Beruflich Dokumente

Kultur Dokumente

A Feasibility Study On Implementing Agile Manufacturing in A Pump Manufacturing Industry

Hochgeladen von

Varun0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

76 Ansichten11 SeitenThis document discusses the feasibility of implementing agile manufacturing in a traditional pump manufacturing industry using computer-aided design (CAD) and computer-aided manufacturing (CAM) technology. It first reviews literature linking CAD/CAM to agile manufacturing. The author then presents a conceptual model for designing agile manufacturing systems along four dimensions: strategies, technology, people, and systems. The model aims to develop integrated agile systems using appropriate strategies and techniques to enable rapid partnership formation, virtual enterprise, and product reconfigurability for mass customization. Finally, the paper discusses characteristics that CAD/CAM and agile manufacturing have in common, such as time compression, cost effectiveness, improved flexibility, speed, and increased efficiency. The research

Originalbeschreibung:

vg

Originaltitel

11mf63

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document discusses the feasibility of implementing agile manufacturing in a traditional pump manufacturing industry using computer-aided design (CAD) and computer-aided manufacturing (CAM) technology. It first reviews literature linking CAD/CAM to agile manufacturing. The author then presents a conceptual model for designing agile manufacturing systems along four dimensions: strategies, technology, people, and systems. The model aims to develop integrated agile systems using appropriate strategies and techniques to enable rapid partnership formation, virtual enterprise, and product reconfigurability for mass customization. Finally, the paper discusses characteristics that CAD/CAM and agile manufacturing have in common, such as time compression, cost effectiveness, improved flexibility, speed, and increased efficiency. The research

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

76 Ansichten11 SeitenA Feasibility Study On Implementing Agile Manufacturing in A Pump Manufacturing Industry

Hochgeladen von

VarunThis document discusses the feasibility of implementing agile manufacturing in a traditional pump manufacturing industry using computer-aided design (CAD) and computer-aided manufacturing (CAM) technology. It first reviews literature linking CAD/CAM to agile manufacturing. The author then presents a conceptual model for designing agile manufacturing systems along four dimensions: strategies, technology, people, and systems. The model aims to develop integrated agile systems using appropriate strategies and techniques to enable rapid partnership formation, virtual enterprise, and product reconfigurability for mass customization. Finally, the paper discusses characteristics that CAD/CAM and agile manufacturing have in common, such as time compression, cost effectiveness, improved flexibility, speed, and increased efficiency. The research

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 11

Abstract Due to the absence of agile characteristics, many

traditional products have been struggling to face the onslaught of

intensive competition. Agile characteristics would enable a

product to be reconfigured quickly in response to the customers

dynamic demands. One of the theoretical propositions is that,

computer-aided design !AD"#computer-aided manufacturing

!A$" technology possesses the capabilities to infuse agile

characteristics in the traditional products. %o e&amine this

theoretical proposition, the research work being reported in this

paper was carried out. During this research, the pump was

chosen as a candidate of traditional product. %he impeller and

casing of the pump were subsequently modelled using !AD

technology and design equations. 'ubsequently, four impeller

and casing models were evolved. %o e&amine the manufacturing

aspect of these models, !A$ technology was used. %his research

outcome indicated the feasibility of converting a traditional

product into an agile compatible product using !AD#!A$

technology.

Keywords( A$) agile manufacturing) !AD) computer-aided

design) !A$) computer-aided manufacturing) pump design)

product design) product development.

*. *+%,OD-!%*O+

Agile manufacturing can be defined as the

capability of surviving and prospering in a

competitive environment of continuous and unpredictable

change by reacting quickly and electively to changing

markets, driven by customer-designed products and

services.

Agile manufacturing is a new e&pression that

issued to represent the ability of a producer of goods and

services to thrive in the face of continuous change. %hese

changes can occur in markets, in technologies, in business

relationships and in all facets of the business enterprise.

Agile manufacturing requires to meet the changing market

requirements by suitable alliances based on core-

competencies, organi.ing to manage change and

uncertainty, and leveraging people and information.

Agile manufacturing is a vision of manufacturing that is

a natural development from the original concept of /lean

manufacturing0. %his requirement for manufacturing to be

able to respond to unique demands moves the balance back

to the situation prior to the introduction of lean

production, where manufacturing had to respond to

1

whatever pressures were imposed on it, with the risks to

cost and quality. %he move to lean production from agile

and vice versa is a ma2or challenging task

%he main ob2ective of this particular classification

is to develop a suitable framework for A$'s along these

four dimensions#criteria. Achieving agility therefore

requires fle&ibility and responsiveness in strategies,

technologies, people and systems. %able 3 shows the

classification of the literature on A$ and the

corresponding references on the basis of strategies,

technologies, systems and people.

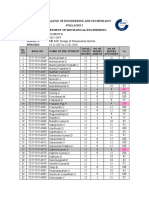

%A456 *

!5A''*7*!A%*O+ O7 A8*56 $A+-7A!%-,*+8

5*%6,A%-,6

!riteria for classification

of the literature

'ub-classification

'trategies

9irtual enterprise

'upply chain

!oncurrent engineering

%echnologies

:ardware ;tools and

equipments

*nformation technologies

'ystems

Design systems

<roduction planning and

control systems

'ystem integration and

database management

<eople

=nowledge workers

%op management support

and employee

empowerment

%raining and education

3.3. A 7,A$6>O,= 7O, %:6 D6'*8+ O7 A8*56

$A+-7A!%-,*+8 '?'%6$'

%his development is based on the literature survey

and its analysis. *t can be seen that most of the literature

on A$ and related issues either deal with strategies or

techniques, but not an integrated view of developing an

A$'. *n this section, an attempt has been made to present

an integrated strategic and techniques framework for the

design and development of A$'s together with people and

systems issues. Agile manufacturing can successfully be

accomplished using various well-defined agile system

architectures. %he system architecture for A$ may include

gokulrajupacet@gmail.com

A FEASIBILITY STUDY ON

IMPLEMENTING AGILE

MANUFACTURING IN A PUMP

MANUFACTURING INDUSTRY

8okulra2u ,,

Department of Industrial Engineering(part time),

P! college of tec"nology, #oim$atore.

control, function, process, information, communication,

distribution, development, and implementation.

6ffective and efficient implementations of A$'s

require enterprise level integration. %he first step in this

direction is to integrate design, process planning and

scheduling. A bidding-based approach to the integration of

computer-aided design, process planning and real time

scheduling can be used for the design and implementation

of A$'.

%he product is represented in a '%6< model with

detailed design and administrative information including

design specifications, batch si.e, and due dates. -pon

arrival at the manufacturing facility, the product is

registered in the shop floor manager which is essentially a

coordinating agent. %he shop floor manager broadcasts the

product0s requirements to the machines. %he shop contains

autonomous machines that have knowledge about their

functionality, capabilities, tooling and schedules.

6ach machine has its own process planner and

responds to the product0s request in a way that is consistent

with its capabilities and capacities. >hen more than one

machine offers certain processes" for the same

requirements, they enter into negotiation. 4ased on

processing time, due date and cost, one of the machines

wins the contract. %he successful machine updates its

schedule and advises the product to request raw material

for processing. %he concept was implemented using a

multi-agent system in an ob2ect-oriented programming

language. %he task of decomposition and planning are

achieved through contract nets. As discussed earlier,

*nternet plays a significant role in A$'s.

4ased on the literature survey, a conceptual model

for the development of A$'s is developed as shown in

7ig. 3. As indicated earlier, the model has been developed

along four key dimensions including strategies,

technology, people and systems. %he main ob2ective here is

to develop integrated A$'s with the help of suitable

strategies and techniques to develop rapid partnership

formation, 96 and reconfigurability for mass

customi.ation. 7urther details of the model are discussed

hereunder.

7*8-,6 3@ A 7,A$6>O,= 7O, %:6 D6'*8+ O7

A8*56 $A+-7A!%-,*+8 '?'%6$'

** 5*%6,A%-,6 '-,96?

%he literature has been presented from the perspectives of

linkage between A$ and !AD#!A$) application studies

on A$.

A.3 5*%6,A%-,6 ,69*6> O+ 5*+=A86 46%>66+

!AD#!A$ A+D A$

%he linkage between !AD#!A$ and A$ is presented as

follows@ $ervyn et al. ABBC" have proposed the idea of the

development of an internet-enabled interactive fi&ture

design system. <an et al. ABBC" have proposed the

application of world wide web to achieve agility in rolling

bearing design. =usiak and :e 3DDE" have proposed four

Fdesign for agility rules. =usiak and :e 3DDG" have

brought out three rules for the design of products for agile

assembly. De 5app et al. ABBH" have presented the

importance of !AD in accurate designing and presented a

case study that investigates the impacts of !AD on design

reali.ation. %he authors have recommended the usage of

!AD for improvement in design accuracy and thereby

achieving lowest pro2ect costs. 5in and -hler ABBA" have

presented how three-dimensional CD" models can reduce

the time to market and insisted that using CD !AD

systems such as <ro#6 results in fewer modifications and

lesser inaccuracies. %hey have also illustrated the same

with a torque converter design assembly as an application

case study. !hang et al. 3DDG" used parametric !AD

software to achieve design automation results which can

be used to

update the design model and the associative

manufacturing model. <erry and 'ohal ABBB" have

emphasised that !AD is one of the key manufacturing

technology and automated system for quick response

practices. ,oy et al. ABBA" have presented that

!AD#!A$ is being accepted in many manufacturing

industries. %hey have also presented that !AD#!A$ have

transformed itself from being an e&pensive tool into a

basic necessity. >ei et al. ABBB" have proposed a design

automation system to reduce research and development

cost and product development time. %his system is

composed of !AD, !A6 and <ires et al. ABBH" have

proposed a procedure to e&tract robot motion information

from !AD data for welding applications. A$ and

!AD#!A$ possess several common aspects. %he linkage

between the characteristics of A$ and !AD#!A$ has

been presented in %able A.

As shown in %able A, A$ possesses characteristics such

as time compression, cost effectiveness, design

changeover, improved fle&ibility, speed, innovation and

increased efficiency. All these characteristics are coherent

with the abilities of !AD#!A$.

%A456 A

5*+=A86 46%>66+ %:6 A$ A+D !AD#!A$

Characteristics of AM

Characteristics of

CAD/CAM

%ime compression

8unasekaran, 3DDE)

*smailet al., ABBI) Onuh

et al., ABBI"

,educed time to market

5in and -hler, ABBA",

fast concept-to-prototype

service

8unasekaran,3DDE"

,educed initial ,educed ,/D cost and

investment cost and

change overcosts

Adeleye and ?usuf,

ABBI) 6lkins et al.,ABBH)

*smail et al., ABBI)

Onuh et al., ABBI"

product design cycle

>ei et al., ABBB",

potential cost savings

De 5app et al., ABBH"

:igher degree of

automation Adeleye

and

?usuf, ABBI"

Design automation

!hang et al., 3DDG"

'peed and fle&ibility in

manufacturing

systemsAdeleye and

?usuf, ABBI"

*mproved quality,

fle&ibility and reliability

8on.ale.-4enito, ABBJ"

*nnovations in

manufacturing

8unasekaran,

3DDE"

<roduct innovation

Onuh and :on, ABB3",

product redesign

8unasekaran, 3DDD"

7easibility of design and

manufacturing

process validation

8unasekaran, 3DDE"

*ncreased accuracy and

efficiency of design

reali.ation De 5app et

al., ABBH".

As shown in %able A, A$ possesses

characteristics such as time compression, cost

effectiveness, design changeover, improved fle&ibility,

speed, innovation and increased efficiency. All these

characteristics are coherent with the abilities of

!AD#!A$.

'ome of the advancements in the application of

advanced technologies for pump designand manufacturing

are being emphasi.ed as follows@ !hen and >ang ABB3"

have investigated !AD#!A$ technologies for

manufacturing centrifugal compressor impellers and

turbine blades. 'pann and :organ ABBI" have claimed

that upfront computational fluid dynamics !7D" has

made its mark on the pump industry, reducing the need for

e&pensive physical tests and cutting new pump

development costs by an average of IJK.

A.A 5*%6,A%-,6 ,69*6> O+ A$ A<<5*!A%*O+

'%-D*6'

9endor et al. ABBEa, b" have infused agility, innovation

and quality of products using agile innovative total quality

function deployment technique. %his technique has been

used to observe the customer needs and incorporate them

into developed matrices with the help of concerned

departments. %his study was implemented and results have

been validated in electronic switches manufacturing

company. 9endor et al. ABBD" have presented an article

related to enhancing competitiveness through total agile

design system %AD'". %he main aim of %AD' is to infuse

product development with A$ concepts to launch in a

short span of time. %he practical feasibility is validated in

manufacturing organi.ation, results prove that

digitali.ation and !AD modeling principles leads way to

driving agility. 8ore et al. ABBD" presented the A$

enablers for manufacturing enterprise to maintain its

competitive advantage in the market tends tenable new

manufacturing strategies and remains to be more

profitable using A$principles.Anoopkumar et al. AB3B"

have done work related to implement agile supply chain,

using agile supply chain responsiveness analysis model to

find the current level of agility of the organi.ation. 7ive

criteria model has been used for evaluation, results have

been analy.ed based upon cost analysis in a switch

manufacturing firm. %he results imply that

implementation of this ideas lead to improvement of the

firm. *nman et al. AB3B" have done work related to 2ust in

time L*%", operation performance and firm performance

regarding A$. $odel has been created and tested based

upon the firm data gathered from e&perts from production

and operations department and calculated using structural

equation modeling technique. %he results depict positive

signs for L*% principles and A$. 8aafar et al. ABBE"

presented an article linking genetic algorithm for

scheduling in

an agile environment. %he system contains a single-

fle&ible machine and sequel machines that are identical.

$inimi.ing the time is the ma2or hallmark of scheduling.

<article swarm-based genetic algorithm is tested for

specific problem. %he results show the reduction in time

compared to genetic algorithm process. $any researchers

have suggested that the utili.ation of technologies leads to

agility enhancement. 7ew researchers have contributed the

utili.ation of technologies in the conte&t of pump design

and manufacturing. 4ut this pro2ect is focused on the

utili.ation of technologies for enhancing agility of pump

design and manufacturing.

During the research being reported here, the

literature was searched to trace the researches and

practices carried out to achieve agility using design

principles and !AD technology. %his search made in

leading databases like 6merald insight, 'cience direct and

6bsco resulted in the identification of 3C relevant papers.

%he contributions of these papers are briefly reported here.

=usiak and :e 3DDG" have proposed three rules for the

design of products for agile assembly. %hree rules for the

design of products for agile assembly froman operational

perspective. Accomplishment of design for agile assembly

by considering the operational issues at the early product

design stage. =usiak and :e 3DDE" have proposed four

rules for designing from agility perspective. %hese rules

allow product and system design for easy scheduling. 5ee

3DDE" has considered A$ in the early design of

components and manufacturing systems. Design for short

manufacturing lead time has Design agility through !AD

been studied in the form of the design rules. Design for

agility rule has been formulated, proved, and substantiated

by numerical results. 9ernadat 3DDD" has discussed

organi.ational, technological and human aspects of agility

with respect to product design, manufacturing system

design and innovation management.

:elander and Liao ABBA" report a model which

enables the participation of customers while designing

products to achieve mass customi.ation. 7or this purpose,

they have proposed an electronic product development

enabled mass customi.ation model. On implementation,

this model will facilitate the customers to e&press their

requirements through electronic media which would be

processed again through electronic devices. %hey have also

suggested the usage of techniques like analytic hierarchy

process and quality function deployment during this

process. An important emphasis of this paper is the need

for integration of all functions, particularly design,

manufacturing and logistics while designing products and

thereby achieving mass customi.ation. Mhan et al. ABBC"

have contributed a model which facilitates the

collaborative product development with the aid of internet.

%his model entails the participation of number of

designers while designing agile products. $ervyn et al.

ABBC" have developed an internet enabled interactive

fi&ture design system. %hey have suggested that an

effective fi&ture design system should be portable on

different operating platforms. <an et al. ABBC" have

proposed a novel approach to implement a design support

system using world wide web to achieve agility in rolling

bearing design. %he web-based distributed system will be

globally accessible on the internet to the users and can be

automatically si.ed according to the demand or

application requirements.

'u and !hen ABBC" have presented a framework of

network support for the integrated design. %his integrated

agile design system integrates stages within the design

process including product design specification, conceptual

design, detailed design and manufacture. %his has been

achieved with the aid of integrating various software

packages into a single environment. Devadasan et al.

ABBJ" have proposed the concepts of design for product as

well as system agility. %hey have adopted a modified

orthogonal array-based model e&ploiting the technique

Ndesign of e&perimentsO in an A$ environment.

4orissovaet al. ABBI" has used the concept of

combinatorial process, equipment and plant design for

achieving agility in manufacturing. %he proposed

approach has been particularly appropriate for the design

of agile plants for families of products. Onuhet al. ABBI"

have evolved a model for agile product design involving

!AD, computer aided manufacturing !A$", rapid

prototyping, and rapid tooling.

%hough many concepts of design engineering

have been proposed in linkage with A$, only scant

researches have taken place in utili.ing the concept of

design engineering with A$. Also, it has been observed

that one of the underutili.ed technology in enabling A$ is

!AD. %his is despite the fact that features like time

composition, increased product variety, achieving lead

time increased customer domain are complementary to

both !AD and A$. $oreover, the products manufactured

by traditional manufacturing organi.ations are not

compatible for attaining agility. %his is due to the

underutili.ation of the !AD technology for enhancing

agility. *n this conte&t, the research reported in this paper

was carried out. %his research was focused towards

e&amining the practicality of achieving agility through the

e&ploitation of !AD technology. :ence, this research was

dominated by a case study which was conducted in a

traditional electronic switch manufacturing organi.ation.

***. $6%:ODO5O8?

5iterature review on A$ ,!AD#!A$ and the

linkage between them

Design of conceptual model for integration of

!AD #!A$ driven agility

'election of suitable organi.ation and product

for carrying out the implementation study

'tudy of e&isting designs of the product as well

as the manufacturing processes

*mplementation study for the designed

conceptual model

9alidation of the results

Derivation of inferences

7*8-,6 A@ $6%:ODO5O8?

%he literature was reviewed from the perspectives

of A$, !AD#!A$ and the linkage between them. %hen,

the conceptual model has been designed based on the

literature review. %his is followed by the selection of a

suitable manufacturing organi.ation as well as the product

for carrying out the implementation study. After

identifying the suitable manufacturing Organi.ation, the

e&isting products manufactured as well as the

manufacturing processes employed were studied.

%hen the deployment of the designed conceptual

model has been done according to the various phases being

planned. %his is followed by gathering the feedback of the

e&perts regarding the outputs generated out of the

implementation study. %his is followed by the derivation of

inferences based on the implementation study e&periences.

C.A. D6'*8+ O7 !O+!6<%-A5 $OD65

%he designed conceptual model is shown in

7igure C. %he motivation behind the development of

conceptual model is that it acts as technology-integrated

product design and development cycle enabling the rapid

design and development of products. As shown, the

customers varied requirements will be collected in the

form of varied product specifications. Once the product

specifications have been finali.ed, the digital versions of

those specifications will be developed using !AD

technology.

<ro2ect

phases

Agile

6nablers %ools

!ustomer

requirement

s

<hase *

'olid

modeling

!AD

<ro-6 <art

model

<hase **

*mproved#

modified

designs

6mpirica

l

equations

<hase ***

Design

validation

!AA

8A$4*%

and

75-6+%

<hase *9

$anufacturi

ng feasibility

study

!A$

<ro-6

$anufacturi

ng

7*8-,6 C@ D6'*8+ O7 !O+!6<%-A5 $OD65

%he design modifications or new product designs are

made using innovation integrated tools. 'ometimes the

usage of the empirical relations also could be employed.

%hen the new designs are practically validated using !AA

software packages. %he manufacturing feasibility of the

developed designs will be carried out using !A$ software

package.

*9. *$<56$6+%A%*O+ '%-D?

%he implementation study has been carried out in

a pump manufacturing organi.ation located in

!oimbatore, %amil +adu, *ndia.

H.3. A4O-% !O$<A+? A+D <,OD-!%'

%he name of the company is FLA? <umps. %he

company has more than 3B numbers of employees. %he

current turnover of the company is *+, 3,BBB,BBB. %he

number of employees currently working in the company is

3I. %he products manufactured by the company include

self-priming pumps and centrifugal pumps. %here e&isted

a need for the case organi.ation to develop new products

thereby enabling agility in product design and

development which motivated to conduct this study.

H.A. !AD $OD65*+8 O7 6P*'%*+8 *$<6556, A+D

!A'*+8 D6'*8+' <:A'6 *"

After studying the e&isting designs and collecting

the AD drawings from the company, the !AD models of

the e&isting impeller and casing designs have been created

using <ro-6.

7*8-,6 C@ !A'*+8

7*8-,6 H@ *$<6556,

H.C. D6965O<$6+% O7 +6> *$<6556, D6'*8+'

<:A'6 **"

%he e&isting design is depicted as FP whereas the

proposed designs are depicted as ?3, ?A, ?C and ?H. %he

design code, head, discharge values, number of vanes and

design criteria used. =eeping the e&isting impeller design

as reference, the new impeller designs were generated

using the empirical equations.

Step 1: Cac!atio" of s#ecific s#ee$

'pecific speed

+s Q

Q

Q3BIB.Hrpm

7rom 7igure G, the efficiency of this pump for %s Q

3,BIB.H rpm and & Q JA.AIJ has been found to be JG.JK.

Step 2: Cac!atio" of o!tsi$e $ia%eter

Outside tip speed

-AQ

Q

QA3.BCm sec

-3

Angular velocity

R Q

Q

Q ADC.AArad sec

-3

%A456 C

'<6!*7*!A%*O+' O7 %:6 6P*'%*+8 A+D

<,O<O'6D *$<6556, D6'*8+'

Design

code

:ead

m"

Discharg

e lps"

+umber of

vanes

'haft

power

:<"

P 3J.JJ C.DI H 3.J

?3 3J.JJ C.DI H 3.J

?A 3G C H 3.J

?C A3 J H C

?H AB H I C

7*8-,6 J@ !-,96 D6<*!%*+8 %:6 ,65A%*O+':*<

46%>66+ 677*!*6+!? A+D '<6!*7*! '<66D

Outer diameter

DAQ

Q

Q 3HC.HCmm

Step 3: Cac!atio" of i%#eer &i$th

*mpeller e&it width

4AQ

Q

Q J.AAHS3B

-C

m

Q J.AAHmm

Step 4: Cac!atio" of i"et $ia%eter

*nitially, the optimum inlet diameter corresponding to an

inlet blade angle '( of AHT should be calculated from

Optimum inlet diameter

DAQ

Q

Q B.BCIJ3m

QCI.J3mm

Step 5: Cac!atio" of o!tet 'a"e a"(e

Assuming the following values for the coefficients, head

coefficient Q B.I, discharge coefficient Q B.BE and slip

coefficient Q B.E

Outlet vane angle

UA Q

Q

Q GB.BA from meridian Q AB from tangential

Step 6: Cac!atio" of ra$i!s of c!r'at!re of 'a"e

!alculation of radius of curvature of vane

,cQ

Q

Q HG.HHmm

Step 7: Cac!atio" for $eter%i"i"( "!%)er of 'a"es

!alculation for determining number of vanes

MQ

Q

V H

%his step marks the end of designing the

impeller. %he derived dimensions of the newly developed

impeller are depicted in 7igure below

7*8-,6 I@ +6> *$<6556, ?3" >*%: D6,*96D

D*$6+'*O+'

J.H. D6965O<$6+% O7 +6> !A'*+8 D6'*8+'

<:A'6 **"

=eeping the e&isting casing design as reference, the

dimensions of the new casing designs are derived using

the following empirical relations. %he development of new

products using creative thinking is a ma2or hallmark of

A$. As a sample, the procedure used to develop a casing

is shown as follows.

Step 1: Cac!atio" for $eter%i"i"( the a)so!te

ta"(e"tia e*it 'eocit+

<eripheral speed of impeller at inlet

-3Q

Q

QJ.CJC m sec

-3

<eripheral speed of impeller at outlet

)3Q A3.BCm sec

-3

Outlet vane angle

U3Q

*nlet flow velocity

9f3Q -3

QJ.CJC

Q A.CE m sec

-3

'ince constant velocity flow is assumed,

*f3 Q *fA Q A.CEm sec

-3

#+, Q 3H.J m sec

-3

Step 2: Cac!atio" for $eter%i"i"( the )ase circe

$ia%eter

4ase circle diameter of casing

DCQ3.3DA

Q 3.3 SB.3HCHC

Q B.3JGEm

Q 3JG.Emm

Assuming the velocity reduction due to increased cross-

sectional area as 3BK,

%he velocity at throat outlet

!WCQB.D!%A

QB.DS3H.J

Q 3C.BJ m sec

-3

Step 3: Cac!atio" for $eter%i"i"( the throat area a"$

throat $ia%eter

%hroat area Q

Q

Q

Q

%hroat diameter d Q

Q

Q 3D.IImm

QB.B3DIIm

Step 4: Cac!atio" for $eter%i"i"( the o#ti%!% throat

area a"$ throat $ia%eter

!alculation for determining the optimum throat area

and throat diameter :owever, the centre of the throat area

will move to a radius of DA Xd"#A, and the velocity

approaching the throat will slowdown in inverse

proportion to the distance from the impeller centre.

%herefore, the throat velocity will diminish to

!WCQ!%A

Q 3H.J

Q 33.HE m sec

-3

%herefore, the corrected area will become

Q

.

Q

%hen corrected throat diameter

Q

Q B.BA3m

Q A3mm

%his step marks the end of designing the casing.

%he !AD model of the newly developed casing design is

shown in 7igure G.

7*8-,6 G@ CD !AD $OD65 O7 %:6 <,O<O'6D

!A'*+8 D6'*8+

H.J. A+A5?'*' O7 *$<6556, D6'*8+' A+D

$A+-7A!%-,*+8 76A'*4*5*%? '%-D?

<:A'6' *** A+D *9"

6ngineering analysis is an important phase in product

design cycle. %he analysis ensures the capability of designs

for further processing. %he proposed new impeller designs

have been sub2ected to flow analysis using 8A$4*% and

75-6+% softwares.

8A$4*% is mesh generation software that provides

interface for creating and meshing the geometries.

8A$4*% acts as a preprocessor for processing the

geometries before performing flow analysis.

75-6+% is a general-purpose !7D software which is

suited for performing fluid flow analysis. *t is a solver

based on the finite volume method. %he post-processing

tools of 75-6+% can be used to generate animations as

well as the generation of reports that convey the results of

!7D analysis. %he generated !AD models of the new

impeller designs are sub2ected to flow analysis. %he

meshing of the impeller designs is carried out using

8A$4*% preprocessor. %he type of mesh element

employed is he&ahedral and fine meshing has been

defined. %he first impeller design after meshing is shown

in 7igure G. %he meshed impeller model has been

sub2ected to flow analysis by importing in the form of

mesh file. %he input parameters have been set as input

flow velocity A.CE m sec

-3

" and outlet pressure

atmospheric pressure". *n our case, the output parameter

to be considered is mass flow rate. %he screen containing

the specification of boundary conditions is shown in

7igure E.

7*8-,6 E@ '!,66+ D6<*!%*+8 %:6 $6':6D

*$<6556, D3"

7*8-,6 D@ '!,66+ 6+A45*+8 %:6 '<6!*7*!A%*O+

O7 *+<-% <A,A$6%6,'

As observed from 7igure D, the mass flow rate is found

to be C.EIHIGJ kg sec

-3

. %he analy.ed designs need to be

sub2ected to manufacturing feasibility analysis to ensure

the manufacturability of designs. %he manufacturing

feasibility study of impeller designs has been carried out

using F!ast !avity module of <ro#6ngineer >ildfire C.B.

After importing the impeller model, the desired shrinkage

allowance needs to be specified. 'ince the impeller

material is ferrite graphite iron, the shrinkage allowance is

3.3.

7*8-,6 D@ '!,66+ 6+A45*+8 %:6 86+6,A%*O+

O7 O-%<-% <A,A$6%6,

9. !O+!5-'*O+'

%oday, the manufacturing organi.ations are facing stiff

competition to meet the varied dynamic requirements of

the customers Wuintana, 3DDE". %hough certain

manufacturing

sectors like mobile phone manufacturers are bringing out

different models within a short period of time, certain

traditional manufacturing sectors like pumps, compressors

and machine tool manufacturers are not able to bring out

different varieties within a short period of time. %he

fundamental reason behind this kind of situation is that,

there is no proper linkage between A$, design

engineering and advanced technologies. %he literature

review on A$ also indicated the missing link between

design engineering and A$ =usiak and :e, 3DDE". %his

typical situation prevailed in the organi.ation where the

case study has been carried out. %he e&periences of

conducting this case study proved the phenomenon that

!AD#!A$ act as enabler for A$ which has been stated

theoretically by many A$ researchers 8unasekaran,

3DDE) Onuh and :on ABB3". *n this conte&t, this study

fulfils the research void. %he opinions of the e&perts

working e&clusively in the design and manufacturing of

pumps also suggested the practical feasibility of the

generated designs. %his kind of technology integration in

the A$ field would enable the traditional manufacturing

organi.ations to survive in the competitive environment of

unanticipated changes to become winners in the global

market scenario 5in and -hler, ABBA) <ires et al., ABBH".

,676,6+!6'

Adeleye, 6.O. and ?usuf, ?.?. ABBI" F%owards agile

manufacturing@ models of competition and performance

outcomes, Int. -. .gile ystems and /anagement, 9ol.

3, +o. 3, pp.DC;33B.

Anoopkumar, 8., Devadasan, '.,., 'hali2, <.,., 9inodh,

'., ,a2anayagam, '. and 6dinbarough, *.AB3B"

F*mplementation of agile supply chain model in an

electronic switches manufacturing company, Int. -.

er0ices and 1perations /anagement, 9ol. I, +o. H,

pp.HJA;HID.

4rown, '. and 4essant, L. ABBC" F%he manufacturing

strategy-capabilities links in mass customi.ation and

agile manufacturing ; an e&ploratory study, Int. -.

1perations and Production /anagement, 9ol. AC, +o. G,

pp.GBG;GCB.

!hang, L.>., 5uh, ?.<. and !hiou, '.'. 3DDG" F*ntegrated

application in !AD#!A$, scheduling and control,

Integrated /anufacturing ystems, 9ol. E, +o. I,

pp.CGE;CEG.

!hen, '-5. and >ang, >-%. ABB3" F!omputer aided

manufacturing technologies for centrifugal compressor

impellers, -ournal of /aterials Processing +ec"nology,

9ol. 33J, +o. C, pp.AEH;ADC.

De 5app, L.A., 7ord, D.+., 4ryant, L.A. and :orlen, L.

ABBH" F*mpacts of !AD on design reali.ation,

Engineering, #onstruction and .rc"itectural

/anagement, 9ol. 33, +o. H, pp.AEH;AD3.

Dereli, %. and Durmusoglu, A. AB3B" FAn integrated

framework for new product development using who-

when-where-why-what-how J>3:", theory of inventive

problem solving and patent information ; a case study,

Int. -. Industrial and ystems Engineering, 9ol. J, +o. C,

pp.CJH;CIJ.

Dowlatshahi, '. and !ao, W. ABBI" F%he relationships

among virtual enterprise, information technology, and

business performance in agile manufacturing@ an

industry perspective, European -ournal of 1perational

2esearc", 9ol. 3GH, +o. A, pp.ECJ;EIB.

6lkins, D.A., :uang, +. and Alden, L.$. ABBH" FAgile

manufacturing systems in the automotive industry, Int.

-. Production Economics, 9ol. D3, +o. C, pp.AB3;A3H.

8aafar, 5.=., $asoud, '.A. and +assef, A.O. ABBE" FA

particle swarm-based genetic algorithm for scheduling

in an agile environment, #omputers and Industrial

Engineering, 9ol. JJ, +o. C, pp.GBG;GAB.

8on.ale.-4enito, L.A. ABBJ" F'tudy of the effect of

manufacturing proactivity on business performance,

Int. -. 1perations and Production /anagement, 9ol. AJ,

+o. C, pp.AAA;AH3.

8ore, A., :aapasalo, :. and %ahtinen, %. ABBD" FAgile

manufacturing enablers for 7innish steel products

network, Int. -. Industrial and ystems Engineering,

9ol. H, +o. C, pp.AJJ;AID.

8unasekaran, A. 3DDE" FAgile manufacturing@ enablers

and an implementation framework, Int. -. Production

2esearc", 9ol. CI, +o. J, pp.3AAC;3AHG.

8unasekaran, A. 3DDD" FAgile manufacturing@ a

framework for research and development, Int. -.

Production Economics, 9ol. IA, +os. 3#A, pp.EG;3BJ.

:asan, $.A., 'hankar, ,., 'arkis, L., 'uhail, A. and Asif,

'. ABBD" FA study of enablers of agile manufacturing,

Int. -. Industrial and ystems Engineering, 9ol. H, +o. H,

pp.HBG;HCB.

:ooper, $.L., 'teeple, D. and >inters, !.+. ABB3"

F!osting customer value@ an approach for the agile

enterprise, Int. -. 1perations and Production

/anagement, 9ol. A3, +os. J#I, pp.ICB;IHH.

*nman, ,.A., 'ale, ,.'., 8reen Lr., =.>. and >hitten, D.

AB3B" FAgile manufacturing@ relation to L*%, operational

performance and firm performance, -ournal of

1perations /anagement, 3E Lune, DO*@

3B.3B3I#2.2om.AB3B.BI.BB3.

*smail, :.'., 'nowden, '.<., <oolton, L., ,eid, *.,. and

Arokiam, *.!. ABBI" FAgile manufacturing framework

and practice, Int. -. .gile ystems and /anagement,

9ol. 3, +o. 3, pp.33;AE.

=im, =.L., 5ee, D.-. and 5ee, $.'. ABBI" FDetermining

product platform elements for mass customisation, Int.

-. Producti0ity and &uality /anagement, 9ol. 3, +os.

3#A, pp 3IA;3EA.

=usiak, A. and :e, D.>. 3DDG" FDesign for agile

assembly@ an operational perspective, Int. -. Production

2esearc", 9ol. CJ, +o. 3, pp.3JG;3GE.

=usiak, A. and :e, D.>. 3DDE" FDesign for agility@ a

scheduling perspective, 2o$otics and #omputer

Integrated /anufacturing, 9ol. 3H, pp.H3J;HAG.

5in, ?.L. and -hler, A. ABBA" F'hortening the design for

assembly process time for torque converter

development, .ssem$ly .utomation, 9ol. AA, +o. C,

pp.AHE;AJD.

Onuh, '.O. and :on, =.=.4. ABB3" F*ntegration of rapid

prototyping technology into 7$' for agile

manufacturing, Integrated /anufacturing ystems, 9ol.

3A, +o. C, pp.3GD;3EI.

Onuh, '., 4ennett, +. and :ughes, 9. ABBI" F,everse

engineering and rapid tooling as enablers of agile

manufacturing, Int. -. .gile ystems and /anagement,

9ol. 3, +o. 3, pp.IB;GA.

<ires, L.+., 8odinho, %. and 7erreira, <. ABBH" F!AD

interface for automatic robotic welding programming,

Industrial 2o$ot, 9ol. C3, +o. 3, pp.G3;GI.

'harifi, :. and Mhang, M. ABB3" FAgile manufacturing in

practice@ application of a methodology, Int. -.

1perations and Production /anagement, 9ol. A3, +os.

J#I, pp.GGA;GDH.

9inodh, '., 'undarara2, 8. and Devadasan, '.,. ABBD"

F%otal agile design system model via literature

e&ploration, Industrial /anagement and Data ystems,

9ol. 3BD, +o. H, pp.JGB;JEE.

9inodh, '., 'undarara2, 8., Devadasan, '.,., =uttalingam,

D., $eenakshi 'undaram, <.5. and ,a2anayagam, D.

ABBEa" F6nhancing competitiveness through !AD

phase of total agile design system, Int. -. Process

/anagement and 3enc"marking, 9ol. A, +o. C, pp.3DG;

AAB.

Das könnte Ihnen auch gefallen

- Manufacturing Facilities Design & Material Handling: Sixth EditionVon EverandManufacturing Facilities Design & Material Handling: Sixth EditionNoch keine Bewertungen

- Mudit Gupta ResumeDokument4 SeitenMudit Gupta ResumeMudit GuptaNoch keine Bewertungen

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesVon EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesBewertung: 4 von 5 Sternen4/5 (4)

- Department of Mechanical Engineering Faculty of Engineering Semester 2 Session 2012/2013 PrototypingDokument4 SeitenDepartment of Mechanical Engineering Faculty of Engineering Semester 2 Session 2012/2013 Prototypingdanish91Noch keine Bewertungen

- Walking the Design for Six Sigma Bridge with Your CustomerVon EverandWalking the Design for Six Sigma Bridge with Your CustomerNoch keine Bewertungen

- Optimizing Current Strategies and Applications in Industrial Engineering (Prasanta Sahoo)Dokument398 SeitenOptimizing Current Strategies and Applications in Industrial Engineering (Prasanta Sahoo)DrSalimASNoch keine Bewertungen

- Case Studies For Learning Automated System IntegrationDokument8 SeitenCase Studies For Learning Automated System IntegrationPradeep PatelNoch keine Bewertungen

- Product Design and Concurrent Engineerin UNIT 1Dokument22 SeitenProduct Design and Concurrent Engineerin UNIT 1Nabila RasgadoNoch keine Bewertungen

- Karan Dwivedi 5 Floor, Yerwada, Pune +91 9850033661: SummaryDokument5 SeitenKaran Dwivedi 5 Floor, Yerwada, Pune +91 9850033661: Summaryniraj3handeNoch keine Bewertungen

- Literature Review On Assembly Line BalancingDokument7 SeitenLiterature Review On Assembly Line Balancingea20cqyt100% (1)

- The Technical Paper Presentation ON: " Rapid Prototyping "Dokument21 SeitenThe Technical Paper Presentation ON: " Rapid Prototyping "roscillaNoch keine Bewertungen

- Design and Production Automation For Mass Customisation - An Initial Framework Proposal Evaluated in Engineering Education and SME ContextsDokument10 SeitenDesign and Production Automation For Mass Customisation - An Initial Framework Proposal Evaluated in Engineering Education and SME ContextsJosip StjepandicNoch keine Bewertungen

- Data-Driven Manufacturing A Paradigm Shift in The Manufacturing IndustryDokument5 SeitenData-Driven Manufacturing A Paradigm Shift in The Manufacturing IndustryIJRASETPublicationsNoch keine Bewertungen

- Thesis Additive ManufacturingDokument4 SeitenThesis Additive Manufacturingbnjkstgig100% (2)

- Line Balancing ThesisDokument8 SeitenLine Balancing Thesisbsgwk8wc100% (2)

- Aditya Penjarla ProfileDokument2 SeitenAditya Penjarla Profileapi-255834785Noch keine Bewertungen

- Automating Knowledge TemplatesDokument0 SeitenAutomating Knowledge Templateschandramohan muruganNoch keine Bewertungen

- Research Papers On Advanced Manufacturing TechnologyDokument4 SeitenResearch Papers On Advanced Manufacturing Technologygz8y0espNoch keine Bewertungen

- Chapter 7: Process PlanningDokument6 SeitenChapter 7: Process Planningஅன்புடன் அஸ்வின்Noch keine Bewertungen

- Thesis of Industrial EngineeringDokument5 SeitenThesis of Industrial Engineeringbarbtillichfargo100% (2)

- Manufacturing Engineering Processes For Off-Road Buggy'S Fuel Tank ProductionDokument12 SeitenManufacturing Engineering Processes For Off-Road Buggy'S Fuel Tank ProductionTJPRC PublicationsNoch keine Bewertungen

- Chapter 6 SolutionDokument18 SeitenChapter 6 SolutionHardik SharmaNoch keine Bewertungen

- Manufacturing Flexibility A Literature Review PDFDokument4 SeitenManufacturing Flexibility A Literature Review PDFafdtliuvbNoch keine Bewertungen

- Lean Agile PaperDokument23 SeitenLean Agile Paperashish patelNoch keine Bewertungen

- Unit-Ii Improving Software EconomicsDokument20 SeitenUnit-Ii Improving Software EconomicsJason HollowayNoch keine Bewertungen

- AnalisBasedSimulation PDFDokument5 SeitenAnalisBasedSimulation PDFRieska foni YuniarNoch keine Bewertungen

- Factory Automation - Automation Project Justification - Just About The Math - IsADokument2 SeitenFactory Automation - Automation Project Justification - Just About The Math - IsARaul GonzalezNoch keine Bewertungen

- The Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingDokument24 SeitenThe Effectiveness of A Vehicle Manufacturing Line Using Probabilistic Process TimingIJRASETPublicationsNoch keine Bewertungen

- Sciencedirect: Joint Optimization of Production Planning and Capacity Adjustment For Assembly SystemDokument6 SeitenSciencedirect: Joint Optimization of Production Planning and Capacity Adjustment For Assembly SystemCESARPINEDANoch keine Bewertungen

- CIM Assignment 6Dokument3 SeitenCIM Assignment 6Abuzar AliNoch keine Bewertungen

- Summer 2006: V Vo Oll.. IIX X September/October 2006Dokument20 SeitenSummer 2006: V Vo Oll.. IIX X September/October 2006Fahmi0% (1)

- Research Article Supply Chain Management System For Automobile Manufacturing Enterprises Based On SAPDokument11 SeitenResearch Article Supply Chain Management System For Automobile Manufacturing Enterprises Based On SAPKase Hija IndiaNoch keine Bewertungen

- Product Planning in Quality Function Deployment Using A Combined Analytic Network Process and Goal Programming Approach - Nguyen Hoang DungDokument20 SeitenProduct Planning in Quality Function Deployment Using A Combined Analytic Network Process and Goal Programming Approach - Nguyen Hoang DungNguyen Hoang DungNoch keine Bewertungen

- The Application of Process Automation and Optimisation in The Rapid Development of New Passenger Vehicles at SAIC MotorDokument15 SeitenThe Application of Process Automation and Optimisation in The Rapid Development of New Passenger Vehicles at SAIC MotorAltairEnlightenNoch keine Bewertungen

- Reconfigurable Manufacturing Systems and Their Enabling Technologies 3Dokument2 SeitenReconfigurable Manufacturing Systems and Their Enabling Technologies 3Anonymous WmMP8H6JGNoch keine Bewertungen

- LCI Report Config - EnglDokument19 SeitenLCI Report Config - EnglMihai Cristian LascuNoch keine Bewertungen

- Android Application For Analysis of Productivity of Precision Machine ShopDokument7 SeitenAndroid Application For Analysis of Productivity of Precision Machine ShopIJRASETPublicationsNoch keine Bewertungen

- Apqp HubDokument11 SeitenApqp HubMohammad KhanjaniNoch keine Bewertungen

- Automotive Engineering Dissertation IdeasDokument7 SeitenAutomotive Engineering Dissertation IdeasPaperWritersCollegeCanada100% (1)

- Research Paper On Assembly Line BalancingDokument8 SeitenResearch Paper On Assembly Line Balancingyfwkdbaod100% (1)

- Master of Business Administration - MBA Semester 2 MB0044-Production & Operations ManagementDokument47 SeitenMaster of Business Administration - MBA Semester 2 MB0044-Production & Operations ManagementASR07Noch keine Bewertungen

- Subject: Production and Operation Management Subject Code: MB0044 Assignment Set - 1Dokument13 SeitenSubject: Production and Operation Management Subject Code: MB0044 Assignment Set - 1amit8214Noch keine Bewertungen

- Modelling Supply Chain PerformanceDokument8 SeitenModelling Supply Chain PerformanceDokajanNoch keine Bewertungen

- Technical Essay: Software Product Lines Tatiana YaldaieDokument6 SeitenTechnical Essay: Software Product Lines Tatiana YaldaieTatiana YaNoch keine Bewertungen

- Atde 16 Atde210123Dokument10 SeitenAtde 16 Atde210123Josip StjepandicNoch keine Bewertungen

- Supplement B Operations Technology: Review and Discussion QuestionsDokument2 SeitenSupplement B Operations Technology: Review and Discussion QuestionsAlejandroV2013Noch keine Bewertungen

- Thesis Production EngineeringDokument6 SeitenThesis Production Engineeringafktgvllsgajfw100% (2)

- Process OptimizationDokument17 SeitenProcess OptimizationshyamkohliNoch keine Bewertungen

- Dan Cartwright Resume 1213Dokument3 SeitenDan Cartwright Resume 1213Daniel CartwrightNoch keine Bewertungen

- Research Paper On Production Planning and ControlDokument8 SeitenResearch Paper On Production Planning and Controlh03318kj100% (1)

- Systems Analysis and Design 9th Edition ReviewDokument49 SeitenSystems Analysis and Design 9th Edition ReviewLoretta Lynn Altmayer79% (14)

- Hydrocarbon Processing 12-2007 Integrated Plant DesignDokument5 SeitenHydrocarbon Processing 12-2007 Integrated Plant DesignRehan MaqboolNoch keine Bewertungen

- MBD Book PDF VersionDokument94 SeitenMBD Book PDF VersionnknfiveNoch keine Bewertungen

- Agile Manufacturing: A Framework For Research and DevelopmentDokument19 SeitenAgile Manufacturing: A Framework For Research and Developmentashenafi woldesenbetNoch keine Bewertungen

- Butterfield Joe Irene C L NG Rajkumar RoDokument13 SeitenButterfield Joe Irene C L NG Rajkumar RoPraveen KachhawahaNoch keine Bewertungen

- Automobile Engineering Research PapersDokument8 SeitenAutomobile Engineering Research Papersfzpabew4100% (1)

- Data ManagementDokument7 SeitenData ManagementDeepak ChachraNoch keine Bewertungen

- Execution Plan PDFDokument9 SeitenExecution Plan PDFVatsal SharmaNoch keine Bewertungen

- Insights May June 2010Dokument24 SeitenInsights May June 2010Santhosh LingappaNoch keine Bewertungen

- College of Engineering and Technology: Criteria 7Dokument14 SeitenCollege of Engineering and Technology: Criteria 7VarunNoch keine Bewertungen

- GL On CM - Internal CirculationDokument2 SeitenGL On CM - Internal CirculationVarunNoch keine Bewertungen

- 18.12.17 To 12.01.18 DTS 'B'Dokument4 Seiten18.12.17 To 12.01.18 DTS 'B'VarunNoch keine Bewertungen

- Yuva IremosDokument9 SeitenYuva IremosVarunNoch keine Bewertungen

- OneDokument15 SeitenOneVarunNoch keine Bewertungen

- The Six Sigma Dmaic Methodology in LogisticsDokument6 SeitenThe Six Sigma Dmaic Methodology in LogisticsVarunNoch keine Bewertungen

- Stroboscope: Non-Contact Speed Measurement High Intensity Flashes Direct Speed Reading in RPM No Shaft ModificationDokument1 SeiteStroboscope: Non-Contact Speed Measurement High Intensity Flashes Direct Speed Reading in RPM No Shaft ModificationVarunNoch keine Bewertungen

- Manuscript Template (Feb 1, 2012)Dokument2 SeitenManuscript Template (Feb 1, 2012)VarunNoch keine Bewertungen

- An Application of DMAIC Methodology For Increasing The Yarn Quality in Textile IndustryDokument16 SeitenAn Application of DMAIC Methodology For Increasing The Yarn Quality in Textile IndustryVarunNoch keine Bewertungen

- JSBM 12086Dokument21 SeitenJSBM 12086VarunNoch keine Bewertungen

- Self Study Report 1Dokument315 SeitenSelf Study Report 1VarunNoch keine Bewertungen

- Published Paper of IJCAS in 2012-2014Dokument114 SeitenPublished Paper of IJCAS in 2012-2014VarunNoch keine Bewertungen

- Information For AuthorsDokument1 SeiteInformation For AuthorsVarunNoch keine Bewertungen

- IJCAS ChecklistDokument2 SeitenIJCAS ChecklistVarunNoch keine Bewertungen

- Structural Analysis of Spar Madeup of Carbon Fibre Composite MaterialDokument6 SeitenStructural Analysis of Spar Madeup of Carbon Fibre Composite MaterialVarunNoch keine Bewertungen

- Rigid BodyDokument38 SeitenRigid BodyVarunNoch keine Bewertungen

- Feed BackDokument15 SeitenFeed BackVarunNoch keine Bewertungen

- Sample CementDokument16 SeitenSample CementsatyaNoch keine Bewertungen

- Industria Auto Din JaponiaDokument76 SeitenIndustria Auto Din JaponiaMircea Dan StanciuNoch keine Bewertungen

- Supply Chain Optimization in Manufacturing Enterprise - ThesisDokument68 SeitenSupply Chain Optimization in Manufacturing Enterprise - ThesisFarhan SarwarNoch keine Bewertungen

- Romme Etal 2023Dokument21 SeitenRomme Etal 2023Samahir ElzakiNoch keine Bewertungen

- Warehousing and Supply Chain ManagementDokument149 SeitenWarehousing and Supply Chain ManagementKrish SathyamoorthyNoch keine Bewertungen

- Danese and Romano (2011) ModerationDokument14 SeitenDanese and Romano (2011) ModerationUmer NaseemNoch keine Bewertungen

- Supplier Evaluation and SelectionDokument15 SeitenSupplier Evaluation and Selectionfatimamaham100% (1)

- MKT 529 Term Paper AgoraDokument37 SeitenMKT 529 Term Paper AgoraIshrat Jahan DiaNoch keine Bewertungen

- CH 20 Im 11 eDokument18 SeitenCH 20 Im 11 eYvette ZapantaNoch keine Bewertungen

- SCM Logistics Analyst JDDokument2 SeitenSCM Logistics Analyst JDPerumal DMNoch keine Bewertungen

- Digital Firm in BangladeshDokument5 SeitenDigital Firm in BangladeshSauravNoch keine Bewertungen

- Proposal of A Concept For Improving The Sustainable Management of Supply Chains in The Textile IndustryDokument6 SeitenProposal of A Concept For Improving The Sustainable Management of Supply Chains in The Textile IndustryGladys ChepkoechNoch keine Bewertungen

- SCM CH-5 Network Design in Supply ChainDokument28 SeitenSCM CH-5 Network Design in Supply ChainSumit KumarNoch keine Bewertungen

- Understanding Economic Change The New Normal?!: 1 CourseDokument32 SeitenUnderstanding Economic Change The New Normal?!: 1 CoursemariaroxxNoch keine Bewertungen

- 5-Vendors Are The King MakerDokument2 Seiten5-Vendors Are The King Makersukumaran3210% (1)

- Porters Five Forces ModelDokument5 SeitenPorters Five Forces Modelsonuka100% (6)

- 13.BSBLDR602 Assessment 4 LearnerDokument16 Seiten13.BSBLDR602 Assessment 4 LearnerSabik NeupaneNoch keine Bewertungen

- COBSTRM Group 1 Webworx Final PaperDokument64 SeitenCOBSTRM Group 1 Webworx Final PaperLiandra Elise EspinosaNoch keine Bewertungen

- Contemporary Logistics 12th Edition Murphy Solutions ManualDokument9 SeitenContemporary Logistics 12th Edition Murphy Solutions Manualchristophercampbellbgsoyepdnx100% (14)

- Chapter 6 LogisticsDokument8 SeitenChapter 6 Logisticseviegonzalez21175% (4)

- Chapter 9 - Achieving Operational Excellence and Customer Intimacy Enterprise ApplicationsDokument16 SeitenChapter 9 - Achieving Operational Excellence and Customer Intimacy Enterprise ApplicationsHASNAT ABULNoch keine Bewertungen

- An Exploratory Study of Retailers' Operational Performance Within UAE Market: A Case StudyDokument11 SeitenAn Exploratory Study of Retailers' Operational Performance Within UAE Market: A Case StudyBOHR International Journal of Operations Management Research and Practices (BIJOMRP)Noch keine Bewertungen

- Individual Report PATAGONIA VfinalDokument9 SeitenIndividual Report PATAGONIA VfinalCeciliaNoch keine Bewertungen

- Brochure EPMDokument7 SeitenBrochure EPMAmit PaulNoch keine Bewertungen

- Global Operations & Supply Chain ManagementDokument37 SeitenGlobal Operations & Supply Chain ManagementAnonymousNoch keine Bewertungen

- PWC Food Fraud Vulnerability AssessmentDokument8 SeitenPWC Food Fraud Vulnerability AssessmentAnous AlamiNoch keine Bewertungen

- Avendus b2b Marketplaces Revolutionizing The Indian b2b Commerce Supply Chain 12 04 Img 64361487bb489Dokument121 SeitenAvendus b2b Marketplaces Revolutionizing The Indian b2b Commerce Supply Chain 12 04 Img 64361487bb489rohit100% (1)

- Deocument 2661Dokument41 SeitenDeocument 2661arlene.sharpe531Noch keine Bewertungen

- Oracle® Mobile Supply Chain Applications: User's Guide Release 11iDokument182 SeitenOracle® Mobile Supply Chain Applications: User's Guide Release 11inabendusenguptaNoch keine Bewertungen

- Proposal - 2302002Dokument19 SeitenProposal - 2302002Gift AtukundaNoch keine Bewertungen

- Beginning AutoCAD® 2022 Exercise Workbook: For Windows®Von EverandBeginning AutoCAD® 2022 Exercise Workbook: For Windows®Noch keine Bewertungen

- AutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsVon EverandAutoCAD 2010 Tutorial Series: Drawing Dimensions, Elevations and SectionsNoch keine Bewertungen

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Von EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Bewertung: 5 von 5 Sternen5/5 (2)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsVon EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNoch keine Bewertungen

- SolidWorks 2015 Learn by doing-Part 1Von EverandSolidWorks 2015 Learn by doing-Part 1Bewertung: 4.5 von 5 Sternen4.5/5 (11)

- Certified Solidworks Professional Advanced Surface Modeling Exam PreparationVon EverandCertified Solidworks Professional Advanced Surface Modeling Exam PreparationBewertung: 5 von 5 Sternen5/5 (1)