Beruflich Dokumente

Kultur Dokumente

1s20 Application

Hochgeladen von

JJG0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

50 Ansichten59 SeitenElectrical arc short circuits in metal clad switchgear and low voltage panels may occur for many different reasons. Defective or ageing insulating materials poor bus or cable connections poor maintenance human error ingress of moisture, dust or vermin abnormal service conditions.

Originalbeschreibung:

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenElectrical arc short circuits in metal clad switchgear and low voltage panels may occur for many different reasons. Defective or ageing insulating materials poor bus or cable connections poor maintenance human error ingress of moisture, dust or vermin abnormal service conditions.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

50 Ansichten59 Seiten1s20 Application

Hochgeladen von

JJGElectrical arc short circuits in metal clad switchgear and low voltage panels may occur for many different reasons. Defective or ageing insulating materials poor bus or cable connections poor maintenance human error ingress of moisture, dust or vermin abnormal service conditions.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 59

THE RELAY SPECI ALI STS

relay monitoring systems pty ltd www.rmpl.com.au

1S20

Arc Fault Monitor

1S20

Arc Fault Monitor

1S20

Arc Fault Monitor

Electrical arc short circuits in metal clad switchgear and low

voltage panels may occur for many different reasons.

defective or ageing insulating materials

poor bus or cable connections

poor maintenance

human error

ingress of moisture, dust or vermin

abnormal service conditions

Arc Fault

Effects and Consequences

ENERGY RELEASED BY ARC FAULT ENERGY RELEASED BY ARC FAULT

PRESSURE

RISE

TEMPERATURE

RISE

VISUAL &

ACCOUSTIC

PHENOMENA

EFFECTS OF

FAULT ARC

CONSEQUENCES

FOR PLANT

MECHANICAL

STRESSING OF

ENCLOSURES

THERMAL STRESSING,

MELTING, FIRE

VAPOURISATION

CONSEQUENCES

FOR PERSONNEL

SHOCK WAVE,

FLYING DEBRIS,

OPENING PANELS

U/V BURNS &

EJECTION OF

FLAMES & HOT

GASES & SMOKE

Switchgear Failure

Effects and Consequences

Switchgear Internal Fault

Example

FAULT TIME

PROTECTION

TRANSFORMER

2 secs

OC-relay

110/22 kV

30 MVA

Switchgear Internal Fault

Example

FAULT TIME

PROTECTION

TRANSFORMER

0.07 secs

Arc protection

110/22 kV

30 MVA

Variable Speed Drive

Fault Example

PROTECTION

TRANSFORMER

Earth leakage

22 kV / 690V

Water Corporation

Western Australia

At approximately 0800 hrs on 25/2/07 No.2 VSD

failed at Tamworth Pumping Station WA. The

PSN electrician was called out to the fault later

that same morning and found the main switch

compartment of the drive badly damaged.

The extent of damage is quite severe and was

contained to the main switch compartment of the

variable speed drive.

The majority of damage appears to have been

originated from the VSD main switch, then

spreading upon explosion to the upper and rear of

the drive and also externally through the

ventilation ducts.

Variable Speed Drive

Fault Example

The earth leakage protection on the #2

VSD 22kV / 690V feeder tripped.

The O/C protection also detected a phase

fault condition.

#2 22kV / 690V Transformer circuit breaker

was found to be in the OFF position.

Judging by the extent of the damage the

protection clearly did not respond quickly

enough.

Variable Speed Drive

Fault Example

Variable Speed Drive

Fault Example

OPERATOR HAZARD IN ADJACENT CORRIDOR

Variable Speed Drive

Fault Example

1S20 ARC FAULT PROTECTION INSTALLED AFTER EARLIER FAULT

Variable Speed Drive

Fault Example

SUBSEQUENT FAULT

As a result of this incident, RMS 1S20 Arc

Fault Monitors and 1S30 Arc Flash Sensors

were installed.

Subsequently several months later another

incident occurred, this time due to the failure

of the IGBT board.

As a consequence, the arc sensors were

triggered by tripping the 22kV circuit breaker

and as can be seen by the photos the

damage was insignificant.

1S30 ARC

SENSOR

ARC FAULT

Variable Speed Drive

Fault Example

SUBSEQUENT FAULT

ARC FAULT

1S20

Arc Fault Monitor

For moderate arc fault currents the trip

time of the over-current stage will be too slow:

For very low arc fault currents the

instantaneous trip stage of a standard

over-current relay cannot be set low

enough.

1S20

Arc Fault Monitor

The degree of damage caused by arcing

depends principally on the duration of the arc.

~100ms Arc Fault Duration

The switchgear needs to be checked & the

insulation resistance measured before power

can be re-established.

~200ms Arc Fault Duration

The power supply will be interrupted; the

switchgear must be checked; power is re-

established only after minor repairs.

1S20

Arc Fault Monitor

~100ms Arc Fault Duration

1S20

Arc Fault Monitor

The degree of damage caused by arcing

depends principally on the duration of the arc.

~500ms Arc Fault Duration

The supply is interrupted, metal parts of the

switchgear are destroyed & poisonous gases

are emitted.

~1s Arc Fault Duration

Destroys most of the switchgear & may cause a

fire, injury to personnel & damage to property.

1S20

Arc Fault Monitor

~500ms Arc Fault Duration

1S20

Arc Fault Monitor

Arguably the greatest risk of arc fault damage

exists at the CB cable termination & in the CB

chamber itself due to the slow clearance times

of the IDMT feeder protection.

The problem of arc faults is most prevalent in

older metal clad switchgear, which already has

operational protection systems.

The CB cable termination is particularly at risk to

ingress of moisture & rodent damage.

System Integration

Trip on arc fault <10ms

Type: 1S20K1 [C] Vx: 48V DC

Serial No: 126578

1S20 Arc Fault Monitor

ARC FAULT TRIP INITIATE

CB

ARC FAULT

MONITOR SENSOR

RESET / TEST

System Functioning

Arc Fault Trip

System Ser vice

DC Fail

GREEN:

RED:

ORANGE:

DARK:

Single Line Diagram

1S30

1S20

Cable box only

Trip on Arc Fault

System Integration

With current check using high speed starter element

Type: 1S20K1 [C] Vx: 48V DC

Serial No: 126578

1S20 Arc Fault Monitor

ARC FAULT TRIP INITIATE

CB

ARC FAULT

MONITOR SENSOR

OVER-CURRENT RELAY

3 Pole OC + EF

RESET / TEST

System Functioning

Arc Fault Trip

System Service

DC Fail

GREEN:

RED:

ORANGE:

DARK:

Single Line Diagram

1S30

1S20

50/51

Cable box only

Trip only if over current starter picked up

Single Line Diagram

Cable box and CT chamber

1S30

1S30

1S20

50/51

Single Line Diagram

1S20

1S30

1S30

1S30

50/51

Trip BUS CB(s)

Cable box, CT and CB chamber

Single Line Diagram

Cable box, CB and BUS chamber

1S20

1S30

1S30

1S30

50/51

Trip BUS CB(s)

Single Line Diagram

BUS chamber

1S20

1S30 1S30

50/51

50/51 50/51

1S20 with 1S30 Optical Sensors

1S30

Arc Sensor

Mounted in each segregated

switchgear chamber

Sensitivity linear in forward

direction through 180

Detects reflected arc light -

mounting position not critical

Burden 2.5mA (quiescent)

Optional rear facing sensor

1S30

Arc Sensor Installation

Mounting position of the

Sensor is not critical.

High sensitivity in

direction of View

1S20 System Testing

Use camera flash to check operation of

arc sensor and pick up of 1S20 trip

contact.

Typical operating range of flash to arc

sensor is 50 to 300mm

1S20 System Testing

CRO trace showing nominal operation time of the trip contacts.

First contact touch at 6.25ms and fully closed by 7.25ms.

1S30

Arc Sensor Installation

1S30 shown mounted on the outside of a switchgear panel

Detector oriented to look through a hole into the switchgear

Switchgear

panel

2 x M4

self threading

mounting screws

(Supplied)

Sealed cable

stress relief

Optical detector

protruding through

hole in panel

1S30

Arc Sensor Installation

1S30 shown mounted on the inside of a switchgear panel

Detector oriented to look out into the switchgear compartment

2 x M4

self threading

mounting screws

(Supplied)

Optical detector

facing away

from panel

1S30

Arc Sensor Installation

The dual optical detector version can be panel mounted

to monitor two adjacent switchgear compartments simultaneously.

Internal partition

between switchgear

compartments

Optical detector

protruding through

compartment divider

into adjacent

switchgear chamber

Optical detector

window facing away

from compartment

divider

1S30

Arc Sensor Installation

Right angle mounting off a surface

Mount off floor or walls within switchgear / BUS bar chamber

Right angle

mounting

bracket

Optical detector

window facing away

from right angle

mounting bracket

Single

optical detector

Dual

optical detector

1S30

Arc Sensor Installation

Flush mount reinforcing plate

1.2mm zinc plated mild steel

2 x M4

self threading

mounting screws

(Supplied)

Flush mount

reinforcing

plate

1S30

Arc Sensor Installation

SENSOR LOCATIONS

Cable Box Arc Fault

13.1kA (50mS)

Fault created in Cable Box by connecting three bushing

connectors with fuse wire.

Sensor fitted to side of box.

Cover after test

Cover as new

Cable Box Arc Fault

Lower portion of Cover

strengthened

Cable Box Arc Fault

Sensor location

CB Chamber Arc Fault

CB chamber fault at 13.1kA (50mS)

Fault initiated by connecting 3 phases of circuit side

of CB with fuse wire

- typical of test leads used during maintenance.

One ARC sensor fitted.

CB Chamber Arc Fault

General views after test

1S20

Does it Work

WILL IT OPERATE UNDER DYNAMIC CONDITIONS? --- YES

HOW FAST DOES IT REMOVE AN INTERNAL FAULT? --- 50-75ms

IS IT EFFECTIVE IN ALL SWITCHGEAR CHAMBERS? --- YES

HOW MUCH DAMAGE IS CAUSED TO THE SWITCHGEAR? --- Minimal

DOES IT IMPROVE SAFETY? --- YES, Significantly

1S30

Arc Sensor

measured current

( increase 1*In ==> 10*In)

arc detection

overcurrent detection

trip output contact

One, two or three independent arc sensor inputs

Two high speed tripping duty arc sense output contacts

<10ms arc fault tripping time

Self supervision with fail alarm contact

Push button reset & self test

1S30 Arc sensor continuous supervision

Compact, economic design

Simple panel mounting for retrofit applications

1S20 Summary

Front Panel Indication

Solid red for 2s followed by:

Alternate red & green until reset.

Green solid

Orange solid

Alternate orange & red.

System healthy

1S30 Arc Sensor service

1S30 Arc Sensor continuous pick up

Flash green 3 times 1S30 Power up test OK

Arc fault trip

Front Panel

FRONT VIEW

Type: 1S20K1 [C] Vx: 48V DC

Serial No: 126578

1S20 Arc Fault Monitor

RESET / TEST

System Functioning

Arc Fault Trip

System Service

DC Fail

GREEN:

RED:

ORANGE:

DARK:

52mm

SERIAL NO. & RATING

LABEL IN THIS POSITION

ON REAR TERMINAL BLOCK

FOR 1S20 [x][A][x] PANEL

MOUNT VERSION

REMOVE FOR

REAR CABLE

ENTRY OPTION

REAR VIEW

REMOVE FOR

TWO M4 OR 4BA

MOUNTING SCREWS

32mm

TOP & BOTTOM REAR

TERMINAL BLOCK

RETAINING SCREWS

31 1mm

ID

+

(

7

5

)

1

1

3

m

m

8

5

m

m

(30) (30)

(

7

5

)

PANEL CUT OUT DETAIL

(Minimum clearance to other devices)mm

1

S

2

0

K

2

(

C

A

B

)

A

U

X

:

3

6

-

1

5

0

V

D

C

S

/

N

:

1

2

3

4

5

6

Panel or Surface Mounting

Panel or Surface Mounting

86mm 25mm

Use double sided tape supplied

Top & bottom positions

24mm

SIDE VIEW

RELAY PANEL

3mm THICK

MAXIMIUM

FRONT PANEL

LABEL

(Supplied with module)

SLIDE OUT CABLE

ENTRY POINTS

3 ON ONE SIDE

1 AT EACH END

TOP & BOTTOM REAR

TERMINAL BLOCK

RETAINING SCREWS

THESE MAY BE

UNSCREWED &

REVERSED TO FIT

FROM THE FRONT OF

THE 1S20 MODULE TO

ALLOW SURFACE

MOUNTING

RETENTION

SHROUD

1S20 Arc Fault Monitor

RESET / TEST

System Functioning

Arc Fault Trip

Sensor 1 Service

Sensor 2 or 3 Service

Continuous Sensor P/U

DC Supply Fail

GREEN:

RED:

ORANGE SOLID:

ORANGE FLASH:

ORANGE / RED:

NONE:

S/N:123457

DIN Rail or Surface Mounting

5mm

82mm 24mm

SIDE VIEW

OPTIONAL

DIN RAIL CLIP

P/N H01180001B

- DIN rail

mount version

DIN RAIL

RELEASE LEVER

SLIDE OUT CABLE

ENTRY POINTS

3 ON ONE SIDE

1 AT EACH END

S/N:123456

1S20K1 (CBB)

ARC FAULT MONITOR

DC Fail

Arc Fault Trip

System Functioning

Sensor 1 Service

Sensor 2 or 3 Service

Continuous Sensor P/U

AUX:36-150V DC

RESET / TEST

NONE:

RED:

GREEN:

ORANGE SOLID:

ORANGE FLASH:

ORANGE / RED:

Switch 1: Optional arc sensor 2 ON or OFF

Switch 2: Arc fault trip indication LED reset

Switch 3: Independent arc trip ON or OFF

Switch 4: Arc fault trip output contact latch function;

ON for LATCHING, OFF for self reset.

Switch 5: Optional arc sensor 3 ON or OFF

1S20

Configuration Settings

ON

ON

ON

ON

ON

OFF

OFF

OFF

OFF

OFF

1: ARC SENSOR 2

2: LATCHING TRIP LED

3: INDEPENDENT ARC TRIP

4: LATCHING TRIP CONTACTS

5: ARC SENSOR 3

1S20

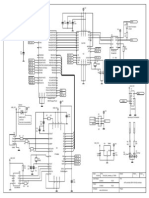

Wiring Termination

1S20 SOCKET TERMINAL LAYOUT

Viewed the from front when un-plugged from the main housing

(Always wire Arc Sensor 1. Arc sensor 2 & 3 optional)

2

2

1

1

3

3

4

4

5

5

6

6

8

8

9

9

12

12

11

11

10

10

1S20

Wiring Application

1S20 application diagram - Circuits shown in de-energised condition

12

8

10

9

9 or 11

5

1

3

11

6

2

4

Vx

+

+

Fail

alarm

Arc 1

Arc 3 Arc 2

Arc fault trip alarm signal to

protection relay status input for comms.

I>start

Control

Protection

1S20

50/51

Overcurrent

relay

Arc fault

relay

I>

CB Aux Switch

Trip Coil

52

T

52 - a

1S20 Ordering Code

Generate the required ordering code as follows: e.g. 1S20-CAB

1 AUXILIARY SUPPLY RANGE

A 20 - 60V DC

C 36 - 150V DC

2 MOUNTING

A Panel mount or surface mount

B DIN rail or surface mount only

3 SENSORS

A Two arc sensor inputs (Default)

B Three arc sensor inputs

PS5R POWER SUPPLY MODULE

Use the PS5R-A24 DIN rail mount module to power a single 1

from an 85-164V AC auxiliary source.

1 2 3

1S20 Arc Fault Monitor Relay

1S30 Ordering Code

Generate the required ordering code as follows: e.g. 1S30 AA

1 DETECTORS

A Single through hole panel detector

B Dual detectors

2 FLUSH MOUNT REINFORCING PLATE

A Not required

B Required

1 2

1S30 Arc Fault Sensor

1S28 Arc Fault Scheme

1S20

Additional Information

Technical Bulletin

User Guide

Price & Availability

www.rmspl.com.au/1s20.htm

Test Manuals

www.rmspl.com.au/search.asp

Other Products

www.rmspl.com.au/products.htm

Das könnte Ihnen auch gefallen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Noch keine Bewertungen

- Arc Guard AbbDokument9 SeitenArc Guard AbbsantoshkumarNoch keine Bewertungen

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Von EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Bewertung: 2.5 von 5 Sternen2.5/5 (3)

- 1 S 20Dokument2 Seiten1 S 20sunny_2502Noch keine Bewertungen

- 7XG3120 - ReyArc Catalogue SheetDokument16 Seiten7XG3120 - ReyArc Catalogue Sheetsameer233100% (1)

- 110 Waveform Generator Projects for the Home ConstructorVon Everand110 Waveform Generator Projects for the Home ConstructorBewertung: 4 von 5 Sternen4/5 (1)

- Protection Earth Leakage: "Si" and "Sie" Type, A & Ac Class RCCBDokument3 SeitenProtection Earth Leakage: "Si" and "Sie" Type, A & Ac Class RCCBa_miticNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Bender Rcm470lyDokument3 SeitenBender Rcm470lyRobert Arias TabrajNoch keine Bewertungen

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsVon EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsBewertung: 3.5 von 5 Sternen3.5/5 (6)

- A Isometer IR475LYDokument3 SeitenA Isometer IR475LYUrsula JohnsonNoch keine Bewertungen

- 3TK28201CB30 Datasheet enDokument4 Seiten3TK28201CB30 Datasheet enivan PaivaNoch keine Bewertungen

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- 19J M100 19J M100S, 19J M150 CJ19M10,20J M100, CJ20M10 20MJ10Dokument29 Seiten19J M100 19J M100S, 19J M150 CJ19M10,20J M100, CJ20M10 20MJ10Marco VegaNoch keine Bewertungen

- 3TK28211CB30 Datasheet enDokument7 Seiten3TK28211CB30 Datasheet enAnonymous SEveDwSUNoch keine Bewertungen

- ABB Substation Automation Trip Circuit Supervision Relay RXTCS Technical Data SheetDokument6 SeitenABB Substation Automation Trip Circuit Supervision Relay RXTCS Technical Data SheetEr Anoop GuptaNoch keine Bewertungen

- ACS710 DatasheetDokument23 SeitenACS710 DatasheetteomondoNoch keine Bewertungen

- AC30 Electronic Pulses Transmitter Technical DescriptionDokument13 SeitenAC30 Electronic Pulses Transmitter Technical DescriptionLizardo Ramos100% (1)

- Allegro ACS 709Dokument17 SeitenAllegro ACS 709David ZammitNoch keine Bewertungen

- ABB2CDS253001R0447Dokument3 SeitenABB2CDS253001R0447Anonymous hXUhpe7SNoch keine Bewertungen

- Reliable test devices for electric power systemsDokument6 SeitenReliable test devices for electric power systemsCoty62Noch keine Bewertungen

- EearDokument14 SeitenEearOswald NgNoch keine Bewertungen

- T A7272pDokument12 SeitenT A7272paaaxxxcccsssNoch keine Bewertungen

- Supresor ElectricoDokument12 SeitenSupresor ElectricoJuan QuezadaNoch keine Bewertungen

- Westermo Ug 6617-2203 mdw-45 RevfDokument16 SeitenWestermo Ug 6617-2203 mdw-45 RevfCarlos CetinaNoch keine Bewertungen

- Measure Earth Leakage with DCM300E ClampmeterDokument2 SeitenMeasure Earth Leakage with DCM300E ClampmeterReginald D. De GuzmanNoch keine Bewertungen

- Type MRTP Supervision For AC Pilot CircuitsDokument8 SeitenType MRTP Supervision For AC Pilot CircuitssmcraftNoch keine Bewertungen

- Saturn GeoDokument4 SeitenSaturn GeoAlexandre EstevesNoch keine Bewertungen

- Abb Insulation MonitoringDokument13 SeitenAbb Insulation MonitoringVaibhav AhujaNoch keine Bewertungen

- 1VET954910-910 Arc EliminatorDokument4 Seiten1VET954910-910 Arc EliminatorprotectionworkNoch keine Bewertungen

- RCB600 :: ROAL Living EnergyDokument10 SeitenRCB600 :: ROAL Living EnergyroalscribdNoch keine Bewertungen

- At The End of This Document You Will Find Links To Products Related To This Catalog. You Can Go Directly To Our Shop by ClickingDokument5 SeitenAt The End of This Document You Will Find Links To Products Related To This Catalog. You Can Go Directly To Our Shop by ClickingAhmad Aliyan Alif Bin IsmailNoch keine Bewertungen

- AC Current Clamp: Instruction SheetDokument6 SeitenAC Current Clamp: Instruction SheetKhaled Aboul-ELaNoch keine Bewertungen

- 13VTL100Dokument104 Seiten13VTL100Pedro GabrielNoch keine Bewertungen

- Int69 Vsy-Ii Protection ModuleDokument1 SeiteInt69 Vsy-Ii Protection Moduleamir12345678Noch keine Bewertungen

- 2CDS252001R0254 Miniature Circuit Breaker s200 2p C 25 ADokument3 Seiten2CDS252001R0254 Miniature Circuit Breaker s200 2p C 25 AEdison LeónNoch keine Bewertungen

- Ssm2120 2 ExpanderDokument12 SeitenSsm2120 2 ExpandershirtquittersNoch keine Bewertungen

- RM4TR32 Schneider Electric Datasheet 10978291Dokument7 SeitenRM4TR32 Schneider Electric Datasheet 10978291carlosvillamar1234Noch keine Bewertungen

- 3TK28251BB40 DatashnDokument4 Seiten3TK28251BB40 DatashnVinicius MateusNoch keine Bewertungen

- O & M of Sub StationDokument94 SeitenO & M of Sub StationAlbert Sekar100% (2)

- C3704Dokument2 SeitenC3704Ardillah PrawiraNoch keine Bewertungen

- 3TK28271AB21_datasheet_enDokument4 Seiten3TK28271AB21_datasheet_enRubicel GalindoNoch keine Bewertungen

- 41 LRM10V4Dokument2 Seiten41 LRM10V4RamachandranVenkatNoch keine Bewertungen

- Principles of Power System ProtectionDokument31 SeitenPrinciples of Power System Protectionmahmoodadeel100% (4)

- Digital Protective RelaysDokument34 SeitenDigital Protective Relayssubho7297648100% (3)

- 09441.003 Lr-20 Series Electrofisher ManualDokument27 Seiten09441.003 Lr-20 Series Electrofisher ManualTantyMaulinaNoch keine Bewertungen

- Recloser - OSM15!27!38 Brochure en NOJA-560-01Dokument12 SeitenRecloser - OSM15!27!38 Brochure en NOJA-560-01Jesús Oziel MartínezNoch keine Bewertungen

- 3797 CT-32D20BDokument12 Seiten3797 CT-32D20BЮрий ЮрченкоNoch keine Bewertungen

- Protection Earth Leak ClassDokument3 SeitenProtection Earth Leak ClassHNmaichoiNoch keine Bewertungen

- 3TK28252BB40 Datasheet enDokument4 Seiten3TK28252BB40 Datasheet enRemei RemeiNoch keine Bewertungen

- UOC III 21 G-III Chassis Service ManualDokument33 SeitenUOC III 21 G-III Chassis Service ManualAlexandra BarzaianuNoch keine Bewertungen

- EMC For Dummies e News FinalDokument26 SeitenEMC For Dummies e News FinalWilson MartinezNoch keine Bewertungen

- Introduction To EMC: Electronic ComponentsDokument26 SeitenIntroduction To EMC: Electronic ComponentsLakshitha Prabath WijesingheNoch keine Bewertungen

- Vital Components and Functions of an Electrical SubstationDokument20 SeitenVital Components and Functions of an Electrical Substationsanju0156100% (1)

- LG CE-29C82I Color TV Service ManualDokument31 SeitenLG CE-29C82I Color TV Service ManualSilomo-saka MambaNoch keine Bewertungen

- ABB MCB CatalogDokument16 SeitenABB MCB CatalogkarthiknmanuNoch keine Bewertungen

- ENMED301055EN - Flite 210 - 042013Dokument2 SeitenENMED301055EN - Flite 210 - 042013Tirthankar DattaNoch keine Bewertungen

- ACS713-Datasheet - Current Sensor ICDokument14 SeitenACS713-Datasheet - Current Sensor ICphase90Noch keine Bewertungen

- Measuring and Monitoring Relays CM-MSS (4), CM-MSS (5) : Thermistor Motor Protection Relay Data SheetDokument6 SeitenMeasuring and Monitoring Relays CM-MSS (4), CM-MSS (5) : Thermistor Motor Protection Relay Data SheetJJGNoch keine Bewertungen

- Handbookofmechan00nord BWDokument296 SeitenHandbookofmechan00nord BWJJG100% (1)

- HS20 Installation Manual 200716-0001Dokument2 SeitenHS20 Installation Manual 200716-0001JJGNoch keine Bewertungen

- Ag1022 Ag1012 User ManualDokument41 SeitenAg1022 Ag1012 User ManualJJGNoch keine Bewertungen

- Cee Motor GuidebookDokument39 SeitenCee Motor Guidebookhansenmike698105Noch keine Bewertungen

- Index 2Dokument4 SeitenIndex 2Alonso CoradoNoch keine Bewertungen

- Single Pole: OVR Type 1+2 Surge Protective DevicesDokument7 SeitenSingle Pole: OVR Type 1+2 Surge Protective DevicesJJG100% (1)

- Measuring and Monitoring Relays CM-MSS (4), CM-MSS (5) : Thermistor Motor Protection Relay Data SheetDokument6 SeitenMeasuring and Monitoring Relays CM-MSS (4), CM-MSS (5) : Thermistor Motor Protection Relay Data SheetJJGNoch keine Bewertungen

- ABB Thermistor RelaysDokument9 SeitenABB Thermistor RelaysJJGNoch keine Bewertungen

- AVR Controlled USB CAN Bus Interface: CANDIP HomepageDokument12 SeitenAVR Controlled USB CAN Bus Interface: CANDIP HomepageJJGNoch keine Bewertungen

- ADokument12 SeitenAAnanda KrishnaNoch keine Bewertungen

- Electric Motors WhitepaperDokument8 SeitenElectric Motors WhitepaperJJGNoch keine Bewertungen

- Abb Ovr Range TvssDokument16 SeitenAbb Ovr Range TvssJJGNoch keine Bewertungen

- AVR USB CAN Bus Interface CircuitDokument1 SeiteAVR USB CAN Bus Interface CircuitAlonso CoradoNoch keine Bewertungen

- Can OpenDokument20 SeitenCan OpenAdha HrustoNoch keine Bewertungen

- TI CAN Bus TutorialDokument15 SeitenTI CAN Bus TutorialMohamedHassanNoch keine Bewertungen

- Pepper Fuchs Solenoid Driver Kfd0 Sd2 Ex1Dokument3 SeitenPepper Fuchs Solenoid Driver Kfd0 Sd2 Ex1JJGNoch keine Bewertungen

- Entropic Correction Coulomb LawDokument17 SeitenEntropic Correction Coulomb LawJJGNoch keine Bewertungen

- EV to LUX Conversion ChartDokument2 SeitenEV to LUX Conversion ChartJJGNoch keine Bewertungen

- Ag1022 Ag1012 User ManualDokument41 SeitenAg1022 Ag1012 User ManualJJGNoch keine Bewertungen

- RF ThrusterDokument1 SeiteRF ThrusterbhaskarsgNoch keine Bewertungen

- NFPA Fire PumpDokument12 SeitenNFPA Fire PumpSyed Faizan AliNoch keine Bewertungen

- Controlled Rectifier D.C. Motor DrivesDokument21 SeitenControlled Rectifier D.C. Motor DrivesJJGNoch keine Bewertungen

- Apex PDFDokument16 SeitenApex PDFvoxdataNoch keine Bewertungen

- Exposure (Photography)Dokument8 SeitenExposure (Photography)JJGNoch keine Bewertungen

- Exposure (Photography)Dokument8 SeitenExposure (Photography)JJGNoch keine Bewertungen

- cs451 cs456Dokument38 Seitencs451 cs456JJGNoch keine Bewertungen

- UC232R SchematicDokument1 SeiteUC232R SchematicJJGNoch keine Bewertungen

- TNL-18 PLC in ControlDokument4 SeitenTNL-18 PLC in ControlJJGNoch keine Bewertungen

- VAr CompensatorsDokument9 SeitenVAr CompensatorsJJGNoch keine Bewertungen

- McDonlads Vs Burger KingDokument6 SeitenMcDonlads Vs Burger KingSamuel Tyre Jr.Noch keine Bewertungen

- Asian Organized CrimeDokument17 SeitenAsian Organized CrimeMagr EscaNoch keine Bewertungen

- Funda PharmaDokument9 SeitenFunda PharmaShiangNoch keine Bewertungen

- Computed Tomography (CT) - BodyDokument7 SeitenComputed Tomography (CT) - Bodyfery oktoraNoch keine Bewertungen

- BrochureDokument2 SeitenBrochureRajib DasNoch keine Bewertungen

- Gimnazjum Exam Practice GuideDokument74 SeitenGimnazjum Exam Practice GuideVaserd MoasleNoch keine Bewertungen

- Structure Dismantling JSADokument2 SeitenStructure Dismantling JSAtnssbhaskar69% (13)

- Oxyprobe PDFDokument16 SeitenOxyprobe PDFSrinivasa RNoch keine Bewertungen

- Product Bulletin - Menopause Balance Complex Cooling LotionDokument2 SeitenProduct Bulletin - Menopause Balance Complex Cooling Lotionshaklee480Noch keine Bewertungen

- Early Signs of AutismDokument27 SeitenEarly Signs of AutismErica Alejandra Schumacher100% (1)

- Escala de Violencia e Índice de SeveridadDokument11 SeitenEscala de Violencia e Índice de SeveridadpsiserviciosprofesioNoch keine Bewertungen

- Aripiprazole medication guideDokument3 SeitenAripiprazole medication guidemissayayaya100% (1)

- Behavior Intervention PlanDokument6 SeitenBehavior Intervention Planapi-308475283Noch keine Bewertungen

- Eng & FLS Standards Rev.1 (Dec. 2018)Dokument72 SeitenEng & FLS Standards Rev.1 (Dec. 2018)Nalan BAHCEKAPILINoch keine Bewertungen

- Barangay Ordinance Vaw 2018Dokument7 SeitenBarangay Ordinance Vaw 2018barangay artacho1964 bautista100% (3)

- 10.1007@978 981 15 4630 3 PDFDokument170 Seiten10.1007@978 981 15 4630 3 PDFRohit G100% (1)

- Prof Educ 2: Foundation of Special and Inclusive EducationDokument12 SeitenProf Educ 2: Foundation of Special and Inclusive EducationNerissa Custosa BastoNoch keine Bewertungen

- ESP Guidance For All Ships V13.7Dokument53 SeitenESP Guidance For All Ships V13.7Jayasankar GopalakrishnanNoch keine Bewertungen

- Extraction and Isolation of Saponins PDFDokument2 SeitenExtraction and Isolation of Saponins PDFMikeNoch keine Bewertungen

- Agri & Food Processing - Biscuit Manufacturing UnitDokument6 SeitenAgri & Food Processing - Biscuit Manufacturing Unitvijayind2006Noch keine Bewertungen

- Makalah ThoughtDokument5 SeitenMakalah Thoughtifa safiraNoch keine Bewertungen

- Frontier DL650 Maintenance Guide Ver 1.0Dokument25 SeitenFrontier DL650 Maintenance Guide Ver 1.0philippe raynalNoch keine Bewertungen

- FAQ: Product RegistrationDokument5 SeitenFAQ: Product RegistrationCalvin WangNoch keine Bewertungen

- EfAD BenchmarkJune2005 UKDokument55 SeitenEfAD BenchmarkJune2005 UKCristina Dobrin ClaudiaNoch keine Bewertungen

- Load Summary for Premise Under 100kVADokument2 SeitenLoad Summary for Premise Under 100kVAMuhammad Zulhelmi ZawawiNoch keine Bewertungen

- Barangay Peace and Order and Public Safety Plan Bpops Annex ADokument3 SeitenBarangay Peace and Order and Public Safety Plan Bpops Annex AImee CorreaNoch keine Bewertungen

- JP - Health and Wholeness Through The Holy CommunionDokument62 SeitenJP - Health and Wholeness Through The Holy Communionjevontan90% (10)

- Discover the flavors of Southwestern Luzon and Bicol RegionDokument5 SeitenDiscover the flavors of Southwestern Luzon and Bicol RegionGraceCayabyabNiduazaNoch keine Bewertungen

- DQ RMGDokument23 SeitenDQ RMGDhaval ChaplaNoch keine Bewertungen

- Personal and Group Trainer Juan Carlos GonzalezDokument2 SeitenPersonal and Group Trainer Juan Carlos GonzalezDidier G PeñuelaNoch keine Bewertungen