Beruflich Dokumente

Kultur Dokumente

The Major Player Database Admin and Project Team

Hochgeladen von

Danudear DanielOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

The Major Player Database Admin and Project Team

Hochgeladen von

Danudear DanielCopyright:

Verfügbare Formate

Case study "HH Gregg: Deciding on a new information technology platform"

Question 1: Identify and critically evaluate the underlying computing architectures in the case

study.

HH Gregg strategy plan are outstanding personal, customer service and competitive pricing through

the team of well trained associated was working well for the company. The strategies of the company

enable managing information technology.

IT architecture is an organzation-specific set of requirements for current and future hardware,

software, network ,data assets ,as well as the human resource needed to acquire, deploy, and

maintain them, to meet the organization's information vision.(et al brown 2012)

Identify The major player Database admin and project team

John Baxter Burns :- initial leader of IDEAS/3000 new plat form project

Stephen R.Nelsu:-Reviewed project scope/option and provide final recommendation

Jack McKinney:- Ran and operate IDEAS/300 including programming and upgrades with ,Irene,

documents functional system requirements

Irene castle :- project manager and reported to burns

Delphi :- finalist

Sentra:- finalist

Former ADI contract

The commuting system of architecture on Gregg's

1985 executive management should need for a computer based management system .the system required

numerous application functions includes (Application software) (NTK)

Inventory management, purchase order management, General lager, Account payable and

receivable, sales order processing and commission management, merchandise warranty tracking

and customer service, advertising accrual and rebates, delivery.

Gregg has follows the procedure to identify and evaluate the vender to meet his system requirement and

managing information technology they revised process that include several venders by:-

Frequent sales presentation

Product demonstration

After that they chose IDEAS/3000 platform from ADI license included copy of source code in COBOL

and basic (the third generation languages).

IDES/3000 is supporting 100 stores

The system support 60 terminal connection

IDEAS/3000 application system operate on HP 3000 server Hardware Expandable memory up to

3MB and 404 MB hard disk drive potential expandable

(Data assets)(BI)

The IDEAS/3000 system was critical to operate Gregg's business and was following integrated in to daily

operation of the company by managing the information technology enhanced the system significantly

changes in business processes and company growth.

(HR)

(EXPANCION PLAN)By 2006, the system has grown to over 60 databases and 3600 program in

additions to COBOL and Basic, The developers also employed six other programming system including

Speed ware

Data Now

Business report writing

(SUPPORTING SOFTWARE)

This has been developed specifically for the HP MPE Operating system.

Current view of the IDEAS/3000 system and associated other software in 2006 (Called the business

application current footprint)

Description System function

HP 3000

-Sales management

-Marketing and Advertizing

-Store operation

-Inventory management

-Delivery

-General account

-HR

Triosoft

-POS

Manual Today

-Merchandising

-supply chain execution

People soft

-Services

-Payroll

-Base benefit/Administration

-Tech pay

-Salary

Issue are raised the Limitations of the IDEAS/3000 system

dependant of HP MPE Operating system

hardware upgrade for additional capacity HP 3000 platform would no longer be

supported

HP issued its plan to discontinue the support of 3000 system in late 2003; the previous CIO believed that

the company needed to get off the old IDEAS/3000 application suite. During that time Gregg's had used

the IDEAS/3000 platform they had been many change in the software technology.

How Gregg's find new application suite that works with UNIX and carries our all needed enterprise

function?

Initial solution by Gregg

December 2003 John Baxter Burns prepared a project definition report titled "Enterprise transition

project".

Goal was to insure orderly transition to need infrastructure based on open system and improve

scalability

Take advantage of new software technology available

"green-field" start -vendors recommend how Gregg could use their software instead of Gregg

telling vendors their need

Narrow /one -side approach isolates the enterprise's strengths

Option Identified

Under previous CIO, John Burks, Tow primary option ware identified

1. Delphi - a full retail application suite

2. Sentara - a retail application development tool combined with off-the-shelf software application

Additional alternatives identified by new CIO, Stephen Nelson after taking over in July 2006

3. Emulator software- allows use of old applications on need hardware and operating system

4. Use of Texas firm to migrate application to an HP UNIX platform

5. EX-ADI contractors re-write entire system into UNIX

6. Do noting

Issue avoidance

Gregg's more proactive after notice the organization action plan with clear expectations of the time frames

and notified in late 2003 of discontinued support, No decision until late 2006. The broader scope to see

initially account for all possible solution.

More proactive before notice

HP 3000 old technology could have been converted sooner

HP UNIX released in 1984

Anticipate future growth

Better relationship with HP support team

Both Sentra and Delphi cost more than $ 15 million and would take longer than 1 year to

implement

Since 2006 heard from EX-ADI contractor to rewrite applications from HP 3000 to HP UNIX

Support cutoff push backed to December 31 ,2020

Migration moved to fiscal year 2009

Cost about $ 5 million

Phase in approach

Gregg to Evaluation his alternatives

1. Key factors compared when evaluating the six alternatives available to HH Gregg include

Adaptability

implementation cost

Annual maintenance cost

Implementation time frame

Implementation method( flash cut Vs Phase-in)

other benefit / risk

2. Other cost consider

Along with the implementation and annual maintenance cost. Nelson must also consider other costs when

evaluating the alternatives including

Training cost

Testing cost

cost to obtain an accurate estimate(Taxes firm)

Costs of lost productivity

cost of future upgrades

3. Grates Risks

Sudden halt of the business during the deployment parts because of

failed database

not working internet connection, or

inability of staff to input or process orders

inability of the new system to handle the load

Unexpected complete system shutdown

incomplete migration of database

4. Option for implementation

Flash cut approach

Delphi

Sentara

UNIX conversion (Texas firm)

Phase in approach

UNIX conversion (EX-ADI)

Emulator software

Evaluate these factors and present this summery to the BOD

vendor Description

Adaptability

Implementat

ion cost

Annual

maintena

nce cost

Timing

Frame

Implementation

Method

Benefits'/Risks

Delphi

Retail application suite

with defined business

process

Requires

revision of

process to

"industry

standard"

$ 15- $20

million

$1 -$2

million

18-24

month

Flash cut

+ Complete business suit

+ move to "industry standard"

- Possible loss of current functionality

-High cost and long implementation time

-Required complete revision of processes

-Significant training requirement

Sentra

Retail application

development tool to

define and re-implement

business processes

Combinatio

n of off-the-

shelf

software

application

and re-

coding of

existing

processes

with

developmen

t tool

$ 20 -$ 12

million

$1 -$2

million

18-24

month

Flash cut

+ re-implement current business processes

+"Powerful tool set" for developing application

+Some "industry standard" plug-and-play

function available

+Lower training cost

-Gap in ability to fully re-implement current

business process(i.e. min/max approach

- high cost and long implementation time

- Potential issue with off-the-shelf software

Emulat

or

Softwa

re

Emulator software

allowing the use of old

application on new

hardware and operating

system

Unable to

support

Gregg's

volume of

transaction

unknown

unknown

unknown

Phase -in

N/A

Texas

firm

Migrate application to an

HP UNIX Platform

Port all

software by

changing

application'

interfaces to

databases

and

operating

system

$4-$5

million

$100000

initial

investment

to determine

unknown

unknown

Flash cut

+ lower costs as compared to Delphi and

Sentra

+ Ability to maintain current business process

+ Limited training required

-"Get nothing new" with system

-No move to "industry standard"

- Requires flash cut implementation

- Significant development staff time

Ex-

ADI

contrac

tor

Hire programmers and

re-write into UNIX

platform internally

Highly

adaptable

due to

internal

control of

developmen

t and

expertise

$4-$5

million

Internal

cost

12 -24

month

Phase -in

+ Allows for phase -in implementation

+ Lower costs as compared to Delphi and

Sentra

+ Ability to maintain current process

+Highly adaptable/customizable

+ Limited training required

-No move to "industry standard"

- Again, nothing necessarily new

Question 2; Given your answer to Question 1 and in driving the company forward, make a well-motivated

recommendation to management with respect to keeping with existing architectures, or moving to different

technologies, or a combination of both.

EX-ADI contractor to rewrite applications from HP 3000 to HP UNIX

Since 2006 Gregg's heard from EX-ADI contractor to rewrite applications from HP 3000 to HP UNIX. Open,

flexible, and just a reliable as HP MPE, HP UNIX is HPs recommended platform for highly available,

business-critical applications. HP servers running HP UNIX boast more than 1000 applications, linear

scalability-up to 40 processors and beyond, and 100% binary compatibility with the Intel Itanium Processor

Family-based Systems.

Gregg's are currently using HP 3000, then Gregg may want to consider porting based HP UNIX server.

This strategy will allow Gregg to convert HP 3000 into an HP UNIX server at no cost to Gregg.

However, it also means youll have to port again in order to get to HP UNIX on IPF in the future. In

that case, it may make more sense to take Gregg's time and port to HP UNIX and IPF at the same time.

If Gregg is developing in Linux you have many deployment options.

If you develop on IA-32 Linux you can compile on IA-32 and deploy on IA-32

If you develop on IPF Linux you can compile on IPF Linux and deploy on IPF Linux and IPF

HP UNIX. IPF HP UNIX can run IPF Linux binaries.

If you develop using Linux on IA-32 or IPF you can compile on IA-32, PA-RISC and IPF

using the same source code. HP UNIX supports 96% of Linux core APIs so Linux developed

source can be compiled on both PA-RISC and IPF versions of HP UNIX.

Benefits of Portable Applications

Some of the tools and strategies available for developing portable applications include using

third and fourth generation languages, standard operating system calls, and networking

integration products. Regardless of the tool, the goal is the same to achieve source code

compatibility and applications that can run on multiple platforms such as MPE and HP UNIX.

3GLs offer a great deal of flexibility because you can put together all the different components

needed to customize the environment control. You have direct access to the network interface

of your operating system. Therefore, writing powerful client/server applications is easier to

achieve with those languages. With databases, 3GLs give you direct access to the database

interface and therefore offer more flexibility in the development of complex programs

Application and Data Interoperability

You may have a variety of databases and database management systems in your environment. It

is likely that you need to access those heterogeneous databases from the HP 3000, and you need

to access the HP 3000 databases from UNIX applications that use independent software vendor

databases. HP provides solutions to these problems.

Implementation Method

Gregg's system is used phased -in implement in the organization. There are three different ways to adopt this

new system.

parallel adoption the old and the new system are running parallel so all the users can get used to the

new system, and meanwhile do their work using the old system.

Phased adoption means that the adoption will happen in several phases, so after each phase the system

is a little nearer to be fully adopted

The big bang adoption, the switch between using the old system and using the new system happens at

one single date, the so-called instant changeover of the system.

Conclusion

We recommend that Gregg's Making the transition from the HP 3000 environment to HP UNIX platforms is in

the end a decision that can provide a solid return on investment. It will open the business/company to newer

innovative technologies allowing the business to be more flexible and adaptive to change and growth

opportunities. Gregg should be used as a framework to enable those responsible for the EX-ADI contractor to

rewrite applications efforts to decide on the appropriate solution that will meet the needs of the organization

within an allocated budget and timeframe.

Question 3: Critically evaluates the data mining and business intelligence aspects at stake

in the case study?

They lacked BI and analytics features, and running queries against the production systems threatened to degrade

performance.

Data minig

In order to gain operational insight and compete more effectively in a changing industry, Norfolk

Southern needed to enable intuitive access to shipping data. Instead of waiting days or weeks for IT to

generate requested reports, business users needed rapid, self-service access to data. Whats more, the

company required enterprise-class technology, not desktop tools. Norfolk Southern wanted to deploy

solutions that could distribute data throughout the organization, even to the front-line workers making

day-today tactical decisions.

datawerhows

Norfolk Southern embraced an integrated data warehouse solution from Teradata as an engine of

change. Although the integrated data warehouse has delivered long-term value to Norfolk Southern,

the greatest impact and results have been realized in four areas: marketing and costing; analytics,

modeling and BI; operational effectiveness; and customer service and support.

Marketing and Costing needs were first addressed by the initial data warehouse solution,

which helped the company understand customer requirements, shape service offerings, and

price transportation offerings.

Analytics, modeling and BI solutions have helped the company use logistics information to

optimize the movement of rail cars, improve operations, gain insight, and innovate for the

future.

Operational effectiveness applications are used by Norfolk Southern to enhance car

management, empty rail car distribution, operational performance, and transportation

modeling.

Customer service and support applications are helping the company optimize trip plans,

enable self-service customer information, and deliver real-time shipment alerts.

Early marketing and costing solutions

In 1995, Norfolk Southern implemented a 1TB data warehouse that allowed managers to access the

vast volumes of data produced by its transactional systems. The warehouse was funded by two

departments: marketing, which sought reports about customer service effectiveness, and cost, which

wanted information about the true costs of moving goods from one point to another.

The first data loaded onto the warehouse was car movement data. Each night, records of the days rail

car movements, such as arrivals and departures, were loaded into the data warehouse. The data was

delivered electronically to the desktops of a few analysts. This information replaced the daily delivery

of tall stacks of green bar report printouts, which were wheeled on hand trucks to users. The electronic

information helped analysts determine car locations and answer customer questions.

The company also developed a homegrown workbench application. The tool helped the marketing

team determine costing for various shipments. Analysts used the data to review traffic patterns and

evaluate demand patterns.

Prior to 2000, customers who needed information would call or fax a Norfolk Southern customer

service agent with questions. Answers would be delivered within minutes, hours, or days, depending

on the complexity of the request.

Behind the scenes, agents placed information requests with IT or navigated difficult-to-use legacy

systems in a search for answers. These customer service processes were costly and time-consuming.

The success of the early data warehouse project and the growing customer demand for information

encouraged Norfolk Southern to load more data into the Teradata warehouse. For example, the team

added details about active railway equipment. Analysts began receiving hourly updates on car

movement. This information helped users begin to support operational decisions

In 2000, the marketing department began to explore using the Internet to phase out telephone- and fax-

based customer information services. The goal was to use the data warehouse as a platform for

servicing customers. The team built a BI application called accessNS, a secure web portal that allows

customers to inquire about their shipments using a Web interface. Soon thereafter, business users

began using Brio tools to create standardized reports from the Teradata warehouse. They also began

using file transfer protocol (FTP) software to upload the data to a corporate intranet.

For the first time, customers could instantly identify shipment locations and get shipment history,

answering such questions as:

Where did my shipment come from?

How long did it take to arrive?

What were the problems along the route?

This departmentally focused application delivered clear, tangible benefits: internal efficiencies, with

time savings and improved customer satisfaction resulting from improved information access.

Business Intelligence Support

As use of the Norfolk Southern data warehousing solutions matured, so did the development of BI and

analytics applications.

In 1999, Norfolk Southern acquired 58% of Conrail. This move increased the companys size by 50

percent, while providing direct track lines to the New York and Philadelphia markets and ownership of

expanded intermodal capabilities. With this acquisition, Norfolk Southern needed not only a new

operating plan; it also required underlying systems and information tools to support the maintenance

and the management of the plan.

The result was the 2002 Thoroughbred Operating Plan (TOP) initiative, which redesigned company

operations.

Prior to TOP, railways like Norfolk Southern would hold or cancel a train if it did not contain enough

tonnage. The priority was to minimize labor costs that is, to operate with the minimum number of

engineers and conductors. A car could lose a day or so while waiting to be filled, and in turn impact

other trains connected to it. Delivery dates could vary within a window of three to five days.

With TOP, management invested in new transactional systems and processes that used operations

research techniques to determine when and how rail cars should move throughout the Norfolk

Southern transportation network. The new system optimized inventory and planned trips.

Once Norfolk Southern crafted this optimized operating plan for its rail cars, employees in various

capacities needed measures, reports, and tools that would help them manage to the plan. Thus, a TOP

steering committee funded a new BI application, which would use data from the warehouse to help the

business manage more effectively.

Norfolk Southern developed a dashboard application that used data from the warehouse to graphically

depict actual performance against the trip plan, for both trains and connections. visualization

technology, the application helped field managers more easily interpret the large volumes of data

generated by the companys minutes, hours or days connections. Since this application was

implemented, the number of missed connections has fallen in greater persentage. Norfolk Southern

also achieved a one-day reduction in rail car cycle time, which translates into millions of dollars of

annual savings.

The TOP BI application analyzed trip plans for every shipment. Norfolk Southern used the data to

determine which trains would handle a shipment; it also identified how, when, and where connections

between the trains would be made. Internal field managers used the insights to help teams stick to the

TOP plan.

Strategy for Norfolk Southern Track 2012

Norfolk Southern has continued to use its Teradata warehouse and BI tools to meet evolving business

goals. A recent program, Track 2012, strives to improve service levels and effectively manage costs

especially fuel use, asset turns, and workforce productivity.

Departments across Norfolk Southern ranging from accounting and human resources to operations

and fleet management have created BI applications that tie into Track 2012 strategies.

Next-Generation BI

After nearly 10 years of successfully using BI tools to gain operational insight, Norfolk Southern was

ready to take its next steps. Throughout 2009 and 2010, the company began upgrading to a new

generation of BI solutions. Business users wanted more intuitive BI tools and they wanted a voice in

choosing them

In 2009, the Norfolk Southern Teradata User Group (TUG) began to discuss the need for a next-

generation BI tool. The BI Special Interest Group (SIG) was tasked with making the selection.

The IT organization created a request for proposal based on the TUG requirements and then conducted

a nine-month evaluation of vendors and products. As the IT organization questioned the vendors about

product features and functionality, business users learned more about the available BI products.

Today the company is in the midst of a multi-year rollout of the enterprise data model to more than 25

business units. But benefits of the deployment are already being realized. The dimensional model lets

users drag and drop elements while setting up hierarchies and drill paths. With our old environment,

it would take a team an average of 500 hours to create parameterized dashboard, and Now they can

do in two hours, because of dimensional model behind it. With the old BI tools, the company had

only 100 power users who queried the system. With NSBI, already 800 users are creating their own

reports. They saw that the warehousing solutions had value and it helped our business partners meet

their goals, too.

As business users see the decision support information their colleagues are generating, more and more

want their own access to the data. Now every department they wants to address their BI needs next.

Operational Effectiveness

The Norfolk Southern data warehousing and BI solutions provide business users with insight into a

variety of operational areas, including car management, empty rail car distribution, and rail operation

performance.

1. Car Management

The first NSBI application is a car management app that launched in late 2009. Managers need to

know where rail cars are at any moment and ensure that cars are efficiently transported to the desired

location. In the past, supervisors manually generated car management reports, but this was a time-

consuming process that often produced dated information. For the first NSBI application, we wanted

to create a tool that was core to the business and would score a big win.

Management of trip plans is executed in the Teradata production systems. Data is loaded into the

warehouse, so queries do not negatively impact production system performance. Another tool, the

intermodal dashboard, uses data from the warehouse and production systems to enhance the ability of

intermodal yards to manage operations. At Norfolk Southern, the Intermodal Division handles routes

that combine shipping and trucking services along with rail. In this way, Norfolk Southern can offer

customers a service that originates at a manufacturing plant and ends at a retail location, for example,

leveraging various modes of transportation along the way.

The intermodal dashboard is updated every 15 minutes. Frequent data updates help yard workers

identify time sensitive shipments that need to be transported or whose owners need to be contacted.

Yard workers can access the dashboard from handheld devices. They can also receive alerts from the

system that tell them which container status needs to be reviewed.

Norfolk Southern is also using scanner-based information to provide updates to customers. Customers

can sign up for event-based text message alerts to be sent to their mobile phones. For example, when a

train passes a scanner, the system sends a text to the customer saying that the train is at the specified

location. Its a simple text message that says the train went by the scanner at this time, says manager

of e-commerce. But the information is so useful for decision making. Its a pretty cool function.

The car management tools deliver true value to Norfolk Southern. Increasing customer visibility into

car operations speeds problem-solving. For example, one customer asked why their routine shipment

was being held for two additional days in a classification yard, explains that. When they

investigated, realized that there was a new trainmaster in that yard who didnt realize that the shipment

didnt need to be reclassified. Once they were able to spot that problem and investigate, they restored

the previous service level and the customer was satisfied. With more current, detailed information

comes higher customer satisfaction. Their goal is to make it easier for customers to do business with

us. With the information, customers can figure out when something changes, and we can get

problems resolved faster. The data makes it easier to resolve issues. Because time-sensitive goods

carry penalties for late delivery, operational efficiency is good for the bottom line. With this data,

They can help customers get their shipments faster, because They know exactly where each container

is and Better operations mean higher profitability.

2. Empty Rail Car Distribution

On large railroad networks, approximately half of all rail cars travel empty. Rail companies that

efficiently move empty cars to the right place at the right time increase profitability. Norfolk Southern

used the Teradata warehouse solutions to improve visibility into its rail car distribution decisions.

With the new BI environment, users can produce standardized reports and drill down for additional

detail. Now its very easy for users to get the empty rail car information they need, support for the

customer service center. They have approximately 80% of the query data in the Teradata warehouse.

By providing users with standardized query answers, NSBI enhances visibility into rail car locations.

The biggest benefit is that the technology helps standardize the answers you get, so everyone sees one

version of the truth. This helps us focus tactical decisions on our strategic goals. When everyone

agrees on the right answer, they can move together toward meeting our goals.

Executives also receive data that helps enhance empty rail car efficiencies. Dashboards summarize

metrics, allow decision makers to drill down and find out why a train missed its connection, and

spotlight opportunities for increased efficiencies. With this information, company executives can

better align tactical decisions with strategic initiatives.

3. Rail Operation Performance

A key component of operational effectiveness for Norfolk Southern is the performance of rail

operations. Decision makers must know whether trains are operating according to schedule and if yard

operations are working as planned .The NSBI environment provides information throughout the

organization. Hundreds of field workers in yards and division offices use the tools to measure

employee performance and identify opportunities for improvement. Staff workers use the information

in weekly calls with field supervisors to determine how they can effectively manage train schedules

and yards where cars are switched. Executives receive summary information via PDFs or smart

phones.

Norfolk Southern has also improved workforce productivity using the NSBI environment. A new

application, Crew Call, "optimizes employee scheduling, ensuring that crews are at the right train at

the right time. By using this application, the company reduced the cost of trains held for crews,

creating a $2.8 million annual savings.

Most of the rail operations performance reports are generated daily some automatically and others

on an ad-hocbasis. Field workers in environments with limited bandwidth can get data from the

corporate portal or via PDFs. Those who need additional data can use NSBI to view more data or

perform diagnostics.

Looking ahead, Norfolk Southern plans to develop additional BI tools to help measure and improve

operational effectiveness. A new connection performance app that measures whether rail car

connections are made on time recently went live. A train performance application is currently in user

acceptance testing. Applications to measure service measurements and crews are in development.

With each successful new use of the NSBI environment, more business users request special projects

so that their organizations can realize the value of the BI tools. Its well understood that the Teradata

technology is of great value to Norfolk Southern and The technology makes it easy for anyone trying

to develop measures, perform analysis, or create reports.

Customer Service and Support

A railroad is essentially a service organization. Pleasing the customer with on-time shipments is

essential. But increasingly, as the industry has become more information-centric, providing customers

with easy access to decision-making data is equally important.

Most Norfolk Southern customers use multiple transportation providers to ship goods. Although many

companies get transportation data from third-party providers, a rail company that can deliver shipment

information in one centralized report, on an e-commerce platform, will win and keep their

business. For this reason, Norfolk Southern has worked diligently to create BI tools that enhance

customer service and support.

The data we have available is tremendously important to our customers. They use the data available to

explore transit times, enhance equipment utilization, validate traffic volumes, and perform trend

analysis.

AccessNS

Norfolk Southern continues to enhance the functionality of the accessNS tool. To create a single

comprehensive data source, the company collects data from the Association of American Railroads

and adds it to the Norfolk Southern transportation reporting systems maintained on the Teradata

Warehouse. More than 14,500 users from 8,000 Norfolk Southern customers use accessNS to get trip

plans, shipment information and other details. These users log into accessNS an average of 15,000

times a day. Customers can access any of the 20 predefined and custom accessNS reports at any time.

They can access current data, which is updated hourly, or they can look at three years of shipment

history. Most other railroads provide no more than 13 months of data.

They can show them the whole trip, from start to finish. This is a real value-add for our customers. For

any customer that ships or receives by rail, we have current and two-year transit times available, down

to the individual moves the shipment made, regardless of whether it was on our railroad.

In addition, a custom-built reporting wizard allows customers to manipulate over 125 fields of

information without writing complex SQL queries. They can modify existing reports or to build new

ones. A drag-and drop interface lets users build queries using sorting, fields, order of columns, limits.

The Report Wizard translates the query into program code.

The users love it,It takes most business users only five to 10 minutes to customize their reports, and

sometimes new users never need to contact us at all while creating their own reports.

accessNS also provides alerting and RSS feed capabilities to customers. Using scanner data, Norfolk

Southern delivers inbound and outbound pipeline reports. They offer train inquiries that show which

cars are en route in a train, as well as the order the cars are in on a particular train.

This information is loaded to Teradata on an hourly basis. As a result, the data becomes available to

customers within 48 minutes. With such rapid notification, customers can schedule receiving

personnel to be available to unload the car at their facility. Customers also can log in to accessNS and

query data directly if they need more information.

The application has generated significant cost savings by eliminating the need for customer service

representatives to create reports for customers. In fact, accessNS delivers 4, 500 reports to users daily.

Between 6,000 and 7,000 time started reports automatically deliver over a million rows of data a day

to customers. To send out this current volume of reports using the old manual processes, Norfolk

Southern would need to hire an additional 47 staff members.

Hot Car Text Messaging

When a rail shipment status changes, Norfolk Southern can immediately notify customers via text

messaging. Customers register for text alerts through accessNS, selecting from more than 90 events

that the Teradata warehouse can monitor. For each selected event, customers can specify up to three

rail cars or pieces of intermodal equipment. They can specify a start date along with the monitoring

duration and enter their cell phone contact information. Each time a specified criterion is met, the Hot

Car Text Messaging application sends a text alert to the customers mobile device. For example, a

customer might monitor estimated time of arrival. If the shipments arrival time is changed by a

Norfolk Southern operation or even by another railroad involved in the transportation route, the

application sends the customer an alert.

By combining faster data access to the Teradata data warehouse with cellular data delivery, the

application lets customers manage rail shipments at any time, from anywhere in the world and This

strategic advantage is critical in the world of just-in-time delivery and has provided customers a better

foundation for making timely business decisions.

The earliest application was designed for any mobile device with texting capabilities. The Norfolk

Southern team is currently developing an Android-powered application that allows customers to

register with accessNS and track up to 10 pieces of equipment.

Giving customers' enhanced visibility has definitely helped our business; Norfolk Southern is the only

railroad to currently offer this functionality. This application gives us a strategic advantage over our

competitors by increasing customer satisfaction and brand loyalty.

Question 4: Given your answer to Question 3 and in driving the company forward, make a well-

motivated recommendation to management with respect to the future direction for the business

intelligence and data mining directions to be undertaken?

Supported by its Teradata Warehouse and BI tools, Norfolk Southern has changed its business model,

enhanced its customer relationships, and become an industry leader despite challenging economic

conditions. Norfolk Southern are pushing change through the industry. As they deploy real-time

information, customers realize that this data can help them. Our competitors are scrambling to develop

these capabilities.

The value of the data access and the insight it delivers is especially high for customers.

Having tremendous volumes of historical customer data available makes Norfolk Southern a

trusted resource for companies that ship goods. Being able to give customers visibility into the

data makes it easier to get new business. The data makes it easier to serve all customers

efficiently. they havent been able to put a dollar amount on the value, but we know it helps.

Teradata has become a tool that customers cannot live without.

Quantifying the value is a challenge. Its difficult to assign solid metrics to the value that the

Teradata solutions have delivered. But if you look at the increasing operating efficiencies, and

you consider the companys improved financial results, you can infer that the technology has

helped Norfolk Southern improve.

Whats more, Norfolk Southern has realized dramatic benefits in several areas:

In marketing and costing, the company improved internal efficiencies, time savings and

customer satisfaction

In analytics, modeling and BI, Norfolk Southern:

Reduced missed connections by 60%

Decreased rail car cycle time by a full day, creating millions of dollars in annual

savings

Optimized car movements and crew scheduling

Improved customer service levels and access to BI

In operational effectiveness, the company:

Created $2.8 million in held-train savings

Improved car connections from 80% to 92%

Increased customer satisfaction through improved visibility into car operations

Reduced financial penalties for late deliveries

In customer service and support, Norfolk Southern:

Improved customers ability to generate BI and make timely decisions

Eliminated the need to hire 47 workers to generate customer reports

Improved the companys competitive differentiation

Looking ahead, Norfolk Southern plans to continue deploying new tools and developing new

applications with this approach, the company can put information into the hands of as many users as

possible. They want to continue expanding access to the data and the bottleneck is not the technology;

its having the people who can access it and use the tools to gain insight.

One thing is certain: with the volumes of data Norfolk Southern has collected and the processing

performance of its technology solutions, users are expecting big things. Norfolk Southern have

mountains of data in our Teradata warehouse, and they are using NSBI to mine and find gold nuggets,

quickly and efficiently and with the success of their projects so far and the interest in new areas of

exploration, theyll never be able to stop the growth!

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Escalator Parts and FunctionsDokument2 SeitenEscalator Parts and FunctionsTrixia Mariz Dimatulac100% (1)

- 36m BowString PDFDokument1 Seite36m BowString PDFD SRINIVASNoch keine Bewertungen

- Underslung MSSDokument12 SeitenUnderslung MSSStrukturas100% (1)

- Lokomotywy Folder en WebDokument17 SeitenLokomotywy Folder en Webcosty_transNoch keine Bewertungen

- Division 14 - Elevator Design Standards 1 GeneralDokument28 SeitenDivision 14 - Elevator Design Standards 1 GeneralAnsara Pasir TumbohNoch keine Bewertungen

- Ge 7ltfDokument20 SeitenGe 7ltfnangkarak8201Noch keine Bewertungen

- Servant Leadership Theory of Robert GreenleafDokument17 SeitenServant Leadership Theory of Robert Greenleafzombieoutlaw5000100% (1)

- Thermoflow GTGsDokument8 SeitenThermoflow GTGsJalal GhelichzadehNoch keine Bewertungen

- Customers' Satisfaction About Services Quality & Services Provided by BASIC Bank Ltd. - A Study On KhulnaDokument16 SeitenCustomers' Satisfaction About Services Quality & Services Provided by BASIC Bank Ltd. - A Study On KhulnaDanudear DanielNoch keine Bewertungen

- Customers' Satisfaction About Services Quality & Services Provided by BASIC Bank Ltd. - A Study On KhulnaDokument16 SeitenCustomers' Satisfaction About Services Quality & Services Provided by BASIC Bank Ltd. - A Study On KhulnaDanudear DanielNoch keine Bewertungen

- 1 Service Quality and CustomerDokument9 Seiten1 Service Quality and CustomerDanudear DanielNoch keine Bewertungen

- An Analysis of The Import Trade Logistics Service Through The EthDokument125 SeitenAn Analysis of The Import Trade Logistics Service Through The EthDanudear DanielNoch keine Bewertungen

- How higher quality leads to lower costs through prevention of costly defects and failuresDokument19 SeitenHow higher quality leads to lower costs through prevention of costly defects and failuresDanudear DanielNoch keine Bewertungen

- Ch02 D (Vergin)Dokument2 SeitenCh02 D (Vergin)Danudear DanielNoch keine Bewertungen

- 2015 Mbl912l Ss1 Lesson 4Dokument25 Seiten2015 Mbl912l Ss1 Lesson 4Danudear DanielNoch keine Bewertungen

- 2015 - MBL912L SS1 - Lesson 5 PDFDokument40 Seiten2015 - MBL912L SS1 - Lesson 5 PDFDanudear DanielNoch keine Bewertungen

- Ch02 C (Vergin Case)Dokument3 SeitenCh02 C (Vergin Case)Danudear DanielNoch keine Bewertungen

- Berhanu-Mbl 923 P Assigment OneDokument17 SeitenBerhanu-Mbl 923 P Assigment OneDanudear DanielNoch keine Bewertungen

- Dissertation PDFDokument158 SeitenDissertation PDFDanudear DanielNoch keine Bewertungen

- 2015 - MBL912L SS1 - Lesson 1 PDFDokument37 Seiten2015 - MBL912L SS1 - Lesson 1 PDFDanudear DanielNoch keine Bewertungen

- Walmart Cost LeaderDokument6 SeitenWalmart Cost LeaderSylvia JohnNoch keine Bewertungen

- Quest For Global DominanceDokument10 SeitenQuest For Global DominanceRahul PadiaNoch keine Bewertungen

- 116 PDFDokument14 Seiten116 PDFDanudear Daniel100% (1)

- Full Text 03Dokument42 SeitenFull Text 03Danudear DanielNoch keine Bewertungen

- Business expansion through employee training and development at AldiDokument4 SeitenBusiness expansion through employee training and development at AldiDanudear Daniel50% (2)

- ContentServer 9 PDFDokument17 SeitenContentServer 9 PDFDanudear DanielNoch keine Bewertungen

- Business Research Slides - 2Dokument111 SeitenBusiness Research Slides - 2Danudear DanielNoch keine Bewertungen

- SelmanDokument9 SeitenSelmankothanzawoo1979Noch keine Bewertungen

- MBL925RDokument12 SeitenMBL925RDanudear DanielNoch keine Bewertungen

- Exam 2013Dokument2 SeitenExam 2013Danudear DanielNoch keine Bewertungen

- S2 CaseStudy TomTomDokument2 SeitenS2 CaseStudy TomTomMuhammad SidikNoch keine Bewertungen

- Configuring ISA Server For Incoming Ping ResponsesDokument227 SeitenConfiguring ISA Server For Incoming Ping ResponsesDanudear DanielNoch keine Bewertungen

- LayersDokument20 SeitenLayersDanudear DanielNoch keine Bewertungen

- The HTTP Status Code in IIS 7Dokument14 SeitenThe HTTP Status Code in IIS 7Danudear DanielNoch keine Bewertungen

- S2 CaseStudy TomTomDokument2 SeitenS2 CaseStudy TomTomMuhammad SidikNoch keine Bewertungen

- Department of Economics: Working PaperDokument44 SeitenDepartment of Economics: Working PaperDanudear DanielNoch keine Bewertungen

- Waterloo Int Case PDFDokument5 SeitenWaterloo Int Case PDFFilip LasockiNoch keine Bewertungen

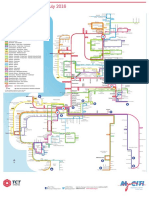

- 697 System MapDokument1 Seite697 System Mapanon_b186Noch keine Bewertungen

- Materi Fisika Listrik 7 Induksi MagnetDokument15 SeitenMateri Fisika Listrik 7 Induksi MagnetTaufik KusumaNoch keine Bewertungen

- RJ45 Interface Module: Product OverviewDokument1 SeiteRJ45 Interface Module: Product OverviewmachinemanNoch keine Bewertungen

- Machine Room NotesDokument2 SeitenMachine Room NotesSayed NagyNoch keine Bewertungen

- AB EPL SP GOXX 2118 B2 (Long Radius Bends Specification)Dokument23 SeitenAB EPL SP GOXX 2118 B2 (Long Radius Bends Specification)sherviny100% (1)

- SkybusDokument25 SeitenSkybusDharmik Dobariya100% (3)

- MastEr Plan BrasiLiaDokument12 SeitenMastEr Plan BrasiLiaLiam PotterNoch keine Bewertungen

- Theme Vii: Text I Modes of Transportation in LogisticsDokument4 SeitenTheme Vii: Text I Modes of Transportation in LogisticsBassma EL GHALBZOURINoch keine Bewertungen

- Grafico GreveDokument354 SeitenGrafico GreveozorioNoch keine Bewertungen

- Park & Ride Facility PlanningDokument11 SeitenPark & Ride Facility PlanningOXNoch keine Bewertungen

- Manufacture & Testing: 1 Recommended Supplier and Manufacturers, Places ofDokument14 SeitenManufacture & Testing: 1 Recommended Supplier and Manufacturers, Places ofMuthu KumaranNoch keine Bewertungen

- Borderou DE PDFDokument2 SeitenBorderou DE PDFIonescu AlexandraNoch keine Bewertungen

- H&ws Final DraftDokument107 SeitenH&ws Final DraftHemanth gowdaNoch keine Bewertungen

- Regional Transportation for Raipur, Bhilai & DurgDokument25 SeitenRegional Transportation for Raipur, Bhilai & DurghimanshusonberNoch keine Bewertungen

- ABU CompactDokument32 SeitenABU CompactPrimož KozlevčarNoch keine Bewertungen

- Railway Signaling BooksDokument2 SeitenRailway Signaling BooksBunkun150% (1)

- Civil 5 PDFDokument29 SeitenCivil 5 PDFSwastika ChandaNoch keine Bewertungen

- Allied Steel Building Change Order DetailsDokument30 SeitenAllied Steel Building Change Order DetailsHéctor Aníbal RodríguezNoch keine Bewertungen

- Explore Valparaiso's Scenic Coastline and Historic Port DistrictDokument88 SeitenExplore Valparaiso's Scenic Coastline and Historic Port DistrictrdmoenenNoch keine Bewertungen

- Trabajo Carretera 1Dokument8 SeitenTrabajo Carretera 1Marie ArriolaNoch keine Bewertungen

- Ways To WembleyDokument14 SeitenWays To WembleyscribdstorageNoch keine Bewertungen

- Case Study Toranomon Hills Mori Tower Tokyo enDokument4 SeitenCase Study Toranomon Hills Mori Tower Tokyo enMochamad TaufikNoch keine Bewertungen