meyerhofsreekx0073916100% (1)

- UG-NX TutorialDokument235 SeitenUG-NX Tutorialesrayansenkeliat50% (2)

- Cat d7 3t Operatons MtceDokument98 SeitenCat d7 3t Operatons MtceMilagros Pullchs AriasNoch keine Bewertungen

- Fatigue ANalysis SN CurveDokument11 SeitenFatigue ANalysis SN CurveM Rafiq RajaNoch keine Bewertungen

- Everything About Conveyor BeltsDokument30 SeitenEverything About Conveyor BeltsJatin DarveNoch keine Bewertungen

- 1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapDokument3 Seiten1 1 To Agartala (India) To Akhura (Bangladesh) : Dimension Details of Pile CapNilay GandhiNoch keine Bewertungen

- Wind Load NSCP 2010 SampleDokument5 SeitenWind Load NSCP 2010 SampleRichard Tagle100% (1)

- Unit Step Functions and Laplace Transforms ExplainedDokument4 SeitenUnit Step Functions and Laplace Transforms Explainedrcarlos_810803Noch keine Bewertungen

- Calculos Caja Circa PDFDokument1 SeiteCalculos Caja Circa PDFrcarlos_810803Noch keine Bewertungen

- Jueves30 01Dokument29 SeitenJueves30 01rcarlos_810803Noch keine Bewertungen

- 3987 386 Interior3dDokument1 Seite3987 386 Interior3drcarlos_810803Noch keine Bewertungen

- CH 05Dokument62 SeitenCH 05rcarlos_810803Noch keine Bewertungen

- CH 03Dokument96 SeitenCH 03Yang Ching HianNoch keine Bewertungen

- Ama2008 2Dokument97 SeitenAma2008 2Associate Professor Dr. Said Elshahat AbdallahNoch keine Bewertungen

- 7-1 Citrus ProcessingDokument20 Seiten7-1 Citrus ProcessingArth PatelNoch keine Bewertungen

- Ejercicio 4 Examen FinalDokument2 SeitenEjercicio 4 Examen Finalrcarlos_810803Noch keine Bewertungen

- ANSYS 10.0 Workbench Tutorial - Exercise 5, Assemblies and ContactDokument36 SeitenANSYS 10.0 Workbench Tutorial - Exercise 5, Assemblies and Contactrcarlos_810803Noch keine Bewertungen

- Stress Strain CurveDokument2 SeitenStress Strain Curvercarlos_810803Noch keine Bewertungen

- Subspace SDokument2 SeitenSubspace Srcarlos_810803Noch keine Bewertungen

- N 0352084089Dokument6 SeitenN 0352084089rcarlos_810803Noch keine Bewertungen

- Classpad 300Dokument670 SeitenClasspad 300rcarlos_810803Noch keine Bewertungen

- AreccoDokument220 SeitenAreccorcarlos_810803Noch keine Bewertungen

- Ex 8 Midsurface ModellingDokument22 SeitenEx 8 Midsurface Modellingrcarlos_810803Noch keine Bewertungen

- Sample Solutions For System DynamicsDokument7 SeitenSample Solutions For System DynamicsameershamiehNoch keine Bewertungen

- Pneumadyne Full Line Catalog 2400Dokument240 SeitenPneumadyne Full Line Catalog 2400rcarlos_810803Noch keine Bewertungen

- CATIA For Industrial EquipmentDokument4 SeitenCATIA For Industrial Equipmentrcarlos_810803Noch keine Bewertungen

- Machine VisionDokument24 SeitenMachine Visionrcarlos_810803Noch keine Bewertungen

- Lean NOx Trap StudyDokument38 SeitenLean NOx Trap Studydhruv royNoch keine Bewertungen

- Effects of Shear Box Size and Silt Content on Strength of Silty SandsDokument7 SeitenEffects of Shear Box Size and Silt Content on Strength of Silty SandsJavier MtNoch keine Bewertungen

- Press q3 Ass 2Dokument5 SeitenPress q3 Ass 2Arslan RaoNoch keine Bewertungen

- DY-560-760G ManualDokument66 SeitenDY-560-760G ManualJose SoMarNoch keine Bewertungen

- Mechanical Engineer Interview Question ListDokument14 SeitenMechanical Engineer Interview Question ListRj SakthiNoch keine Bewertungen

- Allison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogDokument6 SeitenAllison MT (B) 640, 643, 650, 653 Series On-Highway Transmissions Parts CatalogMarcos LunaNoch keine Bewertungen

- Cypecad Vs Etabs - En1Dokument37 SeitenCypecad Vs Etabs - En1dskumar49Noch keine Bewertungen

- r7310306 Heat TransferDokument4 Seitenr7310306 Heat TransfersivabharathamurthyNoch keine Bewertungen

- CHM 101 Lecture Note-Gas LawsDokument11 SeitenCHM 101 Lecture Note-Gas LawsMichael DanielsNoch keine Bewertungen

- Bellow Installation Guideline For Expansion BellowsDokument5 SeitenBellow Installation Guideline For Expansion BellowsPravin SatheNoch keine Bewertungen

- Soldier Pile and Lagging Caltan 1990 Tedds CalcDokument2 SeitenSoldier Pile and Lagging Caltan 1990 Tedds CalcRJSQNoch keine Bewertungen

- PHYS 369 Formula Sheet CombinedDokument4 SeitenPHYS 369 Formula Sheet Combineddarro d92Noch keine Bewertungen

- Inst Headers Install TitianDokument3 SeitenInst Headers Install TitianhuntersgreenNoch keine Bewertungen

- Kinetic and Potential Energy: VocabularyDokument5 SeitenKinetic and Potential Energy: Vocabularykaren cotingjoNoch keine Bewertungen

- Digital Valve Controler DVC6200Dokument48 SeitenDigital Valve Controler DVC6200kkobaseNoch keine Bewertungen

- Instruction Guide Combiflex Crimping ToolDokument2 SeitenInstruction Guide Combiflex Crimping ToolAE,110 KV KanjikodeNoch keine Bewertungen

- CS4002 U-Deck Recommended SparesDokument5 SeitenCS4002 U-Deck Recommended SparesedwinNoch keine Bewertungen

- 323D2L Hyd UENR3910UENR3910-03 SISDokument2 Seiten323D2L Hyd UENR3910UENR3910-03 SISMaury Barrales100% (1)

- The Linea - Heavy Duty Cafe Espresso MachineDokument112 SeitenThe Linea - Heavy Duty Cafe Espresso Machinevicky wicaksanaNoch keine Bewertungen

- Chapter 6 Theory of Flexure PDFDokument88 SeitenChapter 6 Theory of Flexure PDFcoded coderNoch keine Bewertungen

- 8FG D CE049!20!0608 Multi Function DisplayDokument73 Seiten8FG D CE049!20!0608 Multi Function DisplayDuong Van HoanNoch keine Bewertungen

- Prospectus 2019 PDFDokument178 SeitenProspectus 2019 PDFPratik GuptaNoch keine Bewertungen

- Tcont900 InstallerDokument24 SeitenTcont900 Installerapi-279886039100% (2)

- MDL DBL021e PDFDokument4 SeitenMDL DBL021e PDFCesarNoch keine Bewertungen

- Gas Over Oil Actuators GoDokument32 SeitenGas Over Oil Actuators Goaugusto sebastianNoch keine Bewertungen