Beruflich Dokumente

Kultur Dokumente

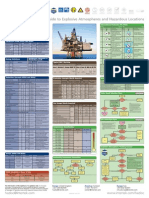

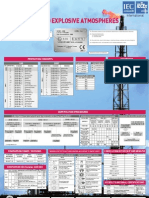

DS51 Non Electrical Wallchart Iss5 0813

Hochgeladen von

perumal13120 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

94 Ansichten1 Seite1) The document provides guidance for manufacturers and end users of non-electrical equipment for use in explosive atmospheres. It classifies gases and vapors according to their ignitability and lists temperature classes for maximum surface temperatures of equipment. (2) For equipment used in explosive atmospheres, it outlines certification requirements including the need for technical files and lists potential ignition sources to consider. (3) It provides an overview of ATEX certification and related services offered by SGS Baseefa including certification of personnel, equipment, quality systems, technical advice and testing.

Originalbeschreibung:

Ex Non Electrical Wall Chart

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden1) The document provides guidance for manufacturers and end users of non-electrical equipment for use in explosive atmospheres. It classifies gases and vapors according to their ignitability and lists temperature classes for maximum surface temperatures of equipment. (2) For equipment used in explosive atmospheres, it outlines certification requirements including the need for technical files and lists potential ignition sources to consider. (3) It provides an overview of ATEX certification and related services offered by SGS Baseefa including certification of personnel, equipment, quality systems, technical advice and testing.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

94 Ansichten1 SeiteDS51 Non Electrical Wallchart Iss5 0813

Hochgeladen von

perumal13121) The document provides guidance for manufacturers and end users of non-electrical equipment for use in explosive atmospheres. It classifies gases and vapors according to their ignitability and lists temperature classes for maximum surface temperatures of equipment. (2) For equipment used in explosive atmospheres, it outlines certification requirements including the need for technical files and lists potential ignition sources to consider. (3) It provides an overview of ATEX certification and related services offered by SGS Baseefa including certification of personnel, equipment, quality systems, technical advice and testing.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 1

NON-ELECTRICAL EQUIPMENT

GUIDANCE FOR MANUFACTURERS AND END USERS

Gas Groups

Gas Representative

Group Test Gas

I Methane

(mining only)

IIA Propane

IIB Ethylene

IIC Hydrogen

Gases are classified according to the

ignitability of gas-air mixture.

Refer to IEC/EN 60079-20-1 for classification

of common gases and vapours.

Temperature Class

T Class Maximum Surface

Temperature

T1 450C

T2 300C

T3 200C

T4 135C

T5 100C

T6 85C

Standards

EN13463-1

EN13463-2

EN13463-3

EN13463-5

EN13463-6

EN13463-8

Concept

general

requirements

flow restriction

flameproof

constructional

safety

control of

ignition

sources

liquid

immersion

Code

fr

d

c

b

k

Zone

2

22

1

21

1

21

1

21

1

21

SGS Baseefa Limited,

Rockhead Business Park,

Staden Lane,

Buxton, SK17 9RZ

tel. +44 (0)1298 766600

fax. +44 (0)1298 766601

e-mail info@baseefa.com

ATEX Coding

II 2 GD

EU

Explosive

atmosphere

symbol

Equipment

group

I - mining

II - non-mining

(*) = in presence of explosive atmosphere

Equipment

category

M1 - energised

M2 - de-energised (*)

1 - very high

protection

2 - high protection

3 - normal protection

Gas Dust

0 20

1 21

2 22

Ingress Protection (IP)

Hazardous area equipment typically requires

a minimum IP rating of IP54 but may be

assessed and tested to the higher ratings below:

DUST

IP 5x - Dust protected

IP 6x - Dust tight

WATER

Protected against:

IP x4 - splashing water

IP x5 - water jets

IP x6 - powered water jets

IP x7 - temporary immersion

IP x8 - continuous immersion

See IEC/EN 60529 for full definition of

IP ratings

Mechanical Protection Concepts

EX

Manufacturers Name

and Address

Product Identification

Serial No. and (or inc.)

Year of Manufacture

ATEX Notified Body

Identification No.

(Zone 0/20 only)

II 1GD IIC T4 ck

Baseefa10ATEX1111X

Gas Group

Protection Concept

Temperature Class

ATEX Coding

ATEX Certificate No.

(or Manufacturers

Technical File No.)

Ambient Range

1180

Tamb -30C to +50C

ABC Engineering

Buxton, SK17 9RZ, UK

Type xyz Pump

2009 s/n 1234

Pub DS51 Issue 5, August 2013

Ignition Risk Assessment

rare

malfunction

N/A

N/A

*

expected

malfunction

N/A

*

**

normal

operation

*

*

**

Category 3 Zone 2/22

Category 2 Zone 1/21

Category 1 Zone 0/20

* Describe the single measure applied to prevent the

ignition source from becoming effective. Where

appropriate refer to standards used and test reports

which substantiate compliance with the standards

** Describe two independent measures used to prevent

ignition source from becoming effective. Again refer to

relevant standards and test reports.

N/A Need not be considered for this zone

Identify all potential

ignition sources

(see table below)

Which apply

to your

product?

Do they occur

during:

GAS

Explosion Non-sparking Other materials

Group metals (*)

IIC 60 5 (hydrogen)

3 (hydrocarbons

Category 1G including acetylene)

IIB 125 10

IIA 125 20

IIC 125 10

Category 2G IIB 250 20

IIA 500 40

IIC 250 20

Category 3G IIB 500 40

IIA 500 80

DUST

Category 1D 125 20

Category 2D 500 80

Category 3D

(*) excluding materials specified in cl. 6.4.2.1 a) of EN13463-1: 2009

Single Impact Energy Limits (Nm)

Technical file

contents

General description

Ignition risk assessment

Design and manufacturing

drawings

Description and explanation

necessary to understand

operation of product

List of standards or other

solutions to meet EHSRs

Calculations and examinations

Test Results

Possible Ignition

Sources

(list from EN 1127-1)

Hot surfaces

Mechanical sparks

Flames, hot gases

Electric sparks

Stray electric currents and

Cathodic protection

Static electricity

Lightning

Electromagnetic waves

Ionising radiation

High frequency radiation

Ultrasonics

Adiabatic compression

Chemical reaction

Minimum ATEX requirements

for non-electrical products

Category 1Zone 0/20 N.B. certification and QA assessment

Category 2Zone 1/21 Manufacturers technical file lodged

with N.B.

Category 3Zone 2/22 Manufacturer stores own technical file

N.B. = Notified Body

ATEX

ATEX and IECEx certification

IECEx Certificate of Personnel Competance

IEC 61508 certification

Quality system approval

Assistance with DSEAR (ATEX User Directive) Implementation

Training & Technical Advice

IECEx Service Facility Certification

Technical file storage

Testing

Baseefa

Services

www.baseefa.com

Das könnte Ihnen auch gefallen

- ExtronicsWallchart 160708Dokument1 SeiteExtronicsWallchart 160708Shyam VarunNoch keine Bewertungen

- Explosion Protection Wall Chart BASEEFADokument1 SeiteExplosion Protection Wall Chart BASEEFAweby98Noch keine Bewertungen

- iUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBDokument1 SeiteiUPS101: XXXX Ii 2 G Ex D (E) Iib T6 GBAdemola Olajide TejumolaNoch keine Bewertungen

- Hazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFDokument1 SeiteHazardous Area Table IEC & NEC (NEMA) Cooper Crouse Hinds PDFAgustinus Made Theo Dwijaya100% (3)

- Intertek Poster A1 (HazLoc - Guide) - 0Dokument1 SeiteIntertek Poster A1 (HazLoc - Guide) - 0Antonio FilipeNoch keine Bewertungen

- Types of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresDokument1 SeiteTypes of Protection for Electrical and Non-Electrical Equipment in Explosive AtmospheresHimanshu ChichraNoch keine Bewertungen

- Atex PDFDokument115 SeitenAtex PDFSanjay Kumar SinghNoch keine Bewertungen

- IECDokument1 SeiteIECJay Jay100% (1)

- MTL Flamable FactsDokument1 SeiteMTL Flamable FactsAdeDCNoch keine Bewertungen

- At ExDokument2 SeitenAt ExMoustafa Ibrahim YehyaNoch keine Bewertungen

- Classification of Hazardous AreasDokument1 SeiteClassification of Hazardous Areasadhi2001Noch keine Bewertungen

- Poster Explosive CEDokument1 SeitePoster Explosive CENico ArdeleanNoch keine Bewertungen

- ATEX-affisch MaluxDokument1 SeiteATEX-affisch MaluxHomer SilvaNoch keine Bewertungen

- Safety. Everywhere.: Electrical Equipment Non-Electrical EquipmentDokument1 SeiteSafety. Everywhere.: Electrical Equipment Non-Electrical EquipmentNavin KeralaNoch keine Bewertungen

- GBDokument11 SeitenGBdungtran77Noch keine Bewertungen

- Hazardous AREA ClassificationDokument10 SeitenHazardous AREA Classificationfarzam100% (1)

- Ingress SafetyDokument1 SeiteIngress Safetyjohn_tigerNoch keine Bewertungen

- ATEX, IECEx, DSEAR Compliance ServicesDokument1 SeiteATEX, IECEx, DSEAR Compliance Servicesperumal1312Noch keine Bewertungen

- Petrel Guide To Hazardous Areas: Atex DirectiveDokument4 SeitenPetrel Guide To Hazardous Areas: Atex DirectivePrabhu SingapuraNoch keine Bewertungen

- ABB Motors for Hazardous AreasDokument65 SeitenABB Motors for Hazardous Areaslaem269Noch keine Bewertungen

- 207-x Marking UkDokument4 Seiten207-x Marking UkgueridiNoch keine Bewertungen

- Feam Junction Box EnclosureDokument36 SeitenFeam Junction Box EnclosureMiky MooseNoch keine Bewertungen

- Lcie Bureau Veritas Atex Poster PDFDokument1 SeiteLcie Bureau Veritas Atex Poster PDFAncaOniscuNoch keine Bewertungen

- Flametec Data SheetDokument1 SeiteFlametec Data SheetDang Ngoc PhuNoch keine Bewertungen

- Equipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonDokument1 SeiteEquipment Certification Guide For Hazardous Areas: North America Atex and Iec Ex ComparisonBalan PalaniappanNoch keine Bewertungen

- North America: Hazardous Areas, Explosive Atmospheres and Equipment GroupDokument1 SeiteNorth America: Hazardous Areas, Explosive Atmospheres and Equipment GroupkazdanoNoch keine Bewertungen

- IECEx Certification Bodies for Explosive Atmospheres EquipmentDokument1 SeiteIECEx Certification Bodies for Explosive Atmospheres EquipmentMrudang MehtaNoch keine Bewertungen

- ATEXDokument2 SeitenATEXvypatilNoch keine Bewertungen

- IEC Standards for Explosive AtmospheresDokument1 SeiteIEC Standards for Explosive AtmospheresMaahiNoch keine Bewertungen

- Atex eDokument1 SeiteAtex egtomyNoch keine Bewertungen

- Area Classification Guide for Flammable AtmospheresDokument1 SeiteArea Classification Guide for Flammable Atmosphereswado11Noch keine Bewertungen

- Marking of Explosion Protected Equipment: DR Johannes Auret Explosion Prevention Specialist, Sallab SAFA Symposium 2019Dokument6 SeitenMarking of Explosion Protected Equipment: DR Johannes Auret Explosion Prevention Specialist, Sallab SAFA Symposium 2019mhafizanNoch keine Bewertungen

- Basics of Explosion Protection - IecDokument4 SeitenBasics of Explosion Protection - IecbenounaomarNoch keine Bewertungen

- 986 07 1006 031 - ManDokument8 Seiten986 07 1006 031 - ManFernando Ledesma RamirezNoch keine Bewertungen

- Instruction Manual for ATEX/IECEx Certified STExC1 Sounder & BeaconDokument9 SeitenInstruction Manual for ATEX/IECEx Certified STExC1 Sounder & BeaconRoberto Martin NavarroNoch keine Bewertungen

- Sira Atex PosterDokument1 SeiteSira Atex PosterRiadh2012Noch keine Bewertungen

- Hazardous AreasDokument4 SeitenHazardous AreasChoochart ThongnarkNoch keine Bewertungen

- E120Dokument10 SeitenE120back1949Noch keine Bewertungen

- Your Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6Dokument1 SeiteYour Safety - Our Reality: Class I, Zone 1, A Ex de IIC T6 Ex de Iic T6 Ex de Iic T6And WebNoch keine Bewertungen

- ATEX and IECEx CertificationDokument1 SeiteATEX and IECEx Certificationmaniking1Noch keine Bewertungen

- ATEX ExplainedDokument1 SeiteATEX Explainedwado11Noch keine Bewertungen

- Instruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust AtmospheresDokument4 SeitenInstruction Manual (Atex) : Bexbgl1D Flameproof Led Beacon For Use in Flammable Gas and Dust Atmospheresgelustan2006Noch keine Bewertungen

- EX Plakat GBDokument1 SeiteEX Plakat GBBohumil NáplavaNoch keine Bewertungen

- Wika Il-10Dokument4 SeitenWika Il-10José MelâneoNoch keine Bewertungen

- WEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishDokument1 SeiteWEG Guide To Explosive Atmospheres Wallchart 50042119 Quick Guide EnglishJohnNoch keine Bewertungen

- Hazardous Area ClassificationsDokument1 SeiteHazardous Area ClassificationsAndrew Bull100% (2)

- Marine Electrical Practice: Marine Engineering SeriesVon EverandMarine Electrical Practice: Marine Engineering SeriesBewertung: 4 von 5 Sternen4/5 (8)

- Industrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionVon EverandIndustrial Applications of Infrared Thermography: How Infrared Analysis Can be Used to Improve Equipment InspectionBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Cryogenics Safety Manual: A Guide to Good PracticeVon EverandCryogenics Safety Manual: A Guide to Good PracticeNoch keine Bewertungen

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsVon EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsBewertung: 5 von 5 Sternen5/5 (1)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsVon EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNoch keine Bewertungen

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesVon EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNoch keine Bewertungen

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsVon EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNoch keine Bewertungen

- Ex ProtectionDokument47 SeitenEx Protection2zece100% (1)

- Understanding ATEXDokument14 SeitenUnderstanding ATEXFavas KvpNoch keine Bewertungen

- Scada: Common System ComponentsDokument9 SeitenScada: Common System Componentsperumal1312Noch keine Bewertungen

- Vedantasara of Sri Ramanujacharya Translated by V KrishnamacharyaDokument494 SeitenVedantasara of Sri Ramanujacharya Translated by V Krishnamacharyaperumal1312Noch keine Bewertungen

- Mechanical and Piping AB-CategoryDokument5 SeitenMechanical and Piping AB-Categoryperumal1312Noch keine Bewertungen

- Medical Aspects of Fitness For Work Offshore - Guidance For Examining PhysiciansDokument80 SeitenMedical Aspects of Fitness For Work Offshore - Guidance For Examining PhysiciansJamie Taylor100% (6)

- An Abridged Version of Kalki's Ponniyin SelvanDokument395 SeitenAn Abridged Version of Kalki's Ponniyin Selvanperumal1312Noch keine Bewertungen

- Laxmi KataxamDokument121 SeitenLaxmi Kataxamperumal1312Noch keine Bewertungen

- iecexOD502 Ed2.0 enDokument14 SeiteniecexOD502 Ed2.0 enperumal1312Noch keine Bewertungen

- ATEX, IECEx, DSEAR Compliance ServicesDokument1 SeiteATEX, IECEx, DSEAR Compliance Servicesperumal1312Noch keine Bewertungen

- Hawke Cable Glands New CatalogueDokument91 SeitenHawke Cable Glands New Catalogueperumal1312Noch keine Bewertungen

- Electrical Equipment in Hazardous AreasDokument10 SeitenElectrical Equipment in Hazardous Areasperumal1312Noch keine Bewertungen

- Bhagavadgiita PDFDokument106 SeitenBhagavadgiita PDFRekhaJanarthananNoch keine Bewertungen

- SUBMERSIBLE PUMP SelectionDokument6 SeitenSUBMERSIBLE PUMP SelectionSyed Muztuza AliNoch keine Bewertungen

- Safety Notice 200508Dokument5 SeitenSafety Notice 200508perumal1312Noch keine Bewertungen

- EN - PDW3000 Gutor UpsDokument4 SeitenEN - PDW3000 Gutor Upsperumal1312Noch keine Bewertungen

- Electrical Equipment Hazardous Area InspectionsDokument16 SeitenElectrical Equipment Hazardous Area InspectionsDebajit BurhagohainNoch keine Bewertungen

- Distributed Generation in Distribution NetworksDokument1 SeiteDistributed Generation in Distribution Networksperumal1312Noch keine Bewertungen

- Edr 5535Dokument15 SeitenEdr 5535perumal1312Noch keine Bewertungen

- Edr 5018Dokument43 SeitenEdr 5018perumal1312Noch keine Bewertungen

- Internal Electrification Work For Cray Technical SpecificationDokument16 SeitenInternal Electrification Work For Cray Technical SpecificationDharmendra ShahNoch keine Bewertungen

- Tyco Raychem Termination KitDokument6 SeitenTyco Raychem Termination Kitperumal1312Noch keine Bewertungen

- Tyco Raychem Termination KitDokument6 SeitenTyco Raychem Termination Kitperumal1312Noch keine Bewertungen

- Assets Training Course Schedule Jul-Sep 2013 Oct-DecDokument1 SeiteAssets Training Course Schedule Jul-Sep 2013 Oct-Decperumal1312Noch keine Bewertungen

- Annamalai University Application For Diploma in Industrial AutomationDokument2 SeitenAnnamalai University Application For Diploma in Industrial Automationperumal1312Noch keine Bewertungen

- Variable Frequency DriveDokument11 SeitenVariable Frequency DriveNAYEEM100% (4)

- Catalog LadderDokument25 SeitenCatalog Ladderjhherb31Noch keine Bewertungen

- Petroleum Refining ProcessDokument76 SeitenPetroleum Refining Processperumal1312Noch keine Bewertungen

- VSDDokument27 SeitenVSDGeoff LitwerNoch keine Bewertungen

- Bill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsDokument8 SeitenBill 192: An Act To Ensure Student Health and Safety in The Classroom by Regulating Ambient Air Quality in SchoolsCtv MontrealNoch keine Bewertungen

- Coa Polivinilpirrolidona K-90 (PVP K-90) Lote 20221019Dokument1 SeiteCoa Polivinilpirrolidona K-90 (PVP K-90) Lote 20221019Ives AlbarracinNoch keine Bewertungen

- EIM GRADE 9 10 Q4 Module 1b - National Electrical Code NEC Provisions in Installing Wiring Devices - GFCI. - FinalDokument23 SeitenEIM GRADE 9 10 Q4 Module 1b - National Electrical Code NEC Provisions in Installing Wiring Devices - GFCI. - FinalTitser Ramca100% (3)

- Weld Procedure Specification (WPS) : Joint Design Welding SequenceDokument1 SeiteWeld Procedure Specification (WPS) : Joint Design Welding SequenceRicardo SoaresNoch keine Bewertungen

- A Comparative Study Between Various Models of Eco-Brick and Hollow BlocksDokument9 SeitenA Comparative Study Between Various Models of Eco-Brick and Hollow BlocksMykaila Ysa ValdezNoch keine Bewertungen

- Rorschach y SuicidioDokument17 SeitenRorschach y SuicidioLaura SierraNoch keine Bewertungen

- Load Summary for Premise Under 100kVADokument2 SeitenLoad Summary for Premise Under 100kVAMuhammad Zulhelmi ZawawiNoch keine Bewertungen

- B-64483EN-2 - 05 - 01 Dual Check Safety - CONNECTION MANUAL - Password - RemovedDokument270 SeitenB-64483EN-2 - 05 - 01 Dual Check Safety - CONNECTION MANUAL - Password - Removedretox9000Noch keine Bewertungen

- 016-5032-002-C - SmarTrax - Case IH STX-Steiger-Quadtrac (AccuGuide-Ready) and New Holland TJ-T90X0-T9XXX (IntelliSteer-Ready) - Installation ManualDokument26 Seiten016-5032-002-C - SmarTrax - Case IH STX-Steiger-Quadtrac (AccuGuide-Ready) and New Holland TJ-T90X0-T9XXX (IntelliSteer-Ready) - Installation ManualAndreyNoch keine Bewertungen

- Archives of Oral Biology 100 (2019) 42-48Dokument7 SeitenArchives of Oral Biology 100 (2019) 42-48pedro cuellar proNoch keine Bewertungen

- 1154ec108nanoelectronics PDFDokument3 Seiten1154ec108nanoelectronics PDFLordwin CecilNoch keine Bewertungen

- SIDCSDokument8 SeitenSIDCSsakshi suranaNoch keine Bewertungen

- Unit Test-Unit 5-Basic TestDokument2 SeitenUnit Test-Unit 5-Basic Testphamleyenchi.6a8txNoch keine Bewertungen

- Questions That Appear On Every NBMEDokument6 SeitenQuestions That Appear On Every NBMESanz100% (1)

- CH 23 PDFDokument42 SeitenCH 23 PDFkrishnaNoch keine Bewertungen

- TLC Analysis of Siling Labuyo Extract ComponentsDokument3 SeitenTLC Analysis of Siling Labuyo Extract ComponentsJan Eric Balete0% (1)

- Louise L HAY AffirmationsDokument10 SeitenLouise L HAY AffirmationsEvi Kutasi100% (2)

- Human Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamDokument23 SeitenHuman Resource Management: Submitted By: Group # 6 Submitted To: Sir Usama NajamkamranNoch keine Bewertungen

- START-HERE Ch11 LectureDokument84 SeitenSTART-HERE Ch11 LecturePraveen VootlaNoch keine Bewertungen

- Physical Therpay Protocols For Conditions of Neck RegionDokument74 SeitenPhysical Therpay Protocols For Conditions of Neck Regionjrpsaavedra4599Noch keine Bewertungen

- (Distracted Subjects) CHAPTER 2. Reading The Language of Distraction - Hamlet, Macbeth, King LearDokument23 Seiten(Distracted Subjects) CHAPTER 2. Reading The Language of Distraction - Hamlet, Macbeth, King LearLCAP ConsultingNoch keine Bewertungen

- Design of Low Cost, Energy Efficient, IotDokument6 SeitenDesign of Low Cost, Energy Efficient, IotRulemaker Studios OfficialNoch keine Bewertungen

- Meditation ProjectDokument2 SeitenMeditation Projectapi-411448305Noch keine Bewertungen

- HRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and ReceptaclesDokument2 SeitenHRLM - Catalogue # Ex Apparatus - AC-Z Series Explosion Proof Plug and Receptaclesa wsNoch keine Bewertungen

- Jeremy Tan Resume and CVDokument3 SeitenJeremy Tan Resume and CVapi-359540985Noch keine Bewertungen

- Ageism PowerpointDokument11 SeitenAgeism Powerpointapi-254132646Noch keine Bewertungen

- Weekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Dokument3 SeitenWeekly Home Learning Plan: Grade 8 - Quarter 2. Week 7Danmer Jude TorresNoch keine Bewertungen

- Examples: Inability To Sit Still, Pacing, Wringing of Hands, or Pulling of ClothingDokument14 SeitenExamples: Inability To Sit Still, Pacing, Wringing of Hands, or Pulling of ClothingFaith Dianasas RequinaNoch keine Bewertungen

- Intermediate Alloy Steels Properties and SpecificationsDokument15 SeitenIntermediate Alloy Steels Properties and Specificationsanon_558118723100% (1)

- Empower Second Edition B1 Unit Progress Test 5 - Version ADokument12 SeitenEmpower Second Edition B1 Unit Progress Test 5 - Version Atheencarnated93Noch keine Bewertungen