Beruflich Dokumente

Kultur Dokumente

Course Specs Chemistry CHED

Hochgeladen von

Reymarr HijaraCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Course Specs Chemistry CHED

Hochgeladen von

Reymarr HijaraCopyright:

Verfügbare Formate

BACHELOR OF SCIENCE IN MARINE ENGINEERING

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2 Function: Marine Engineering

STCW78 as amended

Issue Date : January 2014

Revision Status : 00

Prepared by :

Reviewed by :

Approved by :

Number of pages : 8

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 2 of 8

REVISION HISTORY COURSE SPECIFICATIONS

NO. DATE REVISION

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 3 of 8

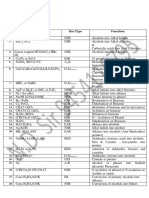

COMPETENCE

KNOWLEDGE,

UNDERSTANDING

AND PROFICIENCY

PERFORMANCE

APPROX

HOURS

Industrial Chemistry

Fundamentals

Acidity/Alkalinity

Defines an atom

Describes a molecule

Defines:

chemical elements

chemical compounds

Explains the difference between compounds and mixtures and names of:

elements

compounds

mixtures

Defines a chemical reaction

Defines an oxide

Uses as necessary the convention denoting elements, compounds and mixtures by letters

and numbers; for example, carbon dioxide represented by CO

2

Explains what is meant by:

solution

solubility

saturated solution

suspension

precipitation

Defines the composition of an atom

Explains the result of an atom gaining or losing electrons

Defines a hydrogen ion

Defines a hydroxyl ion

Given pH values, demonstrates whether a solution is alkaline, neutral or acidic, indicating

its strength or weakness

Uses an indicator such as litmus paper to determine whether a solution is acid or alkaline

10 Hours

6 Hours

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 4 of 8

COMPETENCE

KNOWLEDGE,

UNDERSTANDING

AND PROFICIENCY

PERFORMANCE

APPROX

HOURS

Industrial Chemistry

(Cont)

Corrosion

Defines how metallic hydroxide is formed when an iron is immersed in an acidic solution

Defines the effect of dissolved oxygen and high acidity on polarization

States that boiler water should be alkaline and contain little or no dissolved oxygen

Explains the fundamental process of corrosion

Names common engineering materials which produce passive oxide films

States the main cause of corrosion

Names the components of a galvanic cell and applies these to the corrosion of a metal

Defines that seawater is an electrolyte

Defines an anode

From a list of common metals, selects relative anodes

Defines metals as being noble or base relative to each other

Defines the use of sacrificial anodes

Recognizes the problems if graphite grease is used when seawater is present

Defines practical means of reducing galvanic action in the choice of metal and exposed

surface area

Defines pitting corrosion

Recognizes the process of graphitization of cast iron

Defines the reasons why corrosion increases when seawater velocity increases

Defines the terms and what is meant by stress corrosion and names the metals in which it

commonly occurs

Explains what is meant by dezincification and dealuminification

Defines how the process in the above objective can be prevented

Explains what is meant by fretting corrosion

Defines the factors which increase the rate of fretting

Defines what is meant by corrosion fatigue

Identifies the major factors affecting the corrosion process as:

differential temperatures

stresses within the metal structure

12 Hours

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 5 of 8

COMPETENCE

KNOWLEDGE,

UNDERSTANDING

AND PROFICIENCY

PERFORMANCE

APPROX

HOURS

Industrial Chemistry

(Cont)

Corrosion (Cont)

Water testing and

treatment

variation in crystal structure of the metal

distribution/concentration of impurities in the metal crystals

flow of oxygen to the cathode

flow of carbon dioxide to the anode and cathode

hydroxyl ion concentration of the aqueous solution

Recognizes that some films and coatings on metal surfaces can provide protection so long

as they remain intact

Recognizes that surface preparation prior to the application of protective coatings is very

important

Identifies the important methods of surface protection as:

paints

chemical films

metallic coatings

anodizing

Recognizes the importance of controlling the pH value of aqueous solutions within the

minimum corrosive range

Identifies the chemical additives that can be used to obtain the condition required in the

above objective

Knows the importance of maintaining a gasfree condition in the water used to "feed" a

steam boiler or to circulate in an engine cooling system

Identifies the methods in common use for conditioning the water content of marine Power

plant, e.g. trisodium phosphate, hydrazine

Explains that natural water supplies contain metallic salts in solution

Demonstrates the standard method of measuring metallic salt content, i.e. state the actual

quantity of metallic salt present in a specified quality of water

Knows the standard measurement given in the above objective as in units of "parts per

million" (ppm) or less accurately in '32's' (seawater density measurement)

12 Hours

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 6 of 8

COMPETENCE

KNOWLEDGE,

UNDERSTANDING

AND PROFICIENCY

PERFORMANCE

APPROX

HOURS

Industrial Chemistry

(Cont)

Water testing and

treatment (Cont)

Introduction to Fuels and

Lubricants

Lists the main metallic salts found in:

fresh water

average seawater

Defines:

permanent hardness

temporary hardness

Defines briefly how scale and sludge are produced in a steam boiler

Explains the different effects of using seawater, fresh water and distilled water as boiler

feedwater

Defines the principal objects of treatment of boiler feedwater

Identifies the average carbon, hydrogen, sulphur and ash content of the following fuels:

petrol

kerosene

marine diesel fuel

boiler fuel oil

Defines flashpoint and explains its importance for marine fuels and lubricants

Knows flashpoint temperature for the following hydrocarbons:

petrol

kerosene

marine diesel fuel

boiler fuel oil

lubricating oil

Identifies the minimum closed flashpoint of marine fuels

States the maximum temperature to which fuel oil may be raised

Describes precautions taken on board ship to prevent accidental ignition of the oils listed

in the above objective

Defines viscosity in terms of resistance to flow

14 Hours

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 7 of 8

COMPETENCE

KNOWLEDGE,

UNDERSTANDING

AND PROFICIENCY

PERFORMANCE

APPROX

HOURS

Industrial Chemistry

(Cont)

Physical and Chemical

Properties of Fuels and

Lubricants

Introduction to Fuels and

Lubricants (Cont)

Shore Side and

Shipboard Sampling and

Testing

Interpretation of Test

Results

Contaminants including

microbiological infection

Treatment of Fuels and

Lubricants including

Demonstrates why it is necessary to raise the temperature of some fuel oils

Carries out tests on fuels and lubricants for:

flashpoint

viscosity

Explains the reason why values of flashpoint or of viscosity need to be known for the

following:

fuels and lubricants in storage

transfer of fuels and lubricants

Carries out tests on fuels and lubricants for water content

Appraise the importance and implications of continual monitoring of quality of fuels and

lubricants in efficient operation of machinery

Explain the procedures available for testing fuels and lubricants, including viscosity,

water in oil, density, pour point, total base number (TBN), microbiological contamination

and other contamination

Describe the facilities available for laboratory testing of fuels and lubricants, the properties

that can be determined, and how the results can be interpreted and utilized in

maintenance programme

Outline procedures for dealing with contamination of oils by water, fuel in lubricating oil,

solid debris or other contaminants, including recognition of unacceptable levels and

possible consequences

Examine the causes, symptoms, effects and methods of treatment of oils that have been

infected with microbiological organisms

Detail bunkering procedures and arrangements, explaining the importance of following

correct procedures

Evaluate the operation of centrifugal separators and analyse the factors that affect

2 Hours

2 Hours

2 Hours

4 Hours

Bachelor of Science in Marine Engineering

COURSE SPECIFICATIONS

Industrial Chemistry

Basic Engineering Science IMO Model Course 7.04

Table A-III/2

Form No.:

Issue. Date:

Rev Status: 00

Prepared by:

Reviewed by:

Approved by:

Page: 8 of 8

COMPETENCE

KNOWLEDGE,

UNDERSTANDING

AND PROFICIENCY

PERFORMANCE

APPROX

HOURS

Storage, Centrifuging,

Blending, Pretreatment

and Handling

optimum separation

Explain the function and operation of a shipboard fuel blender and alternative fuel

treatments

Das könnte Ihnen auch gefallen

- Lecture Exe - Personal Safety and Social ResponsibilitiesDokument26 SeitenLecture Exe - Personal Safety and Social ResponsibilitiesReymarr Hijara100% (3)

- Course Specs Mach Shop I CHEDDokument5 SeitenCourse Specs Mach Shop I CHEDReymarr HijaraNoch keine Bewertungen

- Grosked For Review Up 01 Weekly Calendar StyleDokument6 SeitenGrosked For Review Up 01 Weekly Calendar StyleReymarr HijaraNoch keine Bewertungen

- Krispy Kreme Case Study - ReymarrHijaraDokument10 SeitenKrispy Kreme Case Study - ReymarrHijaraReymarr HijaraNoch keine Bewertungen

- 01 - Lecture Exe - Personal Safety and Personal Survival TechniquesDokument3 Seiten01 - Lecture Exe - Personal Safety and Personal Survival TechniquesReymarr HijaraNoch keine Bewertungen

- CMO 31 S. 2013 Annex A - Curriculum BSMT 2013 Mapping - 1st YearDokument4 SeitenCMO 31 S. 2013 Annex A - Curriculum BSMT 2013 Mapping - 1st YearReymarr Hijara100% (1)

- Course Specs Thermodynamics CHEDDokument8 SeitenCourse Specs Thermodynamics CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs E Mat CHEDDokument12 SeitenCourse Specs E Mat CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs General Physics CHEDDokument8 SeitenCourse Specs General Physics CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs Nav II CHEDDokument5 SeitenCourse Specs Nav II CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs General Physics CHEDDokument8 SeitenCourse Specs General Physics CHEDReymarr HijaraNoch keine Bewertungen

- 2Nd Mates Notes (Oow) Part I For Mca Oral Examinations: Table of ContentsDokument18 Seiten2Nd Mates Notes (Oow) Part I For Mca Oral Examinations: Table of ContentsSachin Juyal100% (2)

- Course Specs Mach Shop I CHEDDokument5 SeitenCourse Specs Mach Shop I CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs Electro II CHEDDokument12 SeitenCourse Specs Electro II CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs E Mat CHEDDokument12 SeitenCourse Specs E Mat CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs Nav I CHEDDokument7 SeitenCourse Specs Nav I CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs DWK II CHEDDokument14 SeitenCourse Specs DWK II CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs DWK II CHEDDokument14 SeitenCourse Specs DWK II CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs Pers Man CHEDDokument10 SeitenCourse Specs Pers Man CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs DWK I CHEDDokument6 SeitenCourse Specs DWK I CHEDReymarr HijaraNoch keine Bewertungen

- Course Specs Meteorology CHEDDokument9 SeitenCourse Specs Meteorology CHEDReymarr Hijara100% (1)

- Ship Stability NotesDokument13 SeitenShip Stability NotesDnv Bailey100% (1)

- Rigging of Pilot LaddersDokument6 SeitenRigging of Pilot LaddersReymarr Hijara100% (1)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- General Chemistry Chapter-1Dokument68 SeitenGeneral Chemistry Chapter-1Fnan YemaneNoch keine Bewertungen

- (Pp.401-411) Dry Method-Ex of Magmas and GelsDokument11 Seiten(Pp.401-411) Dry Method-Ex of Magmas and GelsJicah Mae LumbaoNoch keine Bewertungen

- Phytochemical Profile and Free Radical Nitric Oxide (NO) Scavenging Activity of Averrhoa Bilimbi L. Fruit ExtractDokument11 SeitenPhytochemical Profile and Free Radical Nitric Oxide (NO) Scavenging Activity of Averrhoa Bilimbi L. Fruit ExtractVinze AgarcioNoch keine Bewertungen

- Water Treatment Plant1Dokument15 SeitenWater Treatment Plant1Mhssp Co 5 INoch keine Bewertungen

- Docking IntroductionDokument17 SeitenDocking IntroductionPrasath KumarNoch keine Bewertungen

- Compounds and Alloyds of MagnesiumDokument30 SeitenCompounds and Alloyds of MagnesiumJudy PocquiasNoch keine Bewertungen

- Shanmugam 1997 ESR The Bouma Sequence and The Turbidite MindDokument29 SeitenShanmugam 1997 ESR The Bouma Sequence and The Turbidite MindEric EspirituNoch keine Bewertungen

- SahylaDokument7 SeitenSahylademro channelNoch keine Bewertungen

- Organic ReagentsDokument3 SeitenOrganic ReagentsKushagra Rai100% (1)

- Quantity of Casein in Different Sample of MilkDokument8 SeitenQuantity of Casein in Different Sample of MilkIJRASETPublicationsNoch keine Bewertungen

- Water Content of Acacia Honey Determined by Two EsDokument5 SeitenWater Content of Acacia Honey Determined by Two EsDestia AyuNoch keine Bewertungen

- Thermal InsulationDokument28 SeitenThermal Insulationferozbabu100% (2)

- Soalan ObjektifDokument9 SeitenSoalan ObjektifHairul Nizam OmarNoch keine Bewertungen

- Evaporation Chemical Engineering Series 2 PDF FreeDokument52 SeitenEvaporation Chemical Engineering Series 2 PDF FreeBagus Dina AkadahNoch keine Bewertungen

- Edwards SD TRK SD TRM Install 0957864312Dokument2 SeitenEdwards SD TRK SD TRM Install 0957864312Anonymous PersonNoch keine Bewertungen

- Cement Additives and Mechanisms of Action-SLBDokument55 SeitenCement Additives and Mechanisms of Action-SLBMuhammad ImranNoch keine Bewertungen

- A Process Design EngineerDokument10 SeitenA Process Design EngineerjokishNoch keine Bewertungen

- MSDS Coconut Shell Charcoal (Indonesia Kunlun) PDFDokument11 SeitenMSDS Coconut Shell Charcoal (Indonesia Kunlun) PDFGuddu YadavNoch keine Bewertungen

- Charging Phase and Discharging Phase - Electric CircuitsDokument11 SeitenCharging Phase and Discharging Phase - Electric CircuitsRayhan KabirNoch keine Bewertungen

- A Test Tube, 15 MM in Diameter and 15 CM Tall, Hal...Dokument4 SeitenA Test Tube, 15 MM in Diameter and 15 CM Tall, Hal...AliNoch keine Bewertungen

- MPFM Data SheetDokument2 SeitenMPFM Data SheetPedro NuñezNoch keine Bewertungen

- Thesis Experimental Research Lemon: Source of EnergyDokument4 SeitenThesis Experimental Research Lemon: Source of Energyfranz anthonyNoch keine Bewertungen

- Thermal Stress Analysis of Rectangular Plate Due To Convection Using Finite Element MethodDokument7 SeitenThermal Stress Analysis of Rectangular Plate Due To Convection Using Finite Element Methodزهرة اللوتسNoch keine Bewertungen

- Engineeringexperv 00000 I 00146Dokument60 SeitenEngineeringexperv 00000 I 00146LALENoch keine Bewertungen

- Cobalt Free CompositeDokument10 SeitenCobalt Free CompositeFadil KhayrNoch keine Bewertungen

- Cyclic Direct Simple Shear Test ReportDokument12 SeitenCyclic Direct Simple Shear Test ReportSen HuNoch keine Bewertungen

- ElectrolysisDokument300 SeitenElectrolysisberbouNoch keine Bewertungen

- Electromagnetics Field Theory 69 Important MCQDokument12 SeitenElectromagnetics Field Theory 69 Important MCQANIL SinghNoch keine Bewertungen

- Astm 239 PreceeDokument4 SeitenAstm 239 PreceeJesus Antonio Zuniga Martinez100% (1)

- Chapter 2 EnergyDokument6 SeitenChapter 2 EnergyJaishree RamNoch keine Bewertungen