Beruflich Dokumente

Kultur Dokumente

Thermal Expansion of Pipes

Hochgeladen von

onspsnonsCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermal Expansion of Pipes

Hochgeladen von

onspsnonsCopyright:

Verfügbare Formate

Technical Documents

Calculation tables for thermal expansion

Contents

Topic

Page

Thermal expansion ______________________________________________________ 3

1.1

Thermal expansion l ______________________________________________________ 4

1.1.1

NiroSan-, NiroTherm system pipes and copper pipes__________________________ 5

1.1.2

SANHA-Therm system pipe_______________________________________________ 5

1.2

Required expansion bend X between fitting and pipe fastening __________________ 6

1.2.1 NiroSan-, NiroTherm system pipes_________________________________________ 6

1.2.2 SANHA-Therm system pipes______________________________________________ 7

1.2.3

Copper pipes ___________________________________________________________ 7

1.3

Required leg length L of the expansion compensator___________________________ 8

1.3.1 NiroSan-, NiroTherm system pipes_________________________________________ 8

1.3.2 SANHA-Therm system pipes______________________________________________ 9

1.3.3

Copper pipes ___________________________________________________________ 9

1.4

Calculation of the expansion compensation of the SANHA axial compensator ______ 10

1.4.1

Installation diagram for the SANHA axial compensator ________________________ 11

Spacing between pipe mountings__________________________________________ 12

2.1

Maximum mounting spaces for metallic pipes according to EN 806-4 ______________ 13

2.2

Maximum mounting spaces for multilayer pipes according to EN 806-4 _____________ 13

2.3

Maximum mounting spaces for metallic pipes according to DVGW-G 600 TRGI 2008 __ 14

2.4

Maximum mounting spaces for metallic pipes according to TRF 2012 ______________ 14

2.5

Maximum mounting spaces for SANHA system pipes

of carbon steel and stainless steel__________________________________________ 15

No liability is assumed for technical changes and printing errors.

SANHA Technical Documents

1

Thermal expansion

Heat-bearing pipelines and pipelines that are exposed to high temperature from the outside (e.g.

sunlight etc.) expand at different rates depending

on the material. If this thermal expansion of the

lines is prevented, it can result in damage to the

pipes (usually in the form of fatigue fractures). In

order to avoid this, the pipeline must have sufficient space to expand. Often it is possible to take

advantage of the elasticity of the pipe network for

this purpose. To do this it is necessary to provide

sufficiently bendable line sections at the area

where the pipeline changes direction by the correct arrangement of the fastening brackets.

elastic cushion

As a basic principle, there must always

be sufficient scope for expansion between

any two fixed points.

Insofar as the natural routing of the line does

not allow sufficient compensation of the thermal

expansion, this must be realised by the installation

of special components such as axial compensators (SANHA catalogue no. 9872).

If sufficient space is available, a U-pipe compensator can also be used.

elastic cushion

ceiling

The layout data for the necessary expansion

bends and leg lengths of the U-pipe compensator

for the various materials are set out in the tables

below.

In case of concealed installation, unobstructed

thermal expansion must be ensured by coating

the lines with elastic material of sufficient thickness. In particular, ceiling penetrations are to be

cushioned carefully - provided that a fixed point

has not been intentionally placed there

(see Illustrations).

floating

screed

solid ceiling

elastic

collar

cover

insulating layer

SANHA Technical Documents

1.1 Thermal expansion I

Thermal expansion coefficient

Pipe material

Thermal expansion coefficient 10-6 K-1 at 20C to 100C

Stainless steel

16,5

Unalloyed steel

12,0

Copper

16,6

Calculation formula for the thermal expansion:

l = l0 T

l = difference of the thermal length expansion [mm]

l0 = Pipe length [mm]

= Thermal expansion coefficient from table [k-1]

T = Temperature difference between installation temperature and

maximum operating temperature [k]

SANHA Technical Documents

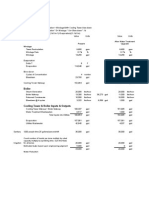

1.1.1 NiroSan- NiroTherm-system pipes and copper pipes

Thermal expansion I (mm)

t [K]

10

20

30

40

50

60

70

0,17

0,33

0,50

0,66

0,83

0,99

1,16

0,33

0,66

0,99

1,32

1,65

1,98

2,31

0,50

0,99

1,49

1,98

2,48

2,97

3,47

0,66

1,32

1,98

2,64

3,30

3,96

4,62

0,83

1,65

2,48

3,30

4,13

4,95

5,78

0,99

1,98

2,97

3,96

4,95

5,94

6,93

1,16

2,31

3,47

4,62

5,78

6,93

8,09

1,32

2,64

3,96

5,28

6,60

7,92

9,24

1,49

2,97

4,46

5,94

7,43

8,91

10,40

10

1,65

3,30

4,95

6,60

8,25

9,90

11,55

l [m]

1.1.2 SANHA-Therm system pipes

Thermal expansion I (mm)

t [K]

10

20

30

40

50

60

70

0,12

0,24

0,36

0,48

0,60

0,72

0,84

0,24

0,48

0,72

0,96

1,20

1,44

1,68

0,36

0,72

1,08

1,44

1,80

2,16

2,52

0,48

0,96

1,44

1,92

2,40

2,88

3,36

0,60

1,20

1,80

2,40

3,00

3,60

4,20

0,72

1,44

2,16

2,88

3,60

4,32

5,04

0,84

1,68

2,52

3,36

4,20

5,04

5,88

0,96

1,92

2,88

3,84

4,80

5,76

6,72

1,08

2,16

3,24

4,32

5,40

6,48

7,56

10

1,20

2,40

3,60

4,80

6,00

7,20

8,40

l [m]

SANHA Technical Documents

1.2 Required expansion bend X

Required expansion bend X between fitting

and pipe fastening

Minimum distance X of the brackets to the

fittings in heat-bearing pipes (tables below)

1.2.1 NiroSan- NiroTherm- system pipes

Necessary length of leg X (m)

I [mm]

10

20

30

40

50

60

70

15

0,52

0,74

0,90

1,04

1,16

1,28

1,38

18

0,57

0,81

0,99

1,14

1,28

1,40

1,51

22

0,63

0,89

1,09

1,26

1,41

1,54

1,67

28

0,71

1,01

1,23

1,42

1,59

1,74

1,88

35

0,80

1,12

1,38

1,59

1,78

1,95

2,10

42

0,87

1,23

1,51

1,74

1,95

2,13

2,31

54

0,99

1,40

1,71

1,98

2,21

2,42

2,61

64

1,08

1,52

1,86

2,15

2,40

2,63

2,85

76,1

1,17

1,66

2,03

2,35

2,62

2,87

3,10

88,9

1,27

1,79

2,20

2,54

2,83

3,10

3,35

108

1,40

1,98

2,42

2,79

3,12

3,42

3,70

d [mm]

1 SANHA Technical Documents

1.2.2 SANHA-Therm system pipes

Necessary length of leg X (m)

I [mm]

10

20

30

40

50

60

70

12

0,47

0,67

0,82

0,94

1,05

1,16

1,25

15

0,53

0,75

0,91

1,05

1,18

1,29

1,39

18

0,58

0,82

1,00

1,16

1,29

1,41

1,53

22

0,64

0,90

1,11

1,28

1,43

1,56

1,69

28

0,72

1,02

1,25

1,44

1,61

1,76

1,91

35

0,81

1,14

1,39

1,61

1,80

1,97

2,13

42

0,88

1,25

1,53

1,76

1,97

2,16

2,33

54

1,00

1,41

1,73

2,00

2,24

2,45

2,65

66,7

1,11

1,57

1,93

2,22

2,49

2,72

2,94

76,1

1,19

1,68

2,06

2,37

2,66

2,91

3,14

88,9

1,28

1,82

2,22

2,57

2,87

3,14

3,40

108

1,41

2,00

2,45

2,83

3,16

3,47

3,74

d [mm]

1.2.3 Copper pipes

Necessary length of leg X (m)

I [mm]

10

20

30

40

50

60

70

12

0,63

0,89

1,09

1,26

1,41

1,54

1,66

15

0,70

0,99

1,22

1,41

1,57

1,72

1,86

18

0,77

1,09

1,33

1,54

1,72

1,89

2,04

22

0,85

1,20

1,48

1,70

1,91

2,09

2,25

28

0,96

1,36

1,66

1,92

2,15

2,35

2,54

35

1,07

1,52

1,86

2,15

2,40

2,63

2,84

42

1,18

1,66

2,04

2,35

2,63

2,88

3,11

54

1,33

1,89

2,31

2,67

2,98

3,27

3,53

64

1,45

2,06

2,52

2,91

3,25

3,56

3,84

66,7

1,48

2,10

2,57

2,97

3,32

3,63

3,93

76,1

1,58

2,24

2,74

3,17

3,54

3,88

4,19

88,9

1,71

2,42

2,97

3,43

3,83

4,20

4,53

108

1,89

2,67

3,27

3,78

4,22

4,62

4,99

d [mm]

SANHA Technical Documents

1.3 Necessary length of leg L

Necessary length of leg L

of the U-pipe expansion compensator

Necessary length of leg L of the double U-bend

as expansion compensating element to take up

the thermal expansion (see tables below)

1.3.1 NiroSan- NiroTherm- system pipes

Necessary length of leg L (m)

I [mm]

10

20

30

40

50

60

70

15

0,30

0,43

0,52

0,60

0,67

0,74

0,80

18

0,33

0,47

0,57

0,66

0,74

0,81

0,87

22

0,36

0,51

0,63

0,73

0,81

0,89

0,96

28

0,41

0,58

0,71

0,82

0,92

1,01

1,09

35

0,46

0,65

0,80

0,92

1,03

1,12

1,21

42

0,50

0,71

0,87

1,01

1,12

1,23

1,33

54

0,57

0,81

0,99

1,14

1,28

1,40

1,51

64

0,62

0,88

1,08

1,24

1,39

1,52

1,64

76,1

0,68

0,96

1,17

1,35

1,51

1,66

1,79

88,9

0,73

1,03

1,27

1,46

1,64

1,79

1,94

108

0,81

1,14

1,40

1,61

1,80

1,98

2,13

d [mm]

SANHA Technical Documents

1.3.2 SANHA-Therm system pipes

Necessary length of leg L (m)

I [mm]

10

20

30

40

50

60

70

12

0,27

0,39

0,47

0,54

0,61

0,67

0,72

15

0,30

0,43

0,53

0,61

0,68

0,75

0,81

18

0,33

0,47

0,58

0,67

0,75

0,82

0,88

22

0,37

0,52

0,64

0,74

0,82

0,90

0,98

28

0,42

0,59

0,72

0,83

0,93

1,02

1,10

35

0,46

0,66

0,81

0,93

1,04

1,14

1,23

42

0,51

0,72

0,88

1,02

1,14

1,25

1,35

54

0,58

0,82

1,00

1,16

1,29

1,41

1,53

66,7

0,64

0,91

1,11

1,28

1,44

1,57

1,70

76,1

0,69

0,97

1,19

1,37

1,53

1,68

1,81

88,9

0,74

1,05

1,28

1,48

1,66

1,82

1,96

108

0,82

1,16

1,41

1,63

1,83

2,00

2,16

d [mm]

1.3.3 Copper pipes

Necessary length of leg L (m)

I [mm]

10

20

30

40

50

60

70

12

0,36

0,51

0,63

0,73

0,81

0,89

0,96

15

0,41

0,57

0,70

0,81

0,91

0,99

1,07

18

0,44

0,63

0,77

0,89

0,99

1,09

1,18

22

0,49

0,70

0,85

0,98

1,10

1,20

1,30

28

0,55

0,78

0,96

1,11

1,24

1,36

1,47

35

0,62

0,88

1,07

1,24

1,39

1,52

1,64

42

0,68

0,96

1,18

1,36

1,52

1,66

1,80

54

0,77

1,09

1,33

1,54

1,72

1,89

2,04

64

0,84

1,19

1,45

1,68

1,88

2,06

2,22

66,7

0,86

1,21

1,48

1,71

1,92

2,10

2,27

76,1

0,91

1,29

1,58

1,83

2,05

2,24

2,42

88,9

0,99

1,40

1,71

1,98

2,21

2,42

2,62

108

1,09

1,54

1,89

2,18

2,44

2,67

2,88

d [mm]

SANHA Technical Documents

1.4 Calculation of the SANHA axial compensator

Technical data for the axial compensator

Dimension

d [mm]

Axial movement*)

axz [mm]

Spring coefficient ( 30%)

C [N/mm]

Effective cross section area

AB [cm2]

15

30

18

30

22

32

28

48

35

47

12

42

90

19

54

10

67

28

64

14

45

46

76,1

14

45

46

88,9

14

84

66

108

14

90

100

*) applies for 1000 load cycles

Service life graph for the SANHA axial compensator

Load cycle factor (AL)

Number of load cycles

10

sur

s

Pre

00%

a

cap

1

city

50%

0%

SANHA Technical Documents

1.4 Calculation of the SANHA axial compensator

Temperature reduction factor

Operating temperature C

20

100

150

200

250

300

350

400

450

500

Operating pressure correction factor Ap Expansion compensation correction factor Af

1,0

0,9

0,85

0,8

0,75

0,67

0,64

0,61

0,59

0,57

1,0

1,0

0,95

0,9

0,87

0,85

0,83

0,8

0,77

0,75

Calculation formula for correction of the nominal pressure of the axial compensator:

PN

pB

Ap

= nominal pressure of the axial compensator [bar]

= maximum operating pressure of the system [bar]

= operating pressure correction factor from table

Calculation formula for correction of the expansion compensation:

ax

l

Af

= corrected axial expansion compensation [mm]

= difference of the thermal expansion [mm]

= expansion compensation correction factor from table

Calculation formula for correction of the load cycle

(1000 load cycles at maximum axial expansion compensation):

ax

AL

axe

PN=pB / Ap

= corrected load cycle [mm]

= load cycle factor from the graph

= corrected axial expansion compensation [mm]

Calculation formula for number of axial compensators:

No.comp. = number of compensators for the selected pipe length [units]

axe

= corrected load cycle [mm]

axz

= axial expansion compensation of the compensator from table [mm]

ax= l / Af

axe= ax / AL

No.comp. = axe / axz

1.4.1 Installation diagram for the SANHA axial compensator

11

SANHA Technical Documents

2

Spacing between pipe mountings

Pipes are to be connected by means of commercial clips direct with the building and may not

be fastened to other pipes.

In order to fulfil the noise control requirements, clips with rubber lining are to be used.

In each case, clips may be attached on the pipe, not on the fitting.

In order not to set unintended fixed points, a certain distance from detours is to be observed.

Since apparatus and device connections function as fixed points, a certain distance is to be

kept also by these.

The tables no. 2.1 to 2.5 refer to the schematic diagramm shown below.

SANHA Technical Documents

2.1 Mounting spaces for metallic pipes (EN 806-4)

Maximum mounting spaces for metallic pipes according to EN 806-4

Pipe outside diameter d [mm]

Pipe size DN

Mounting space of the Mounting space of the

vertical pipe run*

vertical pipe run*

Copper pipe acc. to EN Stainless steel pipe - EN

L1 [m]

L2 [m]

1057 / DVGW GW 392

10312 / DVGW GW 541

10

12

1,00

1,50

12

15

15

1,20

1,80

15

18

18

1,20

1,80

20

22

22

1,80

2,40

25

28

28

1,80

2,40

32

35

35

2,40

3,00

40

42

42

2,40

3,00

50

54

54

2,70

3,60

64

64

3,00

3,60

67

3,00

3,60

65

76,1

76,1

3,00

3,60

80

88,9

88,9

3,00

3,60

100

108

108

3,00

3,60

* Due to the different wall thicknesses and hardnesses, the distances between the brackets for copper pipes

may vary, as a function of the applied local measurements.

2.2

Mounting space for multilayer pipes (EN 806-4)

Maximum mounting spaces for multilayer pipes according to EN 806-4

Pipe outside diameter d [mm]

16

> 16 bis 20

> 20 bis 25

> 25 bis 32

> 32 bis 40

> 40 bis 50

> 50 bis 63

Mounting space L1 / L2 [m]

Cold water

Warm water

0,60

0,70

0,80

0,90

1,10

1,25

1,40

0,25

0,30

0,35

0,40

0,50

0,60

0,75

SANHA Technical Documents

2.3 Mounting spaces for metallic pipes (DVGW-G 600)

Maximum mounting spaces for metallic pipes according to DVGW-G 600 TRGI 2008

2.4

Pipe size DN

Pipe outside diameter d [mm]

Mounting space L1 / L2 [m]

12

15

20

25

32

40

50

65

80

100

15

18

22

28

35

42

54

64

76,1

88,9

108

1,25

1,50

2,00

2,25

2,75

3,00

3,50

4,00

4,25

4,75

5,00

Mounting spaces for metallic pipes (TRF 2012)

Maximum mounting spaces for metallic pipes according to TRF 2012

Nennweite DN

Rohrauendurchmesser d [mm]

Befestigungsabstand L1 / L2 [m]

15

20

25

32

40

50

65

80

100

15

18

22

28

35

42

54

64

76,1

88,9

108

1,25

1,50

2,00

2,25

2,75

3,00

3,50

4,00

4,25

4,75

5,00

SANHA Technical Documents

2.5 Mounting spaces for SANHA system pipes

Maximum mounting spaces for SANHA system pipes of carbon steel and stainless steel

Nennweite DN

Rohrauendurchmesser d [mm]

Befestigungsabstand L1 / L2 [m]

12

15

20

25

32

40

50

65

80

100

15

18

22

28

35

42

54

64 / 67

76,1

88,9

108

1,25

1,50

2,00

2,25

2,75

3,00

3,50

4,00

4,25

4,75

5,00

The values listed

in the table can be used if the rules of the

chosen area of application does not specify rules on the fixing distances.

SANHA GmbH & Co. KG | Im Teelbruch 80 | D-45 219 Essen | Tel.: +49 (0) 2054 925-0 | Fax: +49 (0) 2054 925-250 | info@sanha.com

Das könnte Ihnen auch gefallen

- Basics of Refrigeration CycleDokument2 SeitenBasics of Refrigeration CyclePradeep SukumaranNoch keine Bewertungen

- Ashraed2830120060711Dokument6 SeitenAshraed2830120060711kabardeyNoch keine Bewertungen

- SPEC For Chilled Water Pipework and FittingsDokument4 SeitenSPEC For Chilled Water Pipework and FittingsonspsnonsNoch keine Bewertungen

- 0014-Cpr-001 Concept Phase Report 170409bDokument15 Seiten0014-Cpr-001 Concept Phase Report 170409bonspsnonsNoch keine Bewertungen

- Ahu 01 (STD)Dokument5 SeitenAhu 01 (STD)onspsnonsNoch keine Bewertungen

- Air Distribution Basics and Duct DesignDokument46 SeitenAir Distribution Basics and Duct DesignVali GheorghisorNoch keine Bewertungen

- Pipe Wall Thickness (ASME B31.3)Dokument12 SeitenPipe Wall Thickness (ASME B31.3)Rachmad HidayatNoch keine Bewertungen

- 00 BLANK - Hot and Cold Water LU Calculation SheetDokument17 Seiten00 BLANK - Hot and Cold Water LU Calculation SheetmaxmorekNoch keine Bewertungen

- A O Smith Residential Water Heater CatalogDokument24 SeitenA O Smith Residential Water Heater CatalogonspsnonsNoch keine Bewertungen

- Fire Damper Installation DetailsDokument1 SeiteFire Damper Installation DetailsonspsnonsNoch keine Bewertungen

- WaStop SS - PVC - PE International Version 2014Dokument2 SeitenWaStop SS - PVC - PE International Version 2014onspsnonsNoch keine Bewertungen

- PDO SMO Buildings - Site Visit ReportDokument9 SeitenPDO SMO Buildings - Site Visit ReportonspsnonsNoch keine Bewertungen

- Vibration in Pumps PDFDokument5 SeitenVibration in Pumps PDFonspsnonsNoch keine Bewertungen

- Balancing and Vibration LimitsDokument3 SeitenBalancing and Vibration Limitsramamoorthy_sNoch keine Bewertungen

- Drainge&Waste WaterDokument43 SeitenDrainge&Waste WatermohdnazirNoch keine Bewertungen

- FDS B 4 - CoilDokument1 SeiteFDS B 4 - CoilonspsnonsNoch keine Bewertungen

- 3/5/8 (Soft/standard/hard Membrane) : To Be Updated With The Requirement of The Installation/purposeDokument1 Seite3/5/8 (Soft/standard/hard Membrane) : To Be Updated With The Requirement of The Installation/purposeonspsnonsNoch keine Bewertungen

- CalculationsDokument2 SeitenCalculationsAliAliNoch keine Bewertungen

- Cooling Tower ArticleDokument7 SeitenCooling Tower ArticleAudrey Patrick KallaNoch keine Bewertungen

- ECO V - CatalogueDokument5 SeitenECO V - CatalogueonspsnonsNoch keine Bewertungen

- FLM SpecificationsDokument2 SeitenFLM SpecificationsonspsnonsNoch keine Bewertungen

- Cib HDokument1 SeiteCib HonspsnonsNoch keine Bewertungen

- Icw SpecDokument3 SeitenIcw SpeconspsnonsNoch keine Bewertungen

- Commercial STL HTL Panels SpecificationDokument4 SeitenCommercial STL HTL Panels SpecificationonspsnonsNoch keine Bewertungen

- High TonesDokument2 SeitenHigh TonesonspsnonsNoch keine Bewertungen

- Icc SpecDokument2 SeitenIcc SpeconspsnonsNoch keine Bewertungen

- Barrier Wall SystemsDokument2 SeitenBarrier Wall SystemsonspsnonsNoch keine Bewertungen

- Chiller Barrier Wall SpecificationDokument2 SeitenChiller Barrier Wall SpecificationonspsnonsNoch keine Bewertungen

- High Impact Hard SideDokument2 SeitenHigh Impact Hard SideonspsnonsNoch keine Bewertungen

- Hard Side Cloud SystemDokument2 SeitenHard Side Cloud SystemonspsnonsNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Real and Reactive Power Flow Control With Upfcconnected To A Transmission LineDokument7 SeitenReal and Reactive Power Flow Control With Upfcconnected To A Transmission LineSravan GuptaNoch keine Bewertungen

- Civil Engineer - Structural EngineerDokument88 SeitenCivil Engineer - Structural EngineerEdi Supriyanto0% (1)

- Repairs and Rehabilitation of Bridges PDFDokument9 SeitenRepairs and Rehabilitation of Bridges PDFSourabh NegiNoch keine Bewertungen

- Structures Design Manual PDFDokument265 SeitenStructures Design Manual PDFBart Lucena Jr.Noch keine Bewertungen

- gc9620 20 dc3 AenDokument23 Seitengc9620 20 dc3 AenΔέσποινα ΜιχάλογλουNoch keine Bewertungen

- New ANSI Fall Protection Standards: ANSI Z359.7 and ANSI Z359.14Dokument21 SeitenNew ANSI Fall Protection Standards: ANSI Z359.7 and ANSI Z359.14Chandrasekhar SonarNoch keine Bewertungen

- StructuralModellingManual Arup PDFDokument44 SeitenStructuralModellingManual Arup PDFAie Bantugan100% (8)

- A Methodological Comparison of The Structures of Scientific Research and Engineering Design Their Similarities and DifferencesDokument7 SeitenA Methodological Comparison of The Structures of Scientific Research and Engineering Design Their Similarities and DifferencesSebastian Arango Alzate100% (1)

- Program ESREL2019 PDFDokument59 SeitenProgram ESREL2019 PDFwonsiriNoch keine Bewertungen

- Applied Thermo - 1st ClassDokument10 SeitenApplied Thermo - 1st ClassNur Hanim Abd GhaniNoch keine Bewertungen

- Shaft Vibration MeasurementDokument8 SeitenShaft Vibration Measurementrmsr_7576100% (1)

- PFDDokument4 SeitenPFDGaneshNoch keine Bewertungen

- Introduction To ConstructionDokument25 SeitenIntroduction To ConstructionSyukry RosleNoch keine Bewertungen

- Curriculum Vitae: Nitheesh P.MDokument2 SeitenCurriculum Vitae: Nitheesh P.MNitheesh MohanNoch keine Bewertungen

- Difference Between Software Engineering and Computer ScienceDokument2 SeitenDifference Between Software Engineering and Computer ScienceHemanth Kumar KNoch keine Bewertungen

- Statement of Purpose University: University of Northumbria, UK Course: Engineering (Top-Up)Dokument2 SeitenStatement of Purpose University: University of Northumbria, UK Course: Engineering (Top-Up)akhilNoch keine Bewertungen

- Us Construction PDF FreeDokument499 SeitenUs Construction PDF FreeJAGUAR GAMINGNoch keine Bewertungen

- Steel DetailingDokument3 SeitenSteel DetailingAmanSharmaNoch keine Bewertungen

- Extreme Software Engineering A Hands On Approach PDFDokument2 SeitenExtreme Software Engineering A Hands On Approach PDFShaunNoch keine Bewertungen

- QuotationsDokument4 SeitenQuotationschaitanya12299Noch keine Bewertungen

- MV Series (MV66A-MV106A) - E-Catalogue - ENG - 2Dokument12 SeitenMV Series (MV66A-MV106A) - E-Catalogue - ENG - 2Dhika PurnomoNoch keine Bewertungen

- Ead 330153 00 0602 Cartrigde Fired Pins 2015Dokument24 SeitenEad 330153 00 0602 Cartrigde Fired Pins 2015bmnNoch keine Bewertungen

- Tampak Depan Tampak Samping: Qty: 6 UnitDokument4 SeitenTampak Depan Tampak Samping: Qty: 6 UnitKristian Putra KumajayaNoch keine Bewertungen

- Vasanth 1Dokument3 SeitenVasanth 1Siva KrishnaNoch keine Bewertungen

- Dimensi Wanhui Sheet PileDokument20 SeitenDimensi Wanhui Sheet Pilesiana herawatiNoch keine Bewertungen

- Tekla Structures Functionality Configurations enDokument2 SeitenTekla Structures Functionality Configurations enmixi1978Noch keine Bewertungen

- RCC Pedestal DesignDokument2 SeitenRCC Pedestal DesignsivaNoch keine Bewertungen

- Haris Khan CVDokument3 SeitenHaris Khan CVsurendraNoch keine Bewertungen

- Sanjay SOPDokument2 SeitenSanjay SOPSanjay VenkatesanNoch keine Bewertungen

- Bce 111 Sim WK 1-3Dokument19 SeitenBce 111 Sim WK 1-3Pancho RJNoch keine Bewertungen