Beruflich Dokumente

Kultur Dokumente

Ventilation

Hochgeladen von

ZuberYousufCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Ventilation

Hochgeladen von

ZuberYousufCopyright:

Verfügbare Formate

S

m

o

k

e

C

o

n

t

r

o

l

Colt Car Park

Ventilation Systems

Introduction

Front Cover:The Postbox Apartments, Birmingham

2

CAR PARK VENTILATION SYSTEMS

Car park ventilation systems are required

to achieve two objectives.

Firstly, when the car park is in general

use, it is important that the exhaust gases

produced by vehicles are effectively

removed and that there are no pockets of

stagnant air.

Secondly, in the event of a fire, assistance

needs to be given to the Fire Service to

clear smoke from the car park during and

after the fire.

Car park ventilation systems may in

addition be designed to provide clear

smoke free access for fire fighters to

tackle the seat of the fire, or alternatively

to protect means of escape from the car

park. These more complex systems are in

excess of Building Regulations

requirements and are used as

compensating features when other

requirements are not met.

This leaflet is intended to provide an

understanding of the legislative framework

and how car park ventilation systems can

help meet legislative requirements and

achieve the design objectives.

LEGISLATION AND STANDARDS

The ventilation requirements for car parks

are detailed in:

I Approved Document B to the Building

Regulations (England and Wales);

Scottish Buildings Standards Technical

Handbooks (Scotland); Technical

Booklet E (Northern Ireland).

I Approved Document F - Ventilation

I BS 7346-7: 2006

I CFD Modelling for Car Park

Ventilation Systems a guide for

designers and regulators (FETA, 2007)

I BS 5588 Series

I APEA Code of Practice

I SVA guidance

I BR 368

With regards to BS 7346-7: 2006,

Components for Smoke and Heat Control

Systems. Code of practice on functional

recommendations and calculation

methods for smoke and heat control

systems for covered car parks, this

gives design guidance on ventilation of

car parks, including both Building

Regulations compliant systems and fire

engineered systems.

The Approved Documents describe three

traditional methods of ventilation for car

parks, as follows.

1. Open Sided Car Parks

These are completely above ground level

with permanent wall openings on each

level, equal to 5% of the plan area,

arranged to provide cross ventilation.

These openings are considered to provide

sufficient ventilation for clearance of both

smoke and vehicle exhaust fumes.

2. Naturally Ventilated Car Parks

These have permanent wall openings on

each level, equal to 2.5% of the plan area,

arranged to provide cross flow ventilation.

This is sufficient ventilation

for smoke clearance, but in addition

mechanical extract providing three air

changes per hour is needed to remove

exhaust fumes.

Note: The 5% and 2.5% areas are defined

in the 2006 edition of Approved

Document F as "equivalent areas". For

openings that are obstructed in any way,

by louvres, screens, etc, the aerodynamic

coefficient of the obstruction is required

for the calculation of the equivalent area.

3

3. Mechanically Ventilated Car Parks

Where natural ventilation is not possible, a

mechanical extract system should be used.

For mechanically ventilated car parks, the

basic requirements are that there should be

a mechanical ventilation system that will

provide 6 air changes per hour (ACH) for

general ventilation on all levels and 10

ACH on the fire floor in the event of a

fire. The system should be capable of

operating at temperatures of up to 300C

for 60 minutes and ductwork and fixings

should be made from materials that have a

melting point above 800C. The system

should have at least 2 extract fans, each

providing 50% of the extract, with a

secondary power supply to operate in the

event of a mains power failure. Extract

points should be designed with 50% of the

outlets at high level and 50% at low level.

Colt Car Park Ventilation Systems can be

designed to meet the requirements of other

international standards such as the NFPA

and Australia/New Zealand standards, and

Colt has installations of Car Park

Ventilation Systems in many countries

around the world.

We would be pleased to assist you in the

development of designs for your car park

wherever it may be.

There are a number of issues relating to

ducted mechanical extract systems which

often cause problems for designers:

I The ductwork runs underneath the

ceiling, reducing the already restricted

height normally available.

I Downstand beams require the ducting

to be set down below them, thus

diminishing the height even further.

I Low level extract points are required,

often needing protective barriers to

surround them, and these take up

valuable floor space.

I The ductwork gives the car park a

cluttered look and can interfere with

CCTV coverage.

MECHANICALLY VENTILATED CAR PARKS

East Side Plaza, Gunwharf Quays, Portsmouth

8 Cyclone induction fans and 3 Jetstream impulse fans

move the air from the entrance ramp towards the

extract system, which was also supplied by Colt.

4

Impulse Ventilation Systems

CAR PARK FIRES 2002

I 116 fires (estimated)

occurred in car park

buildings

I Of these 60 fires started in

vehicles

I One of the 60 cases spread

to 9 other vehicles. 1 fire

spread to 1 other vehicle

I Approx 50% of fires were

deliberate

I At least 2 cases of fires in

car park buildings of 14

storeys

Source:BRE

WHAT ARE IMPULSE VENTILATION

SYSTEMS?

In recent years jet fan or impulse

technology has established itself as the

new standard in car park ventilation.

Impulse ventilation systems are an

alternative to ducted mechanical extract

systems, overcoming many of the

problems associated with such systems.

An impulse fan is similar to a tunnel jet

fan, but has a reduced diameter in order to

maximise headroom. It comprises an axial

fan with inlet and exhaust attenuators and

any necessary guards and flow distribution

control devices.

A series of such free- blowing fans,

mounted under the ceiling, induce air

movement from the air inlet openings

towards pre-designated extract points,

moving smoke and fumes with it. The

number and location of fans are carefully

chosen to match the system design

requirements, and in order to ensure that

there are no dead spots for fumes and

smoke to stagnate and collect.

FEATURES AND BENEFITS OF IMPULSE

SYSTEMS

Easier and quicker installation - Impulse

fans are much quicker and easier to install

than extensive ducting

Lower excavation costs - Low profile

fans can be kept within downstand beams

Lower maintenance - No distribution

ductwork to clean

Optimal use of space - Increased

headroom or lower car park build height,

with an increased number of parking bays

Better car park security - No ducting

improves CCTV coverage, keeping the

environment safer and lighter

Sprinklers - Impulse systems are

eminently suitable for use with sprinkler

systems. Where legislation requires

sprinklers, it is possible for the approving

authority to accept the deletion of

sprinklers where an improved car park

ventilation will be installed. In this

instance, the impulse system will need to

be able to maintain clear access conditions

for fire-fighters.

5

The principles of car park impulse ventilation have been developed from procedures used for tunnel ventilation. In the event of a fire, smoke will be pushed and

pulled to the exit. Vehicles in front of the fire will continue through to the exit, whilst vehicles behind the fire will, of course, have to stop. Although trapped, these

vehicles should be safe from the smoke.

vehicle stopped vehicle stopped vehicles will continue driving to the exit

Fan Fan

Tunnel entrance,

fresh air inlet

Fans add momentum to both

the airflow and smoke flow

Colt CPV Unit

CO Detectors

(typically every 400m

2

)

Smoke Detectors

The introduction of CO detectors allows use of a more

sophisticated control system to match the ventilation

rate to the car park usage, further reducing running

costs and noise levels.

Fan positioning needs to take into account roof

geometry (particularly deep downstand roof

beams) and risk of airflow blockage by tall vehicles.

Becad Hospital, Middlesex

By re-assessing the design, Colt was able to

reduce a competitor's 35 impulse fans to 12

Cyclone induction fans.

6

The Colt Jetstream Impulse Unit

THE COLT JETSTREAM IMPULSE UNIT

General description

The Jetstream impulse unit comprises an

axial fan with inlet and discharge

attenuators. Its two sizes, 315mm and

400mm fan diameter, give either 335mm

or 427mm total depth.

Versions

Versions are available to match most

customer requirements:

- Two fan sizes, 400mm and 315mm

diameter, with overall depths of

427mm and 335mm respectively

- Thrusts of up to 50N and 20N

respectively

- Uni-directional or truly reversible for

additional design flexibility

- Two speed, or single speed with

potential for inverter control

- Ambient or high temperature smoke

operation

- A range of attenuator options

Finishes

Jetstream is hot dipped galvanised, with

the option of any polyester powder coating

to a RAL colour. A polyester powder light

grey coating RAL 7035 is standard.

Certification

Jetstream and its standard isolator fully

meet the F300 time/ temperature

classification of the EN 12101-3:2003

standard following independent tests,

demonstrating that the unit will operate at

300C for 120 minutes. It is CE marked.

Test Certificates are available on request.

Noise output

CIBSE Guide Volume A: 2006,

Environmental Design, sets out a

recommended maximum noise level of

NR55 in car parks. All Colt Jetstream

units are designed to achieve a maximum

noise level of NR55 within the car park at

3m from the unit in normal day to day

operation.

Type Jetstream 400 Jetstream 315

CE marking High temperature High temperature

300C for two hours 300C for two hours

Fan diameter 400mm 315mm

Overall height A 427mm 335mm

Overall width C 445mm 400mm

Overall length B 2880mm 1990mm

Thrust 50/ 15* N 20/ 5* N

Motor power 1.3/ 0.28* kW 0.75/ 0.17* kW

* With two speed controls

C

A

B

7

FEATURES AND BENEFITS

Proven performance Independently

tested and certified in accordance with EN

12101-3: 2002

Durable Hot dipped galvanized finish

with a 4mm thick fan casing, resistant to

potential corrosion.

Adjustable pitch aerofoil section

impellers, set and tested in the factory, to

provide optimum aerodynamic

performance.

A minimum protection to IP55 on fan

electrics enables fan maintenance and

cleaning by pressure washing. External

padlockable isolator switch protected to

IP65.

Slimline appearance - Standard version

uses spigot fixing of attenuators and

streamlined attenuator lining to maintain a

slim, clean profile.

Truly reversible - For additional design

flexibility, as part of a comprehensive

scheme, the control system can direct the

airflow in either direction.

A wide variety of silencer arrangements

are available to suit noise criteria.

Quality of manufacture Jetstream is

manufactured under the BS EN 9001

quality standard. Each unit is given a

functional test before despatch.

A Colt impulse ventilation system has been installed at the new

Emirates Stadium, constructed by Sir Robert McAlpine Ltd for

Arsenal Football Club, in north London. Colt also supplied plant

room louvres in a contract worth 1.2 million in total.

The Colt impulse system consists of 59 reversible Jetstream

fans, four 1800mm extract fans, and all their associated carbon

dioxide, smoke and heat detectors and controls.The fans are

mounted under the ceiling around the car park, to move air and

smoke towards each extraction point, avoiding the need for the

extensive ductwork that would be required for a traditional

system.

The benefits of the system include a more open environment,

better CCTV coverage and lower initial and running costs. In

the interests of maximum efficiency, with the reversible impulse

fans linked to a wind direction sensor, the system can move the

airflow around the car park in either a clockwise or anti-

clockwise direction depending on the wind direction.

CASE HISTORY

Arsenal

ARCHITECT: HOK Sport

MAIN CONTRACTOR: Sir Robert McAlpine

SERVICES CONSULTANT: Buro Happold

8

The Design Approaches

THE DESIGN APPROACHES

Smoke Clearance

The systems described in Approved

Documents B and F are not intended to

assist means of escape in case of fire, but

to assist fire fighters by providing smoke

clearance. Even a casual inspection of the

requirements shows that these methods

cannot be expected to do more than limit

smoke density and speed smoke clearance

once the fire is extinguished.

Where impulse fans are used, they are

located over the roadways in a layout

engineered to ensure there are no areas

where it would be possible for fumes to

build up due to lack of air movement. In

most car parks only a single large extract

point is required, located as far as possible

from the main air inlet openings. This

method satisfies the requirements of both

Approved Documents.

These systems are suitable for use in

sprinkler protected car parks. Close

co-ordination is needed to maximise the

benefits of both sprinklers and ventilation.

Smoke Control

The alternative approach is to control

smoke movement in order to provide clear

access for fire-fighters to tackle the source

of the fire. The system requires an

addressable fire detection system so that

the site of the fire can be pinpointed. A

control system then starts the selected

impulse and extract fans to control the

direction of the smoke and provide clear

air upstream of the fire. This will allow

fire fighters to access the car park behind

the fire and bring it under control.

By virtue of the improved fire-fighter

access it may be possible to delete

sprinklers from car parks where they

would otherwise be needed.

This method can also be used to protect

means of escape in large car parks with

excess travel distances. However it is

generally a more expensive option,

requiring more complex controls and

additional extract.

CFD

Design of impulse systems is usually

proven by use of CFD (Computational

Fluid Dynamic) analysis.

This allows detailed computation of

airflow in car parks, taking into account

the often complex geometry of individual

buildings. This is often essential to

demonstrate to the local authority that

designs will perform satisfactorily, by

showing that sufficient air movement is

provided throughout the car park and, for

smoke control systems, the extent of the

smoke spread.

CFD modelling has the objective of

confirming the viability of the ventilation

scheme. Colt offers CFD modelling of the

system and a full technical report for local

authority approval prior to installation.

Just to be sure that its CFD modelling

approach was reliable, Colt undertook a

series of empirical full scale hot smoke

tests. See next section.

Since CFD is a key component of car park

ventilation design, and there has been

inadequate guidance on this element,

members of the Smoke Control

Association have produced A Guide to

CFD in Car Parks to complement BS

7346-7. The guidance will make it easier

for designers to validate their designs and

for building control bodies to sanction

them. This guide is available from the

Federation of Environmental Trade

Associations.

9

Typical CFD plan of a typical car park

CFD showing air speed contours at low

level for smoke control

CFD plan of a typical car park showing

Colt Cyclone fan locations, openings

and areas

Air speed contours at high level,

day-to-day ventilation

Air speed contours at low level,

day-to-day ventilation

The Observatory Apartments,Walsall

10

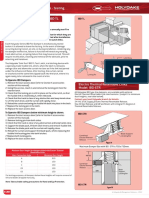

Testing

TESTING UNDERTAKEN BY COLT

In 2004 Colt conducted the first UK full

scale comparative tests between traditional

methods of mechanical ventilation and

impulse ventilation in Bristol.

These tests demonstrated that properly

designed impulse systems can clear the

smoke more quickly than ducted systems.

For more information please see leaflet:

PD 56 Full Scale live Smoke Tests.

A video is available to view at

www.coltinfo.co.uk.

The table shows the range of times taken in the demonstrations to achieve visibility

distances and for the car park to become clear of smoke.

VISIBILITY

Traditional Impulse Induction

10 metres At start 1 minute 1.5 minutes

3.5 minutes 8 minutes 6 minutes

13 minutes 13 minutes 9.5 minutes

23 minutes 16 minutes 12.5 minutes

27 minutes 18.5 minutes 16.5 minutes

41.5 minutes 32.5 minutes 28 minutes

20 metres

30 metres

40 metres

Rear wall details

Clear of smoke

SYSTEM

The Deputy Chief Fire Officer of Avon

Fire & Rescue, Jerry OBrien commented

The speed that the new products cleared the

smoke compared to the old ducted system that

we and maybe some others are using, is just

remarkable. It is very impressive

11

In 2005 Colt carried out large scale hot

smoke testing with the Building Research

Establishment (BRE) in Middlesbrough to

prove both the concept of maintaining

clear areas in a car park and to validate the

CFD modelling approach used by Colt.

The aim of the tests was to demonstrate

how an impulse ventilation system can be

used to control the flow of smoke within a

car park, keeping large areas effectively

smoke free.

The results of the tests clearly indicated

that impulse systems are capable of

controlling the spread of smoke from a car

fire and keeping significant areas of a car

park effectively smoke free. BRE

confirmed that the smoke movement

during the fire with the impulse fans

running was as predicted by the CFD

modelling Colt had carried out before the

tests. For more information please see

leaflet PD 61Impulse Ventilation for

Smoke Control. A video of the tests is

available to view at www.coltinfo.co.uk.

Average smoke temperatures (

o

C)

Time period from ignition Location Measured CFD

210-310s A, 1m above floor 23.4 25.8

210-310s A, 2m above floor 25.9 30.0

210-310s B, 1m above floor 22.0 20.7

210-310s B, 2m above floor 25.8 25.3

210-310s C, 1m above floor 22.6 22.1

210-310s C, 2m above floor 32.1 30.2

Ambient 18.8-19.3 20.0

The table shows time averaged smoke temperatures as recorded during the

demonstrations and predicted by the CFD analysis.

Fire hardened area

600mm downstand

20000

10000

Car

Cyclone

Impulse

Fan

Internal rig size

30m x 35m x 3m high

Containers located to

minimise wind effects

Containers located to

minimise wind effects

2400

35000

END SECTION

3

0

0

0

0

7

2

0

0

7

2

0

0

3

0

0

0

0

7

2

0

0

7

2

0

0

2

4

0

0

3000

G

r

d

l

e

v

e

l

INDUCTION VENTILATION SYSTEMS

Induction ventilation is a further

enhancement of the impulse ventilation

concept.

Using the same principles as impulse

ventilators, induction fans are yet slimmer,

more efficient and powerful, thus reducing

the number of units required. A typical

induction fan has a throw of

approximately 40 m as opposed to 20 m

for an impulse fan. The floor area

ventilated per fan is significantly greater,

equating to a requirement for fewer units.

Slimmer units can allow a reduced

excavation cost and lower car park height.

For comparison purposes, a typical

Impulse Unit such as the Colt Jetstream is

427mm deep, a Colt Cyclone 100 is

320mm deep and a Colt Cyclone 50 is

255mm deep. Ducted systems are often

deeper in places and need to be run under

any downstand beams whereas fans can be

located between them. This demonstrates

the potential savings both in excavation

and in build height for the developer and

contractor.

Fewer units mean lower cabling and

controls requirements and lower

installation and maintenance costs.

In addition, the units are inverter

controlled for a further reduction in power

consumed.

Induction Ventilation Systems

12

Air turbulence is dramatically reduced when using a Colt Cyclone CPV fan

Air turbulence created by the downstands when using a typical impulse fan

In a recent project in the centre of London, Cyclone fans were

specified since they saved significant dig-out costs. The contractor

would have needed to speand an additional 248,000 excavating

an additional 150mm of earth in order to accommodate the greater

unit depths of an alternative system

13

CASE HISTORY

Paradise Street

ARCHITECT: BuildingDesign Partnership

MAIN CONTRACTOR: LaingORourke/Crown House

SERVICES CONSULTANT: WSP

FIRE CONSULTANT: Tenos

In 2006 Colt won the contract for what was

believed to be the UKs first smoke control

system for a car park. It has been designed

specifically to enable occupants to escape from a

car park and to assist fire-fighting crews, rather

than simply as a smoke clearance system that is

commonly applied to car parks.

The 2.5 million project - part of Liverpools

920 million Paradise Street retail, leisure and

residential development- has involved the supply

and installation of a Colt impulse car park

ventilation system for the massive 56,000m

2

,

2,000-space car park that is being built beneath

Chavasse Park in Liverpool.

The four-storey underground car park has been

fitted with 80 Cyclone induction fans and 22

Jetstream impulse fans.These are designed to

keep smoke completely away from the escape

routes without the need for smoke curtains or

physical barriers.

John Perry, senior consultant at Colt, explained:

"Nearly all of the car parks we have done in the

UK so far are smoke clearance systems, not

smoke control systems.With the former, you

have a designated extract rate.

This car park is different because it is so large

(with the largest level being 232m by 95m) that

we have to move smoke from a potential fire

into defined corridors.

So, this is a fully designed scheme rather than a

simple air change rate scheme.We are not

merely clearing the smoke - we are controlling

it."

Prior to the award of the contract, engineers

from Colt and the Building Research

Establishment demonstrated the effectiveness of

the Colt impulse scheme for the Paradise Street

project by conducting a series of hot smoke

tests in a simulated car park in Middlesbrough.

These established the accuracy of CFD

modelling Colt had made before the test, and

predicted that the scheme of impulse fans would

be capable of controlling the spread of smoke

from a car fire and keeping significant areas of

the car park smoke free.

Smoke control for means-of-escape is described

on page 8. See page 19 for a schematic diagram

of this project.

COLT CYCLONE INDUCTION UNIT

General description

The Cyclone induction unit comprises a

backward curved centrifugal impeller with

a high temperature external rotor motor

rated at 300C for one hour, fitted within a

streamlined casing with a directional

outlet diffuser.

Versions

- Two fan sizes, with overall depths of

320mm and 255mm respectively

- Thrusts of 100N and 50N

- Single speed for inverter speed control

Finishes

Cyclone is supplied in polyester powder

light grey RAL 7035, with the option of a

polyester powder coating to any RAL

colour.

Certification

Cyclone 100 and 50 with their standard

isolator fully meet the F300 time/

temperature classification of the EN

12101-3:2003 standard following

independent tests, demonstrating that the

unit will operate at 300C for 60 minutes.

They CE marked. Test Certificates are

available on request.

CE

B

A

C

AIRFLOW

AIRFLOW

The Colt Cyclone Induction Unit

Type Cyclone 100 Cyclone 50

CE marking High temperature High temperature

300C for one hour 300C for one hour

Unit height A 320mm 255mm

Unit length B 1670mm 1260mm

Unit width C 1150mm 820mm

Overall depth 320mm 255mm

Thrust 100 N 50 N

Motor power 2.6 kW 1.4 kW

14

Noise output

CIBSE Guide Volume A: 2006,

Environmental Design, sets out a

recommended maximum noise level of

NR55 in car parks. All Colt Cyclone units

are designed to achieve a maximum noise

level of NR55 within the car park at 3m

from the unit in normal day to day

operation. Lower noise levels are possible

on request.

FEATURES AND BENEFITS

Slimline design Only 320mm or 255mm

deep.

Proven performance Independently

tested and certified in accordance with

EN 12101-3: 2002.

Durable The streamlined casing is

manufactured from 3mm 2-pack epoxy

coated steel with directional outlet

diffuser.

Quality of manufacture Cyclone is

manufactured under the BS EN 9001

quality standard. Each unit is given a

functional test before despatch.

15

The Postbox, Upper Marshall St, is a large mixed use

development comprising apartments and office space in Central

Birmingham spread over three blocks.

Colt provided smoke control systems for the apartment

corridors and underground car park.

On each of the two levels of the car park, four Colt Cyclone

induction fans move the air from the entrance ramp towards

the extract system, which has also been supplied by Colt.The

Colt extract system comprised attenuated high temperature

axial fan units. Colt also provided a main control system as well

as addressable carbon monoxide detectors. For day to day

operation the system monitors the carbon monoxide levels

within the car park and once a set point has been reached the

system increases the ventilation rates.

Emergency control is fully automatic from the fire alarm

detection systems or manually from the Firemans Override

Switches.

Colt was also contracted to provide the CFD report which

confirmed the viability of the ventilation scheme.

CASE HISTORY

The Postbox, Birmingham

CLIENT: Cala Homes

ARCHITECT: Ian Darby Partnership

MAIN CONTRACTOR: Taylor Woodrow

M&E CONTRACTOR: Rotary North West

EXTRACT SYSTEMS

There needs to be an adequately designed

ventilation system to extract the air. In

addition, where the natural air supply is

insufficient, supply fans may also be

required.

Depending on the scope required, Colt is

able to provide a wide variety of

mechanical extract fan and motor

assemblies to suit the required duty and

temperature rating. These include long

case, short case and plate mounted axial

fans.

There are 14 standard sizes ranging from

315mm up to 2000mm diameter, with

duties of up to 100 m

3

/s, and motor power

ratings of up to 75 kW.

All Colt extract fans have been tested to

the exacting standards of EN 12101-3:

2002.

All Colt extract systems are designed to

produce a maximum of 55 dBA externally

at 3m from the extract fan discharge

grilles and NR 55 at 3m inside the car

park in day-to-day mode. Lower noise

levels are possible on request.

Colt is able to mix and match components

to suit the requirements of almost any

mechanical extract system.

OTHER ANCILLARIES

Colt also provide:

I Ductwork, including attenuators,

grilles, volume control dampers, shut-

off dampers, bends and transitions.

I Weathered external terminations,

including louvres, dampers, turrets,

gravity shutters, cowls and motorised

ventilators such as the Seefire and

Meteor.

Extract Systems

16

Extract plant at the Observatory Apartments,Walsall

17

B5 Southside, Birmingham

2 Inlet Fans, 13 Cyclones, 2 Extract

Fans, Dampers and Grilles, CO &

Smoke Detectors

Louvre terminations at the

Observatory Apartments,Walsall

Extract fans at The Foundation, Liverpool Extract plant at Gunwharf Quays, Portsmouth

CONTROLS AND SENSORS

The design of the controls and sensors is

an integral part of the car park ventilation

system. The arrangement of sensors is

determined at the design stage, along with

the controls cause and effect, which

determines the way in which the equipment

responds to any given conditions.

Day to day condition

The simplest (but rarely used) option is to

run the system at a constant speed,

providing a ventilation rate of 6 ACH

throughout the car park. To reduce energy

costs a CO detection system is used to

allow the system to run at a reduced

ventilation rate in periods when vehicle

movements are low.

Using a single output detector, two stage

control can be provided, typically

switching at 15-20ppm of CO. Using

variable output detectors, the system can

provide additional stages or modulate to

match the ventilation rate to the car park

usage.

Fire condition

For a smoke clearance system, detection is

required to indicate which level of the car

park contains the fire, if the car park has

more than one level. Upon detection all

fans on that level operate at high speed, all

other fans are switched off and the extract

fans are switched to full speed, extracting

only from the fire level.

For a smoke control system, addressable

detection is required to pinpoint the fire

location to allow correct selection of fan

operation to maintain the required clear

areas.

Colt can provide carbon monoxide

detectors, heat/smoke sensors and fire

alarm inputs along with all their necessary

controls and battery back up facilities,

linked into an addressable fire detection

system.

Controls & Sensors

J

J

J

J

CO CO

CO CO

HD

HD HD

HD

HD HD

TYPICALCONTROLSCHEMATIC

Extract Fans Inlet Fans

Cyclone

Fans

Cyclone

Fans

Level 2

Level 1

Extract

Damper

Inlet

Damper

Colt Fan Starter Panel

Colt Fire Detection Panel

Carbon Monoxide

Detector

Heat

Detector

Carbon Monoxide

Detector

Heat

Detector

Fire

Rated

Isolator Junction

Box

Junction

Box

Level 1

Loop

Level 2

Loop

Output to Cyclone Fans

Shown left is a typical control system for a two level

car park with CO control, mechanical exhaust and

mechanical inlet

Inlet

Damper

Extract

Damper

18

The Postbox Birmingham

CO Detector

TYPICALSYSTEMDESIGN SCHEMATIC

Extraction via Colt Defender dampers

and AFC ventilators through risers to

roof level extract plant

19

Inlet plenums with airflow controlled

by Colt volume control dampers

Paradise Street Car Park Level B1

Please turn to page 13 for a brief description of this project

Control panel manufactured by Colt undergoing final inspection

Gunwharf Quays, Portsmouth

Air Movement

South side supply air

OTHER REASONS TO CHOOSE COLT:

Colt Smoke Control systems are suited to

both commercial and industrial

buildings, and may be adapted to suit

most architectural requirements.

Over the years Colt has funded a large

proportion of the research into smoke

control, and its representatives maintain

an unparalleled level of technical

expertise.

Colts CFD modelling approach is

reliable and has been confirmed by

empirical full scale hot smoke tests.

Colt's in-house research and

development capability ensures that Colt

fire protection systems are designed,

tested and updated by Colt to meet or

exceed relevant legislation and standards.

The majority of Colt's Smoke Control

systems are manufactured in the UK

under BS EN ISO 9001:2000 and BS EN

ISO 14001:2004.

COLT SERVICE

Part of the Colt Group of companies,

Colt Service offers a comprehensive

range of maintenance packages

incorporating the maintenance and

repair of all building services equipment

including non Colt products.

Colt Service provides a 24 hour, 365

day emergency cover as standard.

MAINTENANCE

Maintenance of a smoke control system

is essential. Regular maintenance

protects your investment and brings

peace of mind that the system will

operate effectively in an emergency.

British Standard BS 5588-12

recommends that smoke control systems

should be serviced at least once a year

and tested weekly.

THE COLT PACKAGE

Colt can offer the complete package,

which could include:

I Scheme design. CFD analysis and

report

I Supply of impulse fans, extract and/or

inlet fans, ductwork (for extract) and

dampers, control systems and wiring,

CO and heat/smoke detectors

I Installation and wiring

I Commissioning

I Service and maintenance.

A free full system check will be carried

out approximately 9 months after a

Smoke Control System has been installed

and commissioned by Colt. Besides the

opportunity to check that the system is

performing as designed, this will allow

for any further training of local personnel

that may be necessary. Assuming that this

visit falls within the warranty period, any

defective parts would be replaced free of

charge. A test certificate will be issued.

S

u

b

j

e

c

t

t

o

m

o

d

i

f

i

c

a

t

i

o

n

.

P

u

b

l

i

c

a

t

i

o

n

n

u

m

b

e

r

P

D

5

2

:

0

2

/

0

8

V

4

C

o

l

t

a

n

d

t

h

e

C

o

l

t

l

o

g

o

a

r

e

r

e

g

i

s

t

e

r

e

d

t

r

a

d

e

m

a

r

k

s

o

f

C

o

l

t

I

n

t

e

r

n

a

t

i

o

n

a

l

L

i

c

e

n

s

i

n

g

L

i

m

i

t

e

d

.

C

o

l

t

I

n

t

e

r

n

a

t

i

o

n

a

l

L

i

c

e

n

s

i

n

g

L

i

m

i

t

e

d

2

0

0

8

.

People feel better in Colt conditions

C

o

l

t

I

n

t

e r n

a

t

i

o

n

a

l

1

9

3

1

-

2

0

0

6

Colt International Limited

New Lane Havant

Hampshire PO9 2LY

Tel +44(0)23 9245 1111

Fax +44(0)23 9245 4220

info@coltgroup.com

www.coltinfo.co.uk

Architectural Solutions

Climate Control

Smoke Control

Service and Maintenance

AMember of the British ParkingAssociation

Das könnte Ihnen auch gefallen

- Technical Document On Smoke Extract & Car Park FansDokument4 SeitenTechnical Document On Smoke Extract & Car Park FansTanveer AzizNoch keine Bewertungen

- % Outdoor Air CalculationDokument6 Seiten% Outdoor Air Calculationamirin_kingNoch keine Bewertungen

- Calculation ExamplesDokument42 SeitenCalculation ExamplesGregNoch keine Bewertungen

- Car Park Ventilation System DesignDokument13 SeitenCar Park Ventilation System Designnakul4491_88890127100% (1)

- The Essentials of Chilled Beams - Part 2: Skills WorkshopDokument3 SeitenThe Essentials of Chilled Beams - Part 2: Skills WorkshoprkibNoch keine Bewertungen

- A Presentation On: Basement VentilationDokument7 SeitenA Presentation On: Basement Ventilationsachin231979100% (1)

- Aldesme - Flash25 Stair PressurisationDokument8 SeitenAldesme - Flash25 Stair PressurisationjaicektmNoch keine Bewertungen

- Ventilation of The Industrial Environment PDFDokument7 SeitenVentilation of The Industrial Environment PDFnelson escuderoNoch keine Bewertungen

- M149content PDFDokument41 SeitenM149content PDFMohamed MasryNoch keine Bewertungen

- Rainwater DesignDokument64 SeitenRainwater DesignarifzakirNoch keine Bewertungen

- ASHRAE Duct Noise Vs VelocityDokument1 SeiteASHRAE Duct Noise Vs Velocityasdthu100% (1)

- Duct Systems DesignDokument4 SeitenDuct Systems DesignFsNoch keine Bewertungen

- Technical Handbook Air CurtainsDokument13 SeitenTechnical Handbook Air Curtainsaca111111Noch keine Bewertungen

- Assignment MechanicalDokument5 SeitenAssignment MechanicalSoufiane RamdaniNoch keine Bewertungen

- Cooling Towers - Source Prediction, Modelling, Specification and Noise Control (Derrick)Dokument15 SeitenCooling Towers - Source Prediction, Modelling, Specification and Noise Control (Derrick)binho58Noch keine Bewertungen

- Basics of Duct DesignDokument2 SeitenBasics of Duct DesignApurv Goyal100% (1)

- Advanced Air Duct Design Part 2Dokument29 SeitenAdvanced Air Duct Design Part 2Timothy Bryant100% (1)

- Air Curtain Guide DesignDokument8 SeitenAir Curtain Guide Designanton7786Noch keine Bewertungen

- Staircase Pressurisation CalculationDokument1 SeiteStaircase Pressurisation CalculationMohammed Faisal Siddiqui100% (1)

- Kitchen HoodDokument10 SeitenKitchen HoodkumarNoch keine Bewertungen

- HVAC in Hospital PDFDokument7 SeitenHVAC in Hospital PDFMohammed Toema100% (1)

- Ides-Edu: Lecture 7: Sizing Natural Ventilation SystemsDokument17 SeitenIdes-Edu: Lecture 7: Sizing Natural Ventilation Systemsabhijeet7362Noch keine Bewertungen

- High Rise Mechanical DesignDokument55 SeitenHigh Rise Mechanical DesignTristan Rice100% (2)

- HVAC Load Calculation FundamentalsDokument3 SeitenHVAC Load Calculation Fundamentalssivajirao70Noch keine Bewertungen

- CAL-03 - Staircase Pressurization CalculationDokument4 SeitenCAL-03 - Staircase Pressurization CalculationAbdul Sami100% (1)

- 01-Pressurization Staircase Fan Calculation SheetDokument9 Seiten01-Pressurization Staircase Fan Calculation SheetHamdy AdelNoch keine Bewertungen

- Review On Design Guides For Smoke Management System in An AtriumDokument23 SeitenReview On Design Guides For Smoke Management System in An AtriumArgile-assholeNoch keine Bewertungen

- Staircase Pressurization Calculation SheetDokument4 SeitenStaircase Pressurization Calculation SheetsmcsamindaNoch keine Bewertungen

- HVAC noise722201320446PM1 PDFDokument90 SeitenHVAC noise722201320446PM1 PDFMohammed Jassim100% (2)

- DampersDokument25 SeitenDampersmpwasaNoch keine Bewertungen

- Design Course Basic - Duct Design 1Dokument30 SeitenDesign Course Basic - Duct Design 1Ali Aimran100% (1)

- Energy Conservation: ASHRAE Standard 90.1. Each New BuildingDokument4 SeitenEnergy Conservation: ASHRAE Standard 90.1. Each New BuildingdemuthuNoch keine Bewertungen

- Kitchen Ventilation ExampleDokument4 SeitenKitchen Ventilation ExamplePretty NatyNoch keine Bewertungen

- Ventilation RatesDokument4 SeitenVentilation RatesReza KhajeNoch keine Bewertungen

- Howden Tunnel VentillationDokument22 SeitenHowden Tunnel Ventillationaastra56Noch keine Bewertungen

- Acmv Technical ReportDokument10 SeitenAcmv Technical Reportarun kurlanNoch keine Bewertungen

- Staircase Pressurization Fan, What Is The Equation To Calculate The Air Flow and Static Pressure For Fan - Bayt PDFDokument3 SeitenStaircase Pressurization Fan, What Is The Equation To Calculate The Air Flow and Static Pressure For Fan - Bayt PDFDesigner ForeverNoch keine Bewertungen

- Duct Presentation MaineDokument22 SeitenDuct Presentation MaineCharmaine ManliguezNoch keine Bewertungen

- Ventilation Fans All RevisedDokument6 SeitenVentilation Fans All RevisedBilal Hussein SousNoch keine Bewertungen

- Direct Expansion Air ConditioningDokument1 SeiteDirect Expansion Air ConditioningPrabhat Kumar100% (1)

- Kubilay2015 PDFDokument18 SeitenKubilay2015 PDFBorisBerezovsky100% (1)

- Carrierdes1 PDFDokument163 SeitenCarrierdes1 PDFDomingo RuizNoch keine Bewertungen

- Dehumidification Equipment Advance ASHRAE Journal PDFDokument6 SeitenDehumidification Equipment Advance ASHRAE Journal PDFThomás ArévaloNoch keine Bewertungen

- Mechanical Ventilation and Smoke Control SystemsDokument45 SeitenMechanical Ventilation and Smoke Control SystemsmitasyahuNoch keine Bewertungen

- Tunnel Fire Ventilation CalculationsDokument6 SeitenTunnel Fire Ventilation Calculationsakat zkyNoch keine Bewertungen

- LouversDokument0 SeitenLouverslara_rajkumar667Noch keine Bewertungen

- Hvac For AuditoriumDokument15 SeitenHvac For AuditoriumkomalNoch keine Bewertungen

- Fire Safety Requirements For General Warehouses PDFDokument6 SeitenFire Safety Requirements For General Warehouses PDFecruz_yhwhNoch keine Bewertungen

- Measurements of Sound Absorption CoefficientsDokument6 SeitenMeasurements of Sound Absorption CoefficientsAgustín AriasNoch keine Bewertungen

- Equal Friction MethodDokument2 SeitenEqual Friction MethodApurv GoyalNoch keine Bewertungen

- Design of Air Conditioning DuctsDokument15 SeitenDesign of Air Conditioning Ductsabidch143Noch keine Bewertungen

- Duct DesignDokument13 SeitenDuct DesignamitNoch keine Bewertungen

- HVAC Report FINALDokument65 SeitenHVAC Report FINALIanNoch keine Bewertungen

- Staircase Pressurization System TestingDokument5 SeitenStaircase Pressurization System TestingJavedNoch keine Bewertungen

- Fans For Metro Tunnel DesignDokument34 SeitenFans For Metro Tunnel Designkailasamvv100% (1)

- CP 13-1999 Mechanical Ventilation and Air-Conditioning in BuildingsDokument55 SeitenCP 13-1999 Mechanical Ventilation and Air-Conditioning in BuildingsHui HuaNoch keine Bewertungen

- Damper Pressure LossDokument2 SeitenDamper Pressure Lossfariboy123Noch keine Bewertungen

- Duct Pressure DropDokument19 SeitenDuct Pressure DropehasayinNoch keine Bewertungen

- Stair PressurizationDokument11 SeitenStair Pressurization185412Noch keine Bewertungen

- Car Park VentilCar Park VentilationationDokument20 SeitenCar Park VentilCar Park VentilationationEdward FrankNoch keine Bewertungen

- B-1 Drinking Fountain Detail - 201407301800472680Dokument1 SeiteB-1 Drinking Fountain Detail - 201407301800472680ZuberYousufNoch keine Bewertungen

- P246-MS-04-M-0026, Rev. 00 - Method Statement For Installation, Testing & Commissioning - MechanicalDokument42 SeitenP246-MS-04-M-0026, Rev. 00 - Method Statement For Installation, Testing & Commissioning - MechanicalZuberYousufNoch keine Bewertungen

- Hira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraDokument4 SeitenHira-044 Amct-Ims-Hse-6003b Permanent Mechanical Installation HiraZuberYousufNoch keine Bewertungen

- MNTQ-CW03-AMCT-MEC-MST-000002 Rev03Dokument21 SeitenMNTQ-CW03-AMCT-MEC-MST-000002 Rev03ZuberYousufNoch keine Bewertungen

- Fire Damper DROP TESTDokument1 SeiteFire Damper DROP TESTZuberYousufNoch keine Bewertungen

- P246-MS-04-M-0022, Rev - 00 - Method Statement - Installation of Drain, Clean Outs, Outlets & CowlsDokument19 SeitenP246-MS-04-M-0022, Rev - 00 - Method Statement - Installation of Drain, Clean Outs, Outlets & CowlsZuberYousufNoch keine Bewertungen

- 14-3 Metal & Plastic RoofingDokument6 Seiten14-3 Metal & Plastic RoofingZuberYousufNoch keine Bewertungen

- Design Calculation Sheet: General AssumptionsDokument8 SeitenDesign Calculation Sheet: General Assumptionszerohot890% (1)

- IOM FNWWHA Ver 9-2016Dokument4 SeitenIOM FNWWHA Ver 9-2016QC RegianNoch keine Bewertungen

- 14-5 Roofing Tiles & ShinglesDokument4 Seiten14-5 Roofing Tiles & ShinglesZuberYousufNoch keine Bewertungen

- 14-4 Roof & Deck InsulationDokument6 Seiten14-4 Roof & Deck InsulationZuberYousufNoch keine Bewertungen

- 17-3 Metal Doors & WindowsDokument10 Seiten17-3 Metal Doors & WindowsZuberYousufNoch keine Bewertungen

- Conversion TablesDokument1 SeiteConversion Tablesmass transferNoch keine Bewertungen

- 14-2 Membrane RoofingDokument16 Seiten14-2 Membrane RoofingZuberYousufNoch keine Bewertungen

- 16-10 Protective Treatment PDFDokument5 Seiten16-10 Protective Treatment PDFZuberYousufNoch keine Bewertungen

- 16 4Dokument5 Seiten16 4Francisco M. RamosNoch keine Bewertungen

- 15-3 Cold StoresDokument5 Seiten15-3 Cold StoresZuberYousufNoch keine Bewertungen

- 16-7 Accuracy of FabricationDokument9 Seiten16-7 Accuracy of FabricationZuberYousufNoch keine Bewertungen

- 16 1Dokument4 Seiten16 1Francisco M. RamosNoch keine Bewertungen

- 16 3Dokument5 Seiten16 3Francisco M. RamosNoch keine Bewertungen

- QCS SpecDokument4 SeitenQCS SpecashrafNoch keine Bewertungen

- Tuv Sud Middle East L.L.CDokument13 SeitenTuv Sud Middle East L.L.CZuberYousufNoch keine Bewertungen

- 16 6Dokument4 Seiten16 6Francisco M. RamosNoch keine Bewertungen

- 16 2Dokument6 Seiten16 2Francisco M. RamosNoch keine Bewertungen

- 16-9 Accuracy of Erected SteelworkDokument8 Seiten16-9 Accuracy of Erected SteelworkZuberYousufNoch keine Bewertungen

- 17-5 Light Metal Support & Cladding SystemDokument3 Seiten17-5 Light Metal Support & Cladding SystemZuberYousufNoch keine Bewertungen

- 17-2 Material Types & FinishesDokument9 Seiten17-2 Material Types & FinishesZuberYousufNoch keine Bewertungen

- Operation & Maintenance Manual For FM200 System Rev. 01Dokument214 SeitenOperation & Maintenance Manual For FM200 System Rev. 01ZuberYousuf50% (6)

- 17 6 WorkmanshipDokument9 Seiten17 6 WorkmanshipSaber AhmadNoch keine Bewertungen

- 17-4 Architectural Metal WorksDokument4 Seiten17-4 Architectural Metal WorksZuberYousufNoch keine Bewertungen

- Universal Alternators Catalog PDFDokument56 SeitenUniversal Alternators Catalog PDFChristopherNoch keine Bewertungen

- 26 Type Brake EquipmentsDokument8 Seiten26 Type Brake EquipmentsRafael SchelbauerNoch keine Bewertungen

- Lift Arm & BOB-TACH - S530 PDFDokument4 SeitenLift Arm & BOB-TACH - S530 PDFeduardo chavezNoch keine Bewertungen

- 530 - Dryers ManualDokument4 Seiten530 - Dryers ManualmecambNoch keine Bewertungen

- Tubo Sin CosturaDokument4 SeitenTubo Sin CosturaJl KaneNoch keine Bewertungen

- GATE 2021 Test Series 1 1 PDFDokument6 SeitenGATE 2021 Test Series 1 1 PDFSatyajit SahuNoch keine Bewertungen

- Wa5471ab SeriesDokument41 SeitenWa5471ab SeriesJahangir JinguNoch keine Bewertungen

- Twin Screw Compressor Performance and Its Relationship With RotorDokument7 SeitenTwin Screw Compressor Performance and Its Relationship With RotorSaeedAkbarzadehNoch keine Bewertungen

- 2018 Ninja400 SM-Update FinalDokument653 Seiten2018 Ninja400 SM-Update FinalThomas Zoumboulias100% (1)

- Unit 3Dokument29 SeitenUnit 3ashok Pradhan100% (1)

- CSTSB4/N4: M4 Sized Stud Type Terminal Blocks, Suitable For Operation With Screwdriver and Nut DriverDokument2 SeitenCSTSB4/N4: M4 Sized Stud Type Terminal Blocks, Suitable For Operation With Screwdriver and Nut Driversamiransw2014Noch keine Bewertungen

- GR00000900 00 PDFDokument64 SeitenGR00000900 00 PDFSaHdo AbdelHamidNoch keine Bewertungen

- Correlation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001Dokument21 SeitenCorrelation of Bendability of Materials With Their Tensile Properties Datsko Bab4480.0001.001lram70Noch keine Bewertungen

- 4 5985707401435677780Dokument3 Seiten4 5985707401435677780Ibrahim AwadNoch keine Bewertungen

- JD - Field Service EngineerDokument2 SeitenJD - Field Service EngineerRajesh PotluriNoch keine Bewertungen

- Smaw PDFDokument10 SeitenSmaw PDFArizapatazoNoch keine Bewertungen

- Refrigerator: Service ManualDokument19 SeitenRefrigerator: Service ManualCesar Calderon GrNoch keine Bewertungen

- K-Max: Industrial RangeDokument16 SeitenK-Max: Industrial RangeAMIR100% (1)

- Penawaran Overhoul Engine Acera 6.4Dokument1 SeitePenawaran Overhoul Engine Acera 6.4Aneh Bin AjaibNoch keine Bewertungen

- 06 Muttoni FernandezDokument47 Seiten06 Muttoni FernandezAltin CeroNoch keine Bewertungen

- Exp-7 Fatigue TestDokument5 SeitenExp-7 Fatigue TestdeathesNoch keine Bewertungen

- MEE322 Final Exam S20Dokument5 SeitenMEE322 Final Exam S20Nabil SweidanNoch keine Bewertungen

- Combustion Instabilities PDFDokument33 SeitenCombustion Instabilities PDFMohamed FaragNoch keine Bewertungen

- Chapter1 Intro ME651Dokument93 SeitenChapter1 Intro ME651Sahastranshu KomalangamNoch keine Bewertungen

- v1903 2203tvengineDokument46 Seitenv1903 2203tvenginehuo sun100% (1)

- BPT 13 Balanced Pressure Thermostatic Steam TrapDokument2 SeitenBPT 13 Balanced Pressure Thermostatic Steam Trapmember1000Noch keine Bewertungen

- WSS - 071 Scour Valve Installations - General Arrangement and DetailsDokument1 SeiteWSS - 071 Scour Valve Installations - General Arrangement and DetailsMyrahma Love100% (1)

- Detroit Parts 8V71 & 12V71Dokument47 SeitenDetroit Parts 8V71 & 12V71indra100% (2)

- Different Types of Moment FramesDokument2 SeitenDifferent Types of Moment FramesRazell RuizNoch keine Bewertungen

- College of Engineering - UOZ Department of Petroleum Engineering Reservoir Fluid Properties Stage: Three Student NamesDokument20 SeitenCollege of Engineering - UOZ Department of Petroleum Engineering Reservoir Fluid Properties Stage: Three Student NamesShaaban HassanNoch keine Bewertungen