Beruflich Dokumente

Kultur Dokumente

Power Plant Energy Saving Tips

Hochgeladen von

Sarah FrazierCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Power Plant Energy Saving Tips

Hochgeladen von

Sarah FrazierCopyright:

Verfügbare Formate

M inim iz e Com pr e sse d A ir Le a k s

Leaks are a significant source of wasted energy in a compressed air system, often wasting

as much as 20-30% of the compressors output. Compressed air leaks can also contribute

to problems with system operations, including:

Fluctuating system pressure, which can cause air tools and other air-operated

equipment to function less efficiently, possibly affecting production

Excess compressor capacity, resulting in higher than necessary costs

Decreased service life and increased maintenance of supply equipment (including the

compressor package) due to unnecessary cycling and increased run time.

Although leaks can occur in any part of the system, the most common problem areas are:

couplings, hoses, tubes, fittings, pipe joints, quick disconnects, FRLs (filter, regulator, and

lubricator), condensate traps, valves, flanges, packings, thread sealants, and point of use

devices. Leakage rates are a function of the supply pressure in an uncontrolled system

and increase with higher system pressures. Leakage rates are also proportional to the

square of the orifice diameter. (See table below.)

Leak Detection

The best way to detect leaks is to use an ultrasonic acoustic detector, which can

recognize high frequency hissing sounds associated with air leaks. These portable units

are very easy to use. Costs and sensitivities vary, so test before you buy. Asimpler

method is to apply soapy water with a paintbrush to suspect areas. Although reliable,

this method can be time consuming and messy.

Compressed Air Motors Steam

Suggested Actions

Fixing leaks once is not enough.

Incorporate a leak prevention

program into your facilitys

operations. It should include

identification and tagging,

tracking, repair, verification,

and employee involvement.

Set a reasonable target for cost-

effective leak reduction5-10%

of total system flow is typical

for industrial facilities.

Once leaks are repaired,

re-evaluate your compressed air

system supply. Work with a

compressed air systems specialist

to adjust compressor controls.

Also look at alternatives to

some compressed air uses. If a

compressor can be turned off,

benefits include cost savings

and a system backup.

References

Improving Compressed Air System

Performance: A Sourcebook for the

Industry, Motor Challenge and

Compressed Air Challenge,

April 1998.

Training

Fundamentals of Compressed Air

Systems - 1 day

Advanced Management of

Compressed Air Systems - 2 days

Offered by the Compressed Air

Challenge. Call the OIT Clearing-

house or visit the BestPractices Web

site (www.oit.doe.gov/bestpractices)

for the latest schedule and

locations.

OFFICE OF INDUSTRIAL TECHNOLOGIES

ENERGY EFFICIENCY AND RENEWABLE ENERGY U.S. DEPARTMENT OF ENERGY

For additional information on

industrial energy efficiency

measures, contact the

OIT Clearinghouse at

(800) 862-2086.

Leakage rates

a

(cfm) for different supply pressures and approximately

equivalent orifice sizes

b

Pressure

Orifice Diameter (inches)

(psig) 1/64 1/32 1/16 1/8 1/4 3/8

70 0.3 1.2 4.8 19.2 76.7 173

80 0.33 1.3 5.4 21.4 85.7 193

90 0.37 1.5 5.9 23.8 94.8 213

100 0.41 1.6 6.5 26.0 104 234

125 0.49 2.0 7.9 31.6 126 284

a

For well-rounded orifices, multiply the values by 0.97, and for sharp-edged orifices,

multiply the values by 0.61.

b

Used with permission from Fundamentals of Compressed Air Systems Training offered by

the Compressed Air Challenge.

BestPractices is part of the Office of

Industrial Technologies (OITs) Industries

of the Future strategy, which helps the

countrys most energy-intensive

industries improve their competitiveness.

BestPractices brings together the best-

available and emerging technologies

and practices to help companies begin

improving energy efficiency, environmental

performance, and productivity right now.

BestPractices focuses on plant systems,

where significant efficiency improvements

and savings can be achieved. Industry

gains easy access to near-term and

long-term solutions for improving the

performance of motor, steam, compressed

air, and process heating systems. In

addition, the Industrial Assessment Centers

provide comprehensive industrial energy

evaluations to small and medium-size

manufacturers.

FOR ADDITIONAL INFORMATION,

PLEASE CONTACT:

Eric Lightner

Office of Industrial Technologies

Phone: (202) 586-8130

Fax: (202) 586-1658

Eric.Lightner@ee.doe.gov

www.oit.doe.gov/bestpractices

OIT Clearinghouse

Phone: (800) 862-2086

Fax: (360) 586-8303

clearinghouse@ee.doe.gov

Please send any comments,

questions, or suggestions to

webmaster.oit@ee.doe.gov

Visit our home page at

www.oit.doe.gov

Office of Industrial Technologies

Energy Efficiency

and Renewable Energy

U.S. Department of Energy

Washington, D.C. 20585

DOE/GO-102000-0988

December 2000

Compressed Air Tip Sheet #3

About DOEs Office of Industrial Technologies

The Office of Industrial Technologies (OIT), through partnerships with industry,

government, and non-governmental organizations, develops and delivers advanced

energy efficiency, renewable energy, and pollution prevention technologies for

industrial applications. OIT is part of the U.S. Department of Energys Office of

Energy Efficiency and Renewable Energy.

OIT encourages industry-wide efforts to boost resource productivity through a

strategy called Industries of the Future (IOF). IOF focuses on the following nine

energy and resource intensive industries:

Agriculture Forest Products Mining

Aluminum Glass Petroleum

Chemicals Metal Casting Steel

OIT and its BestPractices program offer a wide variety of resources to industrial

partners that cover motor, steam, compressed air and process heating systems.

For example, BestPractices software can help you decide whether to replace or

rewind motors (MotorMaster+), assess the efficiency of pumping systems (PSAT),

or determine optimal insulation thickness for pipes and pressure vessels (3E Plus).

Training is available to help you or your staff learn how to use these software

programs and learn more about industrial systems. Workshops are held around the

country on topics such as Capturing the Value of Steam Efficiency, Fundamentals

and Advanced Management of Compressed Air Systems, and Motor System

Management. Available technical publications range from case studies and tip

sheets to sourcebooks and market assessments. The Energy Matters newsletter, for

example, provides timely articles and information on comprehensive energy systems

for industry. You can access these resources and more by visiting the BestPractices

Web site at www.oit.doe.gov/bestpractices or by contacting the OIT Clearinghouse at

800-862-2086 or via email at clearinghouse@ee.doe.gov.

Example

Achemical plant undertook a leak prevention program following a compressed air

audit at their facility. Leaks, approximately equivalent to different orifice sizes, were

found as follows: 100 leaks of 1/32" at 90 psig, 50 leaks of 1/16" at 90 psig, and

10 leaks of 1/4" at 100 psig. Calculate the annual cost savings if these leaks were

eliminated. Assume 7000 annual operating hours, an aggregate electric rate of

$0.05/kWh, and compressed air generation requirement of approximately

18 kW/100 cfm.

Cost savings = # of leaks x leakage rate (cfm) x kW/cfm x # of hours x $/kWh

Using values of the leakage rates from the above table and assuming sharp-edged

orifices:

Cost savings from 1/32" leaks = 100 x 1.5 x 0.61 x 0.18 x 7000 x 0.05 = $5,765

Cost savings from 1/16" leaks = 50 x 5.9 x 0.61 x 0.18 x 7000 x 0.05 = $11,337

Cost savings from 1/4" leaks = 10 x 104 x 0.61 x 0.18 x 7000 x 0.05 = $39,967

Total cost savings from eliminating these leaks = $57,069

Note that the savings from the elimination of just 10 leaks of 1/4" account for

almost 70% of the overall savings. As leaks are identified, it is important to

prioritize them and fix the largest ones first.

Das könnte Ihnen auch gefallen

- Incident ReportDokument24 SeitenIncident ReportSarah FrazierNoch keine Bewertungen

- Health Condition Report of The Fan Bs Fan For Boiler No # 1: ObservationDokument4 SeitenHealth Condition Report of The Fan Bs Fan For Boiler No # 1: ObservationSarah FrazierNoch keine Bewertungen

- Dangote CPPDokument161 SeitenDangote CPPSarah Frazier100% (1)

- Earthing PracticeDokument52 SeitenEarthing PracticeSarah FrazierNoch keine Bewertungen

- 210 MW Power PlantDokument3 Seiten210 MW Power PlantSarah FrazierNoch keine Bewertungen

- WTCDokument57 SeitenWTCSarah FrazierNoch keine Bewertungen

- ABG PresentationDokument28 SeitenABG PresentationSarah Frazier0% (1)

- Valves&Soot BlowersDokument29 SeitenValves&Soot BlowersSarah FrazierNoch keine Bewertungen

- M. Syed Amirsha Hakani, B.EDokument29 SeitenM. Syed Amirsha Hakani, B.ESarah FrazierNoch keine Bewertungen

- Roller MillsDokument27 SeitenRoller MillsSarah FrazierNoch keine Bewertungen

- Proposed Cs3000System Architecture: Remote Operator Stations-Assumed at 50 Mtrs From The Main CRDokument1 SeiteProposed Cs3000System Architecture: Remote Operator Stations-Assumed at 50 Mtrs From The Main CRSarah FrazierNoch keine Bewertungen

- Air Pre HeaterDokument22 SeitenAir Pre HeaterSarah FrazierNoch keine Bewertungen

- Stoker FiringDokument26 SeitenStoker FiringSarah Frazier50% (2)

- FAN-SOUND and Vibration, BalancingDokument33 SeitenFAN-SOUND and Vibration, BalancingSarah FrazierNoch keine Bewertungen

- Boiler Protection AND InterlocksDokument54 SeitenBoiler Protection AND InterlocksSarah Frazier100% (1)

- 3 Nos. 660 MW - Coal Fired Supercritical: Conference - ENERGEX 2008 Date: 26-09-2008Dokument19 Seiten3 Nos. 660 MW - Coal Fired Supercritical: Conference - ENERGEX 2008 Date: 26-09-2008Sarah FrazierNoch keine Bewertungen

- Adjustable Speed Asynchronous Machine in Hydro Power Plants and Its Advantages For The Electric Grid StabilityDokument8 SeitenAdjustable Speed Asynchronous Machine in Hydro Power Plants and Its Advantages For The Electric Grid StabilitySarah FrazierNoch keine Bewertungen

- SHUT DOWN - PpsDokument6 SeitenSHUT DOWN - PpsSarah FrazierNoch keine Bewertungen

- Safety Valve Data SheetDokument3 SeitenSafety Valve Data SheetSarah Frazier100% (1)

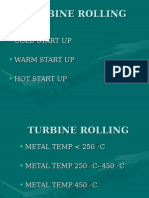

- Turbine RollingDokument39 SeitenTurbine RollingSarah Frazier100% (2)

- Argentina Ver2 3Dokument9 SeitenArgentina Ver2 3Sarah FrazierNoch keine Bewertungen

- (WTC) Repair Welding in Power PlantsDokument23 Seiten(WTC) Repair Welding in Power PlantsSarah FrazierNoch keine Bewertungen

- REM54 ParlistENcDokument158 SeitenREM54 ParlistENcSarah FrazierNoch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 24 Doctors With The Courage To Tell The Truth About Distilled WaterDokument22 Seiten24 Doctors With The Courage To Tell The Truth About Distilled WaterEnglishTutr100% (6)

- Underwater WindmillDokument21 SeitenUnderwater Windmillbhagyashree behera100% (1)

- Civil Engineer Resume 0Dokument2 SeitenCivil Engineer Resume 0Nazee 122333Noch keine Bewertungen

- Trinidad Guardian - 07.10.22Dokument48 SeitenTrinidad Guardian - 07.10.22D-TECH CONTRACTINGNoch keine Bewertungen

- SOFEC CALM BUOY FINAL 3page RedDokument3 SeitenSOFEC CALM BUOY FINAL 3page RedJ. Jorge TorresNoch keine Bewertungen

- 4 Pressure BuoyancyDokument8 Seiten4 Pressure BuoyancythinkiitNoch keine Bewertungen

- SANS 1936-2 Geotechnical Investigations and DeterminationsDokument37 SeitenSANS 1936-2 Geotechnical Investigations and Determinationsdran100% (2)

- Aquaculture Systems: Presented By: M.F.Sc. I YearDokument18 SeitenAquaculture Systems: Presented By: M.F.Sc. I Yearshivani vermaNoch keine Bewertungen

- 7 Water For Life: Being Used YouDokument4 Seiten7 Water For Life: Being Used YouSabari PramanikNoch keine Bewertungen

- Climate and Weather (Esquema)Dokument7 SeitenClimate and Weather (Esquema)Janet Gallardo SerraNoch keine Bewertungen

- Sample Problem Series of 10 Evaporators Multiple Equipment Non Reactive System PDFDokument2 SeitenSample Problem Series of 10 Evaporators Multiple Equipment Non Reactive System PDFPytharix CaineNoch keine Bewertungen

- Cost EstimateDokument1 SeiteCost EstimateCire OmalinNoch keine Bewertungen

- Brief Directions For The Use of Biodynamic Sprays 500, 501 and 508Dokument3 SeitenBrief Directions For The Use of Biodynamic Sprays 500, 501 and 508budhistsluvcopyrightNoch keine Bewertungen

- The Water Purification Process 2Dokument4 SeitenThe Water Purification Process 2Yue YingNoch keine Bewertungen

- MEGECHA Head WORK (Revised) 2Dokument159 SeitenMEGECHA Head WORK (Revised) 2Abiued EjigueNoch keine Bewertungen

- đất nước học AMDokument6 Seitenđất nước học AMDương HoaNoch keine Bewertungen

- Vitra Faucets and AccessoriesDokument272 SeitenVitra Faucets and AccessoriescothacoNoch keine Bewertungen

- Storm Water Pump StationDokument6 SeitenStorm Water Pump StationНемања КараклајићNoch keine Bewertungen

- Renderoc FC (1) Fairing Coat PDFDokument4 SeitenRenderoc FC (1) Fairing Coat PDFPrashant MankarNoch keine Bewertungen

- Gas & Condensate Production Facility Block DiagramDokument5 SeitenGas & Condensate Production Facility Block DiagramAswin TrisaktiNoch keine Bewertungen

- Forward Osmosis - Principles, Applications, and Recent DevelopmentsDokument18 SeitenForward Osmosis - Principles, Applications, and Recent DevelopmentsYuMdzaNoch keine Bewertungen

- 3-00 Hydraulic PrinciplesDokument59 Seiten3-00 Hydraulic Principleskdsessions100% (1)

- Phylum Porifera: / P Ɒ R Ɪ F ƏR ƏDokument4 SeitenPhylum Porifera: / P Ɒ R Ɪ F ƏR ƏPeterjohn QuimingNoch keine Bewertungen

- Hno3 PropertiesDokument2 SeitenHno3 PropertiesAimee Layson PolancoNoch keine Bewertungen

- A BVVVDokument10 SeitenA BVVVDigvijayNoch keine Bewertungen

- Foundations: S V Giri Babu Govt. Polytechnic VijayawadaDokument37 SeitenFoundations: S V Giri Babu Govt. Polytechnic VijayawadaMeenu ChauhanNoch keine Bewertungen

- Oilfield Magazine MayDokument52 SeitenOilfield Magazine MayFSBollNoch keine Bewertungen

- Shristi, Farm StructureDokument70 SeitenShristi, Farm StructureShristi ShefaliNoch keine Bewertungen

- Passive Down Draft Evaporative CoolingDokument2 SeitenPassive Down Draft Evaporative Coolingأمير معروف75% (4)

- Coal Runoff Analysis Complete ReportDokument32 SeitenCoal Runoff Analysis Complete ReportArif SusetyoNoch keine Bewertungen