Beruflich Dokumente

Kultur Dokumente

Thermal Analysis and DC Conductivity of

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Thermal Analysis and DC Conductivity of

Copyright:

Verfügbare Formate

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 02 Issue: 09 | Sep-2013, Available @ http://www.ijret.org 554

THERMAL ANALYSIS AND DC CONDUCTIVITY OF

POLYPYRROLE/YTTRIUM OXIDE COMPOSITES

T.K. Vishnuvardhan

1

, V.R. Kulkarni

2

1

Department of Chemistry, Central college, Bangalore university, Bangalore-560001, Karnataka, India

2

Department of Chemistry, Acharya Institutes of Technology, Soldevanahalli, Bangalore-560107, Karnataka, India

vishnu33vardhan@gmail.com

Abstract

Polypyrrole/Yttrium Oxide (PPy/Y

2

O

2

) Composites are synthesized by chemical method. Thermal stability of the above composites is

characterized by TGA and DSC. Dc conductivity measurements of the composites are also carried out. The results are used to

calculate the activation energy. Sensor activities of the composites are also discussed.

----------------------------------------------------------------------***-----------------------------------------------------------------------

1. INTRODUCTION

Organic and metallo-organic polymers gained importance

because of their electrical, electronic, non-linear optical,

electrochemical and photochemical applications (1-5). In order

to make use of these polymer composites for specific

applications, they are modified either by co-polymerization or

by making blends with other polymers (6). Production of

blends using organic and metallo-organic polymers is an

attempt to derive new polymeric materials by combining the

properties of the individual components of the blend (7). The

use of blends/composites in various electric and electronic

devices attracted attention because of their conducting nature,

chemical stability and the economic viability. Among the

many conducting polymers, PPy seems to be one of the best

candidates for preparing conducting polymer composites since

it is stable both thermally and environmentally (8).

Conductivity of the polymer and polymer composites are

explained by many literatures (9-11).

In this article, we present the study of thermal analysis of the

PPy/Y

2

O

2

composites. The Dc conductivity measurements of

the composites are carried out by two probe method. Results

are fitted with linear fit curve and activation energy is also

calculated. Data is further tested by IV plots.

2. SYNTHESIS OF PPY/YTTRIUM OXIDE

COMPOSITES

The synthesis of PPy/Yttrium oxide composites is similar to

that of pure PPy, except that oxide is present during in situ

synthesis. A 0.02 mole of pyrrole was added drop wise to 100

ml suspension containing 0.06 mole of FeCl

3

and varied

amounts of Y

2

O

3

(10%, 20%, 30%, 40% and 50%)powders

with continuous stirring for 3 hrs. at 0

0

C. The black

precipitate of the PPy/Yttrium oxide composites formed was

collected by filtration and thoroughly washed with distilled

water, until the filtrate became colorless. Any unreacted

pyrrole in the composite was removed by washing the

precipitate with methanol and the composite was dried under

vacuum at room temperature (24

0

C).

The TGA of PPy, PPy/Yttrium oxide composites we recorded

over a temperature range of 26

0

C to 1200

0

C in nitrogen

atmosphere using a STA 409C thermal analyzer, to analyze

the degradation pattern of polymer composites.

Simultaneously, Differential Thermal Analysis (DTA) data

was also recorded. Reference material used in the TGA/DTA

is Alumina with heating rate of temperature is 5

0

C/min.

Differential scanning calorimetric studies on PPy/Yttrium

oxide composites were carried out using a METTLER thermal

analyzer. DSC was recorded from 50

0

C to 600

0

C. The

heating rate was kept constant at 10

0

C per minute.

2.1 Effect of Temperature on Dc Conductivity:

2.1. Pellet Preparation

The powder of the PPy/Y

2

O

2

composites are crushed and

ground finally in the presence of acetone medium in agate,

mortar. Finally ground powder is pressed to form, pellets of

0.1-0.25 cm. thickness and diameter of 10 mm or by applying

a pressure of 90M Pa in a hydraulic press. The thickness of

these pellets was measured using a micrometer screw-gauge.

2.1.2 Preparation of Electrodes on the Pellets

The pellets of Polypyrrole composites are coated with silver

paste on either side of the surfaces. The copper electrodes are

placed on each of the surface to obtain better electrical

contacts.

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 02 Issue: 09 | Sep-2013, Available @ http://www.ijret.org 555

2.1.3 Thermal Analysis:

The DTA and TGA traces of pure PPy and PPy/Y

2

O

2

sample

shows small exothermic dip at 69.9

0

C which may be for the

loss of dopant and an endothermic shoulder at 90.8

0

C

corresponding to the loss of water molecules. This is followed

by the broad exothermic peak may be due to the degradation

of the PPy chains.

Initially the steep trace TGA consists of two stages of weight

loss, one from room temperature to 150

0

C and another from

200 to 400

0

C. Further as the degradation continues and

complete at about 1100

0

C. Steep trace of PPy indicates

amorphous nature. The first stage weight loss may be due to

water and the weight loss found to be 7.02%., the second stage

weight loss may be due to the degradation of PPy-Cl chain,

and the weight loss at this stage is-21.73%. The total weight

loss at 1100

0

C is about -95%.

This ensures the complete degradation of the polymer. The

onset temperature (T

onset

) and T

max

for second step degradation

is 310

0

C and 400

0

C, respectively. These are also confirmed

from the DTG trace. Similarly on set temperature for the

composites are shown in the table

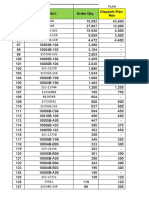

Table 1: Indicate the onset temperature and weight loss from TGA for PPy and PPy/Y

2

O

3

composites

Composites Onset

Temperature

0

C

(from TGA)

Completed

degradation

Temperature

0

C

Total loss

Occurred

(from TGA)

Temperature

At which

Maximum

Weight loss

0

C

(From DTA)

PPy 69.9 1100 95% 704

PPY/20%Y

2

O

3

70.2 1000 80% 846

PPy/50%Y

2

O

3

74.9 920 53% 897

The DSC curve of PPy and PPy/Y

2

O

3

sample have a broad

characteristic endothermic dip indicates the glass transition

temperature of Polypyrrole at 97.32

0

C. The nature of the

curve indicates that the loss of water is overlapping with T

g

of

polymer (which is well matching with the reported value).

Lack of any shoulder or melting peak beyond this region

indicates amorphous nature with less orderness of the polymer

molecules.

The DSC curve of PPy/50%Y

2

O

3

composite trace has a sharp

dip at higher temperature, namely at 125.16

0

C. This

sharpness indicates the better crystalline. It also contains few

more inflection points; one at 295.74

0

C may be due to the

melting of PPy chain, the other at 489.87

0

C may be due to

phase change of Y

2

O

3

.

2.2 Effect of Temperature on Conductivity Ppy/Y2o3

Composites

Figure 1 shows the temperature dependence of

DC

for the

PPy and PPy/Y

2

O

3

Samples. In this figure symbols indicate

log values of experimental conductivities (for temperature

range from 100-200

0

C) for various composites. Solid lines

indicate their fitting by linear fit equation by using the origin

6.0. The conductivity of all the composites shows that, as the

temperature is increased conductivity increases. This figure

also indicates that, conductivity increases as the percentage of

oxide is increased and then for further increase in oxide

content the conductivity decreases. Conductivity of polymer

depends on the conjugation length. In the synthesis process,

pyrrole monomer was first adsorbed on the surface of

Y

2

O

3

Concentration, and as a result, the amount of pyrrole

associated with each CeO

2

concentration, and as a result, the

amount of pyrrole associated with each Y

2

O

3

particle is

diminished.

Figure 1: Arrhenius plot of conductivity of PPy/Y

2

O

3

samples

IJRET: International Journal of Research in Engineering and Technology eISSN: 2319-1163 | pISSN: 2321-7308

__________________________________________________________________________________________

Volume: 02 Issue: 09 | Sep-2013, Available @ http://www.ijret.org 556

The temperature variation of conductivity of PPy composites

is well described by Motts variable range hopping formalism.

This is applicable only in amorphous semiconductors. This is

applicable only in amorphous semiconductors. Larger

activation energy Implies higher potential barrier in the

conduction process originating from the reduction of polymer

chain length. Lower conductivity and higher activation energy

are due to the poor contact between the polymer and oxide

particles. Dispersion of oxide in the conducting polypyrrole

due to percolation introduces more conducting paths resulting

in higher conductivity. Loading in the polymer increases the

conductivity is explained in literature (12)

Table 2: Indicates the activation energy of the conduction

process for PPy/Y

2

O

3

samples

. It indicates that as the

oxide

content Increases the activation energy goes on decreasing.

But in case of PPy/40% Y

2

O

3

shows highest activation energy

Table 2: Activation energy for PPy/Y

2

O

3

composites

composites Activation

Energy me V

Pure PPy 302.85

PPy/10%CeO

2

203.98

PPy/20%CeO

2

194.98

PPy/30%CeO

2

149.51

PPy/40%CeO

2

94.08

PPy/50%CeO

2

393.23

Current Voltage plot of PPy CeO

2

composites:

Figure 2: Representative Current -Voltage plots of PPY/Y

2

O

3

samples

Figure 2 show the current voltage plots of the representative

PPy/Y

2

O

2

composites respectively. They show very good

linearity in the range studied. Beyond this range thermal

fluctuations due to significant joule heating take place and non

linearity sets in.

CONCLUSIONS

PPy/Y

2

O

3

composite shows the high thermal stability due to

metal oxides. Activation energy of these compostes shows

highest for ppy/50% Y

2

O

3

due to more metal oxide particles

increases the higher activation energy. It will be maximum

upto critical percentages latter activation energy decreases.

Current voltage characteristics of these polymer composites

are also accounted. These electrical properties of polymer

PPy/Y

2

O

3

composites have strong applications in battery and

sensor applications.

REFERENCES:

[1]. J. L. Bredas, R. RChance(Eds.), Conjugated Polymeric

Materials-Opportunities in optoelectronics and Molecular

Electronics, NATO Advanced study Series,(Kluwer,

Dordrecht, 1990) p-112.

[2]. S. Bhattacharyya and S. K. Saha, Applied Physics Letters

80, ( 24) 2002, 4612

[3]. J.G. Park, B. Kim, S.H. Lee, Y.W. Park Thin Solid Films

438 439 (2003) 118122.

[4]. T K Vishnuvardhan, V R Kulkarni, C Basavaraja and S C

Raghavendra Bull. Mater. Sci., 29, (1) 2006, 7783

[5]. Jung-Chul Lee , Wonjoo Lee , Sung-Hwan Han, Tae Geun

Kim, Yun-Mo Sung Electrochemistry Communications 11

(2009) 231234

[6]. W.A.Gazotti Jr., GGasalbore-Miceli, S.Mitzakoff,

A.Geri,M.C.Gallazzi, M.A.DePaoli, Electrochem.Acta

44(1999)1965.

[7]. S.Venkatachalam,P.V.Prabhakaran, Eur.Poly.J. 5(1993)29

[8]. Bernd Tiek and walter Gabriel, Polymer, 31 (1990) 20.

[9]. Raghu M, Subramanyam S.V, Chatterjee S, Phys.Rev.B.

1991,43, (5) 4236.

[10]. Epistein A.J, Rommelman H, Abkowitz M, and Gibson

H.W, Phys.Rev.Lett. 1981,47,1549.

[11]. Pople J.A, and Walnsely S.H, Mol. Phys. 5,15(1962).

[12].Geon-Woong Lee, Min Park, Junkyung Kim, Jae Ik Lee

and Ho Gyu Yoon

Composites Part A: Applied Science and

Manufacturing 37,( 5), 2006, 727734

Das könnte Ihnen auch gefallen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Cisco Network DiagramDokument1 SeiteCisco Network DiagramĐỗ DuyNoch keine Bewertungen

- D 2510 - 94 R98Dokument3 SeitenD 2510 - 94 R98David Cazorla100% (1)

- 3-Axially Loaded Compresion Members PDFDokument37 Seiten3-Axially Loaded Compresion Members PDFKellen BrumbaughNoch keine Bewertungen

- Delhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeyDokument6 SeitenDelhi Public School Bangalore North ACADEMIC SESSION 2021-2022 Ut2 Revision Work Sheet TOPIC: Sorting Materials Into Group Answer KeySumukh MullangiNoch keine Bewertungen

- AB-522 Standard Pneumatic Test Procedure RequirementsDokument16 SeitenAB-522 Standard Pneumatic Test Procedure RequirementsShank HackerNoch keine Bewertungen

- Acceleration GrpahDokument14 SeitenAcceleration GrpahRAFAEL TORRESNoch keine Bewertungen

- MILL Series GB-1007 01Dokument20 SeitenMILL Series GB-1007 01Ady IonutNoch keine Bewertungen

- BPSK SimulinkDokument13 SeitenBPSK SimulinkpootommyNoch keine Bewertungen

- Pioneer XDP - 30R ManualDokument213 SeitenPioneer XDP - 30R Manualmugurel_stanescuNoch keine Bewertungen

- Aeroshell Fluid 41 PdsDokument2 SeitenAeroshell Fluid 41 Pdsja.moreno930Noch keine Bewertungen

- Bubbling Kun NiDokument7 SeitenBubbling Kun NiBelen CRNoch keine Bewertungen

- Engine Maintenance PartsDokument13 SeitenEngine Maintenance PartsSerkanAl100% (1)

- Lesson Plan 2 Road FurnitureDokument4 SeitenLesson Plan 2 Road FurnitureShahbaz SharifNoch keine Bewertungen

- Standardization of Naoh 1Dokument3 SeitenStandardization of Naoh 1api-309208977Noch keine Bewertungen

- GMP Male BearingDokument3 SeitenGMP Male BearingMahdi HajizadehNoch keine Bewertungen

- Noise and Vibration During CosntructionDokument12 SeitenNoise and Vibration During Cosntructionpierre3101Noch keine Bewertungen

- Estimation Software For Presure VesselDokument36 SeitenEstimation Software For Presure VesselKarthikeyan Shanmugavel0% (1)

- Biomasse-HKW Sandreuth E NQDokument8 SeitenBiomasse-HKW Sandreuth E NQValeriu StanNoch keine Bewertungen

- CH 4 Data CommDokument4 SeitenCH 4 Data CommHenna ShainaNoch keine Bewertungen

- HiraDokument30 SeitenHiravijay kumar singhNoch keine Bewertungen

- Order Qty Vs Dispatch Plan - 04 11 20Dokument13 SeitenOrder Qty Vs Dispatch Plan - 04 11 20NPD1 JAKAPNoch keine Bewertungen

- How Is Electrical Energy MeasuredDokument4 SeitenHow Is Electrical Energy MeasuredSonya ReddyNoch keine Bewertungen

- Glass Inspection CriteriaDokument4 SeitenGlass Inspection CriteriabatteekhNoch keine Bewertungen

- Structured ProgrammingDokument31 SeitenStructured ProgrammingkakaboomNoch keine Bewertungen

- Creating REST API Using NodeJS and Consuming in AngularJSDokument8 SeitenCreating REST API Using NodeJS and Consuming in AngularJSserignemodouNoch keine Bewertungen

- Riscv SpecDokument32 SeitenRiscv SpeckartimidNoch keine Bewertungen

- AquaCal Tropical Brochure PDFDokument2 SeitenAquaCal Tropical Brochure PDFJC ParedesNoch keine Bewertungen

- How To Measure MTFDokument64 SeitenHow To Measure MTFamtcorporationNoch keine Bewertungen

- Fluid Mechanics Seventh Edition by Frank M. WhiteDokument1 SeiteFluid Mechanics Seventh Edition by Frank M. WhiteDarKaiserNoch keine Bewertungen

- An 80-Mg Railroad Engine A Coasting at 6.5 KM - H Strikes A 20Dokument4 SeitenAn 80-Mg Railroad Engine A Coasting at 6.5 KM - H Strikes A 20Aura Milena Martinez ChavarroNoch keine Bewertungen