Beruflich Dokumente

Kultur Dokumente

Operations Startegy

Hochgeladen von

sampritcCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Operations Startegy

Hochgeladen von

sampritcCopyright:

Verfügbare Formate

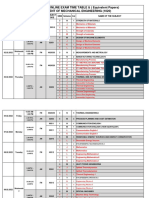

OPERATIONS STARTEGY: ASSIGBNMENT 1

SECTION A:

1) WRITE SHORT NOTES ON

A) JUST IN TIME INVENTORY MANAGEMENT

B) COMPUTER AIDED DESIGN

A) Definition:

Just-in-Time (JIT) inventory management is the process of ordering and receiving inventory for

production and customer sales only as it is needed and not before. This means that the company does

not hold safety stock and operates with low inventory levels. This strategy helps companies lower their

inventory carrying costs.

Just-in-time inventory management is a cost-cutting inventory management strategy though it can lead

to stockouts. The goal of JIT is to improve return on investment by reducing non-essential costs.

Examples:

Just-in-time inventory management is used by Toyota Manufacturing as its inventory management

system.

B) Computer-aided design (CAD) is a computer technology that designs a product and documents

the design's process. CAD may facilitate the manufacturing process by transferring detailed

diagrams of a products materials, processes, tolerances and dimensions with specific

conventions for the product in question. It can be used to produce either two-dimensional or

three-dimensional diagrams, which can then when rotated to be viewed from any angle, even

from the inside looking out. A special printer or plotter is usually required for printing

professional design renderings.

The concept of designing geometric shapes for objects is very similar to CAD. It is called

computer-aided geometric design (CAGD).

CAD is also known as computer-aided design and drafting (CADD)

CAD is used as follows:

1. To produce detailed engineering designs through 3-D and 2-D drawings of the physical

components of manufactured products.

2. To create conceptual design, product layout, strength and dynamic analysis of assembly and the

manufacturing processes themselves.

3. To prepare environmental impact reports, in which computer-aided designs are used in

photographs to produce a rendering of the appearance when the new structures are built.

CAD systems exist today for all of the major computer platforms, including Windows, Linux, Unix and

Mac OS X. The user interface generally centers around a computer mouse, but a pen and digitizing

graphic tablet can also be used. View manipulation can be accomplished with a spacemouse (or

spaceball). Some systems allow stereoscopic glasses for viewing 3-D models.

Most U.S. universities no longer require classes for producing hand drawings using protractors and

compasses. Instead, there are many classes on different types of CAD software. Because hardware and

software costs are decreasing, universities and manufacturers now train students how to use these high-

level tools. These tools have also modified design work flows to make them more efficient, lowering

these training costs even further.

2) How does an operation manager get the advantage of quality management in making

Business decisions?

Operations management is a multi-disciplinary field that focuses on managing all aspects of an

organization's operations. The typical company carries out various functions as a part of its operation. The

dividing of a company's activities into functional categories occurs very early on, even in a company

formed and operated by a single individual. Most companies make a product of some kind or produce a

salable service. They must also carry out a sales and marketing function, an accounting function, and an

administrative function to manage employees and the business as a whole. Operations management

focuses on the function of providing the product or service. Their job is to assure the production of a

quality good and/or service. They apply ideas and technologies to increase productivity and reduce costs,

improve flexibility to meet rapidly changing customer needs, assure a safe workplace for all employees,

and when possible assist in assuring high-quality customer service.

For the most part, the title "Operations Manager" is used in companies that produce a tangible good

manufacturers on the whole. In service-oriented businesses, the person responsible for the operations

manager role is often called by another name, one that addresses the service being offered. Examples

include project manager, consultant, lawyer, accountant, office manager, datacenter manager, etc.

KEY ISSUES IN OPERATIONS

As an organization develops plans and strategies to deal with the opportunities and challenges that arise in

its particular operating environment, it should design a system that is capable of producing quality services

and goods in the quantities demanded and in the time frames necessary to meet the businesses

obligations.

Designing the System

Designing the system begins with product development. Product development involves determining the

characteristics and features of the product or service to be sold. It should begin with an assessment of

customer needs and eventually grow into a detailed product design. The facilities and equipment used in

production, as well as the information systems needed to monitor and control performance, are all a part

of this system design process. In fact, manufacturing process decisions are integral to the ultimate success

or failure of the system. Of all the structural decisions that the operations manager makes, the one likely

to have the greatest impact on the operation's success is choice of the process technology. This decision

answers the basic question: How will the product be made?

Product design is a critical task because it helps to determine the characteristics and features of the

product, as well as how the product functions. Product design determines a product's cost and quality, as

well as its features and performance. These are important factors on which customers make purchasing

decisions. In recent years, new design models such as Design for Manufacturing and Assembly (DFMA)

have been implemented to improve product quality and lower costs. DFMA focuses on operating issues

during product design. This can be critical even though design costs are a small part of the total cost of a

product, because, procedures that waste raw materials or duplicate effort can have a substantial negative

impact on a business's operating profitability. Another innovation similar to DFMA in its emphasis on

design is Quality Functional Deployment (QFD). QFD is a set of planning and communication routines that

are used to improve product design by focusing design efforts on customer needs.

Process design describes how the product will be made. The process design decision has two major

components: a technical (or engineering) component and a scale economy (or business) component. The

technical component includes selecting equipment and selecting a sequence for various phases of

operational production.

The scale economy or business component involves applying the proper amount of mechanization (tools

and equipment) to make the organization's work force more productive. This includes determining: 1) If

the demand for a product is large enough to justify mass production; 2) If there is sufficient variety in

customer demand so that flexible production systems are required; and 3) If demand for a product is so

small or seasonal that it cannot support a dedicated production facility.

Facility design involves determining the capacity, location, and layout for the production facility. Capacity is

a measure of an company's ability to provide the demanded product in the quantity requested by the

customer in a timely manner. Capacity planning involves estimating demand, determining the capacity of

facilities, and deciding how to change the organization's capacity to respond to demand.

Facility location is the placement of a facility with respect to its customers and suppliers. Facility location is

a strategic decision because it is a long-term commitment of resources that cannot easily or inexpensively

be changed. When evaluating a location, management should consider customer convenience, initial

investment necessary to secure land and facilities, government incentives, and operating transportation

costs. In addition, qualitative factors such as quality of life for employees, transportation infrastructure,

and labor environment should also be taken under consideration.

Facility layout is the arrangement of the workspace within a facility. It considers which departments or

work areas should be adjacent to one another so that the flow of product, information, and people can

move quickly and efficiently through the production system.

Implementation

Once a product is developed and the manufacturing system is designed, it must be implemented, a task

often more easily discussed than carried out. IF the system design function was done thoroughly, it will

have rendered an implementation plan which will guide activities during implementation. Nonetheless,

there will inevitably be changes needed. Decisions will have to be made throughout this implementation

period about tradeoffs. For example, the cost of the originally planned conveyor belt may have risen. This

change will make it necessary to consider changing the specified conveyor belt for another model. This, of

course, will impact upon other systems linked to the conveyor belt and the full implications of all these

changes will have to be assessed and compared to the cost of the price increase on the original conveyor

belt.

Planning and Forecasting

Running an efficient production system requires a great deal of planning. Long-range decisions could

include the number of facilities required to meet customer needs or studying how technological change

might affect the methods used to produce services and goods. The time horizon for long-term planning

varies with the industry and is dependent on both complexity and size of proposed changes. Typically,

however, long-term planning may involve determining work force size, developing training programs,

working with suppliers to improve product quality and improve delivery systems, and determining the

amount of material to order on an aggregate basis. Short-term scheduling, on the other hand, is concerned

with production planning for specific job orders (who will do the work, what equipment will be used,

which materials will be consumed, when the work will begin and end, and what mode of transportation

will be used to deliver the product when the order is completed).

Managing the System

Managing the system involves working with people to encourage participation and improve organizational

performance. Participative management and teamwork are an essential part of successful operations, as

are leadership, training, and culture. In addition, material management and quality are two key areas of

concern.

Material management includes decisions regarding the procurement, control, handling, storage, and

distribution of materials. Material management is becoming more important because, in many

organizations, the costs of purchased materials comprise more than 50 percent of the total production

cost. Questions regarding quantities and timing of material orders need to be addressed here as well when

companies weigh the qualities of various suppliers.

BUILDING SUCCESS WITH OPERATIONS

To understand operations and how they contribute to the success of an organization, it is important to

understand the strategic nature of operations, the value-added nature of operations, the impact

technology can have on performance and the globally competitive market place.

3) Describe the principles of the Maruti Car Production System and how it is a departure

from traditional production systems.

The Toyota Production System (TPS) is an integrated socio-technical system, developed by Toyota, that

comprises its management philosophy and practices. The TPS organizes manufacturing and logistics for

the automobile manufacturer, including interaction with suppliers and customers. The system is a major

precursor of the more generic "lean manufacturing." Taiichi Ohno, Shigeo Shingo and Eiji Toyoda

developed the system between 1948 and 1975.

Originally called "just-in-time production," it builds on the approach created by the founder of Toyota,

Sakichi Toyoda, his son Kiichiro Toyoda, and the engineer Taiichi Ohno. The principles underlying the TPS

are embodied in The Toyota Way.

The main objectives of the TPS are to design out overburden (muri) and inconsistency (mura), and to

eliminate waste (muda). The most significant effects on process value delivery are achieved by designing

a process capable of delivering the required results smoothly; by designing out "mura" (inconsistency). It

is also crucial to ensure that the process is as flexible as necessary without stress or "muri" (overburden)

since this generates "muda" (waste). Finally the tactical improvements of waste reduction or the

elimination of muda are very valuable. There are seven kinds of muda that are addressed in the TPS.

1. Waste of over production (largest waste)

2. Waste of time on hand (waiting)

3. Waste of transportation

4. Waste of processing itself

5. Waste of stock at hand

6. Waste of movement

7. Waste of making defective products

The elimination of waste has come to dominate the thinking of many when they look at the effects of

the TPS because it is the most familiar of the three to implement. In the TPS many initiatives are

triggered by inconsistency or over-run reduction which drives out waste without specific focus on its

reduction.

The underlying principles, called the Toyota Way, have been outlined by Toyota as follows:

Continuous improvement

Challenge (We form a long-term vision, meeting challenges with courage and creativity to

realize our dreams.)

Kaizen (We improve our business operations continuously, always driving for innovation and

evolution.)

Genchi Genbutsu (Go to the source to find the facts to make correct decisions.)

Respect for people

Respect (We respect others, make every effort to understand each other, take responsibility and

do our best to build mutual trust.)

Teamwork (We stimulate personal and professional growth, share the opportunities of

development and maximize individual and team performance.)

External observers have summarized the principles of the Toyota Way as:

Long-term philosophy

1. Base your management decisions on a long-term philosophy, even at the expense of short-term

financial goals.

The right process will produce the right results

1. Create continuous process flow to bring problems to the surface.

2. Use the "pull" system to avoid overproduction.

3. Level out the workload (heijunka). (Work like the tortoise, not the hare.)

4. Build a culture of stopping to fix problems, to get quality right from the first.

5. Standardized tasks are the foundation for continuous improvement and employee

empowerment.

6. Use visual control so no problems are hidden.

7. Use only reliable, thoroughly tested technology that serves your people and processes.

Add value to the organization by developing your people and partners

1. Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

2. Develop exceptional people and teams who follow your company's philosophy.

3. Respect your extended network of partners and suppliers by challenging them and helping them

improve.

Continuously solving root problems drives organizational learning

1. Go and see for yourself to thoroughly understand the situation

2. Make decisions slowly by consensus, thoroughly considering all options; implement decisions

rapidly;

3. Become a learning organization through relentless reflection and continuous improvement .

The Toyota production system has been compared to squeezing water from a dry towel. What this

means is that it is a system for thorough waste elimination. Here, waste refers to anything which does

not advance the process, everything that does not increase added value. Many people settle for

eliminating the waste that everyone recognizes as waste. But much remains that simply has not yet

been recognized as waste or that people are willing to tolerate.

People had resigned themselves to certain problems, had become hostage to routine and abandoned

the practice of problem-solving. This going back to basics, exposing the real significance of problems and

then making fundamental improvements, can be witnessed throughout the Toyota Production System.

4) Explain the relationship between production rate and cycle time and their interpretation

in synchronous production. What does it mean for the workstations in a process to be balanced?

A workstation is a special computer designed for technical or scientific applications. Intended primarily

to be used by one person at a time, they are commonly connected to a local area network and run

multi-user operating systems. The term workstation has also been used loosely to refer to everything

from a mainframe computer terminal to a PC connected to a network, but the most common form

refers to the group of hardware offered by several current and defunct companies such as Sun

Microsystems, Silicon Graphics, Apollo Computer, DEC, HP and IBM which opened the door for the 3D

graphics animation revolution of the late 1990s.

Workstations offered higher performance than mainstream personal computers, especially with respect

to CPU and graphics, memory capacity, and multitasking capability. Workstations were optimized for the

visualization and manipulation of different types of complex data such as 3D mechanical design,

engineering simulation (e.g. computational fluid dynamics), animation and rendering of images, and

mathematical plots. Typically, the form factor is that of a desktop computer, consist of a high resolution

display, a keyboard and a mouse at a minimum, but also offer multiple displays, graphics tablets, 3D

mice (devices for manipulating 3D objects and navigating scenes), etc. Workstations were the first

segment of the computer market to present advanced accessories and collaboration tools.

The increasing capabilities of mainstream PCs in the late 1990s have blurred the lines somewhat with

technical/scientific workstations. The workstation market previously employed proprietary hardware

which made them distinct from PCs; for instance IBM used RISC-based CPUs for its workstations and

Intel x86 CPUs for its business/consumer PCs during the 1990s and 2000s. However by the late 2000s

this difference disappeared, as workstations now use highly commoditized hardware dominated by large

PC vendors, such as Dell and HP, selling Microsoft Windows or GNU/Linux systems running on x86-64

architecture such as Intel Xeon or AMD Opteron CPUs.

OPERATIONS STARTEGY: ASSIGBNMENT 2

SECTION A:

1) What is a product life cycle (PLC)? Explain each phases with an example of automobile sector in India.

The product life cycle (PLC)The stages (introduction, growth, maturity, decline) that a product may go

through over time. It includes the stages the product goes through after development, from

introduction to the end of the product. Just as children go through different phases in life (toddler,

elementary school, adolescent, young adult, and so on), products and services also age and go through

different stages. The PLC is a beneficial tool that helps marketers manage the stages of a products

acceptance and success in the marketplace, beginning with the products introduction, its growth in

market share, maturity, and possible decline in market share. Other tools such as the Boston Consulting

Group matrix and the General Electric approach may also be used to manage and make decisions about

what to do with products. For example, when a market is no longer growing but the product is doing

well (cash cow in the BCG approach), the company may decide to use the money from the cash cow to

invest in other products they have rather than continuing to invest in the product in a no-growth

market.

The product life cycle can vary for different products and different product categories. The following

figure illustrates an example of the product life cycle, showing how a product can move through four

stages. However, not all products go through all stages and the length of a stage varies. For example,

some products never experience market share growth and are withdrawn from the market.

2) Manufacturer is always under the dilemma in producing customized products. Why?

Mass Customization is the new paradigm that replaces mass production, which is no longer suitable for

todays turbulent markets, growing product variety, and opportunities for e-commerce. Mass

customization proactively manages product variety in the environment of rapidly evolving markets and

products, many niche markets, and individually customized products sold through stores or over the

internet.

1

Mass customizers can customize products quickly for individual customers or for niche markets at

better than mass production efficiency and speed. Using the same principles, mass customizers can

Build-to-Order both customized products and standard products without forecasts, inventory, or

purchasing delays.

These practical methodologies are taught through Dr. Anderson's in-house seminars and implemented

through his leading-edge consulting.

The M.C. Spectrum

There is a whole spectrum of ways that Mass Customization methodologies can benefit companies. At

the most visible end of the spectrum, companies can mass customize products for individual customers.

The most well know category of individual customization relates to products that people wear (clothing,

shoes, glasses) as well as bicycles and pagers.

Further along the spectrum is niche market customization. For instance, a company that makes

telephones has only a few customers (telephone companies) who want several dozen models in many

colors all with specific phone company logos. Exporters have to deal with many niche market products,

usually a different set of products for each country exported; and even if the differences seem minor,

the sheer variety of SKUs (stock keeping units) can have significant cost and flexibility implications.

Almost all companies could benefit from expansion into niche markets if they could do it efficiently.

At the other end of the spectrum are companies that have tremendous varieties of "standard"

products, for instance, industrial suppliers of valves, switches, instruments, electrical enclosures, or any

company with a catalog over a half an inch thick. As with product customization, there is a great

contrast between how mass producers and mass customizers manufacture a variety of standard

products. The mass-producer has the dilemma of trying to keep large enough inventories to sell a wide

variety of products from stock or alternatively using the slow, reactive process of ordering parts and

building products in very small batches after receipt of orders.

The mass-customizer can use flow manufacturing and CNC programmable machine tools to quickly

and efficiently make different products in a "batch size of one" -- either customized products or any

standard product from a large catalog.

The Need for Speed

Mass customized goods compete with standard goods which may be available right now at stores or

dealers. The biggest appeals of mass customization are being able to (1) provide customized goods, (2)

quickly resupply stores with standard products that have just been sold with built-to-order

replacements, and (3), for industrial suppliers, to be able to respond on-demand to assemblers pull

signals, which may be part of the spontaneous supply chain for the first two cases. For all of these speed

is imperative to minimize mass customizations biggest vulnerability: waiting.

In order to deliver products fast, mass customizers need flow manufacturing to make products fast in

small quantities and a spontaneous supply chain which can assure spontaneous availability of materials

and make parts on-demand.

Mass Customization Depends on Flow Manufacturing

The trend to smaller batches, approaching one, is what is pushing savvy manufacturers toward flow

manufacturing. Mass Customization relies on flow manufacturing to provide the batch-size-of-one

capability. Whether manufacturing a wide variety of standard products or individually customized

products, mass customizers depend on several elements of flow manufacturing to enable them to build

products economically in any order quantity, even as low as one.

Setup and its elimination. Being able to build in a batch (or lot) size of one depends on the elimination

of setup, for instance, to get parts, change dies and fixtures, download programs, find instructions, or

any kind of manual measurement, adjustment, or positioning of parts or fixtures. Mass producers are

forced to make products in batches to spread setup costs among as many products as possible. If setup

can be eliminated, then products could be made to-order as orders came in. This is the essence of

Spontaneous Build-to-Order. Setup elimination is also an essential prerequisite for mass customization

since every product could be different.

Setup and batches can be eliminated by (1) distributing parts at all the points of use to eliminate the

kitting, or the batching of parts, (2) eliminating tooling setup with versatile tool plates or tooling that can

be changed very quickly, (3) consolidating inflexible parts into very versatile standard parts, for instance,

for castings, plastic parts, stampings, extrusions, and bare printed circuit boards, (4) using CNC machine

tools to programmably make a wide variety of parts from standard shapes of raw material, and (5)

eliminating all setup from manual assembly, such as finding and understanding work instructions by

displaying instruction on monitors that instantly and clearly show what is to be done at that workstation

to any product being worked on.

2

Spontaneous Supply Chains

In order to build products on-demand, mass customizers must be able to build parts on-demand from

materials that are always available. This will require a spontaneous supply chain. The first steps in supply

chain management must be supply chain simplification.

Supply Chain Simplification. The simplification steps for supply chain management are standardization,

Automatic resupply techniques, and rationalization of the product line to eliminate or outsource the

unusual, low-volume products that contribute to part variety way out of proportion to their profit

generation ability. The goal of supply chain simplification is to drastically reduce the variety of parts and

raw materials to the point where these materials can be procured spontaneously by automatic and pull-

based resupply techniques. Reducing the part and material variety will also shrink the vendor base,

further simplifying the supply chain.

Standardization. Most products are designed around too many different parts and materials for mass

customization. Ironically, a rampant proliferation of parts is quite unnecessary, but occurs simply

because standardization is not emphasized. Part and material variety can be easily reduced with

standardization techniques by one or two orders of magnitude!

3

Automatic, spontaneous resupply. A key part of the spontaneous supply chain is automatic resupply

techniques such as kanban, "min-max," or breadtruck (free-stock). The simplest version of kanban uses

two bins for each part. After parts are depleted from the first bin, it goes back to its source to be filled,

and could be made in a batch mode if the combination of setup time, run time, and delivery time is

short enough to return the new bin of parts before the other bin runs out. Min-max is a similar concept

usually applied to stacks of raw material like sheet metal; when the "min" level is reached, this triggers

the resupply of enough material to reach the "max" level. Breadtruck or free-stock makes small

inexpensive parts like fasteners freely available at all points of use; these are resupplied automatically

by a supplier who simply keeps the bins full and bills the company monthly. This is much more efficient

than issuing expensive purchase orders for parts that may cost pennies. Parts that qualify can be made

in batches as long as the response time and bin (or delivery) size is adequate.

Spontaneous build-to-order of parts. For parts that do not qualify for kanban, suppliers or in-house

sources would need to implement spontaneous BTO so that they could actually build on-demand to the

pull signals from assembly. Spontaneous BTO of parts may require the development of vendor-partner

relationships for suppliers to establish the ability to build parts in any quantity on-demand.

Designing products for Mass Customization

For fast and easy production, mass customization products should be designed for

manufacturability.

4

A key element of DFM is designing for lean production, build-to-order, and mass

customization. Products should be developed in synergistic product families and be designed around

aggressively standardized parts and materials, designed for no setup, and designed for CNC

programmable machine tools.

How Products are Customized

There are three ways to customize products: modular, adjustable, and dimensional customization.

5

Modular Customization. Modules are "building blocks." Usually modules are literally building blocks

that can customize a product by assembling various combinations of modules. Examples of modules

would include many components in automobiles: engines, transmissions, audio equipment, tire/wheel

options, etc. In electronics, modules would include processor boards, power supplies, plug-in integrated

circuits, daughter-boards, and disk drives. In software, code could be written in modules (objects) that

can be combined into various combinations.

Adjustable Customization. Adjustments are a reversible way to customize a product, such as mechanical

or electrical adjustments. Adjustments could be infinitely variable. Discrete adjustments, or

configurations, would represent few choices, such as those provided by electronic switches, jumpers,

cables, or discrete software controlled configurations. These adjustments and configurations make the

product customizable by the factory, by dealers, or by customer. Software can be customized by user-

defined settings or by table driven programming in which the software is specifically written to

accommodate variables that can be customized by entering customer data into a table. The result is

customized software that does not does not have to be debugged.

6

Dimensional Customization. Dimensional customization involves a permanent cutting-to-fit, mixing, or

tailoring. Dimensional customization could be infinite or have a selection of discrete choices. Examples

of infinite dimensional customization would include the tailoring of clothing, drilling holes in bowling

balls, grinding eyeglasses, mixing of paints or chemicals, machining metal parts, and the cutting of sheet

metal, wire, or tubing. Examples of discrete dimensional customization would be hole punching, and

soldering selected electronic components onto a printed circuit board. Dimensionally customized parts

can be made automatically on CNC equipment running program instructions that are generated on

demand from data that originates in parametric CAD (see discussion below).

How Mass Customization Works

The following examples were created to show mass customization principles for electronic products

(Figure 1) and fabricated parts or products (Figure 2). The author creates perspective illustrations, like

these, for each mass customization client because they show, on one page, the flow of materials and

information through easily recognizable machinery. Further, three-dimensional drawings showing the

actual equipment are more meaningful than two-dimensional block representations to a broad

audience. These can be drawn in 3D CAD solid model software. In the following discussions, bold words

refer to labels on the illustration.

The process starts with a dialog with the customer in which customer queries are quickly answered.

This rapid dialog is the only one (the only two-way arrows in Figure 1) in mass customization, as opposed

to the traditional practice of many length inquires back and forth with Engineering, Procurement, and

Manufacturing departments. Various "what if" scenarios can be explored instantly, complete with price

and availability quotes, using configuration software (called "configurators"), which could be on a

salespersons laptop computer or on the company web-site.

When the customer has optimized the configuration and approves the order, the order information is

sent by modem input to the factory where it enters the order entry database, which accepts the

information and converts it into various data packets that go (1) to on-line assembly instruction

monitors, which tell workers how to assemble each product, and (2) to the parametric CAD/CAM work

station. This is an automatic or semi-automatic computer that accepts customer order data into

parametric CAD drawings, which are drawn with "floating" dimensions that accept the customers data

and then stretch all the part drawings, which also stretches the assembly drawings. Finally, this station

automatically translates these drawings into CNC Programs for the CNC equipment.

Write short notes on:

ERP and Applications

Enterprise resource planning (ERP) is a business management softwareusually a suite of integrated

applicationsthat a company can use to collect, store, manage and interpret data from many business

activities, including:-

Product planning, cost and development

Manufacturing or service delivery

Marketing and sales

Inventory management

Shipping and payment

ERP provides an integrated view of core business processes, often in real-time, using common databases

maintained by a database management system. ERP systems track business resourcescash, raw

materials, production capacityand the status of business commitments: orders, purchase orders, and

payroll. The applications that make up the system share data across the various departments

(manufacturing, purchasing, sales, accounting, etc.) that provide the data.

]

ERP facilitates information

flow between all business functions, and manages connections to outside stakeholders.

Enterprise system software is a multi-billion dollar industry that produces components that support a

variety of business functions. IT investments have become the largest category of capital expenditure in

United States-based businesses over the past decade. Though early ERP systems focused on large

enterprises, smaller enterprises increasingly use ERP systems.

Organizations consider the ERP system a vital organizational tool because it integrates varied

organizational systems and facilitates error-free transactions and production. However, ERP system

development is different from traditional systems development. ERP systems run on a variety of

computer hardware and network configurations, typically using a database as an information repository.

Quality is a never ending quest and Continuous Process Improvement (CPI) is a never ending effort to

discover and eliminate the main causes of problems. It accomplishes this by using small-steps

improvements, rather than implementing one huge improvement. The Japanese have a term for this

called kaizen which involves everyone, from the hourly workers to top-management.

CPI means making things better. It is NOT fighting fires. Its goal is NOT to blame people for problems or

failures. . . it is simply a way of looking at how we can do our work better. When we take a problem

solving approach, we often never get to the root causes because our main goal is to put out the fire. But

when we engage in process improvement, we seek to learn what causes things to happen and then use

this knowledge to:

o Reduce variation.

o Remove activities that have no value to the organization.

o Improve customer satisfaction.

Process improvement is important as Rummler & Brache's research (1995) showed that process account

for about 80% of all problems while people account for the remaining 20%.

CPI Procedure

CPI has been described using a number of models. This manual will use the system approach or ADDIE

(Analysis, Design, Development, Implement, Evaluate) model. There are five phases in this model:

o Analysis Phase Identify areas of opportunity and target specific problems. These areas and

problems are based on team brain-storming sessions, process definition sessions,

recommendations forwarded to the team by organizational members, and other various analysis

techniques.

o Design Phase Generate solutions through brain-storming sessions. Identify the required

resources to implement the chosen solution and identify baselines to measure.

o Development Phase Formulate a detailed procedure for implementing the approved solution.

o Implementation Phase Execute the solution.

o Evaluation Phase Build measurement tools, monitor implementation, and evaluate

measurements to baseline. Please note that this phase is performed throughout the entire

process. The chart below shows that this is a dynamic, not a static model:

Das könnte Ihnen auch gefallen

- BDokument1 SeiteBsampritcNoch keine Bewertungen

- Executive SummaryDokument16 SeitenExecutive SummarysampritcNoch keine Bewertungen

- Scaling TechniqueDokument22 SeitenScaling TechniquesampritcNoch keine Bewertungen

- AnovaDokument46 SeitenAnovasampritcNoch keine Bewertungen

- Agricultural Production - FoodgrainsDokument4 SeitenAgricultural Production - FoodgrainssampritcNoch keine Bewertungen

- Demand and SupplyDokument43 SeitenDemand and SupplysampritcNoch keine Bewertungen

- One Day FDP On - : Technical Session I (10 AM To 1 PM)Dokument2 SeitenOne Day FDP On - : Technical Session I (10 AM To 1 PM)sampritcNoch keine Bewertungen

- Usha Multipurpose Society FinalDokument25 SeitenUsha Multipurpose Society FinalsampritcNoch keine Bewertungen

- EBE Ch14Dokument5 SeitenEBE Ch14Majid AliNoch keine Bewertungen

- Alp 2Dokument1 SeiteAlp 2sampritcNoch keine Bewertungen

- Impact of Women Empowerment Through Self-Help Groups: A Micro Level Study in Rural KarnatakaDokument5 SeitenImpact of Women Empowerment Through Self-Help Groups: A Micro Level Study in Rural KarnatakasampritcNoch keine Bewertungen

- Alp 1Dokument1 SeiteAlp 1sampritcNoch keine Bewertungen

- Inflation and MPDokument38 SeitenInflation and MPsampritcNoch keine Bewertungen

- Graphical SolutionDokument8 SeitenGraphical SolutionsampritcNoch keine Bewertungen

- Set 1Dokument1 SeiteSet 1sampritcNoch keine Bewertungen

- CG Class-1-17.07.2014Dokument60 SeitenCG Class-1-17.07.2014sampritcNoch keine Bewertungen

- Data Analysis: SampritDokument33 SeitenData Analysis: SampritsampritcNoch keine Bewertungen

- Regression Diagnostic Ii: Heteroscedasticity: Damodar GujaratiDokument7 SeitenRegression Diagnostic Ii: Heteroscedasticity: Damodar GujaratisampritcNoch keine Bewertungen

- Facility LocationDokument29 SeitenFacility LocationsampritcNoch keine Bewertungen

- The Linear Regression Model: An Overview: Damodar GujaratiDokument17 SeitenThe Linear Regression Model: An Overview: Damodar GujaratisampritcNoch keine Bewertungen

- Regression Diagnostic I: Multicollinearity: Damodar GujaratiDokument7 SeitenRegression Diagnostic I: Multicollinearity: Damodar GujaratisampritcNoch keine Bewertungen

- DRM QM Assessment 2Dokument1 SeiteDRM QM Assessment 2sampritcNoch keine Bewertungen

- Functional Forms of Regression Models: Damodar GujaratiDokument11 SeitenFunctional Forms of Regression Models: Damodar GujaratisampritcNoch keine Bewertungen

- Limits and Continuity: Thu Mai, Michelle Wong, Tam VuDokument17 SeitenLimits and Continuity: Thu Mai, Michelle Wong, Tam VusampritcNoch keine Bewertungen

- Graphical SolutionDokument8 SeitenGraphical SolutionsampritcNoch keine Bewertungen

- Goalprogramming 161104024800 PDFDokument24 SeitenGoalprogramming 161104024800 PDFANBUKUMAR TNoch keine Bewertungen

- Chapter 12Dokument27 SeitenChapter 12Anonymous iEtUTYPOh3Noch keine Bewertungen

- Dynamic ProgrammingDokument22 SeitenDynamic ProgrammingsampritcNoch keine Bewertungen

- Differential Calculus: By-Shubham Bca 2C A1004816146 To:-Mr. Pream KumarDokument10 SeitenDifferential Calculus: By-Shubham Bca 2C A1004816146 To:-Mr. Pream KumarsampritcNoch keine Bewertungen

- Centre of GravityDokument12 SeitenCentre of GravitysampritcNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Introduction To Business: Managing ProcessesDokument68 SeitenIntroduction To Business: Managing ProcessesTiara RossaNoch keine Bewertungen

- Mohammed Waseem Akram CVDokument5 SeitenMohammed Waseem Akram CVKiran ShivakumarNoch keine Bewertungen

- PG - Design - Enginering Syllabus Year Modified in 2019Dokument38 SeitenPG - Design - Enginering Syllabus Year Modified in 2019vishwajeet patilNoch keine Bewertungen

- SEN 2019 Winter Model Answer PaperDokument22 SeitenSEN 2019 Winter Model Answer Papermansilokhande3012Noch keine Bewertungen

- CAE LAB MANUAL - JNTUA III B TechII SEM / SVTM /M RAMA NARASIMHA REDDYDokument96 SeitenCAE LAB MANUAL - JNTUA III B TechII SEM / SVTM /M RAMA NARASIMHA REDDYreddyNoch keine Bewertungen

- Sheet Metal Nesting Report For Plasma and Laser CuttingDokument1 SeiteSheet Metal Nesting Report For Plasma and Laser CuttingcititorulturmentatNoch keine Bewertungen

- 10 Post Engineer DetachmentDokument2 Seiten10 Post Engineer DetachmentDanilo C Denna Jr.Noch keine Bewertungen

- Mee3502 - Design-Process-Planning-And-Management - Eth - 1.0 - 62 - Mee3502 - 58 AcpDokument3 SeitenMee3502 - Design-Process-Planning-And-Management - Eth - 1.0 - 62 - Mee3502 - 58 AcpwewewewNoch keine Bewertungen

- BladeModeler 12.0 Lecture 1 IntroductionDokument19 SeitenBladeModeler 12.0 Lecture 1 Introductionedwin732367% (3)

- Bs100 Drasec ENGDokument35 SeitenBs100 Drasec ENGallexr092Noch keine Bewertungen

- Module 5Dokument16 SeitenModule 5santosh gillNoch keine Bewertungen

- The Impact of Information Technologies On Organizations and Their Employees R. BakerDokument12 SeitenThe Impact of Information Technologies On Organizations and Their Employees R. BakerOmar HussainNoch keine Bewertungen

- Engineering - GR 2008 CAD StandardsDokument63 SeitenEngineering - GR 2008 CAD Standardscadcamcae01Noch keine Bewertungen

- Advanced TopicsDokument115 SeitenAdvanced TopicspriksemasNoch keine Bewertungen

- Mechanical Design EngineerDokument3 SeitenMechanical Design Engineerhemantsinh22Noch keine Bewertungen

- Computer Aided Design Course Code: 3341904Dokument7 SeitenComputer Aided Design Course Code: 3341904Dhaval UpadhyayNoch keine Bewertungen

- The Federal University of Technology Akure, Nigeria: 2016/2017-2020/2021 SESSIONSDokument68 SeitenThe Federal University of Technology Akure, Nigeria: 2016/2017-2020/2021 SESSIONSOlukolajo JoshuaNoch keine Bewertungen

- Definition of Architecture From Famous Architects:: Caroline BosDokument15 SeitenDefinition of Architecture From Famous Architects:: Caroline BosSaba HajizadehNoch keine Bewertungen

- Licom AlphaCamDokument27 SeitenLicom AlphaCamMario SabatinoNoch keine Bewertungen

- Introduction To Computer Aided Drafting Course Outline Learning OutcomesDokument2 SeitenIntroduction To Computer Aided Drafting Course Outline Learning OutcomesJiremy NoriegaNoch keine Bewertungen

- Integrated Urban Microclimate Assessment Method As A Sustainable Urban Development and Urban Design ToolDokument4 SeitenIntegrated Urban Microclimate Assessment Method As A Sustainable Urban Development and Urban Design ToolstevekardinaljusufNoch keine Bewertungen

- Allplan 2019 EngineeringtutlDokument350 SeitenAllplan 2019 EngineeringtutlFlávio SousaNoch keine Bewertungen

- Mech - Equivalent-Feb 2022Dokument4 SeitenMech - Equivalent-Feb 2022KanagarajanNoch keine Bewertungen

- SolidCAM 2014 EngDokument39 SeitenSolidCAM 2014 EngĆosić AsimNoch keine Bewertungen

- VPM Basic Training Module01 Version07Dokument67 SeitenVPM Basic Training Module01 Version07nishant_satyamite100% (1)

- Rapid Manufacture of Metal Tooling by Rapid Prototyping: Z. Shan, Y. Yan, R. Zhang, Q. Lu and L. GuanDokument7 SeitenRapid Manufacture of Metal Tooling by Rapid Prototyping: Z. Shan, Y. Yan, R. Zhang, Q. Lu and L. GuanjoaquinteromoNoch keine Bewertungen

- Revit 2023 Architecture FudamentalDokument52 SeitenRevit 2023 Architecture FudamentalTrung Kiên TrầnNoch keine Bewertungen

- HyperCAD S enDokument16 SeitenHyperCAD S enPaul VeramendiNoch keine Bewertungen

- ELAC General Catalog 2011 2013Dokument272 SeitenELAC General Catalog 2011 2013xto07Noch keine Bewertungen

- CITD Ug MaterialNX9.0Dokument971 SeitenCITD Ug MaterialNX9.0akshat naiduNoch keine Bewertungen