Beruflich Dokumente

Kultur Dokumente

Ventilator Valve

Hochgeladen von

Thiyagarajan RajendranCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ventilator Valve

Hochgeladen von

Thiyagarajan RajendranCopyright:

Verfügbare Formate

Turbine Ventilation Valve

Type TVV

Compact, robust design

Safe opening by spring force

Designed for frequent start-ups

Shortest stroking times

Custom design for conditions up to

300 bar / 600 C

Redundant control systems available

Application

The Turbine Ventilation Valve TVV is used for large

steam turbines, which are started up through the

IP-turbine. While in IP turbine operation mode, the

HP turbines require cooling. This cooling is

provided by cold steam flow through the HP turbine.

HP Turbine cooling during start-up (Reverse

Flow mode)

During the start-up sequence of the power plant,

the HP Turbine Control Valves as well as the

Turbine Shut-off Valves are closed in order to

eliminate any damage to the HP-Turbine caused by

improper steam conditions. Meanwhile the HP

Turbine Bypass Stations are in operation, leading

the steam to the IP/LP Turbine for the start-up

process (up to approx. 7% load).

During this process, the HP turbine requires

continuous cooling in order to avoid overheating.

Opening the Reverse Flow Valve (RFV) bypasses

the Turbine Check Valve. Opening the Turbine Vent

Valve (TVV) at the same time forces steam to

circulate from the cold reheater line through the HP

Turbine to the condenser, providing the required

cooling effect.

HP Turbine depressurizing at turbine trip or full

load rejection (depressurization mode)

In case of load rejection or turbine trip, the Turbine

Safety Valves close immediately and the HP

Bypass System takes over the steam flow.

To avoid overheating of the still rotating HP turbine,

the turbine must be depressurized immediately.

The Turbine Control System usually triggers

Turbine Safety Valves and the Turbine Vent Valve

TVV at the same time. Opening the Turbine Vent

Valves will evacuate the trapped steam to the

condenser, which leads to an immediate

depressurization of the turbine.

CCI Switzerland

Hegifeldstrasse 10

P.O. Box

CH-8404 Winterthur

Telephone ++41 52 262 11 66

Telefax ++41 52 262 01 65

CCI World Headquarter

22591 Avenida Empresa

Rancho Santa Margarita

CA 92688, U.S.A

Telephone ++1 949 858 18 77

Telefax ++1 949 858 18 78

CCI Sweden

Box 602

SE-661 29

Sffle, Sweden

Telephone ++46 533 689 600

Telefax ++46 533 689 601

CCI Japan

194-2 Shukunosho

Ibaraki-City, Osaka 567

Japan

Telephone ++81 726 41 71 97

Telefax ++81 726 41 71 98

CCI Korea

26-17, 26 Pungmu-Ri

Kimpo-Eup, Kimpo Gun

Kyungi-Do, South Korea

Telephone ++82 31 985 94 30

Telefax ++82 31 985 05 52

CCI Austria

Carlbergergasse 38

P.O. Box 19

AT-1233 Vienna, Austria

Telephone ++43 1 869 27 40

Telefax ++43 1 865 36 03

prods_TVV_rev0.doc / 551 /

16.01.02 / Rev. 0

Function

The valve is kept close by a hydraulic actuator, fed

through the turbines own hydraulic actuation

system whereas it opens by spring force. The

hydraulic pilot system triggered through the

turbine safety system shuts the hydraulic

pressure line and bypasses upper and lower

chamber of the actuator, allowing the pre-tensioned

spring to open the Vent Valve in less than 1

second.

The unique hydraulic control unit allows the

mounting of multiple and/or different types of

solenoid in order to fulfill customer specified

redundancy requirements.

Design

The Turbine Ventilation Valve TVV is an angle body

type, incorporating a pressurized seal bonnet.

Usually in flow-to-close configuration, it can also be

supplied in a flow-to-open configuration.

With the range of available body materials, the

Turbine Ventilation Valve TVV can be applied for

the operating temperatures of todays most

advanced thermal power plants. The valve body

with its spherical shapes is designed for cyclic

operation and frequent start-ups.

Material concentrations and abrupt changes of wall

thickness are avoided.

A welded-in, replaceable seat provides leakage

rates according to ANSI/FCI Class V as a

minimum.

In order to keep opening forces low and predictable,

the stem is sealed by labyrinths with single or

double exhaust.

Technical Specification

Body style Angle, flow to close or flow to open

Spherical shaped body

Pressurized seal bonnet

Pipe connection For steam pipes: butt-welding

according to customers

requirement

For exhaust: flanged according to

DIN or ASME

Steam data range Temperature: ~ 500 - 600 C

Pressure: 300 bar

Trim Unbalanced, Welded-in or

clamped seat

Pressure seal bonnet

Seat-/stem

tightness

ANSI B16-104, class V

DIN 3230, rate 2 / MSS-SP61

(optional)

Actuation Double-acting hydraulic piston

actuator for closing

Spring to open the valve

Options Transition pieces for large pipe

diameters and material

compatibility

Prewarming and drain connection

available on request

Orientation No restrictions

LP IP HP G

LP-Bypass

HP-Bypass

Boiler

Condenser

Steam Turbine

FW-Pump

TVV

RFV

Das könnte Ihnen auch gefallen

- Trip OilDokument3 SeitenTrip Oilchdeepak96100% (1)

- Operator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingVon EverandOperator's Guide to General Purpose Steam Turbines: An Overview of Operating Principles, Construction, Best Practices, and TroubleshootingBewertung: 5 von 5 Sternen5/5 (1)

- Lesson Steam Turbine Technology Turbine Auxiliary and Sub-SystemsDokument26 SeitenLesson Steam Turbine Technology Turbine Auxiliary and Sub-Systemsmister pogiNoch keine Bewertungen

- Thermal Cycles of Heat Recovery Power PlantsVon EverandThermal Cycles of Heat Recovery Power PlantsBewertung: 5 von 5 Sternen5/5 (2)

- Turbine Systems GuideDokument22 SeitenTurbine Systems Guidelavpandey8719100% (2)

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantVon EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryBewertung: 4 von 5 Sternen4/5 (5)

- Feed Water Deaeration in Thermal Power PlantDokument46 SeitenFeed Water Deaeration in Thermal Power PlantAshwani Dogra100% (2)

- Thermal Power Plant: Pre-Operational ActivitiesVon EverandThermal Power Plant: Pre-Operational ActivitiesBewertung: 4 von 5 Sternen4/5 (4)

- Auxiliary Power Consumption Sample for Power PlantsDokument2 SeitenAuxiliary Power Consumption Sample for Power Plantsabhiknit0% (1)

- Air Cooled Condenser and Non PerformanceDokument67 SeitenAir Cooled Condenser and Non Performanceparthi20065768100% (2)

- Salient Features of 500MWDokument63 SeitenSalient Features of 500MWSamNoch keine Bewertungen

- High Silica After Overhaul of Fouled TurbineDokument3 SeitenHigh Silica After Overhaul of Fouled Turbineak_thimiriNoch keine Bewertungen

- Steam Turbine Aux. Steam SystemDokument29 SeitenSteam Turbine Aux. Steam SystemPrasanna Chikkamallaiah100% (1)

- The function of feed water heatersDokument19 SeitenThe function of feed water heatersMarzouk Abdel Wahed Marzouk100% (1)

- Steam Turbine Thermal Stress Online Monitoring Technology - EPRI PDFDokument84 SeitenSteam Turbine Thermal Stress Online Monitoring Technology - EPRI PDFChetan Atrai100% (1)

- Turbine Performance Assesment - BHELDokument36 SeitenTurbine Performance Assesment - BHELscribd free100% (2)

- Seal Oil and Hydrogen SystemDokument34 SeitenSeal Oil and Hydrogen Systemashish_ntpcNoch keine Bewertungen

- Turbine Turning Gear ModuleDokument13 SeitenTurbine Turning Gear ModulePrasanna Chikkamallaiah100% (1)

- Vacuum Systems: Key to Power Plant OperationDokument15 SeitenVacuum Systems: Key to Power Plant OperationzulryNoch keine Bewertungen

- Rafako CFBC Boiler PDFDokument13 SeitenRafako CFBC Boiler PDFadehriya100% (1)

- Upgrade LMZ Turbine K-210-130 Capacity and EfficiencyDokument62 SeitenUpgrade LMZ Turbine K-210-130 Capacity and EfficiencyAnonymous gr5Pr9AVNoch keine Bewertungen

- 3.boiler OperationDokument167 Seiten3.boiler OperationMa Vũng ÁngNoch keine Bewertungen

- Boiler NotesDokument34 SeitenBoiler NotesRakesh Singh BhadoriyaNoch keine Bewertungen

- Emergency HandlingDokument29 SeitenEmergency HandlingSouvik DuttaNoch keine Bewertungen

- performance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFDokument36 Seitenperformance test procedure 最终提交业主版 - 都利项目性能试验大纲(英文)2014-9-30 PDFarunrajmech09100% (1)

- 500 MW Boiler-1Dokument14 Seiten500 MW Boiler-1Priyal Patil100% (1)

- Operation Manual: Lqs-Iicsa Refrigerating Hydrogen DryerDokument35 SeitenOperation Manual: Lqs-Iicsa Refrigerating Hydrogen Dryerdsinghrpd100% (1)

- Steam Gland SealingDokument118 SeitenSteam Gland SealingRyan Wong100% (1)

- 1aha052263 ADokument19 Seiten1aha052263 ATanmay MajhiNoch keine Bewertungen

- 500MW Starting ProceduresDokument38 Seiten500MW Starting Proceduresthangarajm1984Noch keine Bewertungen

- WPCL 4x135MW Power Plant Turbine Operation ManualDokument209 SeitenWPCL 4x135MW Power Plant Turbine Operation ManualsambhuNoch keine Bewertungen

- Boiler Feed Pump SavingDokument28 SeitenBoiler Feed Pump SavingDramebaaz SandeepNoch keine Bewertungen

- Hydrogen / Water - Cooled Turbogenerators: A Mature Technology On The MoveDokument9 SeitenHydrogen / Water - Cooled Turbogenerators: A Mature Technology On The MoveR0B0T2013100% (1)

- HP LP BYPASS SYSTEM ADVANTAGESDokument3 SeitenHP LP BYPASS SYSTEM ADVANTAGESkaruna346Noch keine Bewertungen

- CFBC Boiler Performance Calculation4 PDFDokument43 SeitenCFBC Boiler Performance Calculation4 PDFrizalNoch keine Bewertungen

- GE's 330MW Digital Electro-Hydraulic Control System for Steam TurbinesDokument22 SeitenGE's 330MW Digital Electro-Hydraulic Control System for Steam Turbineskeerthi dayarathnaNoch keine Bewertungen

- WH Vacuum in Steam TurbineDokument2 SeitenWH Vacuum in Steam Turbinemiths_0087Noch keine Bewertungen

- Lesson Turbine Mainte0Ance ProgramDokument2 SeitenLesson Turbine Mainte0Ance Programmister pogiNoch keine Bewertungen

- Boiler Design and Operation ParametersDokument88 SeitenBoiler Design and Operation ParametersNavneet SinghNoch keine Bewertungen

- Condensate Cycle SystemDokument26 SeitenCondensate Cycle SystemBhumit Sagathiya100% (2)

- New Concepts in Supercritical TurbinesDokument37 SeitenNew Concepts in Supercritical TurbinesSushil Lamba100% (1)

- InterlocksDokument26 SeitenInterlocksFelipe SandovalNoch keine Bewertungen

- Stator CW SOP-2Dokument12 SeitenStator CW SOP-2SonratNoch keine Bewertungen

- Steam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestDokument10 SeitenSteam Turbine Cycle: Turbine Cycle, Heat Balance Concept, Thermal Efficiency & PG TestAakash RanjanNoch keine Bewertungen

- Front & Rear Wall BoilerDokument93 SeitenFront & Rear Wall BoilerAravazhi Ramasami Thangaraj100% (1)

- HRSG StartupDokument20 SeitenHRSG StartupKvvPrasad100% (1)

- Turbine Lub Oil SysDokument26 SeitenTurbine Lub Oil SysMohammad Ataullah100% (1)

- Gland Sealing System CompleteDokument46 SeitenGland Sealing System CompleteKumaraswamy75% (4)

- 250MW Thermal Power PlantDokument70 Seiten250MW Thermal Power Plantdileepjana100% (2)

- Turbine Gland Seal Steam SystemDokument15 SeitenTurbine Gland Seal Steam SystemFahad Khalil75% (8)

- Steam Turbine Stop Valve TestingDokument22 SeitenSteam Turbine Stop Valve TestingAbdulyunus Amir100% (3)

- Steam Turbine Generator: Performance Test Protocol GP-TRB-001Dokument48 SeitenSteam Turbine Generator: Performance Test Protocol GP-TRB-001Lucky Cham AguilaNoch keine Bewertungen

- Aux PRDS SystemDokument22 SeitenAux PRDS SystemKhan Ahmed MuradNoch keine Bewertungen

- Increasing Efficiency of Boiler Using ScaphDokument11 SeitenIncreasing Efficiency of Boiler Using ScaphInternational Journal of Innovative Science and Research Technology100% (1)

- Gas-Steam Turbine Technical Data 2012Dokument8 SeitenGas-Steam Turbine Technical Data 2012Ninh Quoc Trung100% (1)

- Presentation On Turbine Protection System: Prepared by Subir BiswasDokument29 SeitenPresentation On Turbine Protection System: Prepared by Subir BiswasJitu Jena100% (2)

- Cold-Start Up of Coal Fired PowerplantsDokument6 SeitenCold-Start Up of Coal Fired PowerplantsAbdulyunus AmirNoch keine Bewertungen

- Presentation Main TurbineDokument45 SeitenPresentation Main TurbineSam100% (1)

- Frankenstein: Penguin Readers FactsheetsDokument4 SeitenFrankenstein: Penguin Readers FactsheetsPatrícia MartinsNoch keine Bewertungen

- SEL SEL Software: Design and Set Your SystemDokument4 SeitenSEL SEL Software: Design and Set Your Systemvanhalenfernando123Noch keine Bewertungen

- Ancient Egypt Achievements Flipped NotesDokument11 SeitenAncient Egypt Achievements Flipped Notesapi-374967196100% (1)

- Interview and Photographic Documentary of Masjid JamekDokument8 SeitenInterview and Photographic Documentary of Masjid JamekSurayyn SelvanNoch keine Bewertungen

- Write Verb to be and Short FormDokument1 SeiteWrite Verb to be and Short FormSvetla Stanoeva0% (1)

- Euthymius and His Monastery in The Judean DesertDokument33 SeitenEuthymius and His Monastery in The Judean DesertnurodaNoch keine Bewertungen

- Issue14final PDFDokument51 SeitenIssue14final PDFPOWER NewsNoch keine Bewertungen

- Index To SpecificationDokument29 SeitenIndex To Specificationsat palNoch keine Bewertungen

- D+A Magazine Issue 085, 2015Dokument116 SeitenD+A Magazine Issue 085, 2015Bùi ThắngNoch keine Bewertungen

- SPLAT Expert Mode TipsDokument11 SeitenSPLAT Expert Mode TipsAndy HarcupNoch keine Bewertungen

- Building Fire FightingDokument9 SeitenBuilding Fire FightingrmaffireschoolNoch keine Bewertungen

- C Is An: Aapl AaplDokument23 SeitenC Is An: Aapl AaplRaghumath ManoharNoch keine Bewertungen

- Housekeeping Work CardsDokument15 SeitenHousekeeping Work Cardsmanish sharma33% (3)

- infoPLC Net ErrorCodes 2015-02-05Dokument556 SeiteninfoPLC Net ErrorCodes 2015-02-05Ivan Cordero ValerianoNoch keine Bewertungen

- Masterbilt BLG HDDokument2 SeitenMasterbilt BLG HDwsfc-ebayNoch keine Bewertungen

- MORTAR MIXESDokument712 SeitenMORTAR MIXESShashank SNoch keine Bewertungen

- Multimedia NetworkingDokument6 SeitenMultimedia Networkingkainat KhalidNoch keine Bewertungen

- ThingWorx Platform Technical Presentation PDFDokument57 SeitenThingWorx Platform Technical Presentation PDFnil_71Noch keine Bewertungen

- Varicondition DX enDokument5 SeitenVaricondition DX encarlos16702014Noch keine Bewertungen

- Project BOQDokument97 SeitenProject BOQThinh Tran100% (3)

- SRS Document On Upsc - Software Requirement Specification Srs SRS Document On Upsc - Software Requirement Specification SrsDokument7 SeitenSRS Document On Upsc - Software Requirement Specification Srs SRS Document On Upsc - Software Requirement Specification SrsKenleeNoch keine Bewertungen

- Ramesh 1Dokument2 SeitenRamesh 1praveen mNoch keine Bewertungen

- BDD Bubble Diagram Analisa Organisasi RuangDokument1 SeiteBDD Bubble Diagram Analisa Organisasi Ruanganon_545295732Noch keine Bewertungen

- CC Marine 2013-14 Catalogue - SailingDokument8 SeitenCC Marine 2013-14 Catalogue - SailingGregGGHNoch keine Bewertungen

- HP Color Laserjet Pro MFP M477 Series: Stunning Speed. Solid SecurityDokument5 SeitenHP Color Laserjet Pro MFP M477 Series: Stunning Speed. Solid Securitygem lihanshNoch keine Bewertungen

- 6 Sat Plumbing QuestionDokument2 Seiten6 Sat Plumbing QuestionMons DelmendoNoch keine Bewertungen

- Brocade Qualification Letter Fos 6.4.0c PDFDokument4 SeitenBrocade Qualification Letter Fos 6.4.0c PDFAshwin VijayNoch keine Bewertungen

- High Speed Counter and TimerDokument34 SeitenHigh Speed Counter and TimerpaldopalNoch keine Bewertungen

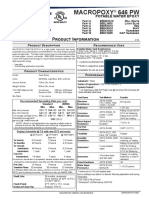

- Macropoxy 646 PW: Protective & Marine CoatingsDokument4 SeitenMacropoxy 646 PW: Protective & Marine CoatingsAnn HewsonNoch keine Bewertungen

- Restricting AD Replication Traffic To A Specific Port (KB224196)Dokument3 SeitenRestricting AD Replication Traffic To A Specific Port (KB224196)AldineYapNoch keine Bewertungen

- The Grid: The Fraying Wires Between Americans and Our Energy FutureVon EverandThe Grid: The Fraying Wires Between Americans and Our Energy FutureBewertung: 3.5 von 5 Sternen3.5/5 (48)

- Industrial Piping and Equipment Estimating ManualVon EverandIndustrial Piping and Equipment Estimating ManualBewertung: 5 von 5 Sternen5/5 (7)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionBewertung: 5 von 5 Sternen5/5 (1)

- Produced Water Treatment Field ManualVon EverandProduced Water Treatment Field ManualBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Renewable Energy: A Very Short IntroductionVon EverandRenewable Energy: A Very Short IntroductionBewertung: 4.5 von 5 Sternen4.5/5 (12)

- Power of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesVon EverandPower of Habit: The Ultimate Guide to Forming Positive Daily Habits, Learn How to Effectively Break Your Bad Habits For Good and Start Creating Good OnesBewertung: 4.5 von 5 Sternen4.5/5 (21)

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- OFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyVon EverandOFF-GRID PROJECTS: A Comprehensive Beginner's Guide to Learn All about OffGrid Living from A-Z and Live a Life of Self-SufficiencyNoch keine Bewertungen

- Asset Integrity Management for Offshore and Onshore StructuresVon EverandAsset Integrity Management for Offshore and Onshore StructuresNoch keine Bewertungen

- Handbook on Battery Energy Storage SystemVon EverandHandbook on Battery Energy Storage SystemBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Idaho Falls: The Untold Story of America's First Nuclear AccidentVon EverandIdaho Falls: The Untold Story of America's First Nuclear AccidentBewertung: 4.5 von 5 Sternen4.5/5 (21)

- The New 3D Layout for Oil & Gas Offshore Projects: How to ensure successVon EverandThe New 3D Layout for Oil & Gas Offshore Projects: How to ensure successBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Shorting the Grid: The Hidden Fragility of Our Electric GridVon EverandShorting the Grid: The Hidden Fragility of Our Electric GridBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Formulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsVon EverandFormulas and Calculations for Drilling, Production, and Workover: All the Formulas You Need to Solve Drilling and Production ProblemsNoch keine Bewertungen

- Build Your Own Electric Vehicle, Third EditionVon EverandBuild Your Own Electric Vehicle, Third EditionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- The Rare Metals War: the dark side of clean energy and digital technologiesVon EverandThe Rare Metals War: the dark side of clean energy and digital technologiesBewertung: 5 von 5 Sternen5/5 (2)

- Transmission Pipeline Calculations and Simulations ManualVon EverandTransmission Pipeline Calculations and Simulations ManualBewertung: 4.5 von 5 Sternen4.5/5 (10)

- Introduction to Power System ProtectionVon EverandIntroduction to Power System ProtectionNoch keine Bewertungen

- Implementing an Integrated Management System (IMS): The strategic approachVon EverandImplementing an Integrated Management System (IMS): The strategic approachBewertung: 5 von 5 Sternen5/5 (2)

- Nuclear Energy in the 21st Century: World Nuclear University PressVon EverandNuclear Energy in the 21st Century: World Nuclear University PressBewertung: 4.5 von 5 Sternen4.5/5 (3)

- ISO 50001: A strategic guide to establishing an energy management systemVon EverandISO 50001: A strategic guide to establishing an energy management systemNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideVon EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideBewertung: 2 von 5 Sternen2/5 (1)

- Energy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksVon EverandEnergy, Light and Electricity - Introduction to Physics - Physics Book for 12 Year Old | Children's Physics BooksNoch keine Bewertungen

- The Way Home: Tales from a life without technologyVon EverandThe Way Home: Tales from a life without technologyBewertung: 4 von 5 Sternen4/5 (45)

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)