Beruflich Dokumente

Kultur Dokumente

Pinion Backlash Measurement 100714

Hochgeladen von

Anand Kesarkar0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

393 Ansichten3 SeitenThis document discusses backlash in gears and gear trains. Backlash is the amount of clearance between mated gear teeth and allows for lubrication, manufacturing errors, load deflection, and thermal expansion. Factors like profile, pitch, and center distance errors affect backlash. In a gear train, backlash is cumulative as each gear introduces some slack. Backlash is properly measured perpendicular to the tooth surface at the pitch circle with a dial indicator. The document describes a case study where backlash was incorrectly measured at the pinion shaft end rather than the tooth, resulting in a reading that was too low. When measured correctly at the tooth, the backlash was within specifications.

Originalbeschreibung:

Pinion Backlash Measurement

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document discusses backlash in gears and gear trains. Backlash is the amount of clearance between mated gear teeth and allows for lubrication, manufacturing errors, load deflection, and thermal expansion. Factors like profile, pitch, and center distance errors affect backlash. In a gear train, backlash is cumulative as each gear introduces some slack. Backlash is properly measured perpendicular to the tooth surface at the pitch circle with a dial indicator. The document describes a case study where backlash was incorrectly measured at the pinion shaft end rather than the tooth, resulting in a reading that was too low. When measured correctly at the tooth, the backlash was within specifications.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

393 Ansichten3 SeitenPinion Backlash Measurement 100714

Hochgeladen von

Anand KesarkarThis document discusses backlash in gears and gear trains. Backlash is the amount of clearance between mated gear teeth and allows for lubrication, manufacturing errors, load deflection, and thermal expansion. Factors like profile, pitch, and center distance errors affect backlash. In a gear train, backlash is cumulative as each gear introduces some slack. Backlash is properly measured perpendicular to the tooth surface at the pitch circle with a dial indicator. The document describes a case study where backlash was incorrectly measured at the pinion shaft end rather than the tooth, resulting in a reading that was too low. When measured correctly at the tooth, the backlash was within specifications.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

L.

Pradhapan, TPL Pune

Backlash measurement in Gears/ Gear Trains

What is Backlash?

The amount of clearance between mated gear teeth. It can be seen when the direction of

movement is reversed and the slack or lost motion is taken up before the reversal of motion is

complete.

Why back lash is required?

Minimum amount of backlash is maintained to prevent jamming. Reasons for the presence of

backlash include allowing for lubrication, manufacturing errors, deflection under load, and thermal

expansion.

What are the actors affecting backlash?

Factors affecting the amount backlash required in a gear train include errors in profile, pitch,

tooth thickness, helix angle and center distance, and run-out. The greater the accuracy the smaller

the backlash needed. Backlash is most commonly created by cutting the teeth deeper into the gears

than the ideal depth. Another way of introducing backlash is by increasing the center distances

between the gears.

L. Pradhapan, TPL Pune

Backlash pertaining to gear train:

In a gear train, backlash is cumulative. When a gear-train is reversed the driving gear is turned a

short distance, equal to the total of all the backlashes, before the final driven gear begins to rotate.

How backlash is measured?

Backlash is measured normal (perpendicular) to the tooth surface on pitch circle with the help of

a dial indicator as shown in below. Backlash is measured at pinion while holding the gear rigid.

Case Study: Measurement of backlash of pinion of gearbox used in Sugar Industry.

Initial information received from Client: Pinion was checked by client at their premises and backlash

was found 0.19mm against requirement of 0.4 to 0.66mm. Since the backlash was less, pinion was

kept unused for want of clarification.

Investigation by TPL on 08.07.14 at client premises and the observations are as below

The method followed by client for the measurement of backlash was wrong. They checked as

follows.

Pinion with shaft assembly Backlash measured on pinion shaft end

L. Pradhapan, TPL Pune

Backlash was measured at pinion shaft end (as shown in above figure) instead of at pinion gear

tooth, which resulted in backlash of 0.19mm and the pinion was kept unused.

Subsequently, the backlash was measured at pinion normal to gear tooth and observed backlash

was 0.59mm which was within acceptable limit of 0.4 to 0.66mm. Method of measurement is shown

below.

Backlash measurement at pinion gear tooth

Conclusion: Even though angle of deflection is same, backlash varied due to variation in pinion pitch

circle diameter and shaft diameter. Since pinion shaft diameter is less in this case compared to pitch

circle diameter of pinion (shown in below figure), backlash measured at shaft end is less compared

to backlash measured at pinion tooth. Hence, backlash measurement of pinion at correct location is

very important and measurement at wrong location resulted in almost rejection of acceptable

pinion.

Backlash measured at pinion tooth

(cord length is more)

Backlash measured at pinion shaft

end (cord length is less)

Diameter of pinion shaft

Pitch circle diameter of pinion

Das könnte Ihnen auch gefallen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Lufkin GearDokument207 SeitenLufkin GearStenlyn LayaNoch keine Bewertungen

- How To Inspect A GearboxDokument12 SeitenHow To Inspect A Gearboxivan wijayaNoch keine Bewertungen

- How To Analyzie Gear FailuresDokument6 SeitenHow To Analyzie Gear FailuresMinhQuân100% (1)

- Girth Gear Inspection PDFDokument2 SeitenGirth Gear Inspection PDFMohammed g100% (1)

- 7300en PDFDokument9 Seiten7300en PDFWaris La Joi WakatobiNoch keine Bewertungen

- Overhauling TP800C Gbox ME-810cDokument10 SeitenOverhauling TP800C Gbox ME-810cwasay0% (1)

- Ultrasonic Inspection of Babbitt Bearing LinersDokument4 SeitenUltrasonic Inspection of Babbitt Bearing LinersEmily BrockNoch keine Bewertungen

- Girth Gear Wear PDFDokument6 SeitenGirth Gear Wear PDFRajib DuttaNoch keine Bewertungen

- Fallas en CojinetesDokument2 SeitenFallas en CojinetesAlfredo OrellanaNoch keine Bewertungen

- How Backlash Affects GearsDokument15 SeitenHow Backlash Affects GearsMohammad Ali TaghdiriNoch keine Bewertungen

- Journal Bearing ClearanceDokument2 SeitenJournal Bearing ClearanceLookman FajarNoch keine Bewertungen

- Gear Box InspDokument19 SeitenGear Box InspdombipinNoch keine Bewertungen

- Exam Basic Reciprocating Compressor AnalysisDokument18 SeitenExam Basic Reciprocating Compressor Analysisjuan lesmes100% (1)

- 14 Shaft Alignment 이해와 절차Dokument25 Seiten14 Shaft Alignment 이해와 절차Rini Dwi AstutiNoch keine Bewertungen

- Bearing FailureDokument5 SeitenBearing Failuremechmaster4uNoch keine Bewertungen

- ROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enDokument156 SeitenROTALIGN Ultra Is Shaft Handbook Edition 1 DOC 40 200-06-12 Web enCeliocp PinheiroNoch keine Bewertungen

- Falk Gear Couplings, All Types Failure Analysis White PaperDokument7 SeitenFalk Gear Couplings, All Types Failure Analysis White PaperNasir InceNoch keine Bewertungen

- Third Generation Air Winch SeriesDokument6 SeitenThird Generation Air Winch Seriesvkannan07666Noch keine Bewertungen

- Shaft Alignment - Rim and Face MethodDokument6 SeitenShaft Alignment - Rim and Face MethodWajdi MansourNoch keine Bewertungen

- Crankshaft AssemblyDokument51 SeitenCrankshaft AssemblySlobodanNoch keine Bewertungen

- Fleet Angle SignificanceDokument13 SeitenFleet Angle SignificanceAshish Kumar JhaNoch keine Bewertungen

- Gear Backlash: 6.1 Types of BacklashesDokument13 SeitenGear Backlash: 6.1 Types of BacklashesRamazan MERALNoch keine Bewertungen

- UBC Guide To BearingsDokument44 SeitenUBC Guide To BearingsRushikesh DandagwhalNoch keine Bewertungen

- Wire Rope InspectionDokument34 SeitenWire Rope Inspectionalaabaghdad100% (1)

- Tilting Pad TroubleshootingDokument7 SeitenTilting Pad Troubleshootinghamedia83Noch keine Bewertungen

- Gear Ring Radial AlignmentDokument2 SeitenGear Ring Radial AlignmentJavier GutierrezNoch keine Bewertungen

- Hydac HandbookDokument22 SeitenHydac Handbookrajayu20002724Noch keine Bewertungen

- Gear Assembly Maintenance Techniques TurbogearsDokument12 SeitenGear Assembly Maintenance Techniques Turbogearshumayun121Noch keine Bewertungen

- NATCOM Alignment TrainingDokument133 SeitenNATCOM Alignment TrainingMohamed M. AfifiNoch keine Bewertungen

- Shaft Tolerances For BearingsDokument1 SeiteShaft Tolerances For BearingsSahil KumarNoch keine Bewertungen

- Rigging Information: Block and Sheave InspectionDokument1 SeiteRigging Information: Block and Sheave InspectionGokul GNoch keine Bewertungen

- Plain Bearings Failure Mode and RectificationDokument13 SeitenPlain Bearings Failure Mode and RectificationengrsurifNoch keine Bewertungen

- Vibration - Case Study On Resolving Bearing Oil WhirlDokument42 SeitenVibration - Case Study On Resolving Bearing Oil WhirlChristian Santillan100% (1)

- HB Clutches The Only One-Way Clutch For Your Hydro-Dynamic Drilling RigsDokument4 SeitenHB Clutches The Only One-Way Clutch For Your Hydro-Dynamic Drilling RigsRafael Charry AndradeNoch keine Bewertungen

- Plain Bearing FailuresDokument7 SeitenPlain Bearing FailuressourajpatelNoch keine Bewertungen

- Belt Preventive Maintenance ManualDokument67 SeitenBelt Preventive Maintenance ManualAbdulrahman AlkhowaiterNoch keine Bewertungen

- 04-Bearing Retention and Clearances PDFDokument31 Seiten04-Bearing Retention and Clearances PDFchanayireNoch keine Bewertungen

- VACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10Dokument1 SeiteVACUUM PUMP DIAGNOSIS (Overall V Spectrum) - Case - Study - 10ho-faNoch keine Bewertungen

- BacklashDokument6 SeitenBacklashvishalNoch keine Bewertungen

- Presentation GearDokument18 SeitenPresentation Gearsou.bera100% (1)

- Bearing Maintenance: Management GuideDokument12 SeitenBearing Maintenance: Management GuideDiego Vicente100% (1)

- Vib Screen - Vib Analysis PDFDokument16 SeitenVib Screen - Vib Analysis PDFAngka SubaronNoch keine Bewertungen

- Loctite Industrial Gearbox Service ManualDokument13 SeitenLoctite Industrial Gearbox Service ManualDumitrescuNoch keine Bewertungen

- Owner Michael Calistrat and Associates Missouri City, TexasDokument8 SeitenOwner Michael Calistrat and Associates Missouri City, Texasjhchung111100% (1)

- How To Analyze Gear FailuresDokument9 SeitenHow To Analyze Gear Failuresrobertoalfaro49100% (1)

- Bearing Installation ProcedureDokument6 SeitenBearing Installation ProcedureHamad KhaledNoch keine Bewertungen

- How To Analyze Gear FailuresDokument9 SeitenHow To Analyze Gear FailuresHudson Saldanha SpiffNoch keine Bewertungen

- Reverse Dial Indicator MethodDokument14 SeitenReverse Dial Indicator MethodvinothenergyNoch keine Bewertungen

- 2 - Rolling Bearing FundamentalsDokument35 Seiten2 - Rolling Bearing FundamentalsZiggy Gregory100% (1)

- Sehs 7654 CM20160713 53120 62927 PDFDokument28 SeitenSehs 7654 CM20160713 53120 62927 PDFnasiramzanNoch keine Bewertungen

- Lafarge Pakistan Cement WPU 200 C380 JCP 09 2011 Assembled ReportDokument25 SeitenLafarge Pakistan Cement WPU 200 C380 JCP 09 2011 Assembled ReportAamirKhanNoch keine Bewertungen

- As 3791-1991 Hydraulic HoseDokument7 SeitenAs 3791-1991 Hydraulic HoseSAI Global - APAC0% (1)

- Bridon Service Procedure 1Dokument5 SeitenBridon Service Procedure 1Ahmed ButtNoch keine Bewertungen

- Propeller Fitting InstructionsDokument7 SeitenPropeller Fitting Instructionsrubens0001Noch keine Bewertungen

- Module4gears 190328033613Dokument39 SeitenModule4gears 190328033613Obaid KhanNoch keine Bewertungen

- UntitledDokument34 SeitenUntitledRA H U LNoch keine Bewertungen

- Drive Axle PDFDokument12 SeitenDrive Axle PDFnamduong368Noch keine Bewertungen

- GearsDokument58 SeitenGearsapi-238832008100% (3)

- Gajra GearsDokument17 SeitenGajra GearsJuhi Yadav100% (2)

- Technology Developed by CoirBoard - 0Dokument16 SeitenTechnology Developed by CoirBoard - 0Anand KesarkarNoch keine Bewertungen

- Dynamic Print Solution: D P E PDokument8 SeitenDynamic Print Solution: D P E PAnand KesarkarNoch keine Bewertungen

- Corona Kavach Policy-Oriental Insurance - Rate ChartDokument3 SeitenCorona Kavach Policy-Oriental Insurance - Rate ChartAnand KesarkarNoch keine Bewertungen

- Breakout Trading Strategies Quick GuideDokument10 SeitenBreakout Trading Strategies Quick GuideAnand Kesarkar100% (1)

- Manufacturing Processes UNIT Test-I - Series A With SolutionsDokument1 SeiteManufacturing Processes UNIT Test-I - Series A With SolutionsAnand KesarkarNoch keine Bewertungen

- The Truth About Fibonacci TradingDokument34 SeitenThe Truth About Fibonacci TradingAnand KesarkarNoch keine Bewertungen

- Astm A70Dokument1 SeiteAstm A70Anand KesarkarNoch keine Bewertungen

- Dss 2205 Wps PQR WPQDokument8 SeitenDss 2205 Wps PQR WPQAnand KesarkarNoch keine Bewertungen

- Let's Discuss Your Next Project.: Contact USDokument8 SeitenLet's Discuss Your Next Project.: Contact USAnand KesarkarNoch keine Bewertungen

- Cap 3 Dse CutoffDokument614 SeitenCap 3 Dse CutoffAnand KesarkarNoch keine Bewertungen

- Unit 3 PDDDokument6 SeitenUnit 3 PDDAnand KesarkarNoch keine Bewertungen

- Standard Operation ProcedureDokument3 SeitenStandard Operation ProcedureAnand KesarkarNoch keine Bewertungen

- Change Address Contact Details Email IdDokument1 SeiteChange Address Contact Details Email IdAnand KesarkarNoch keine Bewertungen

- WPQ Is 2062 Haresh Shah W1Dokument1 SeiteWPQ Is 2062 Haresh Shah W1Anand KesarkarNoch keine Bewertungen

- MSRTC - Online Reservation SystemDokument1 SeiteMSRTC - Online Reservation SystemAnand KesarkarNoch keine Bewertungen

- PDD Unit 1Dokument27 SeitenPDD Unit 1Anand KesarkarNoch keine Bewertungen

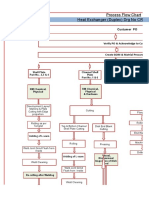

- Process Flow Chart - Heat ExchangerDokument7 SeitenProcess Flow Chart - Heat ExchangerAnand KesarkarNoch keine Bewertungen

- Wps Is 2062 GR B Butt-OkDokument2 SeitenWps Is 2062 GR B Butt-OkAnand Kesarkar33% (3)

- Maths Shortcuts by DayTodayGKDokument20 SeitenMaths Shortcuts by DayTodayGKAnand KesarkarNoch keine Bewertungen

- New PDD 4Dokument27 SeitenNew PDD 4Anand KesarkarNoch keine Bewertungen

- Ch6 RegulatorsDokument62 SeitenCh6 RegulatorssadyehclenNoch keine Bewertungen

- Tutorial UnifiDokument5 SeitenTutorial UnifiDanielTylerNoch keine Bewertungen

- Isuzu Commercial Truck Forward Tiltmaster Service Manual Supplement 2003 PDFDokument215 SeitenIsuzu Commercial Truck Forward Tiltmaster Service Manual Supplement 2003 PDFArnel AlmenarioNoch keine Bewertungen

- Suzuki XF650 Freewind Model HistoryDokument5 SeitenSuzuki XF650 Freewind Model HistoryGeorge BaculimaNoch keine Bewertungen

- Fabrication Work ShopDokument2 SeitenFabrication Work ShopcilacapNoch keine Bewertungen

- Reciprocating Pump - Components, Working and Uses - The ConstructorDokument1 SeiteReciprocating Pump - Components, Working and Uses - The ConstructorIrshad AfridiNoch keine Bewertungen

- Cat G3516A: Natural Gas Generator SetsDokument5 SeitenCat G3516A: Natural Gas Generator SetsRecovery MailNoch keine Bewertungen

- Deutsche BankDokument10 SeitenDeutsche BankSurabhi MattaNoch keine Bewertungen

- Manual de Armado de CarpaDokument5 SeitenManual de Armado de Carpafrancisco velascoNoch keine Bewertungen

- Cambridge Igcse Ict Coursebook With Cd-Rom Revised EditionDokument10 SeitenCambridge Igcse Ict Coursebook With Cd-Rom Revised EditionRini SandeepNoch keine Bewertungen

- Speed Control of DC Motor Using PWMDokument8 SeitenSpeed Control of DC Motor Using PWMsunny kumarNoch keine Bewertungen

- Lab#11Dokument4 SeitenLab#11Electro OpNoch keine Bewertungen

- Hydraulic Power Units P 635: Instruction Manual For Rescue EquipmentDokument68 SeitenHydraulic Power Units P 635: Instruction Manual For Rescue EquipmentForum PompieriiNoch keine Bewertungen

- Ambulance ChecklistsDokument1 SeiteAmbulance Checklistsgede aris prayoga mahardikaNoch keine Bewertungen

- E-Governor IntroductionDokument13 SeitenE-Governor Introductionbalu9999Noch keine Bewertungen

- USG 2 Data Sheet Issue 1.00Dokument2 SeitenUSG 2 Data Sheet Issue 1.00tariktunadNoch keine Bewertungen

- AQ Academy - Wireless Nurse Call - CablingDokument15 SeitenAQ Academy - Wireless Nurse Call - CablinggallNoch keine Bewertungen

- 750to850 Retrofit-A2Dokument38 Seiten750to850 Retrofit-A2이성종Noch keine Bewertungen

- AccessoriesDokument222 SeitenAccessoriesEliecer godoy100% (1)

- AC Compressor - RemovalDokument13 SeitenAC Compressor - RemovalSean HildrethNoch keine Bewertungen

- The Official Book For The Commodore 128Dokument230 SeitenThe Official Book For The Commodore 128DustdragonNoch keine Bewertungen

- New Creta BrochureDokument13 SeitenNew Creta BrochureNitinNoch keine Bewertungen

- STTH3L06: Turbo 2 Ultrafast High Voltage RectifierDokument10 SeitenSTTH3L06: Turbo 2 Ultrafast High Voltage RectifierIwankIppoNoch keine Bewertungen

- Ficha Tecnica FTS20.Dokument14 SeitenFicha Tecnica FTS20.milton cardenasNoch keine Bewertungen

- IP Link Device Interface Communication SheetDokument5 SeitenIP Link Device Interface Communication SheetJuan CoronelNoch keine Bewertungen

- Appendix: - Optional FunctionDokument11 SeitenAppendix: - Optional FunctionArvin ArmojallasNoch keine Bewertungen

- Electrical Distribution Equipment in Data CentersDokument15 SeitenElectrical Distribution Equipment in Data CentersJorge PeraltaNoch keine Bewertungen

- Pin Configuration of 8085Dokument3 SeitenPin Configuration of 8085sarthakNoch keine Bewertungen

- Zfe 2016 en PDFDokument41 SeitenZfe 2016 en PDFProfessor Marcus LopesNoch keine Bewertungen

- Candy Go147-01Dokument51 SeitenCandy Go147-011cvbnm0% (1)