Beruflich Dokumente

Kultur Dokumente

Hydrotest Exemption Details

Hochgeladen von

joseph.maquez240 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten4 SeitenHydrotest Exemption Details

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHydrotest Exemption Details

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

120 Ansichten4 SeitenHydrotest Exemption Details

Hochgeladen von

joseph.maquez24Hydrotest Exemption Details

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 4

650-680

Title: API 650 Hydrostatic Test Exemptions

Date: 1-11-2010 (revised 7-3-2012); revised (4-24-13) revised (11-7-13) revised (2-4-14)

Contact: Name: David Clark

Company: Bukeye !ar"ners# $%!%

!&one: 21'-240-(4)7

*-mail: dllark+,ukeye%om

Purpose: -i.&li.&"s "o "&e !ur&aser and /a,ria"or# 0a"ors "o onsider ,e0ore makin. a deision no" "o

&ydro"es" an 1!2 )(0 "ank 0ollo3in. 0a,ria"ion i0 3a"er is no" availa,le%

ource: 4"ar"ed as an e-mail 0rom B&ana 5is"ry rela"in. "o 6ues"ions a,ou" &ydros"a"i "es" e7emp"ions in 1!2

)(0 and &o3 "&ey are applied or in"erpre"ed%

!e"ision: 7

Impact: 8&is &an.e# &i.&li.&"s "o "&e !ur&aser and /a,ria"or# "&e issue o0 no" ondu"in. a &ydro"es" i0

3a"er is no" availa,le and "&e ondi"ions "o onsider prior "o makin. "&a" deision%

5a9or impa"s inlude:

1% /or "&e &ydros"a"i "es" e7emp"ion "&e only e00e" on desi.n is "&a" 0or "&e 0ounda"ion in 3&i&

ase "&e produ" load is inreased ,y 10 :

2% 8&ere is no impa" on s&ell desi.n

3% 8es"in. no3 re6uires "es" ,y produ" ins"ead o0 "es" ,y 3a"er% 4u,se6uen" drainin. and

inspe"ion is s"ill re6uired% (No "imin. 0or "&e drainin. and inspe"ion is spei0ied%)

4% 1ll s&ell in"erse"ions mus" no3 ,e radio.rap&ed (8&is inludes appendi7 1 "anks )%

(% 1s ,e0ore all s&ell seams ,elo3 desi.n li6uid level re6uire an addi"ional e7amina"ion ,e0ore

0irs" 0ill; ei"&er li6uid pene"ran" or vauum ,o7 e7amina"ion# &o3ever# a pressure "es" o0 "&e

s&ell (,elo3 li6uid level) is no" onsidered a su,s"i"u"e e7amina"ion%

#ac$%round: 4"ar"ed as an e-mail 0rom B&ana 5is"ry rela"in. "o 6ues"ions a,ou" &ydros"a"i "es" e7emp"ions in 1!2

)(0 and &o3 "&ey are applied or in"erpre"ed%

1" "&e sprin. 2012 mee"in.# Dou. 5iller ommissioned Dave Clark# 4"eve Caru"&ers# ;o&n $ie, and

<ik <u00 "o de"ermine re6uiremen"s and su,mi" a ne3 dra0"% /irs" se"ion 7%3%( 3as ,roken do3n

in"o ou"line 0orma"# and "&en addi"ional re6uiremen"s 3ere de"ermined%

10"er "&e 0all 2013 mee"in.# David <osenkran"=# ;o&n $ie,# >a&-kan C&an# $arry -iner and 5a""

/e.en,us& 0rom 4?D provided inpu" re.ardin. up-0ron" "ank desi.n ri"eria%

Current

&ordin%:

*7erp" 0rom 4e"ion 7%3

*7erp" 0rom appendi7 $ &eklis"

Proposal: 7.3.5 Testing of the Shell

After the entire tank and roof structure is completed, the shell (except for the shell of tanks designed in

accordance with Appendix F) shall be strength- tested and the foundation initially loaded by one of the

following methods, as specified on the Data Sheet, ine !"#

!$ %f water is a&ailable for testing the shell

!$!$ the tank shall be filled with water as follows#

a$ fill to the maximum design li'uid le&el, H( or

b$ for a tank with a gas li'uid - tight roof, fill to )* mm (+ in$) abo&e the weld connecting the roof

plate or compression bar to the top angle or shell( or

c$ fill to a le&el lower than that specified in Subitem ! or + ,$-$)$!$!$a or ,$-$)$!$!$b when restricted

by o&erflows, an internal floating roof, or other freeboard by agreement between the .urchaser

and the /anufacturer, or

d$ fill to a le&el of seawater producing a bottom of shell hoop stress in the first shell course e'ual to

that produced by a full-height fresh water test$

!$+$ 0he tank shall be inspected fre'uently during the filling operation$ , and Any welded 1oints abo&e

the test-water le&el shall be examined after the test is complete in accordance with %tem + ,$-$)$+$!

below$ 0his test 0he tank hydrostatic test shall be conducted before permanent external piping is

connected to the tank and before any welds are painted$ Attachments to the shell defined in )$2$!$!,

located at least ! m (- ft) abo&e the water le&el, and roof appurtenances may be welded during the

filling of the tank$ After completion of the hydro-test, only non-structural small attachments may be

welded to the tank in accordance with ,$+$!$!!$

+$ %f sufficient water to fill the tank is not a&ailable and hydrostatic test exemption is specified by the

purchaser,

+$!$ the tank may be tested shall be examined by one of the following#

a$ coating painting all of the 1oints on the inside with applying highly penetrating oil, such as

automobile spring oil, to all of the 1oints on the inside and carefully examining the outside of

the 1oints for leakage prior to( or

b$ applying &acuum to either side of the 1oints or, if abo&e the li'uid le&el, applying internal air

pressure as specified for the roof test in ,$-$, and carefully &isually examining the 1oints for

leakage( or

c$ 3sing any combination of the methods stipulated in ,$-$)$+$!$a or ,$-$)$+$!$b$Subitems ! and +$

+$+$ Additional re'uirements shall include all of the following#

a$ 0he design for the tank foundation bearing capacity under normal operating modes, excluding

wind or seismic, shall be based on !$! times the specific gra&ity of the stored product or !$*,

whiche&er is greater$ 0he design basis for the storage tank shall be the greater of the specific gra&ity

of the product intended for normal operation or !$*, including tank shell thickness and foundation

design considerations$

b$ All tank shell weld intersections shall be radiographed, regardless of thickness$

c$ 3pon completion of these re'uirements, the first filling of the tank shall be conducted according

to section ,$-$4 as if it were a hydrostatic test, including appropriate personnel and fire safety

precautions, and in accordance with all pro&isions of ,$-$)$!$! and ,$-$)$!$+, except that the tank

need not be filled abo&e the maximum operating le&el$

d$ All radiography or other 5D6 and any welding abo&e the hydrostatic test le&el shall be

completed prior to testing with product$

7.3.6 Hydrostatic Testing Requirements

7.3.6.1 0his 0he tank hydrostatic test of the tank shall be conducted before permanent external piping is

connected to the tank except for piping that is necessary to fill and empty the tank, which should ha&e a

flexible component to allow for settling$ Attachments to the shell defined in )$2$!$!, located at least ! m (- ft)

abo&e the water le&el, and roof appurtenances may be welded during the filling of the tank$ After completion of

the hydro-test, only non-structural small attachments may be welded to the tank in accordance with ,$+$!$!!$

Any welded 1oints abo&e the test-water le&el shall be examined for leakage by one of the following methods#

!$ coating all of the 1oints on the inside with a highly penetrating oil, such as automobile spring oil, and

carefully examining the outside of the 1oints for leakage(

+$ applying &acuum to either side of the 1oints or applying internal air pressure as specified for the roof test in

,$-$, and carefully &isually examining the 1oints for leakage( or

-$ using any combination of the methods stipulated in Subitems ! and +$

----E!ER"TS #R$% &""E'() * ----

13. Foundation: Furnished by*_________________________________________ Type* ________________________________

Soil Allow. Bearing Pressure* ________ Per Spec.* _________________________________ Anchors: Sie* _____ !ty* _____

Foundation "esign #oads: Base Shear Force: $ind* _____ Seis%ic* _____ &'erturning (o%ent: $ind* ______ Seis%ic*

_____

)ing Forces: $eight o* Shell + )oo* ,ew* _______ -orroded* _______ )oo* #i'e #oad* _______ .nternal Pressure* _______

Partial /acuu%* ________ $ind* ________ Seis%ic* ________ 0ydrotest 12e%ption desi.n per 3.3.4.5.5 _______

Botto% Forces: Floor $t. ,ew* ______ -orroded* ______ Product $t.* ______ $ater $t.* _____ .nternal Pressure* ______

Partial /acuu%* _________ &ther Foundation #oads* ____________________ (in. Pro6ection o* Fdn. Abo'e 7rade: ________

18. Pressure Test 9See 3.3.4:

; )esponsibility *or 0eating Test $ater< i* )e=uired: Select one.

; 0ydro>Test Fill 0eight* or hydro>test e2e%ption: See 3.3.4< F.8.8< and F.3.?.

!ationale: 2n "&e presen" lan.ua.e o0 1!2 )(0# '()(5 Testin% o* t+e +ell ,650- Ele"ent+ Edition- .une /00'-

Addendum /- 0o"em1er /0023- "&ere are no re6uiremen"s "o evalua"e "&e s&ell and 0ounda"ion

desi.n# "ou.&ness re6uiremen"s# and ND* re6uiremen"s 3&en &ydros"a"i "es"in. is no" per0ormed% 1

poll o0 "&e mem,ers o0 "&e Desi.n and /a,ria"ion 4u,ommi""ees 3as "aken re.ardin. "&is issue%

8&e ma9ori"y o0 "&e responden"s 3ere in 0avor o0 inreasin. er"ain re6uiremen"s; &o3ever a

onsensus ould no" ,e es"a,lis&ed% Durin. "&e /all 2010 4"andards mee"in. in Nas&ville# "&e

4C148 /a,ria"ion 4u,.roup a.reed "o "&e proposed lan.ua.e addi"ion &i.&li.&"ed in <ed 2"alis%

8&is &an.e &i.&li.&"s "&e issues deemed impor"an" "o respondin. mem,ers o0 "&e previous poll

"aken%

Das könnte Ihnen auch gefallen

- Curriculum Vitae: INDIA: +91-8344756618Dokument4 SeitenCurriculum Vitae: INDIA: +91-8344756618Ujwal KhandokarNoch keine Bewertungen

- Velosi Proposal For Pressure Vessel Design VerificationDokument5 SeitenVelosi Proposal For Pressure Vessel Design VerificationShahbaz Khan33% (3)

- HOSE TEST METHODS GUIDEDokument5 SeitenHOSE TEST METHODS GUIDEtriagusmanNoch keine Bewertungen

- Rotating Equipment Installation Procedure Method StatementDokument28 SeitenRotating Equipment Installation Procedure Method Statementmanoj thakkarNoch keine Bewertungen

- Test Pack Table of ContentsDokument1 SeiteTest Pack Table of ContentsRavindra S. JivaniNoch keine Bewertungen

- Howto-Recommended Guidelines For Testing of Heat ExchangersDokument1 SeiteHowto-Recommended Guidelines For Testing of Heat ExchangersSam_1_Noch keine Bewertungen

- MSDS for Naphthenic Spent CausticDokument7 SeitenMSDS for Naphthenic Spent Causticjbloggs2007Noch keine Bewertungen

- Inspection of Static & Rotating Equipment InstallationDokument3 SeitenInspection of Static & Rotating Equipment InstallationNaiyer KarimiNoch keine Bewertungen

- Pump Alignment.Dokument3 SeitenPump Alignment.sen_subhasis_58100% (1)

- Basket Design Details As Per DNV StandardDokument4 SeitenBasket Design Details As Per DNV StandardmirraoNoch keine Bewertungen

- LEEAOffshore Crane Inspection CourseDokument1 SeiteLEEAOffshore Crane Inspection CourseVignesh MadhavanNoch keine Bewertungen

- Pressure Testing Safety EssentialsDokument7 SeitenPressure Testing Safety EssentialsSuleyman HaliciogluNoch keine Bewertungen

- Indirect Water Bath Heater Design ChecklistDokument4 SeitenIndirect Water Bath Heater Design ChecklistThiruppathirajanNoch keine Bewertungen

- Test Pack Flow ChartDokument1 SeiteTest Pack Flow ChartHum Hum100% (1)

- Polyken Utility Tape 900 910 908 911 920Dokument2 SeitenPolyken Utility Tape 900 910 908 911 920Tracy EvansNoch keine Bewertungen

- Inspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Dokument3 SeitenInspection and Test Plan For Shell and Tube Heat Exchanger - Sample01Mohamed AtefNoch keine Bewertungen

- Piping and Vessels Preparation For Commissioning - Part 2Dokument12 SeitenPiping and Vessels Preparation For Commissioning - Part 2MohamedNoch keine Bewertungen

- EQPT-02-21 Pipe Strain For Rotating EquipmentDokument2 SeitenEQPT-02-21 Pipe Strain For Rotating EquipmentAmanSharmaNoch keine Bewertungen

- Engineering Management Professional with Over 11 Years' ExperienceDokument5 SeitenEngineering Management Professional with Over 11 Years' Experiencehammad aslamNoch keine Bewertungen

- Infield Pipelines, Internal Condition Monitoring and InspectionDokument20 SeitenInfield Pipelines, Internal Condition Monitoring and InspectionMariluz HCNoch keine Bewertungen

- MisalignmentDokument44 SeitenMisalignmentRajesh ThakurNoch keine Bewertungen

- Attachment #4 - Inspection Test Plan ITP - Line Pipes CoatingDokument7 SeitenAttachment #4 - Inspection Test Plan ITP - Line Pipes CoatingLarry UbuNoch keine Bewertungen

- Pulling Exchanger Bundles SafelyDokument6 SeitenPulling Exchanger Bundles SafelygururajNoch keine Bewertungen

- STANDARDDokument1 SeiteSTANDARDomar sadiqNoch keine Bewertungen

- KSE Interview Preparation NotesDokument47 SeitenKSE Interview Preparation NotesJunaid btNoch keine Bewertungen

- JG 5 - MMI Inspection Engineer (Facilities & Equipments)Dokument5 SeitenJG 5 - MMI Inspection Engineer (Facilities & Equipments)bintogeorgev862Noch keine Bewertungen

- Static and Rotating Equipment PDFDokument4 SeitenStatic and Rotating Equipment PDFjpr220022Noch keine Bewertungen

- ITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CDokument2 SeitenITP For Inspection Fin-Fan Cooler 03-E-2A (1 & 2) B1CAmel Rayhan Aira100% (5)

- HYDROTESTDokument144 SeitenHYDROTESTJean GheorgheNoch keine Bewertungen

- ITR-B (Piping) Witness Joint1Dokument1 SeiteITR-B (Piping) Witness Joint1Momo ItachiNoch keine Bewertungen

- Shaft Alignment - Vibration Analysis - OutlineDokument4 SeitenShaft Alignment - Vibration Analysis - OutlineElias RizkNoch keine Bewertungen

- Air Testing TanksDokument2 SeitenAir Testing TanksTatiana CruzNoch keine Bewertungen

- Centrifugal pump maintenance scheduleDokument3 SeitenCentrifugal pump maintenance schedulemhnmndrkNoch keine Bewertungen

- Testing ProcedureDokument6 SeitenTesting Procedure810806100% (1)

- Question About Inspection A Pump: Comments Rated To Be "Almost" Good AnswersDokument4 SeitenQuestion About Inspection A Pump: Comments Rated To Be "Almost" Good AnswerspeakfortuneNoch keine Bewertungen

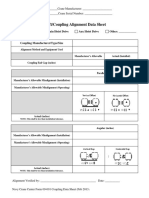

- Shaft/Coupling Alignment Data Sheet: Equipment (Check One) : Main Hoist Drive Aux Hoist Drive OtherDokument2 SeitenShaft/Coupling Alignment Data Sheet: Equipment (Check One) : Main Hoist Drive Aux Hoist Drive OtherBrad BorgesNoch keine Bewertungen

- Liquid NitrogenDokument8 SeitenLiquid NitrogenAshwin KumarNoch keine Bewertungen

- 1-Check List CF PumpDokument2 Seiten1-Check List CF PumpStarla HillNoch keine Bewertungen

- Equipment SpecificationDokument8 SeitenEquipment SpecificationPraveen ChandrakarNoch keine Bewertungen

- Piping ForemanDokument3 SeitenPiping ForemanManoj MissileNoch keine Bewertungen

- Sulzer Tower Field Service 042014Dokument8 SeitenSulzer Tower Field Service 042014Ângela de CarvalhoNoch keine Bewertungen

- Mechanical Equipment TestingDokument12 SeitenMechanical Equipment TestingChemi YeNoch keine Bewertungen

- Pneumatic Test ProcedureDokument12 SeitenPneumatic Test ProcedurePower Power100% (4)

- Inspection and Test Plan For Pressure VesselDokument2 SeitenInspection and Test Plan For Pressure Vesselalokbdas50% (2)

- Erection & Installation ProcedureDokument3 SeitenErection & Installation ProcedureForos IscNoch keine Bewertungen

- Pipeline Leak Repair Solutions for Corrosion, Damage and TheftsDokument6 SeitenPipeline Leak Repair Solutions for Corrosion, Damage and TheftsGhufran Ahmed BalaNoch keine Bewertungen

- Preliminary Report of Findings from Trailer Mounted Test SeparatorDokument12 SeitenPreliminary Report of Findings from Trailer Mounted Test SeparatorGood GamerNoch keine Bewertungen

- Jacking Procedurefor Construction of Tanks OLDDokument10 SeitenJacking Procedurefor Construction of Tanks OLDVikram RangasamyNoch keine Bewertungen

- Bolt Torquing Specialist Massy Wood GroupDokument2 SeitenBolt Torquing Specialist Massy Wood GroupMarkus Landington100% (1)

- QCF301 Hydro Test PackDokument1 SeiteQCF301 Hydro Test Packminhnn0% (1)

- Underground Piping Pressure Test RecordDokument1 SeiteUnderground Piping Pressure Test RecordPaulSwinbankNoch keine Bewertungen

- Pipe Strain Check ProcedureDokument1 SeitePipe Strain Check Procedurekamal arabNoch keine Bewertungen

- Pressure TestingDokument30 SeitenPressure TestingKaushal Gandhi100% (1)

- Technical Bid Evaluation of Vendor Spring Hanger Offers With PDFDokument3 SeitenTechnical Bid Evaluation of Vendor Spring Hanger Offers With PDFAmjadali ChoudhariNoch keine Bewertungen

- Mechanical Engineer Adnan SarfrazDokument6 SeitenMechanical Engineer Adnan SarfrazbillNoch keine Bewertungen

- Eqpt Check List-Pre InspectionDokument51 SeitenEqpt Check List-Pre Inspectionarifayee-1Noch keine Bewertungen

- Hydrostatic Test ProcedureDokument7 SeitenHydrostatic Test Procedurelaleye_olumideNoch keine Bewertungen

- Comprehensive Written Operating ProceduresDokument6 SeitenComprehensive Written Operating ProceduresChinedum IkeaguNoch keine Bewertungen

- Precommissioning ChecklistDokument13 SeitenPrecommissioning ChecklistJavier R- Colina M.Noch keine Bewertungen

- Checklist For Inspecting Vessels Loading Propylene Oxide PODokument7 SeitenChecklist For Inspecting Vessels Loading Propylene Oxide POmorgoths100% (1)

- Business TipsDokument4 SeitenBusiness Tipsjoseph.maquez24Noch keine Bewertungen

- High Fiber FoodsDokument3 SeitenHigh Fiber Foodsjoseph.maquez24Noch keine Bewertungen

- WPS & PQRDokument84 SeitenWPS & PQRjoseph.maquez24100% (4)

- Monterey's Hog Contract Growing Monterey Foods Corporation ProvidesDokument5 SeitenMonterey's Hog Contract Growing Monterey Foods Corporation Providesjoseph.maquez24Noch keine Bewertungen

- Asme IxDokument95 SeitenAsme Ixjoseph.maquez24Noch keine Bewertungen

- VALVE SPECIFICATIONDokument112 SeitenVALVE SPECIFICATIONjoseph.maquez24Noch keine Bewertungen

- Drive TestDokument3 SeitenDrive Testjoseph.maquez24Noch keine Bewertungen

- Valve Procurement SpecsDokument39 SeitenValve Procurement Specsjoseph.maquez24100% (2)

- CAr ChecklistDokument3 SeitenCAr Checklistjoseph.maquez24Noch keine Bewertungen

- Ejemplos RT PlacasDokument4 SeitenEjemplos RT PlacasNacho CajalNoch keine Bewertungen

- Singapore Zoo Park MapDokument1 SeiteSingapore Zoo Park MapKenneth TanNoch keine Bewertungen

- Valve Storage ProcedureDokument1 SeiteValve Storage Procedurejoseph.maquez24Noch keine Bewertungen

- Stainless SteelDokument8 SeitenStainless SteelAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- Fundamentals of Holiday Detection-TestDokument4 SeitenFundamentals of Holiday Detection-TestromeshmoreyNoch keine Bewertungen

- Stainless SteelDokument8 SeitenStainless SteelAlvaro Alexis Mendoza PradaNoch keine Bewertungen

- Wellforce Membrane Tanks: For Potable Water Pressure SystemsDokument2 SeitenWellforce Membrane Tanks: For Potable Water Pressure Systemsqwerty_conanNoch keine Bewertungen

- Quotation For A Granite Line PolisherDokument7 SeitenQuotation For A Granite Line PolisherKrishna Kant JethliyaNoch keine Bewertungen

- Kuettner Shaft-Furnace PDFDokument6 SeitenKuettner Shaft-Furnace PDFSamiran BanerjeeNoch keine Bewertungen

- SOS Service Fluid Analysis PDFDokument12 SeitenSOS Service Fluid Analysis PDFCorina StanculescuNoch keine Bewertungen

- Matrix Grease 2021Dokument11 SeitenMatrix Grease 2021dcvxt9w56xNoch keine Bewertungen

- Index TermsDokument90 SeitenIndex TermsAlfonso MartínezNoch keine Bewertungen

- MmeDokument114 SeitenMmemanojNoch keine Bewertungen

- Materials Glossary 2Dokument458 SeitenMaterials Glossary 2Lailanie BrionesNoch keine Bewertungen

- CATALOGO - Tube, Plates, Flanges & FittingsDokument170 SeitenCATALOGO - Tube, Plates, Flanges & FittingsTayyab ZubairNoch keine Bewertungen

- VW Fluid Capacity Chart 2001Dokument5 SeitenVW Fluid Capacity Chart 2001WILLIAM ROMERONoch keine Bewertungen

- Pengaruh Volume Agregat Halus Terhadap Sifat Segar Dan Kuat Tekan Pada High Volume Fly Ash Concrete (Hvfac)Dokument8 SeitenPengaruh Volume Agregat Halus Terhadap Sifat Segar Dan Kuat Tekan Pada High Volume Fly Ash Concrete (Hvfac)Der'z gamersNoch keine Bewertungen

- Case Study of Combination Ways of Steel and Timber in Japanese BuidingsDokument10 SeitenCase Study of Combination Ways of Steel and Timber in Japanese Buidingsmarya54100% (3)

- Saw Choosing GuideDokument96 SeitenSaw Choosing GuideAnonymous nKOyHbNoch keine Bewertungen

- Maintenance Schedule 12V16V4000Gx3x MS50061 - 03EDokument10 SeitenMaintenance Schedule 12V16V4000Gx3x MS50061 - 03EDavid J. Moya Flores100% (1)

- Electric Heating: Understanding the BasicsDokument21 SeitenElectric Heating: Understanding the BasicsGopi RamNoch keine Bewertungen

- Garage in A BoxDokument24 SeitenGarage in A BoxJohn SmithNoch keine Bewertungen

- Internal Combustion Engine TypesDokument35 SeitenInternal Combustion Engine TypesMuhammad FaizNoch keine Bewertungen

- Cartridge Heaters FIREROD ImmersionDokument3 SeitenCartridge Heaters FIREROD ImmersionEliasNoch keine Bewertungen

- Micro MachiningDokument302 SeitenMicro Machiningapulavarty100% (2)

- For Guidance For Guidance For Guidance For Guidance: Australasian HFG Standard Components WTPL Water Treatment Plant RoomDokument1 SeiteFor Guidance For Guidance For Guidance For Guidance: Australasian HFG Standard Components WTPL Water Treatment Plant Roommorton1472Noch keine Bewertungen

- Ide For Commissioning, Operation and Maintenance of Hydraulic Turbines - Commission Electrotechnique Internationale - SPLN 20a - 1978Dokument23 SeitenIde For Commissioning, Operation and Maintenance of Hydraulic Turbines - Commission Electrotechnique Internationale - SPLN 20a - 1978Aris CahyonoNoch keine Bewertungen

- C-9 Fender SystemDokument31 SeitenC-9 Fender Systemanupbhansali2004Noch keine Bewertungen

- Presentation ElectricalDokument29 SeitenPresentation ElectricalSazid RajaNoch keine Bewertungen

- Global Aluminum Alloy Conversion Chart: Delivering Engineered SolutionsDokument1 SeiteGlobal Aluminum Alloy Conversion Chart: Delivering Engineered SolutionsJOENoch keine Bewertungen

- Introduction to Production and Operations ManagementDokument268 SeitenIntroduction to Production and Operations ManagementRavuri KishoreNoch keine Bewertungen

- Garment DyeingDokument25 SeitenGarment DyeingSivakumar KNoch keine Bewertungen

- De303 01Dokument55 SeitenDe303 01Muhammad ImranNoch keine Bewertungen

- G4 Consuption Per MonthDokument2 SeitenG4 Consuption Per MonthInam alamNoch keine Bewertungen

- AGCO Beauvais Engineering: General Specification For Cast IronsDokument8 SeitenAGCO Beauvais Engineering: General Specification For Cast IronsRafa Lopez PuigdollersNoch keine Bewertungen

- Csi Masterformat 1995 Edition PDFDokument2 SeitenCsi Masterformat 1995 Edition PDFrobelineNoch keine Bewertungen