Beruflich Dokumente

Kultur Dokumente

0354 98361100041N

Hochgeladen von

16mariusOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

0354 98361100041N

Hochgeladen von

16mariusCopyright:

Verfügbare Formate

Naeimi, H., et al.

: A Parametric Design of Compact Exhaust Manifold Junction in

THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1023-1033 1023

A PARAMETRIC DESIGN OF COMPACT EXHAUST MANIFOLD

JUNCTION IN HEAVY DUTY DIESEL ENGINE USING

COMPUTATIONAL FLUID DYNAMICS CODES

by

Hessamedin NAEIMI

a*

, Davood DOMIRY GANJI

a

Mofid GORJI

a

, Ghasem JAVADIRAD

b

, and Mojtaba KESHAVARZ

b

a

Faculty of Mechanical Engineering, Babol University of Technology, Babol, Iran

b

Iran heavy diesel MFG. Co. (DESA), Amol, Iran

Original scientific paper

UDC: 621.43.041.6:519.872

DOI: 10.2298/TSCI100417041N

Nowadays, computational fluid dynamics codes are prevalently used to simulate

the gas dynamics in many fluid piping systems such as steam and gas turbines,

inlet and exhaust in internal combustion engines. In this paper, a computational

fluid dynamics software is used to obtain the total energy losses in adiabatic

compressible flow at compact exhaust manifold junction. A steady-state one-

dimensional adiabatic compressible flow with friction model has been applied to

subtract the straight pipe friction losses from the total energy losses. The total

pressure loss coefficient has been related to the extrapolated Mach number in the

common branch and to the mass flow rate ratio between branches at different

flow configurations, in both combining and dividing flows. The study indicate

that the numerical results were generally in good agreement with those of expe-

rimental data from the literature and will be applied as a boundary condition in

one-dimensional global simulation models of fluid systems in which these com-

ponents are present.

Key words: Diesel engines, exhaust manifold junction, pressure loss coefficient,

numerical simulation, experimental data

Introduction

The appropriate selection of turbocharging system type and the reasonable design of

exhaust manifold configurations in heavy-duty Diesel engines is very significant since the

performance of a four-stroke turbocharged Diesel engine is greatly affected by the gas flow in

the exhaust manifold [13]. At the present time, several different turbocharging systems are

usually adopted: the constant pressure turbocharging system, the pulse turbocharging system,

the pulse converter (PC) turbocharging system, and the compact exhaust manifold or modular

pulse converter (MPC) turbocharging system, etc. In the constant pressure turbocharging

system, the exhaust ports of all cylinders are connected to a single manifold to damping

unsteady gas flow from cylinders. Hence, the pressure in the turbine inlet is almost steady.

Corresponding author: e-mail: hessam.naeimi@gmail.com

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

1024 THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1025-1035

This allows the turbine to operate at optimum efficiency at specified engine conditions. This

matter is a major advantage of this type of turbocharging. However, the significant

disadvantages of the constant pressure turbocharging are poor turbocharging acceleration and

performance at low speed and load. In the case of the pulse turbocharging system, the exhaust

gases coming from two or three cylinders, which have minimum interference in scavenging

process base on the firing order, are discharged into a common branch exhaust pipe. It aims to

make maximum use of the energy available in the high pressure and temperature exhaust

gases. This turbocharging system has good turbocharger acceleration and performance at low

speed and part load.

However, its application is limited by the number of the exhaust manifold and the

design of the exhaust manifold with large numbers of cylinders is complex. In addition the

turbine efficiency with one or two cylinder per turbine entry or at very high rating is poor [4].

Pulse converter turbocharging system has been developed to overcome the disadvantage of

the pulse turbocharger. In this system, many cylinders are connected to a single low volume

manifold. So that the pressure variation at the turbine entry is reduced and its result the

turbine efficiency is improved. However, the PC turbocharging system has poor performance

at very low speed/load and is only suitable for engines with certain numbers of cylinders (e. g.

four, eight, sixteen, etc.) [5]. Nowadays, the

MPC turbocharging system has become

popular because the structure of its exhaust

manifolds is simple. In this kind of turbo-

charging system, as it is shown in fig. 1, all

the exhaust ports are connected to a common

exhaust duct by a distinct pulse converter.

This system intends to preserve the pulsing

energy of exhaust gases coming from

cylinders and transmit it to the turbine inlet

while reduces the backflow toward cylinders

during scavenging as possible [6].

Nowadays, the 1-D models are used in the global simulation of steady and transient

compressible flow in pipe systems, such as BOOST (AVL) [7], and GT POWER [8]. These

models are utilized as well as to analysis of internal combustion engine performance at

various operating conditions. However, the fluid flow through the compact exhaust manifold

junctions, as its geometry, is 3-D and highly turbulent. Since the total pressure loss

coefficients must be obtained separately and added to these models as special boundary.

Unfortunately there is not enough pressure loss data in literature especially for compressible

flow in compact exhaust manifold. The largest source of the experimental result for pressure

loss in T junction have been perform by Miller [9]. Basset et al. [10] compared different

modelling techniques. A multi-dimensional computer program was developed by Chiatti et al.

[11]. These cods were used to simulate the flow within different components of the exhaust

system in internal combustion engine (ICE). Commercial codes, such as Star-CD, Fluent, or

Fire-AVL were used by Shaw et al. [12], and Gan et al. [13]. Abou-Haidar et al. [14] and

Pearson et al. [15] utilized 1-D and 2-D models to simulate the wave propagation

phenomenon. Most of the works have been focused on designing manifolds of ICE. In the

present work, a commercial computational fluid dynamics (CFD) package, FLUENT [16] is

used to obtain the total energy losses in adiabatic compressible flow at compact exhaust

Figure 1. Modular pulse converter junction of

Chan [17]

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1023-1033 1025

manifold junction. The numerical results were generally in good agreement with the steady

flow measurements of Chan [17].

Mathematical model

The fluid flow studied is governed by three-dimensional compressible adiabatic

steady-state form of the Reynolds-averaged Navier-Stokes (RANS) conservation equations

and the additional equations describing the transport of other scalar properties. They may be

written in Cartesian tensor notation as:

( ) 0

i

i

u

x

(1)

k

k

eff

2

( ) ( )

3

j

i

i j ij i j

i i j j i j

i j

u

u u p

u u u u

x x x x x x x

p

x x

(2)

0 eff eff

( ) ( )

i i i

i j j

u h u u

x x x

(3)

Different turbulence models based on RANS equations is available for studying the

Reynolds stresses and the turbulent diffusivity terms. In this work, the two equations turbulent

model k-eRNG will be used and different turbulent models were compared. The random

number generation (RNG) model has an additional term in its equation that significantly

improves the accuracy for rapidly strained flows. The effect of swirl on turbulence is included

in the RNG model, enhancing accuracy for swirling flows. The turbulence kinetic energy, k,

and its rate of dissipation, e, are obtained from the following transport equations:

t

k

( )

div( U) div 2

t ij ij

k

k E E

t

(4)

2

t

1 t 2

( )

div( ) div grad 2

ij ij

U C E E C

t k k

(5)

The coefficients of eqs. (4) and (5) are shown

in tab. 1.

Definition of junction pressure

loss coefficient

The studying here for calculation of the pressure loss at compact exhaust manifold

will be limited by duct configuration and flow direction. Actually, there are six individual

flow types for a generalized three-pipe junction (fig. 2) and twelve loss coefficients associated

2

t

0.0845

k

C C

(6)

Table 1. Coefficients of k-e RNG model

C

1e

C

2e

s

k

s

e

1.42 1.68 1.0 1.3

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

1026 THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1025-1035

with it. In this study (as shown in fig. 2), we

have considered two flow types, one from

combining flow type and another dividing

flow.

The total pressure loss coefficient K

ij

, given

by eq. (7), is defined as the ratio of the total

pressure drop in the direction of positive mass

flow to the dynamic-pressure (P

d

) in the

common branch that witch the total flow is

passing [9]:

where

t

if

if

i i j

j i j

u Q Q

u

u Q Q

(8)

Notice that the dynamic-pressure (P

d

) in the leg carrying the total flow for

compressible flow is obtained from:

* *

d 0t st

P P P (9)

So, the four loss coefficients for the combining and dividing flow as shown in fig. 2

are calculated as:

combining flow

2 2

1 s1 3 s3

13

13

*

3 03 3

1 1

2 2

u P u P

P

K

P P P

(10)

2 2

2 s2 3 s3

23

23

*

3 03 3

1 1

2 2

u P u P

P

K

P P P

(11)

dividing flow

2 2

3 s3 1 s1

31

31

*

3 03 3

1 1

2 2

u P u P

P

K

P P P

(12)

2 2

3 s3 2 s2

32

32

*

3 03 3

1 1

2 2

u P u P

P

K

P P P

(13)

When the Mach number of air flow is less than 0.2, the air passing of compact

exhaust manifold can be considered incompressible. The loss coefficient for incompressible

Figure 2. Schematic of modular pulse

converter junction

2 2

si s

2

d

t

1 1

2 2

1

2

i j i

ij

ij

u P u P

P

K

P

u

(7)

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1023-1033 1027

flow is independent of common branch much number and just changes with mass flow ratio.

However, the value of loss coefficient for compressible flow does vary with common branch

much number, too.

Computational domain

The flow domain as shown in fig. 3 has a three-pipe intersection. An unstructured,

non-uniform mesh, a detail of the grid in the intersection of the branches region, the mesh

structure on the symmetry plane and a detail of the mesh at the cross-section are illustrated.

Due to the symmetry of modular exhaust junction, in all flow configurations the

computational domain can be considered one half of the actual volume. In order to make sure

that the accuracy of results was independent of computations grid, calculations were carried

out with several different grid resolutions as well as modifying the distance of the wall-

adjacent cells to the wall. For all mass flow rates simulated, the y

+

value is maintained within

the recommended range, 30 < y

+

< 500. The number of cells of the mesh finally used was

186,354.

Figure 3. 3-D computational domain, mesh structure in the plane of symmetry and in the

cross-sectional of a branch at compact manifold junction simulated

In all of the studied cases here, the much number of the outlet exhaust manifold is

assumed constant and is 0.25. Outlet pressure and temperature was fixed of 300 Pa and 300 K,

respectively. So, based on the target mass flow rate ratio (q), desired mass flow rate for each

branch has been studied. Since the air flow was supposed compressible, a mass flow rate and

static pressure at the inlet and outlet boundary condition has been chosen, respectively. Also,

for simulating the turbulent flow, the turbulence intensity and the hydraulic diameter were set

to 3.5% and 50 mm, respectively, as turbulence parameters in both of the combining and

dividing flow. Flow is adiabatic and non-slip condition with wall roughness height is used for

wall condition.

Evaluating the pipe wall friction factor

In estimating pressure loss due to compact exhaust manifold, the pressure

measurements location is great importance. The pressure should be measured in fully

developed flow region. So that the one dimensional Fanno flow model could be used. In other

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

1028 THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1025-1035

words, if the pressure measuring location was

not selected correctly the result would not be

reliable. Figure 4 demonstrates the total pres-

sure changes in symmetry surface of different

compact exhaust manifolds having different

branch lengths.

As can be seen from fig. 4, the total pressure

of the flow in manifolds having length equal or

greater then 18D remains constant. Thus, the

flow condition for compact exhaust manifold

having aforesaid branch length will be fully

developed. The pipe friction factor is defined in

eq. (14) as:

w

2

1

2

f

u

(14)

It is common practice, in wave-action simulation, to use a constant value of f

in the

region of 0.004-0.01. In fact, the curve on the Moody diagram for a smooth pipe (D 2.5 mm)

gives value in the range of 0.0035 to 0.008 for Reynolds numbers in the range of 110

4

to

510

5

. For Reynolds numbers in the range of 510

3

Re 10

8

and relative roughness values

in the range of 10

6

D/D 10

2

, Swamee et al. [18] propose the following relationship:

2

10

0.25

5.74

log

3.7 Re

f

D

(15)

Equation (15) can be applied to give either a value for at every mesh point and time

step of the calculation or to give an average value for each point section comprising manifold

[19].

Using 1-D and adiabatic flow conditions between two points in Fanno flow, Mach

number can be calculated from eq. (16). Then all thermo-fluid properties extrapolated can be

obtained and the total pressure loss coefficient computed from eq. (7):

2

2

2

2 1 2

2 2 2

2

2 1 1

1

1

1

1 1 1 1 1

2

ln ln

1

2 2

1

2

M

x x M

f

D

M M M

M

(16)

Results and discussion

Different turbulent models implemented in fluent have been compared. The k-e

standard and RNG with standard wall functions, k-w

standard and Spalart-Allmaras

turbulence models have been used in preliminary simulations at different flow configurations.

In fig. 5, the total pressure loss coefficients obtained with each turbulence model are

represented against a mass flow rate between branches and compare with experimental data

by Chan [17].

Figure 4. Total pressure curve in symmetry

surface of common branch

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1023-1033 1029

It can be observed that in the both

flow types, loss coefficient predicted by

k-e RNG turbulence model is in a good

agreement with reference data. As a

result, this turbulence model will be used

in all simulations.

Combining flow

The compact exhaust manifold with

combining flow type has been simulated

with different mass flow rate ratio, q = 0.1

to 0.9, for combining flow type. Figure 6

shows the simulation results on the

velocity contour on the symmetry plane

in the compact manifold near the junc-

tion for three flow ratios.

Figure 5. Comparison between different turbulence

models (combining flow)

Figure 6. Predicted combining flows

for the centre plane of the compact

manifold

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

1030 THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1025-1035

Mainly, the multi-dimensional undesirable phenomena, such as flow separation,

turbulent mixing, eddies production etc. caused to decrease the total energy of fluid flow. By

increasing the mass flow rate in branch 1, the flow velocity increases in throat area and then

the effect of flow separation and vortex formation due to the changing cross section in flow

upstream increases. So, the pressure loss coefficient is increased. Most published

experimental data for pressure loss coefficients are for T-junctions with a straight branch. The

only data for compact exhaust manifold comparable with the present investigation is that

reported by Chan [17]. A comparison between the predicted and reported pressure loss

coefficients is given in tab. 2. The predicted pressure loss coefficient is in good agreement

with the reported value.

Table 2. Comparison of junction pressure loss coefficients for combining flow

Throat area (At) is one of the important

parameters in compact manifold design.

Compact exhaust manifold works as fluid

diode which allows exhaust gas to move from

cylinder to the turbine and limits the flow

returning from manifold to the cylinder. This

will be done by decreasing the throat area.

With this decrement in throat area, the

velocity will be increased and the pressure will

be decreased. So, it will avoid back pressure in

exhaust manifold hence flow returning to the

cylinder will be limited. Hence, in this study

the effect of the area ratio of At/Ap on the

pressure loss coefficient has been investigated.

Figures 7 and 8 show the variation of the loss

coefficients K

13

and K

23

with mass flow rate

for three different At/Ap of 0.3, 0.35, and 0.4.

As shown in figs. 7 and 8, the pressure loss coefficient in each branch will be increased with

flow rate. In lower flow rates, the ratio of At/Ap has not significant effect on the pressure loss

coefficient. However, in the higher flow ratio of the branch 1 to branch 3, K

13

will be

increased with At/Ap decrease. The situation happens in reverse form for K

23

. It can be con-

q

K

13

K

23

Predicted Exp. [17] Predicted Exp. [17]

0.1 0.7 n. a. 3.44 n. a.

0.2 0.21 0.29 2.16 1.97

0.3 1.2 n. a. 1.7 n. a.

0.4 2.01 2.31 1.11 1.28

0.5 3.19 n. a. 0.74 n. a.

0.6 5.2 5.64 0.35 0.23

0.7 7.46 n. a. 0.05 n. a.

0.8 10.4 11.88 0.32 0.48

0.9 13.57 n. a. 0.52 n. a.

Figure 7. Effect of At/Ap on pressure loss

coefficient K

13

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1023-1033 1031

cluded from above that in a specific flow rate,

magnitude of K

23

and K

13

will be decreased

with At/Ap ratio increase.

Dividing flow

Figure 9 shows the predicted dividing

flow-patterns near the intersection for three

different flow ratios. In low mass flow rate

ratio (q = 0.1) eddies are seen in side branch

(branch 1 ). By addition of flow ratio (q =

= 0.5), the location of recirculation region in

the branch changes and velocity increases in

throat. By further increases of velocity, we

accost chock fig. 9(c). The hoped-for full

range up to q = 0.9 could not be obtained

despite adequate pressure being available

upstream. In dividing flow, q ranged from 0.1 up to a maximum of about 0.6, which was

effectively the choking limit. The predicted and reported pressure loss coefficients for

dividing flows for flow ratios up to 0.6 is shown in tab. 3.

Figure 8. Effect of At/Ap on pressure loss

coefficient K

23

Figure 9. Predicted dividing flows for the

centre plane of the compact manifold

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

1032 THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1025-1035

Table 3. Comparison of junction pressure loss coefficients for combining flow

As seen from tab. 3, the simulation results are in good agreement with experimental

data. For mass flow rate ratio more than 0.6, a shock wave is developed when the supersonic

flow passes through the side branch 1 . So, the pressure loss coefficient can not be obtained

for larger mass flow rate.

Conclusions

In this paper a computational fluid flow model, k- RNG, has been used to obtain

the pressure loss coefficient in compact exhaust manifold junction. Also, to subtract the

frictional losses from the total energy losses, the 1-D Fanno flow model has been used. A

comparison between the predicted and experimental data shows this model and methodology

is in generally good for the estimate of the pressure losses in both combining and dividing

flow. But the maximum mass flow rate of the divided flow was 0.6, because a limit caused by

chocking.

Finally, these coefficients can be used as boundary conditioning in 1-D software

such as GT-Power to simulate the complete engine cycle. As a suggestion for future work, we

can optimize the design parameters of the compact manifold.

Nomenclature

A pipe cross-sectional area, [m

2

]

At trot area, [m

2

]

Ap area at P cross-sectional, [m

2

]

D internal diameter, [m]

E

ij

rate of deformation, [s

1

]

f friction factor, []

h

0

stagnation enthalpy, [Jkg

1

]

K total pressure loss coefficient, []

k turbulent kinetic energy, [m

2

s

1

]

M total pressure loss coefficient, []

P

s

static pressure, [Pa]

P

0

stagnation pressure, [Pa]

Q mass flow rate, [kgs

1

]

q mass flow rate ratio, []

Re Reynolds number, []

U average gas velocity, [ms

1

]

u

i

time-averaged gas velocity, [ms

1

]

y

+

sublayer scaled distance y

+

= u

y/, []

Greek symbols

ratio of specific heats = c

p

/c

v

, []

non-dimensional roughness, [m]

turbulent dissipation rate, [m

2

s

3

]

absolute viscosity, [Pas]

t

turbulent viscosity, [Pas]

gas density, [kgm

3

]

eff

apparent stress tensor, [Pa]

v

Rayleigh dissipation function, [Pas

1

]

ij

Kronecker delta, []

junction lateral branch angle

Subscripts

i,j Branch leg index

* Extrapolated properties to the junction

1, 2 Inlet (combining flow) or outlet

(dividing flow) branches

3 Common branch

q

K

31

K

32

Predicted

Exp. [17]

Predicted

Exp. [17]

0.1 0.46 n. a. 0.386 n. a.

0.2 1.11 1.53 0.29 0.316

0.3 1.8 n. a. 0.28 n. a.

0.4 3.5 3.92 0.3 0.285

0.5 6.0 n. a. 0.32 n. a.

0.6 10.6 9.57 0.35 0.309

Naeimi, H., et al.: A Parametric Design of Compact Exhaust Manifold Junction in

THERMAL SCIENCE, Year 2011, Vol. 15, No. 4, pp. 1023-1033 1033

References

[1] Kesgin, U., Effect of Turbocharging System on the Performance of a Natural Gas Engine, Energy

Conversion and Management, 46 (2005), 1, pp. 11-32

[2] Galindo, J., et al., Design of an Exhaust Manifold to Improve Transient Performance of a High-Speed

Turbocharged Diesel Engine, Experimental Thermal and Fluid Science, 28 (2004), 8, pp. 863-875

[3] Kesgin, U., Study on the Design of Inlet and Exhaust System of a Stationary Internal Combustion

Engine, Energy Conversion and Management, 46 (2005), 13-14, pp. 2258-2287

[4] Hu, X., Lawless, P. B., Predictions of On-Engine Efficiency for the Radial Turbine of a Pulse

Turbocharged Engine. SAE paper 2001-01-1238, 2001

[5] Bassett, M. D., Pearson, R. J., Winterbone, D. E., Steady-Flow Loss-Coefficient Estimation for Exhaust

Manifold Pulse Converter Type Junctions, SAE paper 1999-01-0213, 1999

[6] Yang, S. Y., Deng, K. Y., Cui, Y., Simulation and Experimental Research on a Mixed Pulse Converter

Turbocharging System, Journal of Automobile Engineering, 221 (2007), 2, pp. 215-223

[7] ***, BOOST, User manual for AVL BOOST, AVL List GmbH, Department for Applied Thermo-

dynamics, 1996, http://www.avl.com

[8] ***, GT Power Users manual. GT Suite Version 5.1. Gamma Technologies Inc., USA, 2000

[9] Miller, D. S., Internal Flow Systems, 2

nd

ed., Craneld: The British Hydromechanics Research

Association, Cranfield, UK, 1990

[10] Basset, M. D., Winterbone, D. E., Pearson, R. J., Modelling Engines with Pulse Converted Exhaust

Manifolds using One-Dimensional Techniques, SAE paper 2000-01-0290, 2000

[11] Chiatti, G., Chiavola, O., Multicode Prediction of the Influence of the Exhaust System on the

Performance of a Turbocharged Engine, J. Eng. Gas Turbines Power, 124 (2002), 3, pp. 695-701

[12] Shaw, C. T., et al., Modelling the Effect of Plenum-Runner Interface Geometry on the Flow through an

Inlet System, SAE paper 2000-01-0569, 2000

[13] Gan, G., Riffat, S. B., Numerical Determination of Energy Losses at Duct Junctions, Appl. Energy 67

(2000), 3, pp. 331-340

[14] Abou-Haidar, N. I., Dixon, S. L., Pressure Losses in Combining Subsonic Flows through Branched

Ducts, Trans. ASME, J.Turbomach, 114 (1992), 1, pp. 264-270

[15] Pearson, R. J., et al., Multidimensional Wave Propagation in Pipe Junctions, SAE paper 1999-01-1186,

1999

[16] ***, FLUENT User's Guide, Fluent Inc., New York, USA, 1995

[17] Chan, C. L., An Investigation of the Performance of a Diesel Engine Fitted with Compact Manifold, M.

Sc. thesis, University of Manchester, Institute of Science and Technology, Manchester, UK, 1985

[18] Swamee, P. K., Jain, A. K., Explicit Equations for Pipe-Flow Problems, J. Hydraulic Div. Proc. ASCE,

102 (1976), 5, pp. 657-664

[19] Winterbone, D. E., Pearson, R. J., Theory of Engine Manifold Design. Wave Action Methods for IC

Engines, Professional Engineering Publishing, London, 2000

Paper submitted: April 17, 2011

Paper revised: May 3, 2011

Paper accepted: May 6, 2011

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Method Statement of T-Beams PDFDokument14 SeitenMethod Statement of T-Beams PDFKAmi KaMranNoch keine Bewertungen

- How To Use This ActionDokument3 SeitenHow To Use This Action16mariusNoch keine Bewertungen

- Engdyn 2014.1 ManualDokument743 SeitenEngdyn 2014.1 Manual16mariusNoch keine Bewertungen

- Catalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFDokument123 SeitenCatalog Prince Hydraulic Cylinders Valves Pump Motors Accessories PDFBruno CecattoNoch keine Bewertungen

- David Mixson - Motorcycle Smarts - Overcome Fear, Learn Control, Master Riding Well (2021)Dokument124 SeitenDavid Mixson - Motorcycle Smarts - Overcome Fear, Learn Control, Master Riding Well (2021)16mariusNoch keine Bewertungen

- Dhananjayan Uta 2502M 12145Dokument91 SeitenDhananjayan Uta 2502M 1214516mariusNoch keine Bewertungen

- Magneziu FinalDokument98 SeitenMagneziu Final16mariusNoch keine Bewertungen

- Eco-Effectiveness of Modular Products and Fleets Within The Automotive IndustryDokument228 SeitenEco-Effectiveness of Modular Products and Fleets Within The Automotive Industry16mariusNoch keine Bewertungen

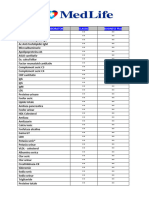

- Lista Analizelor Incluse in Pachetele de Beneficii MedlifeDokument12 SeitenLista Analizelor Incluse in Pachetele de Beneficii Medlife16mariusNoch keine Bewertungen

- SV650 Parts FicheDokument64 SeitenSV650 Parts FicheJb HarradineNoch keine Bewertungen

- C. Echipament ElectricDokument46 SeitenC. Echipament ElectricSmaranda MititeluNoch keine Bewertungen

- FZ6 MaintenanceDokument2 SeitenFZ6 Maintenance16mariusNoch keine Bewertungen

- 181Dokument10 Seiten18116mariusNoch keine Bewertungen

- WPG DocloadDokument212 SeitenWPG Docload16mariusNoch keine Bewertungen

- RoughnessDokument7 SeitenRoughnesssptbalaNoch keine Bewertungen

- 8c27d Manual en Ro BGDokument58 Seiten8c27d Manual en Ro BGCraciun DanielNoch keine Bewertungen

- حساسات الكراون PDFDokument15 Seitenحساسات الكراون PDFMarranNoch keine Bewertungen

- Akinlade ThesisDokument298 SeitenAkinlade Thesis16mariusNoch keine Bewertungen

- Flores 2006 JFMDokument20 SeitenFlores 2006 JFM16mariusNoch keine Bewertungen

- Viscous Flow in DuctsDokument13 SeitenViscous Flow in DuctsLászló CzétányNoch keine Bewertungen

- Ryan Everett Honors Thesis GaleriiDokument109 SeitenRyan Everett Honors Thesis Galerii16mariusNoch keine Bewertungen

- 10 M M Rahman 29072010 8 CleanDokument14 Seiten10 M M Rahman 29072010 8 CleanPaul Praveen PeterNoch keine Bewertungen

- Ryan Everett Honors Thesis GaleriiDokument109 SeitenRyan Everett Honors Thesis Galerii16mariusNoch keine Bewertungen

- 2007 - Terry HendricksDokument181 Seiten2007 - Terry Hendricks16mariusNoch keine Bewertungen

- Full Text ThesisDokument239 SeitenFull Text Thesis16mariusNoch keine Bewertungen

- 10 M M Rahman 29072010 8 CleanDokument14 Seiten10 M M Rahman 29072010 8 CleanPaul Praveen PeterNoch keine Bewertungen

- 239Dokument30 Seiten23916mariusNoch keine Bewertungen

- Universitatea Tehnică Din Cluj-Napoca: Material: Data: Scara: Verificat DesenatDokument1 SeiteUniversitatea Tehnică Din Cluj-Napoca: Material: Data: Scara: Verificat Desenat16mariusNoch keine Bewertungen

- !etd - Send FileDokument272 Seiten!etd - Send File16mariusNoch keine Bewertungen

- Dac Lab 5Dokument14 SeitenDac Lab 516mariusNoch keine Bewertungen

- Kingspan 30 GSNDokument1 SeiteKingspan 30 GSNNoella AguiarNoch keine Bewertungen

- Total Aircraft Washing System: Mudmaster Mudmaster MudliteDokument2 SeitenTotal Aircraft Washing System: Mudmaster Mudmaster MudliteAli Abu ShhiwaNoch keine Bewertungen

- Manuel Alava 01-12-10 PLDokument3 SeitenManuel Alava 01-12-10 PLAshley RodriguezNoch keine Bewertungen

- LEM 91-161 Fla E 0612Dokument13 SeitenLEM 91-161 Fla E 0612Julen IturriozNoch keine Bewertungen

- 6 Chapter 6 9781786393814Dokument41 Seiten6 Chapter 6 9781786393814yunicenjeNoch keine Bewertungen

- CP Inf4Dokument357 SeitenCP Inf4Rugwed JadhavNoch keine Bewertungen

- Carcass Strength Relationships Conveyor BeltsDokument9 SeitenCarcass Strength Relationships Conveyor Beltseduardo_chaban100% (1)

- Comparative Superlative With Key PDFDokument1 SeiteComparative Superlative With Key PDFAnonymous 8AHCMsPuNoch keine Bewertungen

- Abnormal Uterine Bleeding - Surgical ManagementDokument14 SeitenAbnormal Uterine Bleeding - Surgical ManagementNikhil DevNoch keine Bewertungen

- Intercont Tersus DatasheetDokument5 SeitenIntercont Tersus DatasheetJocemir FerstNoch keine Bewertungen

- HorticultureDokument12 SeitenHorticultureवरुण राठीNoch keine Bewertungen

- Web Based Bus Tracking SystemDokument4 SeitenWeb Based Bus Tracking SystemKrishna EelaNoch keine Bewertungen

- Listening DictationDokument3 SeitenListening DictationThảo ĐinhNoch keine Bewertungen

- Bushing TestingDokument8 SeitenBushing TestingjoseNoch keine Bewertungen

- Parasites in Reptile PDFDokument21 SeitenParasites in Reptile PDFRamadhani SyafitriNoch keine Bewertungen

- Who Has Allergies & Why: Allergies, Also Known As Allergic Diseases, Are A Number of Conditions Caused byDokument6 SeitenWho Has Allergies & Why: Allergies, Also Known As Allergic Diseases, Are A Number of Conditions Caused byJun Dl CrzNoch keine Bewertungen

- Infant of A Diabetic MotherDokument17 SeitenInfant of A Diabetic MotherLovina Falendini AndriNoch keine Bewertungen

- Bold Face Actions - G 450Dokument4 SeitenBold Face Actions - G 450sohaib arifNoch keine Bewertungen

- Chemistry Lab ReportDokument9 SeitenChemistry Lab Reportapi-327824087Noch keine Bewertungen

- Catalogo Smartline Transmitter Family Ferrum Energy 变送器Dokument12 SeitenCatalogo Smartline Transmitter Family Ferrum Energy 变送器peng chaowenNoch keine Bewertungen

- IJHIM 6 - Nur Husnina (36 SD 42)Dokument7 SeitenIJHIM 6 - Nur Husnina (36 SD 42)RSU Sayang BundaNoch keine Bewertungen

- Architecture of HimalayasDokument3 SeitenArchitecture of HimalayasAndrea CaballeroNoch keine Bewertungen

- Chapter 6 Introduction To Thermodynamics PDFDokument17 SeitenChapter 6 Introduction To Thermodynamics PDFSaurav PaulNoch keine Bewertungen

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterDokument14 SeitenDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazNoch keine Bewertungen

- Unit II Construction PracticesDokument61 SeitenUnit II Construction PracticesiploguNoch keine Bewertungen

- Strength of Materials: 2. Assume Missing Data, If Any, SuitablyDokument2 SeitenStrength of Materials: 2. Assume Missing Data, If Any, SuitablynvnrevNoch keine Bewertungen

- American National Standard Safety Signs: ANSI Z535.1-2016Dokument42 SeitenAmerican National Standard Safety Signs: ANSI Z535.1-2016Luis Enrique GonzalesNoch keine Bewertungen

- Effect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionDokument13 SeitenEffect of Chloride Ions On The Corrosion of Galvanized Steel Embedded in Concrete Prepared With Cements of Different CompositionAbubakar Yakubu YakubuNoch keine Bewertungen