Beruflich Dokumente

Kultur Dokumente

Keeping Your Control Valves in Good Health

Hochgeladen von

ashry09Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Keeping Your Control Valves in Good Health

Hochgeladen von

ashry09Copyright:

Verfügbare Formate

Keeping your control valves in good health

Whether that brand new control valve in your system is the frst one

you have ever had to look after or if you are an old hand at valve

maintenance with tens of valves in your system, there are a few simple

guidelines and reminders for keeping it operating at optimal

performance.

Initially we would recommend physically checking on your valve at

least every 12 weeks or so, assuming you everything is running fne in

the system. his inspection is really to check for any leaks in the

tubing, checking pressure gauges to ensure valve is actually doing

what it is supposed to and generally inspecting for anything that !ust

looks abnormal.

If it is determined that something is wrong, always ensure you have

the correct instruction manual for the valve. hese days all

manufacturers have these available

on their websites. "s a note of

caution, these valves ate under

pressure and care should be taken to

bleed pressure o# the valve before

you start to take any valves apart. $"s a

typical e%ample in a &' valve with

1((psi in the line, there is at least

2,)(( lbs of force trying to push that

cover o# the valve, so safety frst*+

,ome simple tasks that can be performed to ensure smooth operation

in future are outlined here-

.ilot system shut o# ballvalves

/%ercise the three isolating cocks on the main valve. hese are

located in front of the strainer on the upstream side of the valve, on

the valve bonnet on top of the valve, and below the pressure0reducing

pilot on the valve downstream. 1iving the isolating cock a momentary

2uarter turn to the closed position, then returning it to the open

position is su3cient. 4pen position is when the handle of the isolating

cock is inline with its body.

"ir in the .ilot ,ystem

"ir is your number one enemy in the pilot system as it will give false

readings and cause poor valve operation. 5leed air from the valve

bonnet. If the valve is e2uipped with a position indicator, on top of the

position indicator is a bleed cock. 4pen the bleed cock slightly by

turning the handle counter0clockwise. 4therwise, bleed the air from the

high point of the valve. If the water runs clear, and no air bubbles are

seen in the glass of the position indicator close the bleed cock. If air is

present $the water will be foamy white+ run the water until the air is

gone.

,trainers

.ilot systems rely on a supply of clean water, usually taken from the

inlet of the valve. /ither e%ternal or 6ush clean type strainers can be

installed. If tan e%ternal strainer is installed a simple occasional 6ush is

a good idea. 7ormally 8 9 : seconds is su3cient time to clean the

strainer screen. /%perience will dictate if it needs to be 6ushed longer

than this, but it is unlikely in a municipal system. " number of water

utilities install a ball valve on the 6ushing plug of the strainer, allowing

operators to give a short 6ush everytime they are in the valve station.

$his certainly helps to eliminate those problem calls later as a plugged

strainer causes a valve to remain open*+

;educing .ilot

/nsuring the control valve pilot is still operational is a simple task. "s a

cautionary note 9 before you make any pressure ad!ustment, ensure

that this is acceptable for the system and any ,<"=" alarm controls

that may be triggered by a change in pressure. o e%ercise the

pressure0reducing pilot, loosen the lock nut on the pilot ad!usting screw

and turn clockwise to increase the pressure : psi above the normal set

point. <heck that the downstream pressure gauge is tracking the

ad!ustments you are making. hen turn the ad!usting screw counter0

clockwise to reduce the pressure to : psi below the set point. =oes the

pressure gauge track this also> ?inally, turn the ad!usting screw

clockwise to increase the pressure back to the original set point, and

tighten the lock nut. If for some reason the pressure gauge is not

moving as you ad!ust the screw, you either have a bad gauge or a pilot

that needs looking at.

@ain valve 6ows

Aust like we all like to take our cars out for an occasional run to give

them a good workout, the valves also need to see some decent 6ow

occasionally. =uring a ma!or fre 6ow is not a good time to fnd out your

main valve will not open fully.

1et some 6ow through the valve station to open the the peak

demandBfre06ow valve. $his could be as simple as opening a hydrant

on the outside of the valve station+. If you have stations or vaults that

have two valves in in parallel, with one valve handling normal 6ow and

the other valve handling large or fre 6ows, the larger valve should be

operated for a minimum of : minutes. his can be done by closing the

isolating cock on the downstream side of the smaller valve pilot system

$the cock below the pressure0reducing pilot+. his will close the smaller

valve and cause the larger valve to open and allow 6ow into the

system. he above four steps can be followed for the larger valve

while it is in the 6owing mode.

his is also a good time to ensure the main line control isolating valves

are in good working order. he gate or butter6y valves used to isolate

the control valve should also be checked to ensure they are operational

if they are needed.

5y following this simple routine your valves should give years of

trouble free service. 4f course such variables as pressures, operational

use, water 2uality $hardness, =, etc.+ all have an e#ect on the

periods between ma!or valve overhauls.

5elow are some simple chart that you may fnd useful for basic valve

troubleshooting.

Das könnte Ihnen auch gefallen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- 27 Differences Between ArcGIS and QGISDokument30 Seiten27 Differences Between ArcGIS and QGISashry09Noch keine Bewertungen

- 3 Gaikindo Wholesales Data Jannov2018Dokument3 Seiten3 Gaikindo Wholesales Data Jannov2018ashry09Noch keine Bewertungen

- JtExpo Infrastructure AIM CommitteeDokument39 SeitenJtExpo Infrastructure AIM Committeeashry09Noch keine Bewertungen

- Case Study of Seosan Smart Water ManagementDokument20 SeitenCase Study of Seosan Smart Water Managementashry09Noch keine Bewertungen

- Naskah PublikasiDokument13 SeitenNaskah Publikasiashry09Noch keine Bewertungen

- ch57 PDFDokument18 Seitench57 PDFashry09Noch keine Bewertungen

- White PaperDokument6 SeitenWhite Paperashry09Noch keine Bewertungen

- GGIS Strategic Plan Approved FinalDokument102 SeitenGGIS Strategic Plan Approved Finalashry09Noch keine Bewertungen

- Metrogis 2016 Work PlanDokument26 SeitenMetrogis 2016 Work Planashry09Noch keine Bewertungen

- 49 Water UtilitiesDokument24 Seiten49 Water Utilitiesashry09Noch keine Bewertungen

- 01 MR Brian Borg - GIS in Water Utilities 0Dokument32 Seiten01 MR Brian Borg - GIS in Water Utilities 0ashry09Noch keine Bewertungen

- The Water Technology Sector in The USDokument68 SeitenThe Water Technology Sector in The USashry09Noch keine Bewertungen

- EGIS Operating GuidelinesDokument8 SeitenEGIS Operating Guidelinesashry09Noch keine Bewertungen

- Arcgis Geoevent Server:: Internet of Things (Iot)Dokument5 SeitenArcgis Geoevent Server:: Internet of Things (Iot)ashry09Noch keine Bewertungen

- CoGIS 5.1 MobileUserGuide enDokument21 SeitenCoGIS 5.1 MobileUserGuide enashry09Noch keine Bewertungen

- How DMI 65 WorksDokument7 SeitenHow DMI 65 Worksashry09Noch keine Bewertungen

- Activating DMI 65 Step by Step ProcedureDokument3 SeitenActivating DMI 65 Step by Step Procedureashry09Noch keine Bewertungen

- XiLog PDFDokument2 SeitenXiLog PDFashry09100% (1)

- Erandika Manawadu ThesisDokument126 SeitenErandika Manawadu Thesisashry09Noch keine Bewertungen

- Swan What Are Smart Water Networks PDFDokument1 SeiteSwan What Are Smart Water Networks PDFashry09Noch keine Bewertungen

- Building Symbol LibrariesDokument18 SeitenBuilding Symbol Librariesashry09Noch keine Bewertungen

- 16 Tang KeyserDokument9 Seiten16 Tang Keyserashry09Noch keine Bewertungen

- TBT No 2 Boundary Valve ManagementDokument5 SeitenTBT No 2 Boundary Valve Managementashry09Noch keine Bewertungen

- Development of A GIS-Based Information System For Watershed Monitoring in Mato Grosso, Central BrazilDokument15 SeitenDevelopment of A GIS-Based Information System For Watershed Monitoring in Mato Grosso, Central Brazilashry09Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- of OzymandiasDokument19 Seitenof OzymandiaskeshavNoch keine Bewertungen

- Yeshua (Chord Chart)Dokument1 SeiteYeshua (Chord Chart)unitedpursuit67% (3)

- Universal Studio MapDokument1 SeiteUniversal Studio MapTiffany Fitri HariyantoNoch keine Bewertungen

- Nine Old MenDokument2 SeitenNine Old MenLouise Herrey-JanseNoch keine Bewertungen

- +A Touch of Jazz - Nick Ayoub - SATB (Sax Ensemble)Dokument8 Seiten+A Touch of Jazz - Nick Ayoub - SATB (Sax Ensemble)John SuskeyNoch keine Bewertungen

- PTS English XIIDokument2 SeitenPTS English XIIIrsyad MubarokNoch keine Bewertungen

- History of WargamingDokument6 SeitenHistory of Wargamingreaper6969100% (1)

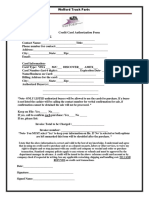

- Credit Card Authorization Form WoffordDokument1 SeiteCredit Card Authorization Form WoffordRaúl Enmanuel Capellan PeñaNoch keine Bewertungen

- Beetlejuice StudyGuide OnlineFinal PDFDokument12 SeitenBeetlejuice StudyGuide OnlineFinal PDFIndah Gustri Rahayu33% (3)

- Skyview Bar MenuDokument19 SeitenSkyview Bar Menucelinadaoud4Noch keine Bewertungen

- 2022-2023 The Second Mid-Term TestDokument3 Seiten2022-2023 The Second Mid-Term TestKhải VõNoch keine Bewertungen

- Bass Clef Harmony Chords and ScalesDokument12 SeitenBass Clef Harmony Chords and ScalesBarney GNoch keine Bewertungen

- Jah Heavy LoadDokument1 SeiteJah Heavy LoadMijail MijailNoch keine Bewertungen

- PalestineDokument5 SeitenPalestinebrettNoch keine Bewertungen

- Gatewise Releases New Online Management Portal For Multifamily CommunitiesDokument2 SeitenGatewise Releases New Online Management Portal For Multifamily CommunitiesPR.comNoch keine Bewertungen

- Delivery Note2 - 0000012704 - EnQuestDokument3 SeitenDelivery Note2 - 0000012704 - EnQuestrburtonshawNoch keine Bewertungen

- Astron Power SupplyDokument8 SeitenAstron Power Supplydmechanic8075Noch keine Bewertungen

- (English For Economics) Final Assignment - Case 2Dokument13 Seiten(English For Economics) Final Assignment - Case 2Khánh Linh QuáchNoch keine Bewertungen

- Verona Medical Group - DENT-X EVA 2010Dokument4 SeitenVerona Medical Group - DENT-X EVA 2010VeronaMedicalGroupYYNoch keine Bewertungen

- Ingles 2019 - 2Dokument9 SeitenIngles 2019 - 2Jairo Antonio Aristizabal PernettNoch keine Bewertungen

- Hots and Cools: Menu D&C PatenDokument3 SeitenHots and Cools: Menu D&C PatenEldikoNoch keine Bewertungen

- Optimal Blackjack Strategy: The Rules of PlayDokument3 SeitenOptimal Blackjack Strategy: The Rules of PlayrajNoch keine Bewertungen

- Expressionism Movement FactfileDokument4 SeitenExpressionism Movement FactfilealiciaNoch keine Bewertungen

- Art, Politics and New Media: Randall PackerDokument5 SeitenArt, Politics and New Media: Randall Packerrikrik1212Noch keine Bewertungen

- Rhino m1011 Embosser Kit User GuideDokument16 SeitenRhino m1011 Embosser Kit User Guidemmihai_popa2006Noch keine Bewertungen

- U27 Alice in Wonderland Episode 7Dokument5 SeitenU27 Alice in Wonderland Episode 7jksalmNoch keine Bewertungen

- Literary DevicesDokument31 SeitenLiterary DevicesMarvin PilienNoch keine Bewertungen

- Stack008 V2Dokument1 SeiteStack008 V2Kryštof PaličkaNoch keine Bewertungen

- Film Adaptation: Five AnalysesDokument7 SeitenFilm Adaptation: Five Analysesprpr_rina6095Noch keine Bewertungen

- Reading Comprehension: The Coach Did Not Want To Lose The Game Amir Would Cause Him To Lose The GameDokument3 SeitenReading Comprehension: The Coach Did Not Want To Lose The Game Amir Would Cause Him To Lose The GameDiyana MahashimNoch keine Bewertungen