Beruflich Dokumente

Kultur Dokumente

Tesf U: ES ISO 11540:2013

Hochgeladen von

Nese WakOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Tesf U: ES ISO 11540:2013

Hochgeladen von

Nese WakCopyright:

Verfügbare Formate

ICS: 97.

190

Published by Ethiopian Standards Agency

ESA

Caps for writing and marking instruments

intended for use by children up to 14 years

of age -

Safety requirements

(Identical with ISO 11540:1993)

ES ISO 11540:2013

First edition

tesf

u

Digitally signed by

tesfu

DN: cn=tesfu,

o=ESA, ou=SDD,

email=melkamtesf

a@gmail.com,

c=ET

Date: 2013.01.26

11:36:54 +03'00'

II

Foreword

This Ethiopian Standard has been prepared under the direction of the Technical Committee for Personal safety - Protective

clothing & equipment (TC 84 ) and published by the Ethiopian Standards Agency (ESA).

The standard is identical with ISO 11540:1993, Caps for writing and marking instruments intended for use by children

up to 14 years of age - Safety requirements , published by International Organization for Standardization (ISO).

For the purpose of this Ethiopian Standard, the adopted text shall be modified as follows.

The phrase International Standard shall be read as Ethiopian Standard; and

A full stop (.) shall substitute comma (,) as decimal marker.

ES ISO 11540:2013

Caps for writing and marking instruments intended for

use by children up to 14 years of age - Safety

requirements

1 Scope

This International Standard specifies safety require-

ments for taps for writing and marking instruments

which are designed or clearly intended for use by

children up to 14 years of age. A test procedure for

verifying the cap Performance is given in annex A.

Caps for writing and marking. instruments which are

not designed or intended for use by children, e.g.

jewellery pens, expensive fountain pens, professional

technical pens, as well as transit taps for refills are

not covered by this Standard.

NOTE 1 Caps which do not comply with clause 3 should

have the instrument or its packaging labelled with a waming

as to the dangers of asphyxiation from pen taps.

2 Definitions

For the purposes of this International Standard, the

following definitions apply.

2.1 writing and marking instruments: Any instru-

ment with a detachable cap and a self-contained res-

ervoir of ink or other marking fluid.

2.2 cap: Detachable closure designed to protect the

applicator of the writing, marking or similar fluid.

3 Requirements

3.1 General

Caps shall comply with the performante requirements

of 3.2, 3.3.1 or 3.3.2.

3.2 Cap size

When a cap is presented with its main axis perpen-

dicular to a ring gauge of diameter 16 +ito5 mm and

part of the cap enters that gauge, at least 5 mm of the

length of the cap shall not pass freely through it (see

figure 1).

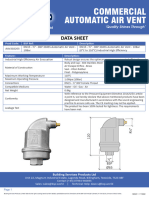

Dimensions in millimetres

+0,05

Q916 0

N C

a) Direction of fall

b) Ring gauge

c) Cap

Figure 1

ETHIOPIAN STANDARD ES ISO 11540:2013

ESA

ISO 11540:1993(E)

Caps which comply with this subclause are deemed

to be too large to present an inhalation hazard.

3.3 Ventilated taps

3.3.1 Vent area

entirely enclosed, shall be

encompassed by a thin

wrapped tautly around any

the main axis or to the

figure 2).

A continuous air passage of at least 6,8 mm* shall

extend for the length of the cap body. The cross-

sectional area of the continuous air passage, if not

that area that would be

piece of cotton thread

section perpendicular to

largest dimension (see

Where a Clip or other protrusion is the means of pro-

viding the air passage, it shall be securely fixed and

shall not be more than 2 mm short of either end of

the cap body. However, the Clip may extend any dis-

tance beyond the end of the cap body.

Caps complying with this requirement are deemed

not to present an asphyxiation hazard.

3.3.2 Air flow

Caps shall permit a minimum air flow of 8 I/min

measured at room temperature, with a maximum

pressure differente of 1,33 kPa when tested in ac-

cordante with annex A.

NOTE 2 A Single circular orifice with a Cross-sectional

area of approximately 3,4 mm* tan be expected to satisfy

this criterion, but multiple smaller orifices may require a

larger total Cross-sectional area.

Caps complying with this requirement are deemed

not to present an asphyxiation hazard.

4 Marking

Writing or marking instruments should be legibly and

indelibly marked on the instrument or its packaging

with the following:

a) the name, trademark or other means of identifying

the manufacturer/supplier;

b) reference to this International Standard, i.e.

ISO 11540.

Dimensions in millimetres

a)

b)

a) Line of cotton thread

b) Included area

Figure 2

ES ISO 11540:2013

ESA

ISO 11540:1993(E)

Annex A

(normative)

Test for air flow

A.l Principle

The test cap is fully inserted into an elastomeric tube

of the appropriate diameter and the air flow through

the tube and the pressure differente are measured in

both directions.

A.2 Apparatus (see figure A. 1)

A.2.1 Air supply, pulse-free, at a rate c

25 I/min and within the pressure range

50 kPa.

A.2.2 Flow regulator, capable of control

flow with an accuracy of + 0,I I/min.

A.2.3

tween

+ 0,2 -

A.2.4

ure of

A.2.5

)f at least

4 kPa to

ing the air

Flow gauge, capable of measuring flow be-

5 I/min and 25 I/min with an accuracy of

/min.

Pressure gauge, capable of measuring press-

at least 4 kPa to an accuracy of &- 0,OI kPa.

Coupling and tubing, suitable for connecting

the equipment described above in accordance with

figure A.1 .

A.2.6 Elastomeric tubing, with an internal diameter

of 80 % to 85 % of the circumscribing circle of the

cap to be tested, measured at its widest Point. The

wall thickness of the tubing shall be

0,75 mm + 0,25 mm and the Shore A hardness shall

be 55 + I.

-

A.3 Procedure

A.3.1 Cut the elastomeric tubing (A.2.6) into a

length such that when the cap is inserted there is a

relaxed diameter of tubing at both ends of the cap

when connected to the apparatus.

A.3.2 Apply a soap Solution or other suitable low

viscosity Iubricant to the full internal area of the tub-

ing.

A.3.3 Insert the cap into approximately the centre

of the tube length and ensure that as far as practi-

cable the cap is parallel to the major axis of the tubing.

A.3.4 Using suitable connectors and tubing (A.2.51,

connect the tube/cap assembly (A.3.3) to the appara-

tus as in figureA.1.

A.3.5 Turn on the air supply (A.2.1) and adjust the

flow until the pressure gauge (A.2.4) indicates a

e differente of 1,33 kPa. pressu

A.3.6

WJW

A.3.7

Record the flow-rate indicated on the flow

A.2.3) at this pressure.

Turn off the air supply, remove and reverse

the tube/cap assembly and repeat A.3.4 to A.3.6.

A.3.8 Test IO taps, giving a total of 20 air flow re-

sults. Record separately the air flows for each cap

tested and report the minimum air flow recorded.

ES ISO 11540:2013

ESA

ISO 11540:1993(E)

b)

/

Cl d) e)

a) Flow control valve

b) Flowmeter

c) Pressure gauge

d) Tubing

e) Cap

f) Air supply

g) Air exhaust

Figure A.l

ES ISO 11540:2013

ESA

The Head Office of ESA is at Addis Ababa.

011- 646 06 85, 011- 646 05 65

011-646 08 80

2310 Addis Ababa, Ethiopia

E-mail: info@ethiostandards.org,

Website: www.ethiostandards.org

Organization and Objectives

The Ethiopian Standards Agency (ESA) is the national standards body of Ethiopia

established in 2010 based on regulation No. 193/2010.ESA is established due to the

restructuring of Quality and Standards Authority of Ethiopia (QSAE) which was

established in 1970.

ESAs objectives are:-

Develop Ethiopian standards and establish a system that enable to

check whether goods and services are in compliance with the

required standards,

Facilitate the countrys technology transfer through the use of

standards,

Develop national standards for local products and services so as to

make them competitive in the international market.

Ethiopian Standards

The Ethiopian Standards are developed by national technical committees which are

composed of different stakeholders consisting of educational Institutions, research

institutes, government organizations, certification, inspection, and testing

organizations, regulatory bodies, consumer association etc. The requirements and/

or recommendations contained in Ethiopian Standards are consensus based that

reflects the interest of the TC representatives and also of comments received from

the public and other sources. Ethiopian Standards are approved by the National

Standardization Council and are kept under continuous review after publication and

updated regularly to take account of latest scientific and technological changes.

Orders for all Ethiopian Standards, International Standard and ASTM standards,

including electronic versions, should be addressed to the Documentation and

Publication Team at the Head office and Branch (Liaisons) offices. A catalogue of

Ethiopian Standards is also available freely and can be accessed in from our

website.

ESA has the copyright of all its publications. No part of these publications may be

reproduced in any form without the prior permission in writing of ESA.

International Involvement

ESA, representing Ethiopia, is a member of the International Organization for

Standardization (ISO), and Codex Alimentarius Commission (CODEX). It also

maintains close working relations with the international Electro-technical

Commission (IEC) and American Society for Testing and Materials (ASTM).It is a

founding member of the African Regional Organization for standardization

(ARSO).

More Information?

Contact us at the following address.

Standard Mark

E

t

h

i

o

p

i

a

n

S

t

a

n

d

a

r

d

s

A

g

e

n

c

y

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Revenue Cycle: Introduction To Accounting Information Systems, 7eDokument47 SeitenThe Revenue Cycle: Introduction To Accounting Information Systems, 7eontykerlsNoch keine Bewertungen

- Unit 2 - Practice 1Dokument11 SeitenUnit 2 - Practice 1Mauricio MartinezNoch keine Bewertungen

- Voyage Planner Installation and Operation Instructions 81339-3-EnDokument32 SeitenVoyage Planner Installation and Operation Instructions 81339-3-EnIonutz Ionutz100% (1)

- Kirloskar Technologies P. LTD.: Appraisal FormDokument4 SeitenKirloskar Technologies P. LTD.: Appraisal Formdihudi.prasantaNoch keine Bewertungen

- Personal branding worksheet to define your brand identityDokument5 SeitenPersonal branding worksheet to define your brand identityՀայկուհի Գրիգորյան100% (3)

- Information Systems Analysis: Topic 7: Process-Oriented IS MethodologiesDokument24 SeitenInformation Systems Analysis: Topic 7: Process-Oriented IS MethodologiesAkuzike NgukuNoch keine Bewertungen

- ZXSDR BS8900B Outdoor Cabinet Macro Base Station Product Description PDFDokument48 SeitenZXSDR BS8900B Outdoor Cabinet Macro Base Station Product Description PDFK OuertaniNoch keine Bewertungen

- FRDM-KE06Z Quick Start Guide (Rev 1.0)Dokument9 SeitenFRDM-KE06Z Quick Start Guide (Rev 1.0)BOLFRANoch keine Bewertungen

- Fine Pitch LED Display Series TV-PH125-YM SpecsDokument1 SeiteFine Pitch LED Display Series TV-PH125-YM SpecsJUANSOLUSINDONoch keine Bewertungen

- Chapter 22 Transport LayerDokument25 SeitenChapter 22 Transport LayerAnonymous ey6J2bNoch keine Bewertungen

- Power Transmission Line in No Load ConditionDokument5 SeitenPower Transmission Line in No Load Conditionjupiter marsNoch keine Bewertungen

- Sentinel LM Programmer/'s Reference ManualDokument474 SeitenSentinel LM Programmer/'s Reference ManualAshish JoshiNoch keine Bewertungen

- Lee Et Al. - 1997 - Facilities and Workplace Design An Illustrated Guide PDFDokument244 SeitenLee Et Al. - 1997 - Facilities and Workplace Design An Illustrated Guide PDFJônatas Silva100% (1)

- BSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022Dokument1 SeiteBSP - Commercial AAV - 10bar - DataSheet - V1.1 - 11-2022j.iqubalNoch keine Bewertungen

- ABAP ObjectsDokument3 SeitenABAP ObjectsvenkatNoch keine Bewertungen

- Spark 2000 Ul: Instruction ManualDokument65 SeitenSpark 2000 Ul: Instruction ManualMárcio Fernandes0% (1)

- Connecting Networks ILMDokument282 SeitenConnecting Networks ILMRuy Pequeno CidNoch keine Bewertungen

- JM JTManualDokument23 SeitenJM JTManualcuongNoch keine Bewertungen

- PCChips P53G Manual PDFDokument53 SeitenPCChips P53G Manual PDFsander100% (1)

- A1. J1939 Fmis and DescriptionsDokument3 SeitenA1. J1939 Fmis and Descriptionsabdelhadi houssinNoch keine Bewertungen

- Design approach analysis for inset-fed rectangular microstrip patch antennaDokument4 SeitenDesign approach analysis for inset-fed rectangular microstrip patch antennaNam TàoNoch keine Bewertungen

- Bugs Fixed in Each 19.0.0.0.0 Grid Infrastructure Release UpdateDokument56 SeitenBugs Fixed in Each 19.0.0.0.0 Grid Infrastructure Release UpdateAuttapol TunwilaiNoch keine Bewertungen

- 1 Ai Chapter-One Edited14Dokument53 Seiten1 Ai Chapter-One Edited14Miraj SherifNoch keine Bewertungen

- Alarms and Error Codes 88 SeriesDokument40 SeitenAlarms and Error Codes 88 SeriesOzgyur MehmedovNoch keine Bewertungen

- BWT61 ManualDokument38 SeitenBWT61 ManualDMaccNoch keine Bewertungen

- SV-Is5 User Manual - 100224Dokument205 SeitenSV-Is5 User Manual - 100224Kỹ Sư Tđh100% (1)

- DMC 550Dokument45 SeitenDMC 550Pandu Sandi PratamaNoch keine Bewertungen

- JuanPay Payment Gateway Services OverviewDokument26 SeitenJuanPay Payment Gateway Services Overviewpatricia_arpilledaNoch keine Bewertungen

- Kioti Daedong RX6030, RX6630, RX7330, RX7630 Tractors Service Manual 07-2015Dokument19 SeitenKioti Daedong RX6030, RX6630, RX7330, RX7630 Tractors Service Manual 07-2015LisakolyNoch keine Bewertungen

- Web Design I: Course DescriptionDokument7 SeitenWeb Design I: Course DescriptionGrantham UniversityNoch keine Bewertungen