Beruflich Dokumente

Kultur Dokumente

Assembly Instructions For VF Pinch Valves 100 250mm

Hochgeladen von

pruna1045Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Assembly Instructions For VF Pinch Valves 100 250mm

Hochgeladen von

pruna1045Copyright:

Verfügbare Formate

Technical details subject to change without notice.

AKO UK Ltd

12 Rutherford Way, Drayton Fields Industrial Estate, Daventry, Northamptonshire, NN11 8XW

Tel: 01327 312 747 Fax: 01327 312 565 E-mail: sales@ako-valves.com Web: www.pinch-valves.com

M

A

V

0

0

3

_

e

n

-

0

6

/

2

0

1

0

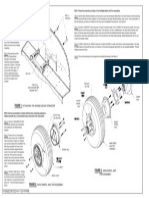

Removing the old sleeve

Loose bolts (C), take off fanges (B).

Pull out old sleeve (D) by using a pipe wrench.

If helpful, lubricate AKO mounting paste (MP200) between rubber

and internal body surface.

Clean all valve parts and inspect for wear.

Installation of the new sleeve

Picture 1: Lubricate following parts with AKO mounting paste (MP200)

- inside and outside surfaces of sleeve (D),

- cones of fanges (B) and

- inside surface of body (neck area).

Caution: Do not use any grease or oily paste!.

Picture 2: Push sleeve (D) into body (A) until it is centred.

Picture 3: Assemble fange (B) onto body and fx it with 2 or 4

mounting bolts (C), washer and nuts. Tighten them counter clock-

wise until fange cone touches the sleeve.

Picture 4: Put opposite side of fange (B) into sleeve (D) and tight-

en second bolt (C), washer and nut until it touches the sleeve.

Picture 5: Push mounting pipe into the valve (5/6 length of the

sleeve). Put 3 bar air through the air inlet to pressurize the

sleeve.

Picture 6+7: Use a spanner and push the sleeve behind the cone

from the fange (B). Tighten mounting bolts (30Nm) from second

fange (B) and assemble completely with the remaining bolts (C).

Bolts have to be tightened. Release control air. Assemble counter

fange as described in picture 5, 6+7. Again, release control air

and remove mounting pipe. Make sure that all mounting bolts have

been replaced by assembling bolts (C). Verify bolts are tight.

Picture 8: Put mounting wood into valve assembly, with the small

part facing to the air inlet. Pressurise valve with 3 bar and keep the

wood in stable position. Sleeve must close in lip-shape position

viewing to air inlet. Alternatively assembly: Valve can be assem-

bled under a mechanical press. Caution: Do not use any sharp

tools during assembly, it may damaged valve parts!

*Replacement-/ Maintenance parts: Sleeve (D) and fanges (B).

Assembly tool: AKO mounting set (i.e. W125) consists of mount-

ing paste, mounting pipe, mounting wood, assembling screws,

nuts and bolts.

Assembly Instruction for AKO Pinch Valve

Series V+VF DN 100 to 250 mm

Picture 1 Picture 2

Picture 3 Picture 4

Picture 5 Picture 6 Picture 7

* Flange (B) Body (A)

* Sleeve (D) Screws (C)

Control air

Picture 8

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Hub Reduction, InstallingDokument16 SeitenHub Reduction, InstallingwawanNoch keine Bewertungen

- Installation and Unpacking Guide for Konica 7075 Main BodyDokument11 SeitenInstallation and Unpacking Guide for Konica 7075 Main BodyNistor SilviuNoch keine Bewertungen

- Maintenance / Repair of Pinch Valves Series VMC DN 100, Type G, M, R, RA, T, TADokument1 SeiteMaintenance / Repair of Pinch Valves Series VMC DN 100, Type G, M, R, RA, T, TAElleuch HaithemNoch keine Bewertungen

- ArnottDokument23 SeitenArnottJeremy CallinanNoch keine Bewertungen

- Acura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairDokument11 SeitenAcura TSX Sport Wagon L4-2.4L 2011 Timing Chain: Service and RepairCarlos Gunter Tamayo MoralesNoch keine Bewertungen

- Toyota Hiace MantenimientoDokument20 SeitenToyota Hiace Mantenimientofranktrevi75% (4)

- 8th Gen Shifter Cables Install GuideDokument15 Seiten8th Gen Shifter Cables Install GuideHybrid Racing100% (1)

- Cat c15 Cylinder Head InstallationDokument7 SeitenCat c15 Cylinder Head InstallationMUHSIN MTNoch keine Bewertungen

- Isc 300Dokument37 SeitenIsc 300AwanNoch keine Bewertungen

- Remove & Install Bucket CylinderDokument6 SeitenRemove & Install Bucket CylinderKevin DayNoch keine Bewertungen

- Project Photos: Section 1 - Removing The Intake ManifoldDokument33 SeitenProject Photos: Section 1 - Removing The Intake ManifoldGabriel Usaga CNoch keine Bewertungen

- Inlet and Exhaust Valve Seals - Remove and Install: ShutdownDokument3 SeitenInlet and Exhaust Valve Seals - Remove and Install: ShutdownLuis TepezanoNoch keine Bewertungen

- Bo016t06 Moonroof Stuck Bo016t06 Moonroof Stuck Bo016t06 Moonroof Stuck Bo016t06 Moonroof StuckDokument10 SeitenBo016t06 Moonroof Stuck Bo016t06 Moonroof Stuck Bo016t06 Moonroof Stuck Bo016t06 Moonroof StuckVicenteRocabadoNoch keine Bewertungen

- Timing Chain Service and Repair Acura RSX 2.0 2004: Auto-Tensioner Removal/InstallationDokument15 SeitenTiming Chain Service and Repair Acura RSX 2.0 2004: Auto-Tensioner Removal/InstallationCarlos Gunter Tamayo MoralesNoch keine Bewertungen

- Repair Procedure HS14 - S7.4x2.5 - 26-10-7632Dokument9 SeitenRepair Procedure HS14 - S7.4x2.5 - 26-10-7632Cesar Camones100% (1)

- Timing Chain Service Cam Chain Removal Installation Acura RDX 2.3LDokument12 SeitenTiming Chain Service Cam Chain Removal Installation Acura RDX 2.3LCarlos Gunter Tamayo MoralesNoch keine Bewertungen

- 10 Ft. Square Steel Gazebo Assembly ManualsDokument9 Seiten10 Ft. Square Steel Gazebo Assembly ManualsgillerdoitNoch keine Bewertungen

- Duke XC SL Race ServiceDokument10 SeitenDuke XC SL Race ServicesilverapeNoch keine Bewertungen

- ManualDokument4 SeitenManualMano Negra100% (1)

- Camshaft removal and installationDokument9 SeitenCamshaft removal and installationpizandolaNoch keine Bewertungen

- Recon Service GuideDokument12 SeitenRecon Service GuideJuho KauppinenNoch keine Bewertungen

- Gto Montaje de AlastraDokument88 SeitenGto Montaje de AlastraTecnico Artes GraficasNoch keine Bewertungen

- CE3458 Parts ManualDokument84 SeitenCE3458 Parts ManualMrbigg10Noch keine Bewertungen

- Van'S Aircraft, Inc.: Figure 1: Attaching The Engine Mount StandoffDokument1 SeiteVan'S Aircraft, Inc.: Figure 1: Attaching The Engine Mount StandoffMark Evan SalutinNoch keine Bewertungen

- Cylinder Head 3sfeDokument27 SeitenCylinder Head 3sfePham Huy83% (18)

- 2012 Dorado Pro Service ManualDokument29 Seiten2012 Dorado Pro Service ManualSea RidersNoch keine Bewertungen

- 10 - Timing Chain - InstallationDokument7 Seiten10 - Timing Chain - Installation08088338Noch keine Bewertungen

- 24 Serrage D'une Culasse.Dokument6 Seiten24 Serrage D'une Culasse.AliHabesNoch keine Bewertungen

- Timing Belt: Service and Repair 2002 Acura Truck MDX V6-3.5LDokument16 SeitenTiming Belt: Service and Repair 2002 Acura Truck MDX V6-3.5LCarlos Gunter Tamayo MoralesNoch keine Bewertungen

- AFC06901 (Balancines)Dokument12 SeitenAFC06901 (Balancines)salvador montenegroNoch keine Bewertungen

- SM - Volvo Ec210b LC Ec210blc ExcavatorDokument18 SeitenSM - Volvo Ec210b LC Ec210blc ExcavatorNikitko Dmitry33% (3)

- DR Service InstructionsDokument4 SeitenDR Service InstructionsCentral HydraulicsNoch keine Bewertungen

- Remo TBDokument5 SeitenRemo TBTyler MacNoch keine Bewertungen

- Pilot WheelBearing ReplaceDokument11 SeitenPilot WheelBearing ReplaceValerie LambNoch keine Bewertungen

- Air Compressor - XMLDokument19 SeitenAir Compressor - XMLAnjaliNoch keine Bewertungen

- 3 4 PDFDokument104 Seiten3 4 PDFPriscila RodriguesNoch keine Bewertungen

- EC210 - Track Motor, DisassemblyDokument14 SeitenEC210 - Track Motor, DisassemblyPreett Rajin MenabungNoch keine Bewertungen

- 2008 CIVIC - Rear Door Panel Removal/Installation: Special Tools RequiredDokument9 Seiten2008 CIVIC - Rear Door Panel Removal/Installation: Special Tools RequiredAllen SimonNoch keine Bewertungen

- Clorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsDokument29 SeitenClorius Controls 3-Way Control Valves TYPE Soft Seated: Nodular Cast Iron, DN 80 - 300 MM InstructionsromanNoch keine Bewertungen

- Iom TorqmaxDokument10 SeitenIom TorqmaxReddy SadhanaNoch keine Bewertungen

- ELE Volumeasure InstructionDokument12 SeitenELE Volumeasure InstructionSteve MamonNoch keine Bewertungen

- Assembly and Disassembly Procedure for Screw Type Fuel Gas CompressorDokument16 SeitenAssembly and Disassembly Procedure for Screw Type Fuel Gas Compressorhitesh bhoiNoch keine Bewertungen

- RAV Engine ManualDokument24 SeitenRAV Engine ManualIsaac Okorie zakuNoch keine Bewertungen

- 38-character for fuel rail shimmaxx installation guideDokument3 Seiten38-character for fuel rail shimmaxx installation guidefred_ums6558Noch keine Bewertungen

- Timing Belt: Service and Repair Acura TL V6 3.2 2006Dokument16 SeitenTiming Belt: Service and Repair Acura TL V6 3.2 2006Vicctor PiñaNoch keine Bewertungen

- Pistons and Connecting Rods - AssembleDokument5 SeitenPistons and Connecting Rods - Assembleeshopmanual limaNoch keine Bewertungen

- Remove Instrument Panel and ComponentsDokument7 SeitenRemove Instrument Panel and ComponentsGary BallNoch keine Bewertungen

- Inst HvcapDokument4 SeitenInst HvcapVũ Hằng PhươngNoch keine Bewertungen

- Model H 65sa: 1. Precautions in Disassembly and ReassemblyDokument6 SeitenModel H 65sa: 1. Precautions in Disassembly and ReassemblyanthonypardoNoch keine Bewertungen

- Instructions: High Pressure Float Valve Régulateur Modulant de Niveau Haute Pression HFIDokument4 SeitenInstructions: High Pressure Float Valve Régulateur Modulant de Niveau Haute Pression HFIcaovadio88Noch keine Bewertungen

- Mazda Remote Starter InstallDokument22 SeitenMazda Remote Starter Installscubaryan100% (1)

- 10 Ft. X 12 FT. Steel Gazebo Assembly & Instructions ManualsDokument9 Seiten10 Ft. X 12 FT. Steel Gazebo Assembly & Instructions ManualsgillerdoitNoch keine Bewertungen

- Gear Group (Front) - Install: Disassembly and AssemblyDokument5 SeitenGear Group (Front) - Install: Disassembly and AssemblygustavoNoch keine Bewertungen

- Pc200-8 Valve ClearanceDokument3 SeitenPc200-8 Valve ClearanceAl FurkhanNoch keine Bewertungen

- Desarmado y Armado Bomba 312cDokument22 SeitenDesarmado y Armado Bomba 312cJhon VillamizarNoch keine Bewertungen

- Spare parts list and fitting instructionsDokument4 SeitenSpare parts list and fitting instructionsRoberto RossiNoch keine Bewertungen

- A Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsVon EverandA Guide to Making a Leather Wallet - A Collection of Historical Articles on Designs and Methods for Making Wallets and BillfoldsNoch keine Bewertungen

- 3 Declaratie Privind Beneficiarul Real PJDokument2 Seiten3 Declaratie Privind Beneficiarul Real PJpruna1045Noch keine Bewertungen

- 1' Cerere de Inscriere - Actualizare Date - Persoane Juridice - Format A4Dokument4 Seiten1' Cerere de Inscriere - Actualizare Date - Persoane Juridice - Format A4pruna1045100% (1)

- Promag 50 Manual BA046DEN - 1209 PDFDokument122 SeitenPromag 50 Manual BA046DEN - 1209 PDFViệt DũngNoch keine Bewertungen

- 06 Plan Subsol STAPDokument1 Seite06 Plan Subsol STAPpruna1045Noch keine Bewertungen

- Iso 9001 2008 enDokument1 SeiteIso 9001 2008 enpruna1045Noch keine Bewertungen

- 04 SPAU Conducta RefulareDokument1 Seite04 SPAU Conducta Refularepruna1045Noch keine Bewertungen

- En Manual Sensor PHD ORPDokument56 SeitenEn Manual Sensor PHD ORPpruna1045Noch keine Bewertungen

- Aeration Tank2000 ModelDokument1 SeiteAeration Tank2000 Modelpruna1045Noch keine Bewertungen

- Aeration Tank2000 ModelDokument1 SeiteAeration Tank2000 Modelpruna1045Noch keine Bewertungen

- Aeration Tank2000 ModelDokument1 SeiteAeration Tank2000 Modelpruna1045Noch keine Bewertungen

- Aeration Tank2000 ModelDokument1 SeiteAeration Tank2000 Modelpruna1045Noch keine Bewertungen

- Aeration Tank2000 ModelDokument1 SeiteAeration Tank2000 Modelpruna1045Noch keine Bewertungen

- Submit Report As JobDokument2 SeitenSubmit Report As JobFrederico MorgadoNoch keine Bewertungen

- CVJuan David Ramírezdelos RíosDokument1 SeiteCVJuan David Ramírezdelos Ríositzel083Noch keine Bewertungen

- SQL Introduction and Practical ExamplesDokument97 SeitenSQL Introduction and Practical ExamplesRajiv Kumar100% (1)

- FLS DemonstrationDokument30 SeitenFLS DemonstrationLeah UljerNoch keine Bewertungen

- Development of A Buffer Monitoring DashboardDokument47 SeitenDevelopment of A Buffer Monitoring DashboardtelegenicsNoch keine Bewertungen

- 115 SstigDokument109 Seiten115 SstigMahesh DubliNoch keine Bewertungen

- IPC-6012B Table of Contents: About 261,000 Results (0.47 Seconds)Dokument2 SeitenIPC-6012B Table of Contents: About 261,000 Results (0.47 Seconds)Moganraj MunusamyNoch keine Bewertungen

- RSRed DS RS200L Mod v5Dokument2 SeitenRSRed DS RS200L Mod v5liebherrmanNoch keine Bewertungen

- AOPEN DEV8430 Preliminary DatasheetDokument2 SeitenAOPEN DEV8430 Preliminary DatasheetMarisa García CulpiánNoch keine Bewertungen

- MAD111 Chapter 5 Counting FundamentalsDokument115 SeitenMAD111 Chapter 5 Counting FundamentalsMinh VuNoch keine Bewertungen

- Digital Notebook Instruction + HelloDokument9 SeitenDigital Notebook Instruction + HelloBelen DozaNoch keine Bewertungen

- CCFL Inverter ZXDokument26 SeitenCCFL Inverter ZXcuzquilloNoch keine Bewertungen

- C5G - R1C - Roboshop Program 2.0.0Dokument82 SeitenC5G - R1C - Roboshop Program 2.0.0kukaNoch keine Bewertungen

- An Efficient Approach of Taking Quick and Simple Notes in The Air Through Smart Note TakerDokument9 SeitenAn Efficient Approach of Taking Quick and Simple Notes in The Air Through Smart Note TakerRoney George100% (1)

- Addons Mozilla Org en US Firefox Addon Save As PDF Utm SourcDokument5 SeitenAddons Mozilla Org en US Firefox Addon Save As PDF Utm SourcThanga PandiNoch keine Bewertungen

- Performance: Lenovo Legion 5 Pro 16ACH6HDokument5 SeitenPerformance: Lenovo Legion 5 Pro 16ACH6HsonyNoch keine Bewertungen

- Xh31a 0000 0002 - R1BDokument30 SeitenXh31a 0000 0002 - R1Bs07081991100% (1)

- Lecture - 5: DC-AC Converters: Ug - ProgramDokument54 SeitenLecture - 5: DC-AC Converters: Ug - ProgramArife AbdulkerimNoch keine Bewertungen

- Forward Error Correction (FEC)Dokument6 SeitenForward Error Correction (FEC)gamer08Noch keine Bewertungen

- DatasheetDokument21 SeitenDatasheetziya tutuNoch keine Bewertungen

- Basic Discrete StructureDokument57 SeitenBasic Discrete StructureAhmed Iqbal100% (1)

- Paper 1 - Summary Revision Notes - OL CSDokument53 SeitenPaper 1 - Summary Revision Notes - OL CSjanaNoch keine Bewertungen

- BOP Replacement Parts CatalogDokument60 SeitenBOP Replacement Parts Catalogdesavinicius100% (1)

- PDFlib TutorialDokument258 SeitenPDFlib TutorialGasNoch keine Bewertungen

- GR00005200D 13a PDFDokument187 SeitenGR00005200D 13a PDFbitadminaccNoch keine Bewertungen

- Ibm Websphere Application Server Advanced Edition, v3.5 - Websphere Jms - Jta Support For Mqseries (370K) WasDokument49 SeitenIbm Websphere Application Server Advanced Edition, v3.5 - Websphere Jms - Jta Support For Mqseries (370K) Wasimene IBNoch keine Bewertungen

- Satelec-X Mind AC Installation and Maintainance GuideDokument50 SeitenSatelec-X Mind AC Installation and Maintainance Guideagmho100% (1)

- Surge Protector Vs UPS Vs Power StripDokument4 SeitenSurge Protector Vs UPS Vs Power StripTransformerOptimusNoch keine Bewertungen

- WP SOX ComplianceDokument13 SeitenWP SOX ComplianceanandsivNoch keine Bewertungen