Beruflich Dokumente

Kultur Dokumente

HP Series

Hochgeladen von

Margaret DaughertyOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

HP Series

Hochgeladen von

Margaret DaughertyCopyright:

Verfügbare Formate

TECHNICAL BULLETIN HP-S-DIFF-TB

03-07

Model HP-1+6+S is a heavy duty, high pressure

reducing differential regulator. The internal trim is of a

pressure balanced design, with the diaphragm having both

up and down stops. Inlet pressure may be as high as

3000 psig (207 Barg). Outlet pressure may be as high as

1500 psig (103 Barg). Diferential pressures may vary from

15-150 psid (1.0-10.3 Bard).

MODEL HP-1+6+S

"HIGH" PRESSURE DIFFERENTIAL

REDUCING REGULATOR

FEATURES

High pressure operation.

CS and SST body/spring chamber materials.

NACE or Non-NACE constructions.

Anti-blowout adjusting screw assembly with

closing cap.

Standard non-asbestos gaskets

APPLICATIONS

Most commonly applied to develop a constant dif-

ferential pressure across a rotating shaft seal to provide

proper sealing and lubricating conditions over varying

pressure ranges.

For gaseous and non-flashing, non-cavitating liquid

services.

STANDARD/GENERAL SPECIFICATIONS

1/2, 3/4, 1, 1-1/2

(DN15, 20, 25, 40)

Std. NPT.

Opt-30 Welded-on RF flanges;

pressure cl asses 600# ( PN10) ,

900# (PN150), 1500# (PN260).

Body Sizes:

End

Connections:

Body/Spring

Chamber/

Spacer

Materials:

Inlet Pressure:

CS/CS/CS or SST/SST/SST.

CS = Carbon Steel

SST = Stainless Steel

Up to 3000 psig (207 Barg). May be

limited by end connection.

MODEL HP-1+6+S

CAUTION

Do NOT Apply in Steam Service!

Do NOT Apply in Oxygen Service!

CAUTION

HP 1+6+S Option contains single diaphragm con-

struction. In the event of diaphragm failure, the

process fuid will mix with the loading fuid.

HP-S-DIFF-TB 2

Up to 1500 psig (103 Barg). May be

limited by end connection.

-20 to +400F (-29 to +205C).

Liquid 600 psig (41.4 Bard).

Gas 1500 psig (103 Bard).

15-150 psid (1.0-10.3 Bard)

with multiple range springs.

Up to 4.40 Cv.

Design is pressure-balanced.

Composition Seat

Trim Designation No. S40T.

Temp Range: -20 to +400F

(-29 to 205C)

Materials

Piston and Cylinder 316 SST.

Diaphragm and Quad Ring

Fluorocarbon elastomer.

Seat and Backup Ring TFE.

Piston Spring

Nace - Inconel X-750

Non-Nace - 302 SST

NOTE: Cashco, Inc. does not rec-

ommend metal seated trim on any

service where the fow will be dead

ended down stream of the pressure

reducing regulator. Use composition

seat for dead end service.

Std. Non-asbestos.

Cylinder Gskt. Graphite/NBR.

O-rings

Fluorocarbon Elastomer (FKM).

Backup Rings PTFE-split.

All bolting is alloy steel, zinc plated.

Studs: ASTM A-193, Gr. B7.

Nuts: ASTM A-194, Gr. 2H.

Cap Screws: ASTM A-193, Gr. B7.

Note: Al l studs are el ongated to

allow bracket mounting; bracket sup-

plied by customer.

ASTM A479, S31600, Annealed.

Spring Chamber Zone

Closing Cap 316 SST.

Adj. Screw Jam Nut 316 SST.

Adj. Screw 17-4 PH SST.

Adj. Screw Housing* 316 SST.

Pressure Plate -

Std. Sizes 1/21" (DN15-25)

316 SST.

Size 1-1/2 (DN40) CS with CS

body; SST with SST body.

Opt-40 316 SST, all sizes.

Spring Button -

Std. CS body, All sizes except

1-1/2 (DN40) CS.

CS body 1-1/2 (DN40) Brass.

SST body SST.

Opt-40 All sizes, all body ma-

terials SST.

Range Spring Epoxy coated if CS.

Std. CS body Steel.

SST body Inconel X-750.

Opt-40 Inconel X-750.

*Welded to spring chamber.

Body Zone

Pusher Plate 316 SST.

Enamel per Cashco Speci fi cati on

#S-1545 for CS units. No painting of

SST units.

Flange Bolting:

Body Cap:

Miscellaneous

Internals

Materials:

Painting:

FLANGED END CONNECTI ONS.

Wel ded- on pressure cl asses 600#

( PN110) , 900# ( PN150) or 1500#

(PN260) raised face flanges for CS

or SST bodi es. Pi pe ni ppl es and

flanges of same basic materials as

body. Pipe nipples are seal welded

after screwing into body; flanges are

socket welded to pipe nipples. Flange

pressure class is same for inlet and

outlet.

Wi t h 900# ( PN150) and 1500#

(PN260) flanges, the outlet pressure

rating is limited by the bodys rating.

For 600# flanges, the outlet pressure

rating is limited by the fanges rating.

See Table 2.

All welding procedures in compliance

with ASME Boiler & Pressure Vessel

Code, Section IX, and American Petro-

leum Institute API-614 requirements.

OPTION SPECIFICATIONS

Outlet Pressure:

Temperature

Range:

Maximum

Pressure

Drop:

Diferential

Pressure

Range:

Capacity:

Internal Valve

Trim:

Gaskets/Seals:

Option -30:

Body Size Dif. Pressure Range

inch (DN) psid (Bard)

1/2", 3/4"

& 1"

(15, 20,

& 25)

15 - 40 (1.0-2.8)

30 - 150 (2.1-10.3)

1-1/2" (40)

30 - 100 (2.1-6.9)

80 - 150 (5.5-10.3)

HP-S-DIFF-TB 3

a. Body Service Fluid What is it? Liquid or gas?

Specifc gravity or weight density? Is it corrosive?

b. Loading Service Fluid What is it? Liquid or gas?

Specifc gravity or weight density? Is it corrosive?

c. Inlet Pressure P

1

(upstream pressure? Max, Norm,

Min conditions?)

d. Loading Pressure P

LOAD

MAX

, P

LOAD

NORM

, P

LOAD

MIN

?

e. Di fferenti al Pressure P

DI FF

or P

SET

? Al l owabl e

devi ati on of P

DI FF

f rom P

LOAD

MAX

to P

LOAD

MI N

; i . e. ,

acceptable droop?

Cashco recommends that all Model HP-1+6+S units be sized and selected by Factory personnel. The following data

must be available for a proper sizing and selection

Figure1: HP-1+6+S Graph 1

Differential pressure reducing regulators operate in

accordance with the parameters as indicated in Fig. 1.

Sometimes called tracking regulators, a differential re-

ducer always has the P

2

-Outlet Pressure greater than the

P

LOAD

- loading Pressure by a relatively constant pressure

diferential determined by the range spring setting. (See

Graph 1.)

If P

LOAD

decreases by 15 psig (1 barg), then P

2

will also

decrease by the same 15 psig (1 Barg). If P

LOAD

increases

by 29 psig (2 Barg), then P

2

increases by 29 psig (2

Barg). Thus, P

2

tracks P

LOAD

, with the differential pressure

between P

LOAD

and P

2

bei ng rel ati vel y constantl y at

P dif, as determined by the range spring set pressure.

APPLICATION AND SELECTION

FUNCTIONAL OPERATION

OF DIFFERENTIAL PRESSURE REDUCING REGULATORS

exterior of the regulator is not directly

exposed to a sour gas environment, bur-

ied, insulated, or otherwise denied direct

atmospheri c exposure. Ei ther of the

available trim designs are in compliance.

Diaphragm flange bolting is standard

bol t i ng, and meet s NACE MRO175

Section 6.3 requirements.

NACE CONSTRUCTION. For applications

where gas or liquid is classified as sour

due to presence of H

2

S. Both CS and SST

body/spring chamber constructions avail-

able to meet NACE requirements.

I nternal wetted porti ons meet NACE

Standard MRO175 revision, when the

Option -40:

f. Desired Capacity Cv, GPM, SCFH at P

LOAD

MAX

and

P

LOAD

MIN

thru body?

g. Body Fluid Temperature T

1

?

h. Loading Fluid Temperature T

LOAD

?

i. Minimum Ambient Temperature T

AMB

?

j. Body Fluid Viscosity CP, SSU, CS?

HP-S-DIFF-TB 4

Diferential

Pressure P Dif

BODY SIZES 1-1/2" (DN40)

Cv @ % Droop

psid (Bard) 10% 20% 30%

15 (1.0) .42 .84 1.27

25 (1.7) .98 1.96 2.95

40 (2.8) 1.69 2.71 3.65

50 (3.4) 1.75 3.30 4.00

75 (5.2) 1.80 3.90 4.23

100 (6.9) 1.70 3.24 3.92

150 (10.3) 1.80 3.96 4.40

TECHNICAL SPECIFICATIONS

TABLE 1

CAPACITY TABLE - Cv FULL PORT

Material

English Units Metric Units

Temperature

F

Working Pressure Classes

Temperature

C

600 psig 900 psig 1500 psig 600 Barg 900 Barg 1500 Barg

Carbon

Steel

Flanged

ANSI

B16.5

-20 to +100 1480 2220 3705 102.0 153.1 255.5 -29 to +38

200 1350 2025 3375 93.1 139.6 232.7 93

300 1315 1970 3280 90.6 135.8 226.2 149

400 1270 1900 3170 87.5 131.0 218.6 205

Stainless

Steel

Flanged

ANSI

B16.5

-20 to +100 1440 2160 3600 99.3 148.9 248.2 -29 to +38

200 1240 1860 3095 85.5 128.2 213.4 93

300 1120 1680 2795 77.2 115.8 192.7 149

400 1025 1540 2570 70.7 106.2 177.2 205

TABLE 2

PRESSURE vs. TEMPERATURE RATINGS

METRIC CONVERSION FACTOR: psig / 14.5 = Barg

METRIC CONVERSION FACTOR: Cv / 1.16 = kv

Diferential

Pressure P Dif

BODY SIZES 1/2", 3/4", 1" (DN15, 20, 25)

Cv @ % Droop

psid (Bard) 10% 20% 30%

15 (1.0) .24 .44 .61

25 (1.7) .51 .92 1.33

40 (2.8) .53 .83 1.11

50 (3.4) .55 1.05 1.50

75 (5.2) .61 1.15 1.65

100 (6.9) .55 1.10 1.59

150 (10.3) .63 1.28 1.70

HP-S-DIFF-TB 5

ENGLISH (in)

SHIPPING

WEIGHT

LBS

SIZE

IN

A B C D E F G H I K

1/2, 3/4, 1 1.00 1.88 12.72 2.94 1.81 4.38 6.25 3.62 5.38 13.00 30

1-1/2 1.66 2.44 14.47 3.56 2.19 6.69 7.62 4.00 6.75 15.00 60

METRIC UNITS (mm)

SHIPPING

WEIGHT

KGS

SIZE

DN

A B C D E F G H J K

15, 20, 25 25 48 323 75 46 111 159 92 137 330 13.6

40 42 62 368 90 56 170 194 102 171 381 27.2

DIMENSIONS

WEIGHTS & DIMENSIONS

F (NPT)

G DIA.

K (FLG'S)

H DIA.

J DIA.

C

B

A

D

E

1/2" (DN15) NPT

Loading Connection

HP-S-DIFF-TB 6

Figure 3

1-1/2" (DN40) Body Size

Figure 2

1/2", 3/4" & 1" Body Size

(DN15, 20, 25)

POSITION OF MOUNTING BRACKET STUDS

Position of longer studs used for

mounting customer supplied bracket.

Position of two "Short" Cap Screws

must straddle 1/2" (DN15) NPT Loading

Pressure Connection.

BODY SIZE

NUMBER OF

BOLT HOLES

BOLT CIRCLE

POSITION

in (DN) A B

1/2, 3/4, 1 (15, 20, 25) 14 5-3/8 12 - 51'-25" 25 - 42'-51"

1-1/2 (40) 18 6-3/4 10 20

HP-S-DIFF-TB 7

NOTES

Cashco, Inc

P.O. Box 6

Ellsworth, KS 67439-0006

PH (785) 472-4461

Fax (785) 472-3539

www.cashco.com

E-mail: sales@cashco.com exportsales@cashco.com

Printed in U.S.A. Model HP-S-Dif-TB

A

MODEL HP-1+6+S PRODUCT CODE 03/16/07

TABLE 3 - BODY/SPRING

CHAMBER MATERIALS

Body / Sp. Ch. CODE

CS/CS 5

SST/SST A

TABLE 2 - SIZES

Size

CODE

in (DN)

1/2" (15) 4

3/4" (20) 5

1" * (25) * 6

1-1/2" (40) 8

* Available Only for Drwg.#32911

Select from TABLE 7

TABLE 1 - MODELS

Description CODE

Model HP-1+6+S (Opt-40)

"NACE" Construction

Diferential

Pressure Reducing Regulator

3N

Model HP-1+6+S

"NON-NACE" Construction

Diferential

Pressure Reducing Regulator

3S

TABLE 5 - END CONNECTIONS

Description CODE

NPT - Screwed 1

-30 Opt.- 600 LB RF Flgs. * 8

-30 Opt.- 900 LB RF Flgs. * 9

-30 Opt.- 1500 LB RF Flgs. * A

*Nipples & fanges of same material as body.

CS or SST bodies only.

TABLE 6- RANGE SPRINGS

SIze psig (Barg) CODE

All 15-40 * (.69-10.3) 1

1/2"-1" 30-150 * (2.1-10.3) 2

1-1/2"

30-100 * (2.1-6.9) 3

80-150 * (5.5-10.3) 4

TABLE 7 - OPTIONS

Service Application Body Material

CODE

DRAWING #

NACE Service (Opt -40) SST 32907

NACE Service (Opt -40) CS 32909

Non-NACE Service CS 32911

4 T X

TABLE 4 - Std. or CE Marked Products

(See Cashco Spec. #7E13)

Description CODE

Standard 7

CE Marked Unit

Consult Factory for Special Code

(PED does not apply to DN25

and below)

E

Table

1

Table

2

Table

3

Table

4

Table

5

Table

7

Table

7

Table

6

Table

7

Table

7

Table

7

"HIGH" PRESSURE DIFFERENTIAL

Das könnte Ihnen auch gefallen

- Yhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerDokument1 SeiteYhl/ Ar Ali/ Subardi 11/6/2012 Scale Units MM No Scale CoolerMargaret DaughertyNoch keine Bewertungen

- VibrationDokument24 SeitenVibrationDaniel Codina100% (1)

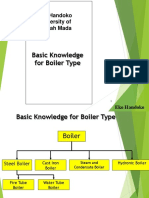

- BoilerDokument90 SeitenBoilerMargaret DaughertyNoch keine Bewertungen

- EAM MetersDokument20 SeitenEAM MetersVictor MillanNoch keine Bewertungen

- CATERPILLAR KRA Gas Lift DrawwingSEK PDFDokument3 SeitenCATERPILLAR KRA Gas Lift DrawwingSEK PDFMargaret DaughertyNoch keine Bewertungen

- Caps and lifting levers parts referenceDokument1 SeiteCaps and lifting levers parts referenceMargaret DaughertyNoch keine Bewertungen

- Piping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFDokument1 SeitePiping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFMargaret DaughertyNoch keine Bewertungen

- 9 07sek PDFDokument1 Seite9 07sek PDFMargaret DaughertyNoch keine Bewertungen

- Piping and Instrumentation Diagram - Legend Sheet 3 of 9 - EDokument1 SeitePiping and Instrumentation Diagram - Legend Sheet 3 of 9 - EMargaret DaughertyNoch keine Bewertungen

- Big Joe Type 630SEK PDFDokument12 SeitenBig Joe Type 630SEK PDFMargaret DaughertyNoch keine Bewertungen

- Piping and Instrumentation Diagram - Legend Sheet 1 of 9 - Id PDFDokument1 SeitePiping and Instrumentation Diagram - Legend Sheet 1 of 9 - Id PDFMargaret DaughertyNoch keine Bewertungen

- Cat D-3600sek PDFDokument2 SeitenCat D-3600sek PDFMargaret DaughertyNoch keine Bewertungen

- Piping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFDokument1 SeitePiping and Instrumentation Diagram - Legend Sheet 2 of 9 - E PDFMargaret DaughertyNoch keine Bewertungen

- astroSEK PDFDokument9 SeitenastroSEK PDFMargaret DaughertyNoch keine Bewertungen

- Agco Type81sek PDFDokument15 SeitenAgco Type81sek PDFMargaret DaughertyNoch keine Bewertungen

- Crankcase Ventilation (LEBW4958)Dokument20 SeitenCrankcase Ventilation (LEBW4958)József Nagy100% (2)

- Drum Gauges PDFDokument2 SeitenDrum Gauges PDFMargaret DaughertyNoch keine Bewertungen

- Caterpillar G3500 Top End Overhaulesek PDFDokument18 SeitenCaterpillar G3500 Top End Overhaulesek PDFMargaret Daugherty75% (4)

- Klinger Product CatalogueDokument248 SeitenKlinger Product Cataloguemar_marcusNoch keine Bewertungen

- Proposal Budgetary LevelGauges - KLINGER - 200110 PDFDokument2 SeitenProposal Budgetary LevelGauges - KLINGER - 200110 PDFMargaret DaughertyNoch keine Bewertungen

- Cat & DdsekDokument1 SeiteCat & DdsekMargaret DaughertyNoch keine Bewertungen

- CATERPILLAR KRA Gas Lift DrawwingSEK PDFDokument3 SeitenCATERPILLAR KRA Gas Lift DrawwingSEK PDFMargaret DaughertyNoch keine Bewertungen

- Air Comp INGERSOLL-RAND SEK PDFDokument16 SeitenAir Comp INGERSOLL-RAND SEK PDFMargaret Daugherty100% (1)

- DB GB PDFDokument8 SeitenDB GB PDFMargaret DaughertyNoch keine Bewertungen

- 3500 Engine Oil and Filter - ChangeSEK PDFDokument11 Seiten3500 Engine Oil and Filter - ChangeSEK PDFMargaret DaughertyNoch keine Bewertungen

- 3500 TroubleshootingSEK PDFDokument33 Seiten3500 TroubleshootingSEK PDFMargaret Daugherty50% (2)

- CATERPILLAR Manual For Altronic Digital Monitor CAS-2140SEK PDFDokument16 SeitenCATERPILLAR Manual For Altronic Digital Monitor CAS-2140SEK PDFMargaret DaughertyNoch keine Bewertungen

- 03 Tablas Catsek PDFDokument10 Seiten03 Tablas Catsek PDFMargaret DaughertyNoch keine Bewertungen

- Cat D-3600sek PDFDokument2 SeitenCat D-3600sek PDFMargaret DaughertyNoch keine Bewertungen

- ARIEL CompressorSEK PDFDokument80 SeitenARIEL CompressorSEK PDFMargaret Daugherty100% (1)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Outcome of Pelvic Fractures Identi Fied in 75 Horses in A Referral Centre: A Retrospective StudyDokument8 SeitenOutcome of Pelvic Fractures Identi Fied in 75 Horses in A Referral Centre: A Retrospective StudyMaria Paz MorenoNoch keine Bewertungen

- Treating and Preventing Ear Infections in ChildrenDokument4 SeitenTreating and Preventing Ear Infections in ChildrenbehrangNoch keine Bewertungen

- Edan Sonotrax ManualDokument47 SeitenEdan Sonotrax ManualDaniel GalindoNoch keine Bewertungen

- Sir PapsDokument15 SeitenSir PapsRey Niño GarciaNoch keine Bewertungen

- R02.4 Standard III (A) - AnswersDokument11 SeitenR02.4 Standard III (A) - AnswersShashwat DesaiNoch keine Bewertungen

- UntitledDokument77 SeitenUntitledVedranL84Noch keine Bewertungen

- Everything You Want To Know in ChennaiDokument428 SeitenEverything You Want To Know in ChennaiBalamuruganNoch keine Bewertungen

- Time ManagementDokument30 SeitenTime ManagementVaibhav Vithoba NaikNoch keine Bewertungen

- High Containment Labs and Other Facilities of The US Bio Defense ProgramDokument1 SeiteHigh Containment Labs and Other Facilities of The US Bio Defense ProgramHRCNoch keine Bewertungen

- Frontline ArticleDokument7 SeitenFrontline Articleapi-548946265Noch keine Bewertungen

- Veterinary Medicines ReportDokument28 SeitenVeterinary Medicines Reportvikram chhabraNoch keine Bewertungen

- 1.4 Market FailureDokument42 Seiten1.4 Market FailureRuban PaulNoch keine Bewertungen

- Boge Screw UsaDokument40 SeitenBoge Screw UsaAir Repair, LLC100% (1)

- FAQ For Company Law 2013Dokument24 SeitenFAQ For Company Law 2013Archanat07100% (1)

- UntitledDokument193 SeitenUntitledurosNoch keine Bewertungen

- Vodafone Idea Limited: PrintDokument2 SeitenVodafone Idea Limited: PrintPrakhar KapoorNoch keine Bewertungen

- MEMBERS AREA IndexDokument13 SeitenMEMBERS AREA IndexshahidsarkNoch keine Bewertungen

- GS I: Factors Driving Development of Global Textile IndustriesDokument54 SeitenGS I: Factors Driving Development of Global Textile IndustriesAMIT RAJNoch keine Bewertungen

- B Fire BehaviorDokument39 SeitenB Fire BehaviorDon VitoNoch keine Bewertungen

- Palm Avenue ApartmentsDokument6 SeitenPalm Avenue Apartmentsassistant_sccNoch keine Bewertungen

- CCE Format For Class 1 To 8Dokument5 SeitenCCE Format For Class 1 To 8Manish KaliaNoch keine Bewertungen

- Physiology of Women Reproduction SystemDokument52 SeitenPhysiology of Women Reproduction Systemram kumarNoch keine Bewertungen

- Forced Retirement - Government Retirement AccountsDokument3 SeitenForced Retirement - Government Retirement AccountsMark HarrisonNoch keine Bewertungen

- Product and Service Costing: Job-Order System: Questions For Writing and DiscussionDokument22 SeitenProduct and Service Costing: Job-Order System: Questions For Writing and Discussionsetiani putriNoch keine Bewertungen

- 4th QUARTER EXAMINATION IN TLE 8Dokument3 Seiten4th QUARTER EXAMINATION IN TLE 8judy ann sottoNoch keine Bewertungen

- Non-Directive Counselling RogersDokument5 SeitenNon-Directive Counselling RogersSanjeev ChaudharyNoch keine Bewertungen

- Rhodes-Solutions Ch2 PDFDokument16 SeitenRhodes-Solutions Ch2 PDFOscar GarzónNoch keine Bewertungen

- Cottonhill - Red Collection PDFDokument33 SeitenCottonhill - Red Collection PDFVioricaNoch keine Bewertungen

- Hydrogen DryerDokument2 SeitenHydrogen Dryersanju_cgh5518Noch keine Bewertungen

- High Flyers / Answer Key G / Unit 4: GrammarDokument8 SeitenHigh Flyers / Answer Key G / Unit 4: GrammarDian Novyta AriantiNoch keine Bewertungen