Beruflich Dokumente

Kultur Dokumente

Citizen M16 - 2

Hochgeladen von

Favoreel PatrickOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Citizen M16 - 2

Hochgeladen von

Favoreel PatrickCopyright:

Verfügbare Formate

M3 Programming

5-69

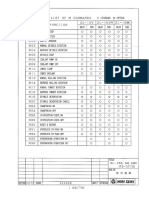

5.5.6 T codes and arguments for each machining pattern

Machining

pattern

Specified axis

control group and tool

T code Argument

4 digits 2 digits Q1 H X Z Y A W K3 E

Alternate

machining

(G610)

$1 Tool on gang tool

post

G611 \ \ \ \ \ \ \ \ \

G612 \ \ \

Tool on turret tool

post

G611 \ \ \

G612 \ \ \ \ \

$3 Tool on back 3-spindle tool

post

\ \ \ \ \ \ \

Back spindle \

Two-saddle

machining

(G620)

$1 Tool on gang tool

post

G621 \ \ \ \ \ \ \ \

G622 \ \ \ \ \ \ \

$2 Tool on turret tool

post

G621 \ \ \

G622 \ \ \ \ \

$3 Tool on back 3-spindle tool

post

\ \ \ \ \ \ \

Back spindle \

Front/back

parallel

machining

(G630)

$1 Tool on gang tool post \ \ \ \ \ \ \ \

$2 Tool on turret tool

post

G632 \ \ \ \ \

$3 Tool on turret tool

post

G633 \ \

Tool on back

3-spindle tool post

G633 \ \ \ \ \ \ \

Back spindle G633 \

Front/back

parallel

machining

(G635)

$1 Tool on gang tool post \ \ \ \ \ \ \ \

$2 Tool on turret tool

post

G637 \ \ \ \ \

Tool on back

3-spindle tool post

G638 \ \ \ \ \ \ \

Back spindle G638 \

Tool on turret tool

post

G638 \ \

Simultaneous

3-lines

machining

(G640)

$1 Tool on gang tool post

\ \ \ \ \ \ \ \

$2 Tool on turret tool post

\ \ \ \

Pick-off (G650) $1, $2 Depending on the previous machining pattern

$3 Back spindle

\

\: Specification permitted : Specification not permitted

Notes

- You can specify only the T codes and arguments shown in the above table.

- For the machining patterns, see <Section 5.7 Special G Codes 1 and 2>.

Field Code Changed

M3 Programming

5-70

5.6 G Functions (G Codes)

A G function is expressed with G followed by a 2-digit number. It is also called a preparation function.

G functions are provided for the NC unit to control axes (X1, Z1, Y1, X2, Z2, X3, and Z3).

Command format

G

Examples: G00 Rapid feed positioning

G01 Linear interpolation

5.6.1 G code list

Once the G functions of groups A, D, F, and H in the table below are specified, they are enabled until

another G function of the same group is specified. They are called modal G codes. The G functions of

group C are enabled only when specified.

G code list

G code Function Group

*G00 Rapid feed positioning A

G01 Linear interpolation A

G02 Circular interpolation (clockwise) A

G03 Circular interpolation (counterclockwise) A

G04 Dwell C

G28 Reference point return C

G32 Single Point thread cutting A

G35 Arc threading (clockwise) (optional) A

T36 Arc threading (counterclockwise) (optional) A

*G40 Tool nose radius compensation cancel J

G41 Tool nose radius compensation left ON J

G42 Tool nose radius compensation right ON J

*G43 Back spindle feed per rotation OFF K

G44 Back spindle feed per rotation ON K

G50 Coordinate system setting/Main spindle speed clamp

setting

C

G76 Multiple repetitive threading cycle H

G79 Face drilling cycle (optional) H

G80 Face synchronized cross tapping mode OFF (optional) H

G84 Face cross tapping mode ON (optional) H

G88 Synchronized cross tapping mode ON (optional) H

G90 Longitudinal turning canned cycle H

G92 Thread cutting canned cycle H

G96 Constant surface speed control ON F

*G97 Constant surface speed control OFF F

G98 Millimeters per minute feed D

*G99 Millimeters per revolution feed D

M3 Programming

5-71

Notes

- You can specify G codes of different groups together in the same block.

- You cannot specify a G code and T together in the same block.

- You cannot execute a 3-digit G code in the MDI mode.

- Single block operation is disabled while G32, G35, G36, G76, G79, G84, G88, G90, or G92 is enabled.

If any of the G codes is called during single block operation, the operation continues until the G code is

canceled. If the axis control group $1, $2, or $3 enters such a state, all the other axis control groups

operate continuously.

- The asterisk * prefixed to G codes indicate the specification in the power-on state.

M3 Programming

5-72

5.6.2 Back spindle feed control (G43, G44)

The feed per rotation command can be specified for the back spindle.

Command format

G43 Back spindle feed per rotation OFF

G44 Back spindle feed per rotation ON

The feed rate of feed per rotation is generally determined by the main spindle speed. When the G44 is

specified for machining a workpiece at the back spindle, feed per rotation is performed at the back spindle

speed in the specified axis control group.

In general, you do not have to specify G43 and G44. When a machining pattern is switched, the

machining pattern command automatically acts as the back spindle control command.

The following table shows back spindle control for each machining pattern:

Machining pattern $1 $2 $3

Machining pattern cancel (G600) OFF OFF ON

Alternate machining (G610) OFF OFF ON

Two-saddle machining (G620) OFF OFF ON

Front/back parallel machining (G630) OFF ON ON

Front/back parallel machining (G635) OFF ON ON

Simultaneous 3-lines machining

(G640)

OFF OFF ON

Pick-off (G650)

Depending on the

previous machining

pattern

Depending on the

previous machining

pattern

Depending on the

previous machining

pattern

M3 Programming

5-73

5.7 Special G Codes 1 and 2

The commands of G codes 1 and 2 are specific to this machine. They enable machining that extends

over multiple axis control groups.

You can simplify programs (e.g., decrease of operating time) and improve productivity by using the

commands effectively.

Command format

G

5.7.1 List of special G codes 1

G code Function

G231 Pick-off cancel

G600 Machining pattern cancel

G610 Alternate machining

G611 Alternate machining Gang tool post select

G612 Alternate machining Turret select

G620 Two-saddle machining

G621 Two-saddle machining C axis at $1 side enabled

G622 Two-saddle machining C axis at $2 side enabled

G630 Front/back parallel machining

G632 Front/back parallel machining - Back turret select

G633 Front/back parallel machining - Back 3-SP. select

G635 Front/back parallel machining

G637 Front/back parallel machining Back turret select

G638 Front/back parallel machining Back 3-SP.select

G640 Simultaneous 3-lines machining

G650 Pick-off, Center-support

G999 Last program execution

Axis control groups

Specify the G commands except G611, G612, G621, G622, G632, G633, G635 and G638 for all axis

control groups $1, $2, and $3.

The program automatically enters $1, $2, and $3 in the queuing state in order to synchronize them with

each other, and then it proceeds to the next operation.

Notes

- You cannot use special G codes 1 with M, S, or T codes in the same block.

- You cannot execute special G codes 1 in the MDI mode.

M3 Programming

5-74

5.7.2 List of special G codes 2

G code Function

G113 Spindle synchronization control cancel

G114.1 Spindle synchronization control (optional)

G114.2 Spindle synchronization control for polygon machining (optional)

G114.3 Spindle synchronization control for hobbing (optional)

G126 Superimposition of an arbitrary pair of axes

G140 Arbitrary axis change

G201 Front product separation [$1 only]

G500 Coordinate system shift OFF

G501 Coordinate system shift ON

G813 Spindle synchronization control cancel

G814 Spindle synchronization control (optional)

G899 Non-conform material phase adjustment [$1 only]

Axis control groups

Specify the G commands for only axis control group $1, $2, or $3 that needs them.

Notes

- You cannot use special G codes 2 with M, S, or T codes in the same block.

- You cannot execute G201 in the MDI mode.

- G113 and G813 have the same function.

M3 Programming

5-75

5.7.3 Last program execution (G999)

This command must be specified in the last portion (end process) of each axis control group ($1, $2, $3)

program that includes the last program.

In general, the last program is executed to perform back machining for workpieces with which front

machining is completed. The back machining is performed in the last cycle while the machine is in the

stopped state (e.g., 1-cycle stop or product counting by the counter).

Specify the G999 command for each axis control group to automatically enter the axis control groups in

the queuing state. The last program between G999 and N999 is executed in the 1-cycle or 1-block

operation mode.

Be sure to specify the N999 command at the end of the last program contents of each axis control group.

To finish program creation, specify three commands following N999 at the end of the end process. The

commands must be specified in the sequence of M02, M99 and then %.

Command format

G999 Last program execution

Axis control groups

Specify this command for all the axis control groups $1, $2, and $3.

Program sample

$1 $2 $3

G610 G610 G610

M56

G999 ............................ Last program G999 ............................ Last program G999 ............................ Last program

: : :

: Contents of the last program : Contents of the last program : Contents of the last program

: : :

N999 N999 N999

M02 M02 M02

M99 M99 M99

% % %

Notes

- Cancel the coordinate system shift command and compensation command before executing the G999

command.

- Specify the machining pattern command to execute the last program after the G999 command.

- See <Section 7.5.2 Last part function>.

M3 Programming

5-76

5.7.4 Non-conform material phase adjustment (G899)

A phase shift occurs between the spindle and guide bushing and between the main spindle and back

spindle when machining non-conform materials (hexagonal material, etc). Use this command to store

the values of phase shifts in the memory of the NC unit.

Be sure to specify this command when mounting the non-conform material chuck and guide bushing.

The command is for adjustment and is not written in the program. It is used for the MDI operation.

Command format

G899 R1 K1 C1

Axis control groups

Specify this command for $1. You can execute the command in only the MDI mode.

Argument

- R1: Specify this argument to store the values of phase shifts (back spindle included) in the memory of

the NC unit. The back spindle rotates when the G899 command is executed.

- K1: This argument does not execute the back chuck to close.

- C1: Specify this argument to phase the front C axis (C1 axis) and the back C axis (C2 axis) with each

other. The position of the front C1 axis at 0

o

matches the position of the back C axis at 0

o

after

pick-off operation. The C1 argument must be specified with the R1 argument.

Procedure

Adjusting the phase between the main spindle and guide bushing

1. Put a material (non-conform material) through the main spindle and guide bushing.

2. Execute G899 in the MDI mode. The main spindle chucks the material and adjusts the phase.

Adjusting the phase between the main spindle and back spindle

(Phase adjustment between the front C axis and the back C axis)

1. Put a material (non-conform material) through the main spindle, guide bushing, and back spindle.

2. Execute G899R1(C1) in the MDI mode. The main and back spindles chuck the material and adjust

the phase.

M3 Programming

5-77

Notes

- Specify the R1 argument whenever using the K1 argument. They must be specified in the format of

G899 R1 K1.

- In a material exchange program, specify the M26 (G/B phase adjustment) command before the

command to insert a material into the guide bushing.

- Specify the G814 R0, G114.1 H1 D0-2 R0 (spindle synchronization control) command before the

command to chuck the material with the main and back spindles. This will cause the phase difference

stored by G899 to be automatically added.

M3 Programming

5-78

5.7.5 Spindle synchronization control (G114.1, G814, G113, and G813) optional

These commands control the speed and phase of a spindle in synchronous with another spindle.

Use a spindle synchronization control command when you need to synchronize two spindles with each

other. For example, use the command in the following cases: the back spindle re-chucks the workpiece

that is now chucked by the main spindle, a workpiece is machined chucked by both the main spindle and

the back spindle, and a polygonal workpiece is re-chucked by adjusting the phases of the two spindles.

The G814 command defines the main spindle (S1) as the reference spindle and the back spindle (S2) as

the synchronized spindle, and synchronizes the two spindles with each other.

The G114.1 command specifies a reference spindle and synchronized spindle, and synchronizes the two

spindles with each other.

The G113 and G813 command cancels the synchronization of two spindles that was specified by a spindle

synchronization command.

Command format

G814 R Spindle synchronization

G114.1 H1 D2 R Spindle synchronization

G813 Spindle synchronization cancel

G113 Spindle synchronization cancel

Argument

- H: Specify the reference spindle and the direction in which the spindle rotates. When (+)1 is

specified, the main spindle rotates forward.

- D: Specify the spindle to be synchronized and the direction in which the spindle rotates. When

2 is specified, the back spindle rotates backward.

- R : Specify the amount (angle) of the phase shift between synchronous spindles. The value of

R argument is added to the value that is stored by the non-conform material shift adjustment

command (G899). The R argument is valid for a clockwise shift viewed from the main

spindle. If the R argument is not specified, the value that is stored by the non-conform

material shift adjustment command (G899) is used.

Setting range: 0 to 359.999

Notes

No phase adjustment is made if the R argument is omitted for G114.1 H1 D-2.

M3 Programming

5-79

5.7.6 Front product separation (G201)

Use this command to collect a workpiece chucked by the main spindle.

The workpiece is collected by the workpiece receiver mounted on the turret tool post, and then it is

transferred into the product receiver box.

CAUTION

For M2032 model, be sure to specify the C1 argument in the G201 command. If the C1

argument is not specified, the system does not collect workpieces.

Command format

G201 X F A T H U C1 Z R1 Front product separation

Axis control groups

Specify this command for $1.

Argument

- X : Specify the X1 axis work coordinate as the end position in the cut-off process.

- F : Specify the X1 axis feed rate in the cut-off process.

- A : Specify the X1 axis position for end-position queuing. When the X1 axis reaches the work

coordinate specified by the A argument during cut-off machining, positioning of the

workpiece receiver of the turret tool post is completed (X2 axis product collection position).

The end-position queuing is not performed unless the A argument is specified.

- T : Specify the tool number for turning the workpiece receiver. The tool number of the tool

opposite to (180

o

apart) the tool with the workpiece receiver mounted must be specified.

- H : Specify a low speed at which the turret tool post turns. If the H argument is not specified,

the turret tool post turns at the default speed 4320 (rotation every 5 seconds).

To rotate it every 60 seconds: Specify H360 = (60 60 seconds) 360.

To rotate it every 5 seconds: Specify H4320 = (60 5 seconds) 360.

- U : Specify dwell time after the workpiece receiver is positioned.

If the U argument is not specified or "0" is specified, the turret tool post (X2 axis) starts

moving backward after the X1 axis reaches to the position specified by the X argument.

M3 Programming

5-80

- C1: Set the position of Z2 axis to retract point (Z2-axis machine coordinate: 4.0 mm) when

workpiece is to be collected in product chute. For M2032 model, be sure to specify the C1

argument. This argument is disabled in the machine of M1216 model.

When this argument is not specified, the Z2 axis is positioned at the forward end position.

- Z : Specify the position of Z2 axis in relative to the current position when workpiece is to be

collected in product chute. When this argument is not specified, the Z2 axis is positioned at

the forward end position. The direction of Z argument (signs) is determined as minus (-) to

the left side and plus (+) to the right side when viewed from the front of the machine.

When both Z and C1 arguments are specified at the same time, Z argument precedes C1

argument.

Note: Specifying the range between Z2=0.0 and Z2=4.0 of machine coordinates will

cause an alarm because the turret cannot rotate within this range.

- R1: Specify this argument to collect the workpiece, which is cut off on the front side, into the

workpiece receiver without pick-off operation. Use the R1 argument in the following

conditions: the setting switch $2$3 or $3 cycle start is disabled in the Set SW screen, the

back machining specified in the program is canceled, and only front machining is performed.

The R1 argument is useful when the diameter of the workpiece to be chucked by the back

spindle is not corrected or when you want to see only front machining. Do not specify the

R1 argument during ordinary program operation with "$1 $2 $3 cycle start enabled".

Specify the R1 argument in the G650 mode.

M3 Programming

5-81

Program sample

Ordinary product collection

$1 $2 $3

:

:

G610 G610 G610

(G611)

T0100

T2000

G00 X21.0 Z25.0

G201 X-3.0 F0.03

A1.0 T2500 U1.0 C1

Production collection

:

:

Product collection with the $2 or $3 program stopped ($2 or $3 cycle start disabled)

$1 $2 $3

: : :

G610 G610 G610

: :

T2000 Selection of workpiece separator :

G630 G630 G630

: G632 G632

: :

: T2000

: G00 X20.0 Z-10.0

: M16

: M72

: M10

: G04 U1.0

M3 S1=3400 M11

T0100 M73

G00 X21.0 Z50.0 M33 T2500

M24 S2=3400

G650 G650 G650

G00 Z-2.0

G98 G01 Z35.0 F5000

M15

!3L1 !1L1

M73

:

G201 X-3.0 F0.03 A1.0 T2500 R1 U1.0

C1

Production collection

:

M3 Programming

5-82

Operation sample

(1) The workpiece receiver

is selected.

(2) When the X1 axis reaches

the work coordinate

specified by the A argument

during cut-off machining, the

workpiece receiver has

moved to the product

collection position.

Cut-off

machining

(4) The workpiece receiver

moves to the return

position of the tool on the

turret tool post.

(5) The workpiece

receiver turns toward

the product receiver

box.

(3) Cut-off

Comment [ER1]: word

M3 Programming

5-83

Notes

- You cannot use the G201 command for arc cut-off machining. To perform arc cut-off machining, use

the M32 and M33 commands. See <Section 5.11.4 Positioning of the workpiece receiver for

front/back products (M32)> or <Section 5.11.5 Front and back product separation (M33)>.

- You can also use the command explained in <Section 5.11.5 Front and back product separation

(M33)> to collect cut-off workpieces with the workpiece receiver mounted on the turret tool post.

- To collect workpieces chucked by the back spindle, see <Section 5.11.5 Front and back product

separation (M33)> or <Section 5.11.6 Sequential operation of the workpiece unloading device (M34)

optionalSequential operation of the workpiece unloading device (M34) optionalSequential

operation of the workpiece unloading device (M34) optionalSequential operation of the workpiece

unloading device (M34) optionalSequential operation of the workpiece unloading device (M34)

optional>.

- You can specify the G201 R1 argument in the G650 mode. An alarm is issued if the argument is

specified in a different mode.

- Be sure to delete the command G201 with R1 argument of $1 from the program after workpieces were

collected by $1 with the G201 R1 argument specified. An alarm is issued if the continuous automatic

operation is performed while the command G201 with R1 argument is still specified under three axis

control groups cycle start are enabled.

- If the override is changed or operation is performed with the handle in program check mode when the

G201 command is executed, the end position specified by the A argument may not match the operation.

- Arguments C1 or Z is specified in G201, the Z2 axis returns to the forward end position after products

are collected.

M3 Programming

5-84

5.7.7 Pick-off cancel (G231)

During cut-off machining, this command cancels the pick-off mode specified by the G650 pick-off

command. Use the G231 command to move the turret tool post (Z2 axis) and the back headstock (Z3

axis) to the fixed points for the next process (machining pattern) when the X1 (X2) axis in the cut-off

process is at an arbitrary position.

Command format

G231 X F A W(1,2,3) I Pick-off cancel

Axis control groups

Specify this command for $1.

Argument

- X : Specify the X1 (X2) axis work coordinate as the end position in the cut-off process.

- F : Specify the X1 (X2) axis feed rate in the cut-off process.

- A : Specify the X1 axis position for start-position queuing. When the X1 axis reaches the work

coordinate specified by the A argument during cut-off machining, the turret tool post (Z2

axis) and the back headstock (Z3 axis) start moving. If the cut-off machining is performed

with a tool on the turret tool post in the G612 mode of the G610 mode, the X2 axis is

specified for start-position queuing.

- W1: Specify this argument to move the Z2 and Z3 axes to the fixed points of the G610 mode.

The turret tool post (Z2 axis) moves to the forward end position at the rapid feed rate. The

back headstock (Z3 axis) moves to the backward end position at the rapid feed rate. The

turret tool post does not move in the G612 mode of the G610 mode or unless the X2 axis is

at the return position of the turret tool post.

- W2: Specify this argument to move the Z2 and Z3 axes to the fixed points of the G632 and G637

mode. The turret tool post (Z2 axis) moves to the end face of the workpiece on the back

side at the rapid feed rate. The back headstock (Z3 axis) moves to the zero point for back

machining at the rapid feed rate. The turret tool post does not move in the G612 mode of

the G610 mode or unless the X2 axis is at the return position of the turret tool post.

- W3: Specify this argument to move the Z3 axis to the fixed point in the G633 and G638 mode.

The back headstock (Z3 axis) moves to the backward end position at the rapid feed rate.

- I The I argument is valid only when the W argument is 2 (fixed point in the G632 and G637

mode). Specify the amount of shift from the zero point for back machining with the Z3 axis.

(Specify the I argument when the Z2 axis stroke is too short for drilling with a tool on the

turret tool post for back machining. The Z2 and Z3 axes shift the distance specified by the I

argument.)

M3 Programming

5-85

Program sample

When switching to the G610 mode after pick-off operation:

$1 $2 $3

G610 G610 G610

: :

G99 M03 S1=1500 :

T0100 :

G00 X13.0 Z85.0 T01 T4000

G650 ............................................. Pick-off G650 ......................... Pick-off G650 ......................... Pick-off

G00 Z2.0

M24 S2=1500

G98 G01 Z50.0 F1000

M15

!3L1 !1L1

G231 X3.0 F0.03 A1.0

W1 ...................................... Pick-off cancel

(When the X1 axis reaches the work

coordinate 1.0, the turret tool post moves

to the forward end position, and the back

headstock moves to the backward end

position.)

(G610) (G610) (G610)

: : :

When switching to the G630 (G632) mode after pick-off operation:

$1 $2 $3

G630 G630 G630

: G632 G632 I30.0

G99 M03 S1=1500 :

T0100 :

G00 X13.0 Z85.0 T4000

G650 ............................................. Pick-off G650 ......................... Pick-off G650 ......................... Pick-off

M33 T2500 G00 Z2.0

M24 S2=1500

G98 G01 Z50.0 F1000

M15

!3L1 !1L1

G231 X3.0 F0.03 A1.0 W2 I30.0

........................................... Pick-off cancel

(When the X1 axis reaches the work

coordinate 1.0, the turret tool post moves

to the end face of the workpiece on the back

side, and the back headstock moves to the

zero point for back machining.)

(G630) (G630) (G630)

: (G632) (G632 I30.0)

: :

M3 Programming

5-86

Notes

- The superimposition of the Z1 and Z3 axes is canceled when the G231 command is executed.

- To maintain the superimposition of the Z1 and Z2 axes, execute the G231 command after executing the

G650 command in the G620 mode.

- The turret tool post (Z2 axis) does not move in the following cases:

The G650 has been executed in the G612 (turret select) mode of the G610 modes.

The X2 axis is not at the return position of the turret tool post.

- The turret tool post (Z2 axis) does not move if the G231 command is executed during front and back

product separation (M33) by the workpiece receiver mounted on the turret tool post or during selection

of a tool on the turret tool post, for $2 in the G650 mode.

- When a value greater than 0 is specified for the A argument, an alarm is issued if 0 is specified for the

"Tubing Bar Stock I.D." in the machining data.

- The G231 command does not have an argument for return to the fixed point in the G620 mode.

Specify the W3 argument to move the Z3 axis backward.

- The G231 does not permit arc cut-off machining.

M3 Programming

5-87

5.8 M Functions (M Codes)

5.8.1 M code list

M code Function Remarks

M00 Program Stop Automatic operation is stopped.

M01 Optional Stop Automatic operation is stopped when the switch is turned

ON.

M02* Cycle Stop 1-cycle stop point

M03 Main Spindle Forward Rotation The main spindle starts rotating forward.

M04 Main Spindle Reverse Rotation The main spindle starts rotating backward.

M05 Main Spindle Stop The main spindle stops rotating.

M06* Main Spindle Chuck Close The main spindle chuck closes.

M07* Main Spindle Chuck Open The main spindle chuck opens.

M08 Enable Bar Stock Exchange Program The workpiece replacement program starts.

M09 Bar Stock Exchange Program Complete The workpiece replacement program terminates.

M10* Knock-Out Advance The knock-out axis of the back spindle moves forward.

M11* Knock-Out Retract The knock-out axis of the back spindle moves backward.

M15* Back Spindle Chuck Close The back spindle chuck closes.

M16* Back Spindle Chuck Open The back spindle chuck opens.

M18* Enable Main Spindle C-Axis Sequential operation of spindle C axis ON

(optional to M1216)

M20 Main Spindle Index and C-Axis Release The main spindle hold Off

M23 Back Spindle Forward Rotation The back spindle starts rotating forward.

M24 Back Spindle Reverse Rotation The back spindle starts rotating backward.

M25 Back Spindle Stop The back spindle stops rotating.

M26 Execute Guide Bushing Phasing The phases of the spindle and guide bushing are aligned.

M28* Main Spindle Index Sequential operation of main spindle indexing

M31 Workpiece Conveyor On The workpiece conveyor is turned ON. (Optional)

M32* Front and Back Basket Positioning The workpiece separator is positioned to collect products

from the main/back spindle. (Turret)

M33* Front and Back Product Separation

(Turret)

Products are collected from the main/back spindle. (Turret)

M34* Sequential operation for unloading

workpieces

Sequential operation for unloading workpieces (Optional)

M35* Product Unloading Movement Command The workpiece unloading device is moved to unload

products from the machine.

M36 Rotary Guide Bushing Torque Lower Limit

L Selection

The guide bushing torque is set to 0%.

M37 Rotary Guide Bushing Torque Limit Off The guide bushing torque is set to 100%.

M38 Bar Loader Torque Off, Synchronization

Control On

Synchronization of the Z1 axis and bar loader ON (optional)

M39 Bar Loader Torque On, Synchronization

Control Off

Synchronization of the Z1 axis and bar loader OFF

(optional)

M40* Turret Advance (Z2 axis) The turret tool post moves to the main spindle side.

M41* Turret Retract (Z2 axis) The turret tool post moves to the back spindle side.

M46 Bar Loader Torque 0

M48 Enable Back Spindle C-Axis Sequential operation of back spindle C axis ON (optional)

M50 Back Spindle Pick-Off Failure Detection Rotate the spindle at a low speed after cut-off machining,

and enter M50.

M51* Tool Breakage Detection On A cut-off tool break is detected. (Optional)

M52 Coolant On Coolant starts discharging.

M53 Coolant Off Coolant stops discharging.

M54 Bar Loader Torque Off The bar loader feed is stopped. (Optional)

M55* Bar Loader Start Workpiece replacement is started. (Optional)

M3 Programming

5-88

M code Function Remarks

M56 Products Count Products are counted.

M57 Cycle Stop (Sub Program) 1-cycle stop point (for subprograms)

M61 to

M69

External M Code Use the codes to add optional functions.

M72 Back Spindle Air Blow On The back spindle air blower is turned ON.

M73 Back Spindle Air Blow Off The back spindle air blower is turned OFF.

M75 Back Spindle Torque Upper Limit H

Selection

The back spindle torque is set to 50%.

M76* Back 3-spindle tool post interference check

disabled

The function to check for interference with a tool (T41) on

the back 3-spindle tool post is disabled.

M77 Waiting for Completion of Spindle

Synchronization

The queuing state is placed until the main and back spindles

are synchronized.

M78 Back Spindle Indexing Sequential operation of back spindle indexing (optional)

M79 Back Spindle Indexing Cancel. Back

Spindle C-Axis Cancel

Back spindle hold OFF (optional)

M80 Gang Tool Spindle Forward Rotation The tool spindle of the gang tool post starts rotating forward.

M81 Gang Tool Spindle Reverse Rotation The tool spindle of the gang tool post starts rotating

backward.

M82 Gang Tool Spindle Stop The tool spindle of the gang tool post stops rotating.

M83 Turret Tool Spindle Forward Rotation The tool spindle of the turret tool post starts rotating forward.

M84 Turret Tool Spindle Reverse Rotation The tool spindle of the turret tool post starts rotating

backward.

M85 Turret Tool Spindle Stop The tool spindle of the turret tool post stops rotating.

M86 Cutting start interlock ON The cutting start interlock is enabled.

M87 Cutting start interlock OFF The cutting start interlock is disabled.

M88* Interference Check Disabled The interference check function is disabled.

M89* Interference Check Enabled The interference check function is enabled.

M92 Error Detect On Error detection ON (Use M92 when edge precision is

required.)

M93 Error Detect Off Error detection OFF

M94 Back Spindle Speed Fluctuation Detection

On

The back spindle speed change detection function is enabled.

M95 Back Spindle Speed Fluctuation Detection

Off

The back spindle speed change detection function is

disabled.

M96 Main Spindle Speed Fluctuation Detection

On

The main spindle speed change detection function is

enabled.

M97 Main Spindle Speed Fluctuation Detection

Off

The main spindle speed change detection function is

disabled.

M98 Sub Program Subprograms are called.

M99 Return to Main Program Be sure to specify M99 at the end of the main program and

subprograms.

M100 Grip Bar Stock The bar loader clamps the workpiece. (optional)

M101 Release Bar Stock The bar loader releases the workpiece. (optional)

M102 Release Bar Stock Quickly The bar loader releases the workpiece quickly. (optional)

M103 Release Bar Stock, Slide Channel Forward The bar loader releases the workpiece, and the rail moves

forward. (optional)

M104 Slide Channel Forward The bar loader rail moves forward. (optional)

M105 Slide Channel Back The bar loader rail moves backward. (optional)

M106 Stabilizer Close The bar loader support closes. (optional)

M107 Stabilizer Open The bar loader support opens. (optional)

M108 Master Measure Start Automatic measurement (optional)

M109 Work Measure Start Automatic measurement (optional)

M3 Programming

5-89

M code Function Remarks

M110 Work hand air blow ON (optional)

M111 Work hand air blow OFF (optional)

M112 Input G/B Phase Data In general, the phase is automatically controlled by G999.

M113 Sequential operation for long workpiece

device

Performs sequential operation for long workpiece device.

(Optional in M12 and M16)

M114 Automatic Measure Sensor Centering Automatic measurement (optional)

M115 Centering is Completed Automatic measurement (optional)

M116 Work Hand Close U33J (optional)

M117 Work Hand Open U33J (optional)

M118 Measuring Jaw Close Automatic measurement (optional)

M119 Measuring Jaw Open Automatic measurement (optional)

M120 Back Spindle Phase Memory In general, the phase is automatically controlled by G999.

M123 Back Spindle Torque Lower Limit L

Selection

The back spindle torque is set to 25%.

M124 Back Spindle Torque Limit Off The back spindle torque is set to 100%.

M125 NC Reset & Rewind Used in macro (not used in ordinary operation)

M126 Non-Conditional Optional Stop Used in macro (not used in ordinary operation)

M127 Request for Recalculation Used in macro (not used in ordinary operation)

M128 Back Tool Spindle Forward Rotation The spindle of the back tools starts rotating forward.

(optional)

M129 Back Tool Spindle Reverse Rotation The spindle of the back tools starts rotating backward.

(optional)

M130 Back Tool Spindle Stop The spindle of the back tools stops rotating. (optional)

M136 Additional coolant pump ON (optional)

M137 Additional coolant pump OFF (optional)

M138 Additional coolant valve ON (optional)

M139 Additional coolant valve OFF (optional)

M142 Main spindle C axis holdup ON

M143 Main spindle C axis holdup OFF

M144 Back spindle C axis holdup ON

M145 Back spindle C axis holdup OFF

M147* Turret tool post retraction (X2 axis) The turret tool post moves to the return position.

M151* Gang tool post retraction (X1 axis) The gang tool post moves to the return position.

M154 R.G.B. belt breakage detection Belt breakage of the rotary guide bushing is detected.

(optional)

M155* Sequential operation of bar stock exchange Materials are changed sequentially.

M160 S1 cutting start interlock ON

M161 S1 cutting start interlock OFF

M162 S2 cutting start interlock ON

M163 S2 cutting start interlock OFF

M164 S3 cutting start interlock ON

M165 S3 cutting start interlock OFF

M166 S4 cutting start interlock ON

M167 S4 cutting start interlock OFF

M168 S6 cutting start interlock ON

M169 S6 cutting start interlock OFF

M171* Back spindle moves backward. The back headstock moves to the return position.

Notes

- The M codes marked an asterisk (*) used macros.

- Specify these macro M codes alone. Do not specify these codes along with any other code in the same

block.

- The above M codes include options. For the options, see <Chapter 3 Device Specifications>.

M3 Programming

5-90

5.8.2 Cutting start interlock enabled/disabled (M86, M87, and M160-M169)

The cutting start interlocks are automatically turned ON/OFF when the machining pattern is changed. In

general, you do not have to turn ON/OFF the cutting start interlocks by using the M codes.

Command format

M86 Cutting start interlock enabled

(The cutting start interlock of a specified axis control group is set back to original.)

M87 Cutting start interlock disabled

(All the cutting start interlocks of a specified axis control group are disabled.)

M160 S1 cutting start interlock enabled (Main spindle)

M161 S1 cutting start interlock disabled (Main spindle)

M162 S2 cutting start interlock enabled (Back spindle)

M163 S2 cutting start interlock disabled (Back spindle)

M164 S3 cutting start interlock enabled (Tool spindle of gang tool spindle)

M165 S3 cutting start interlock disabled (Tool spindle of gang tool spindle)

M166 S4 cutting start interlock enabled (Tool spindle of turret tool spindle)

M167 S4 cutting start interlock disabled (Tool spindle of turret tool spindle)

M168 S6 cutting start interlock enabled (Tool spindle of back 3-spindle tool post)

M169 S6 cutting start interlock disabled (Tool spindle of back 3-spindle tool post)

Relationship between the machining patterns and cutting start interlocks:

Machining pattern S1 S2 S3 S4 S6

$1 $2 $3 $1 $2 $3 $1 $2 $3 $1 $2 $3 $1 $2 $3

Machining pattern cancel (G600) \ \ \ \

Alternate machining (G610) \ \ \ \

Two-saddle machining (G620) \ \ \ \ \ \

Front/back parallel

machining (G630)

G632 \ \ \ \

G633 \ \ \ \

Front /back parallel

machining (G635)

G637 \ \ \ \

G638 \ \ \ \

Simultaneous 3-lines machining

(G640)

\ \ \ \ \ \ \

Pick-off, center support (G650) Depending on the previous machining pattern

\: Cutting start interlock enabled

Note

S6 (tool spindle of the back 3-spindle tool post) is optional.

M3 Programming

5-91

5.8.3 Gang tool post retraction (M151)

The M151 command moves the gang tool post (X1 axis) to the return position.

Command format

M151

Axis control groups

$1, $2, $3

Program sample

$1

G600

T0200

:

M151 ...................................... The gang tool post retraction

:

Note

The gang tool post X1 axis cannot be specified after the M151 command is executed. To specify the X1

axis again, specify the machining pattern.

M3 Programming

5-92

5.8.4 Turret tool post retraction (M147)

The M147 command moves the turret tool post (X2 axis) to the return position.

Command format

M147

Axis control groups

$1, $2, $3

Program sample

$1

G630

G632

T2100

:

M147 ....................................... The turret tool post retracts.

:

Note

The turret tool post X2 axis cannot be specified after the M147 command is executed. To specify the X2

axis again, specify the machining pattern.

M3 Programming

5-93

5.8.5 Back headstock retraction (M171)

The M171 command moves the back headstock (Z3 axis) to the return position.

Command format

M171

Axis control groups

$1, $2, $3

Program sample

$1

:

T4100

G00 Z-1.0 0 T01

G01 Z3.0 F

M171 ...................................................... The back headstock retracts.

:

Note

The back headstock Z3 axis cannot be specified after the M171 command is executed. To specify the Z3

axis again, specify the machining pattern.

M3 Programming

5-94

5.8.6 The turret tool post advance and retract (M40 and M41)

When the command to move the turret tool post forward (M40) is specified, the turret tool post moves its

return position (X2), and then it moves to the front machining reference point (Z2).

When the command to move the turret tool post backward (M41) is specified, the turret tool post moves

its return position (X2), and then it moves to the position 5.0 mm away from the end face of the

workpiece on the back side ("Back Spindle Chuck POS" + value specified by the I argument).

The following are examples of using the M41 and M40 commands:

In case of the next machining pattern of G610 is G630, if machining with a gang tool still continues at

completion of machining with a tool on the turret tool post of $1, execute the M41 command to move the

turret tool post toward the back spindle in advance. Conversely, in case of the next machining pattern of

G630 is G610 (G620, G640) if machining with a tool on the gang tool post still continues at completion

of machining with a tool on the turret tool post of $2, execute the M40 command to move the turret tool

post toward the main spindle in advance.

Command format

M40 Z Turret advance (Z2)

M41 I Turret retract (Z2)

Axis control groups

The following table shows the machining patterns and axis control groups with which the M40 and M41

commands are enabled:

Machining pattern $1 $2 $3

Machining pattern cancel (G600)

Alternate machining (G610)

G611

M40 Z

M41 I

G612

M40 Z

M41 I

Two-saddle machining (G620)

Front/back parallel machining (G630)

G632 M40 Z

G633 M40 Z

Front/back parallel machining (G635)

G637 M40 Z

G638 M40 Z

Simultaneous 3-lines machining (G640)

Pick-off (G650)

Argument

- Z : Specify this argument to change the point to which the turret tool post (Z2 axis) moves. For

example, when Z-5.0 is specified, the turret tool post (Z2 axis) moves to the position 5.0 mm

away from the forward end position. If the argument is not specified, the turret tool post

(Z2 axis) moves to the forward end position (the position opposite to the gang tool post).

- I : Specify the amount of shift from the zero point of the work coordinate system of the Z3 axis.

This I argument is equivalent to the G632, G637 I argument.

M3 Programming

5-95

Operation sample

(2)

(1)

(3)

T21 T25

Turret Turret

(1) The M41 command is executed in the G612 mode, and the turret tool post moves its return position.

The turret tool post moves in only the direction of the X2 axis.

(2) The Z2 axis moves to "Back Spindle Chuck pos." specified in the machining data.

(3) The tool pre-selected in the G611 mode is called.

Comment [ER2]: word

M3 Programming

5-96

Program sample

$1 $2 $3

G610 G610 G610

T2100 T4100

: :

G612 T4000

T0200

:

M41 ................................................... Turret retract

(When machining with the tool on the

turret tool post is completed, the turret tool

post is moved backward to get ready for

machining in the G630 mode.

This command is valid when machining

with a gang tool is performed at the end in

the G610 mode.)

G611

T2500 .............................. Pre-selection of the tool

(The tool to be used in the G630 mode is

pre-selected.)

:

G630 G630 G630

: G632 G632

: :

: M40 ................................ Turret advance

:

:

:

:

(When machining with the tool

on the turret tool post is

completed, the turret tool post is

moved forward to get ready for

machining in the G610

mode. This command is valid

when machining on the $1 side

takes more time than the

machining with the tool on the

turret tool post.)

G610 G610 G610

: :

Notes

- You can execute the M40 command with only the machining pattern G630, and the M41 command

with only the machining pattern G610.

- If you have specified the I argument in the M41 command, specify the I argument in the G632

command as well.

M3 Programming

5-97

5.8.7 R.G.B. belt breakage detection (M154) optional

This command detects belt breakage of the rotary guide bushing, and places the machine in 1-cycle stop

state.

Command format

M154

Axis control groups

$1, $2, $3

Program sample

$1 $2 $3

:

T0100

G00 X33.0 Z30.0 T01

G650 G650 G650

G00 Z-1.0

G98 G01 Z10.0 F3000

M154 ............... R.G.B. belt breakage detection

G4 U0.5

M15

!3L1 !1L1

G99 G1 X-4.0 F0.03

M5

M7

G00 X-4.0 Z0 T00

:

Note

Execute the M154 command in the state in which the spindle speed is constant. Execution of M154

during acceleration/deceleration or constant surface speed control may cause the machine to malfunction.

M3 Programming

5-98

5.8.8 Sequential operation for bar stock replacement (M155)

If the machine is equipped with an automatic magazine bar loader, you can use the M155 command to

remove a bar remnant and supply bars.

Command format

M155 U A X Z K1 W F S R1 M1 T B

Axis control groups

$1

Arguments

- U : Specify the positioning point for deburring a bar remnant. The default is Tool Positioning

Point in the machining data.

- A : Specify the feed rate at which the axis moves to the positioning point for deburring the bar

remnant. The default is F0.1.

- X : Specify the distance by which the X axis moves for deburring the bar remnant. Deburring

is not performed unless the X argument is specified.

- Z : Specify the distance by which the Z axis moves for deburring the bar remnant. Deburring is

not performed unless the Z argument is specified.

- K1: Specify this argument not to stop coolant before drawing the bar remnant. The coolant

stops if the K1 argument is not specified.

- W : Specify the distance by which the Z axis moves when drawing the bar remnant and when

supplying bars. The default is 30 mm.

- F : Specify the feed rate at which the Z axis moves when drawing the bar remnant and when

supplying bars. The default is F0.5.

- S : Specify the speed at which the main spindle rotates when drawing the bar remnant and when

supplying bars. The default is 1000 min

1

.

- R1: Specify this argument not to stop the main spindle after drawing the bar remnant. The main

spindle stops if the R1 argument is not specified.

- M1: When using non-conform materials, specify this argument to adjust the guide bushing phase

before workpiece insertion. The guide bushing phase is not adjusted unless the M1

argument is specified.

- T : Specify the dwell time from when the chuck closes after workpiece replacement. The

default is 2 seconds.

- B : Specify the dwell time between the coolant oil ON and the cut-off machining . The default

is 0 second.

M3 Programming

5-99

Operation sample

(1) The tool moves to the position determined by (Bar Stock O.D. in the machining data + value

specified by the U argument) at the feed rate specified by the A argument.

(2) The Z axis advances the distance specified by the Z argument.

(3) The machine executes the chamfering function for the bar remnant at the Cut-Off Feed in the

machining data, depending on the values of the X and Z arguments.

(4) The coolant is turned OFF. It is not turned OFF if the K1 argument is specified.

(5) The main spindle rotates at the speed specified by the S argument.

(6) The tool moves to the position determined by (Bar Stock O.D. in the machining data + value

specified by the U argument). At the same time, the bar remnant is drawn by the amount specified

by the W argument, from the guide bushing at the feed rate specified by the F argument.

(7) The main spindle stops. It does not stop if the R1 argument is specified.

(8) The feed torque of the automatic magazine bar loader is turned off.

(9) The main spindle chuck opens.

(10) Material replacement is carried out.

(11) The main spindle chuck closes.

(12) Dwell time specified by the T argument

(13) The main spindle rotates at the speed specified by the S argument.

(14) If the M1 argument is specified, the guide bushing phase is adjusted.

(15) A material is inserted by the amount specified by the W argument, at the feed rate specified by the F

argument.

(16) The coolant is turned ON.

(17) The main spindle rotates at the Cut-Off Speed in the machining data.

(18) The machine performs cut-off machining until reaching the Cut-Off End (DIA) (in the machining

data) at the Cut-Off Feed in the machining data.

M3 Programming

5-100

Overview of deburring (chamfering) of a bar remnant

The tool moves to the

position determined by

(Bar Stock O.D. in the

machining data + value

specified by the U

argument).

The Z axis advances the

distance specified by the Z

argument.

The machine executes the

chamfering function for the

bar remnant, depending on

the values of the X and Z

arguments.

The tool moves to the position determined

by (Bar Stock O.D. in the machining data

+ value specified by the U argument). At

the same time, the bar remnant is drawn

by the amount specified by the W

argument.

Example:

The following table shows the values of the X argument

(distance by which the X axis moves for deburring) and Z

argument (distance by which the Z axis moves for deburring) if

C0.5 is to be set for the deburring (chamfering) of the bar

remnant:

* Specify 1.0 for the U argument (positioning point for

deburring) in this case.

Width Hight X argument Z argument

2.0mm 0.728mm 3.4 1.7

3.0mm 1.092mm 4.2 2.1

Width

Hight

20

Comment [ER3]: word

M3 Programming

5-101

Program sample

$1 $2 $3

:

T0100

G00 X33.0 Z30.0 T01

G650 G650 G650

G00 Z1.0

G98 G01 Z10.0 F3000

G4 U0.5

M15

!3L1 !1L1

G99 G1 X4.0 F0.03

M8

M8

/M155 X3.4 Z1.7 ....... Sequential operation of bar

stock exchange

M9

M5

M7

G00 X4.0 Z0 T00

:

M3 Programming

5-102

5.9 Exclamation (!) Symbol (Queuing Command)

To synchronize multiple axis control groups with each other, specify this function to place an axis control

group's program in the queuing state while the operation of another axis control group's program is in

progress.

Command format

! ! L Multi-axis control group program queuing

Argument

- ! : Specify the axis control group number (1 to 3) of an axis control group which enters the

queuing state while the operation of another axis control group is in progress.

- L : Queuing ID number (0 to 8999)

Program sample

Multi-axis control group program queuing pattern

$1 $2 $3

: : :

: !1L1 :

!2L1 : :

: : :

: !3L2 !2L2

: : :

: : :

: !1!3L3 !1!2L3

!2!3L3 : :

: : :

: : :

: : :

!2!3L4 !1!3L4 !1!2L4

M56

G999 G999 G999

N999 N999 N999

M02 M02 M02

M99 M99 M99

% % %

M3 Programming

5-103

Note

- If a wrong queuing ID number is specified, the operation is unable to proceed because the program

remains in the queuing state.

- To queue all the three axis control groups, specify two queuing codes for the two other axis control

groups.

If the same ID number is used, either of the two other axis controls is specified with one queuing code

and the other is specified with two queuing codes. As a result, an axis control group does not queue.

In this case, the execution sequence is not simultaneous.

Program sample

a. Correct queuing pattern

$1 $2 $3

: : :

: : :

!2!3L11 : Queuing with $3 :

: !1!3L11 :

: Queuing with $2 : :

: !1!2L11

Queuing with $3

b. Pattern in which either of the two other axis controls is specified with one queuing code and

the other is specified with two queuing codes

$1 $2 $3

: : :

: : :

!2!3L11 : Do not queuing :

: !1L11 :

: Queuing with $2 : :

: !1L11

Queuing with $3

Queuing codes !2!3 are specified for $1 in the program sample of b. Thus, $1 queues with $2 and $3.

However, only !1 is specified for $2 and $3, so $2 and $3 do not queue. If $2 or $3 queues with $1, the

next block is executed.

As a result, the passing time of L11 is different between $2 and $3 according to the contents described

before ID number L11 in the program, and the execution sequence is not simultaneous either.

This specification may be useful for shortening operation time. However, if the contents described after

L11 in the program or the cutting conditions are changed, interference may occur. Therefore, the

specification is not recommended.

M3 Programming

5-104

5.10 Secondary Machining Programs

5.10.1 Positional relation between spindles for secondary machining

Turret tool post

The following figure shows the spindle positions of the turret tool post for secondary machining when

viewed from the end face of the material:

Gang tool post

Tools for secondary machining are mounted on the spindle GSC607 or GSE507. The tools indicated in

parentheses ( ) are used for M20 or M32.

Note

Use the synchronous tapping function or floating chuck to perform tapping with a gang tool.

Tool mounted on the outer diameter drilling

spindle KSC106, KSC206, or KSC303

(KSC110, 310, 910)

Tool mounted on the milling spindle KSM106 or

KSM406 206 (KSM110, 406)

Tool mounted on the end face

drilling spindle GSE507 (GSE607)

Tool mounted on the outer diameter

tapping spindle KST406 (KST110)

Tool mounted on the slitting spindle

KSS345 or KSS450 (KSS660, 663, 260,

263)

Tool mounted on the end face drilling

spindle KSE106 or KSE403 (KSE110,

210, 310)

Tool mounted on the outer diameter

drilling spindle GSC607 (GSC510, 507)

Comment [ER4]: m2pro5115a.wmf

Comment [ER5]: m2pro5115b.wmf

M3 Programming

5-105

5.10.2 Transition between turning and secondary machining

Transition from turning to secondary machining

To switch from turning to secondary machining, specify the commands in the format shown below.

Program sample

- Main spindle indexing

M05 G98 M8 S=

M28 S0 (or T0600 E0)

- Main spindle C axis indexing

M05 G98 M8 S=

M18 C0 (or T0600 E0)

Functions of the words:

M05 .......... Main spindle stop

G98 .......... Millimeters per minute feed (mm/min)

M8 .......... Rotate the tool spindle

Gang tool post Turret tool post Back 3-spindle tool

post

Tool spindle forward rotation M80 M83 M128

Tool spindle reverse rotation M81 M84 M129

Tool spindle stop M82 M85 M130

S= .......... Speed command

S3 Tool spindle of the gang tool post

S4 Tool spindle of the turret tool post

S6 Tool spindle of the back 3-spindle tool post

M28 S0 .......... Return to zero point for main spindle indexing

When performing secondary machining consecutively, you do not have to enter the above commands for

each secondary machining. Once the commands are entered at the beginning, they are enabled until the

overall secondary machining is completed.

Notes

- The command "return to zero point for main spindle indexing" is used to maintain the same indexing

position of a workpiece during secondary machining.

If a workpiece is machined in the sequence of turning, secondary machining, turning, and then

secondary machining, this command enables the workpiece to always stop at the same position (the

angle of rotation).

- S6 (tool spindle of the back 3-spindle tool post) is optional.

M3 Programming

5-106

Transition from secondary machining to turning

To switch from secondary machining to turning, specify the commands in the format shown below.

Program sample

- Main spindle indexing

M8

M20

M03 S1= G99

- Main spindle C axis indexing

M8

M20

M03 S1= G99

Functions of the words:

M8 .......... Stop the tool spindle (M82 or M85)

M20 .......... Main spindle index and C-axis release

G99 .......... Millimeters per revolution feed (mm/rev)

S1= .......... Main spindle rotation

M03 .......... Main spindle forward rotation

M3 Programming

5-107

5.10.3 Coordinate system shift (G500 and G501)

The shift amount specific to each spindle for secondary machining is initially set. Consequently, when a

tool is set at the reference position, the program zero point does not match the tool reference point. To

match them each other, use the coordinate system shift programs (G500 and G501).

U

W

Rotary tool on the turret tool post

2

0

20.0

Rotary tool on the gang tool post

10

Program zero point X0, Z0

Program zero point X0, Z0

Shift program G501

B021 executed

Shift program G501

A011 executed

Program zero point X0, Z0 Comment [ER6]: m2pro-j.wmf

Comment [ER7]: m2pro-h.wmf

Comment [ER8]: m2pro-i.wmf

M3 Programming

5-108

Command format

G500 A(B) A Coordinate system shift OFF

G501 A(B) A Coordinate system shift ON

Argument

- A: For the tool spindle of the gang tool post, specify the corresponding value shown in the table

below.

- B: For the tool spindle of the turret tool post, specify the corresponding value shown in the table

below.

- : Specify the spindle number.

- A: Specify the direction in which the tool spindle rotates. 1: Forward, 0: Backward

M3 Programming

5-109

M12, M16

Tool post Shift program Tool spindle Function

Shift amount

U W

Gang

G500A011 GSC607

Outer diameter milling spindle

Shift OFF

0.0 10.0

G501A011 Shift ON

Turret

G500B011 MSC106

Outer diameter drilling spindle

Shift OFF

0.0 20.0

G501B011 Shift ON

G500B021 MSC206, 303, MST406

Outer diameter tapping spindle

Shift OFF

40.0 20.0

G501B021 Shift ON

G500B031 MSE106, 403

End face drilling spindle

Shift OFF

20.0 0.0

G501B031 Shift ON

G500B041 MST306

End face tapping spindle

Shift OFF

16.0 0.0

G501B041 Shift ON

G500B051 MSM106

Milling spindle

Shift OFF

20.0 20.0

G501B051 Shift ON

B500B060 MSM206

Milling spindle

Shift OFF

14.0 20.0

G501B060 Shift ON

G500B071 MSS345 (center)

Slitting spindle

Shift OFF

5.0 0.0

G501B071 Shift ON

G500B081 MSS345 (tool nose)

Slitting spindle

Shift OFF

40.0 22.5

G501B081 Shift ON

G500B121 MSS450 (center)

Slitting spindle

Shift OFF

10.0 0.0

G501B121 Shift ON

G500B131 MSS450 (tool nose)

Slitting spindle

Shift OFF

40.0 25.0

G501B131 Shift ON

G500B141 MSF150, 250 (center)

Side cutter spindle

Shift OFF

10.0 5.0

G501B141 Shift ON

G500B151 MSH132

Hobbing spindle

Shift OFF

22.0 20.0

G501B151 Shift ON

G500B160 MSP160

Polygonal spindle

Shift OFF

40.0 0.0

G501B160 Shift ON

M3 Programming

5-110

M20, M32

Tool post Shift program Tool spindle Function

Shift amount

U W

Gang

G500A011 GSC507, 510

Outer diameter milling spindle

Shift OFF

0.0 15.0

G501A011 Shift ON

Turret

G500B011 KSC110, 310, 910

Outer diameter drilling spindle

Shift OFF

30.0 25.0

G501B011 Shift ON

G500B011 KST110

Outer diameter tapping spindle

Shift OFF

30.0 25.0

G501B011 Shift ON

G500B020 KSE310

End face drilling spindle

Shift OFF

50.0 0.0

G501B020 Shift ON

G500B021 KSE110, 210

End face drilling spindle

Shift OFF

50.0 0.0

G501B021 Shift ON

G500B021 KST510, 610

End face tapping spindle

Shift OFF

50.0 0.0

G501B021 Shift ON

G500B030 KSM110

Milling spindle

Shift OFF

50.0 25.0

G501B030 Shift ON

G500B090 KSM406

Milling spindle

Shift OFF

40.0 25.0

G501B090 Shift ON

G500B041 KSS260 (center)

Slitting spindle

Shift OFF

40.0 0.0

G501B041 Shift ON

G500B051 KSS260 (tool nose)

Slitting spindle

Shift OFF

20.0 30.0

G501B051 Shift ON

G500B041 KSS263 (center)

Slitting spindle

Shift OFF

40.0 0.0

G501B041 Shift ON

G500B101 KSS263 (tool nose)

Slitting spindle

Shift OFF

23.0 31.5

G501B101 Shift ON

G500B120 KSS660 (center)

Slitting spindle

Shift OFF

44.0 0.0

G501B120 Shift ON

G500B130 KSS660 (tool nose)

Slitting spindle

Shift OFF

16.0 30.0

G501B130 Shift ON

G500B120 KSS663 (center)

Slitting spindle

Shift OFF

44.0 0.0

G501B120 Shift ON

G500B180 KSS663 (tool nose)

Slitting spindle

Shift OFF

19.0 31.5

G501B180 Shift ON

G500B081 KSF160, 163

Side cutter spindle

Shift OFF

30.0 7.0

G501B081 Shift ON

G500B161 KSH132

Hobbing spindle

Shift OFF

8.0 25.0

G501B161 Shift ON

G500B170 KSP380

Polygonal spindle

Shift OFF

30.0 0.0

G501B170 Shift ON

M3 Programming

5-111

Main shift programs and program points (M12, M16)

- Outer diameter drilling spindles (MSC106, MSC206, MSC303, and MST406) and outer diameter

tapping spindle (MST406)

20

With MSC206 (B021)

Turret

2

0

8

0

6

0

20

- Milling spindles (MSM106 and MSM206)

With MSM106 (B051)

Turret

1

0

5

0

6

0

20

20

- End face drilling spindles (MSE106 and MSE403) and end face tapping spindle (MST306)

With MSE106 (B031)

Turret

1

0

6

0

5

0

- Slitting spindle (MSS345)

With MSS345 (B071)

Turret

| 45

22.5

2

0

5

7

.

5

6

0

2

.

5

With MSS345 (B081)

Comment [ER9]: word

Comment [ER10]: word

Comment [ER11]: word

Comment [ER12]: word

M3 Programming

5-112

Main shift programs and program points (M20, M32)

- Outer diameter drilling spindles (KSC110, KSC310, and KSC910) and outer diameter tapping

spindle (KST110)

25

With KSC110 (B011)

Turret

1

5

1

1

0

9

5

25

- Milling spindles (KSM110 and KSM406)

With KSM110 (B030)

Turret

2

5

7

0

9

5

25

25

- End face drilling spindles (KSE110 and KSE310) and end face tapping spindle (KST510)

With KSE110 (B021)

Turret

2

5

9

5

7

0

- Slitting spindle (KSS660, KSS663, KSS260, and KSS263)

With KSS260 (B041)

Turret

| 60

22.5

7

5

9

5

With KSS260 (B051)

2

0

Comment [ER13]: word

Comment [ER14]: word

Comment [ER15]: word

Comment [ER16]: word

M3 Programming

5-113

Program sample

$1 $2 $3

G610 G610 G610

(G611)

:

:

M05 G98 M83 S4=460

G612

T2100 E0

G501 B031 ........... Coordinate system shift

ON

G00 X8.0 T21

G01 Z4.5 F132

G00 Z-0.5 T00

G500 B031 ........... Coordinate system shift

OFF

:

:

M3 Programming

5-114

5.10.4 Back spindle indexing (M78 and M79) optional

The back spindle can be indexed at 1-degree intervals. It is indexed in the direction in which the spindle

rotates forward.

Command format

M78 S Back spindle indexing

M79 Back spindle indexing cancel

Axis control groups

With the machining patterns G610, G620, and G633 in G630, specify the command for $3.

With the other machining patterns, specify the command for $2.

Argument

- S : Specify the indexing angle. The value must be specified in the range 0 to 359 with an

absolute command.

Program sample

M25 .......... Back spindle stops.

G04 U0.5 .......... Dwell

M78 S0 .......... Back spindle indexing

Machining program

M79 .......... Back spindle indexing cancel

G04 U0.5 .......... Dwell

M23 S2= .......... Back spindle rotates forward.

Notes

- If the back spindle is rotating, stop the back spindle to index it with the M78 S0 command.

- To return to the turning process, execute the M79 command to cancel back spindle indexing, then

execute the M23 S2= command to rotate the back spindle.

M3 Programming

5-115

5.10.5 Back spindle C axis indexing (M48) optional

The back spindle C axis can indexed at 0.001-degree intervals.

The back spindle C axis is turned ON when this command is executed. Zero point C0 is indexed, and

then the coordinate system is set with the position as C0.

Use a plus (+) sign to express indexing in the direction in which the back spindle rotates forward, and

define the indexing as "forward indexing". Use a minus () sign to express indexing in the direction in

which the back spindle rotates backward, and define the indexing as "backward indexing". When

viewed from the end face of the material, the counterclockwise rotation indicates "forward indexing" and

the clockwise rotation indicates "backward indexing".

A plus (+) sign is omitted.

Command format

M48 C Enable back spindle C-axis

Axis control groups

For the machining patterns G610, G620, and G633 in G630, specify the M48 command for $3.

For the other machining patterns, specify the command for $2.

Argument

- C : Specify an indexing angle in the range 99999.999 to 99999.999.

Note

- When the M48 C command is specified, ordinary C-axis commands are enabled.

Example:

G50 C (H ) H is an incremental command.

G00 C (H )

G01 C (H ) F

M3 Programming

5-116

5.10.6 Circular interpolation in a secondary machining process

The circular interpolation feed is enabled on the following three planes in the secondary machining

process:

X-Y plane: G17

Z-X plane: G18 .......... Plane mode selected for ordinary turning process

Y-Z plane: G19

Generally, the Z-X plane (G18) is selected at power-on or reset. This plane is used for circular

interpolation (G02 or G03) in the turning process. To use the circular interpolation on a different plane

in the secondary machining process, execute the plane selection command G17 or G19.

Be sure to reselect the Z-X plane (G18) to return to the turning process.

G03

G02

G02

G02

G03

G03

X-Y plane

+Z

(direction to the

center of spindle)

+Y (direction to right angle of the centers of the spindle and tool spindle)

Y-Z plane

X-Z plane

+X (direction to the center of tool spindle)

X

Y

G02

G03

X

Z

G02

G03

Y

Z

G03

G02

G17 (X-Y) plane G18 (Z-X) plane G19 (Y-Z) plane

Comment [ER17]: word

Comment [ER18]: word

Comment [ER19]: word

Comment [ER20]: word

M3 Programming

5-117

Command format

G17

G18

G19

Axis control groups

Specify the commands for axis control groups in which circular interpolation is used.

M3 Programming

5-118

5.10.7 Program sample including secondary machining processes

The following is a program sample in which machining is carried out in the sequence of outer diameter

machining (turning), outer diameter drilling (secondary machining), slitting (secondary machining), and

then cut-off machining (turning).

Program sample

$1 $2 $3

G50 Z0

G610 G610 G610

(G611)...................................................... Gang tool post select

G99 M06

G00 X21.0 Z0.5

M03 S1=

G612 ....................................................................... Turret select

T0

T2

N01 ................................................... Outer diameter machining

G00 X Z

:

N02 G611 ................................................. Gang tool post select

T2

G00 X Z

:

N03 G612 .............................................................. Turret select

T0

G00 X Z

M05 G98 M83 S4=

M28 S0

....... Command to switch to

secondary machining

process

G501 B011 ..................... Command to specify shift ON for

outer diameter drilling spindle

:

G500 B011 ..................... Command to specify shift OFF for

outer diameter drilling spindle

T2

N04

G501 B011

:

G500 B011

M85

M20

M03 S1= G99

......... Command to switch to

turning process

N05 G611 ....... Selection of a gang tool, and cut-off machining

T2

G00 X Z

M3 Programming

5-119

$1 $2 $3

:

M05

M07

G00 X3.0 Z0 T00

M56

G999 G999 G999

N999 N999 N999

M02 M02 M02

M99 M99 M99

% % %

M3 Programming

5-120

5.10.8 Program sample including main spindle indexing

Program sample

$1 $2 $3

G50 Z0

G610 ............................................ Alternate machining G610 .........Alternate machining G610 ... Alternate machining

(G611)

M06

G00 X Z0.5

M03 S1 = G99

G612

T

:

G611

G00 X Z

T

:

G612

M05 G98

M83 S4=

M28 S0

......... Spindle indexing for

switching to secondary

machining process, and

determination of zero

point (0)

2-face width end milling

G501 B051

G00 X Z

G01 X F

M28 S180.0 ...... Positioning at 180 from zero point

G01 X F

M28 S90.0 ........... Positioning at 90 from zero point

G500 B051

M80 S3=

T 00 X

Key grooving

G611

G501 A011

G00 X Z

G01 Z F100

G01 X F

G500 A011

M3 Programming

5-121

$1 $2 $3

M82 M85

M20

M03 S1= G99

...............Command to

switch to

turning

process

G611

T 00

:

M05

M07

G00 X3.0 Z0 T00

M56

G999 G999 G999

N999 N999 N999

M02 M02 M02

M99 M99 M99

% % %

M3 Programming

5-122

5.11 Back Machining Programs

5.11.1 Back machining process

This section explains workpiece pick-off by the back spindle, machining with tools on the back 3-spindle

tool post, and machining with tools on the turret tool post.

Program sample

$1 $2 $3

Preparation process

Inner diameter machining

with tools on the gang tool

post and turret tool post

(Alternate machining command)

Front/back parallel machining

Drilling with tool on

the back 3-spindle

tool post

Outer diameter machining

with tools on the gang tool

post and turret tool post

(Alternate machining command)

Outer diameter

machining with tool

on the gang tool

post

Front/back parallel

machining

Back drilling with tool

on the turret tool post

Outer diameter machining

in back machining with

tool on the turret tool post

Production

collection

Production

collection

Cut-off process Pick-off

End process End process End process

Notes

- When the program completes, the machine stops with the workpiece chucked to the back spindle.

- The program runs two cycles to complete the machining of a workpiece.

- To complete the machining of a workpiece in a cycle, include the back machining program in the last

program execution (G999). The machine performs the back machining after the cut-off process to

complete the workpiece in a cycle. Select the menu key [Last PRT] to execute the last program.

M3 Programming

5-123

5.11.2 Pick-off and end process

The back spindle picks off workpieces in the cut-off process.

Then, the back spindle moves to the return position, and the end process starts.

Cut-off tool

X1 axis

Guide bushing

The main spindle is

rotating forward.

Z1 axis

Back spindle

Z3 axis

The back spindle is

rotating backward.

(Workpiece-c

hucked

length)

1

(Work-

piece

protrusion

length)

2

(Workpiece length)

(Cut-off length) L

(Cut-off

tool width)

a

3 (Amount of tool shift)

Work zero

point

Shifted

tool point

Standard

tool point

Comment [ER21]: m2pro-084.wmf

M3 Programming

5-124

Program sample

$1 $2 $3

G610 G610 G610

: :

: :

G99 M03 S1=1500 :

(1

)

T0100 :

(2

)

G00 Z85.0 T4000 ............................ Back spindle

(3

)

G650 ..................................... Pick-off G650 ...................... Pick-off G650 ..................................... Pick-off

(4) G00 Z2.0 ....... Positioning at Z2.0

(5) M24 S2=1500

(6) G98 G01 Z50.0 F1000

G04 U0.5

(7) M15.................... The back spindle

chuck closes.

(8

)

!3L1 (8) !1L1

G00 X17.0

(9

)

G01 X1.0 F0.03 ....... Cut-off

machining

G610 G610 (10) G610

(11) X3.0 : :

: : :

:

1. The cut-off tool is selected.

2. The tool moves to the position specified for cut-off machining in the longitudinal direction. (Z1 axis)

3. The pick-off command (G650) is executed. (Command for the superimposition of the end face of the

workpiece (zero point) and the end face of the back spindle)

4. The back spindle moves to a position close to the end face of the workpiece.

5. The back spindle rotates in the same direction and at the same speed as for the main spindle.

6. The feed per minute command is executed to move the back spindle to the workpiece chuck position.

(Z3 axis)

7. The back spindle chuck closes.

8. The queuing state is placed.

9. Cut-off machining starts.

10. The back spindle moves to the return position.