Beruflich Dokumente

Kultur Dokumente

Equilibrio Dehydration

Hochgeladen von

sejerson07Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Equilibrio Dehydration

Hochgeladen von

sejerson07Copyright:

Verfügbare Formate

SE $@@

Q?.7Mla m.3

sp~ -J-

Water Equi l i bri um i n the Dehydrati on of Natural

Gas Wi th Tri ethyl ene Gl ycol

A. ROSMAN

ABSTRACT

To develop reliable design data foT glycol

contractors, gas-liquid equilibna in the system water-

methane- trietbylene glycol (TEG) tuere investigated

experimentally.

Eqrii[ibrium va[ues vury little at the

TEG concentrations used in modern

design, but increase significantly with

uwter concentration in the contacting

with increasing equilibrium ternperoture.

very Aigh

corrtactor

increasing

TEG, and

\Jarious methods of data correlation are described

and compared with experimental data, The

correlation provides the means /or extending the

rrstilts o/ this investigation to other pressures and

tcmp~raturcs.

INTRODUCTION

Water removal is a fundamental operation in

natural gas processing. Hydrate formation, corrosion,

and the formation of liquid water that might separate

in the transmission lines are some of the problems

caused by an excess of water in the gas. Of the

methods available for gas dehydration, water

absorption is by far the most generally used.

Glycols, especially triethylene glycol (TEG), are

the preferred absorbents.

A survey of the literature on the water dew

point of natural gas over glycol solutions reveals

significant disagreements. A sampling of published

dewpoint data for gas in equilibrium \vith TEG

(Fig. 7) illustrates the prevailing confusion. Scant,

but still contradictory, information was published

for glyco] concentrations in excess of 99.8 weight

percent. Data in that range are needed in designing

modern glycol contractors where the water dewpoint

temperature must be reduced by more than 100 F.

The main reason for discrepancies in experimental

results is the difficulty of measuring accurately

very small amounts of water in gas. Water is easily

adsorbed on the surfar. s of experimental apparatus.

Normally acceptable data scatter looms large in

relation to the low water concentrations that must

Paper SPE 4040 WJS presented at SPE-AIME 47th Annual

Fall Meeting, held in San Antonio, Tex., Oct. 8-11, IQ72. ~

Copyright 1973 American In. titute of Mining, Meta Ilurg~cal,

and Petroleum Engineers, Inc.

preferences given Kt end Of PaP~r.

This paper will be printed in ?ransactions volume 2S5, which

will cover 1073.

oCTOBER. 1973

CHEVRON OIL FIELD RESEARCH CO.

LA HABRA, CALIF.

be measured. Attempts ro establish water dew

points on the basis of plant performance have been

more successful]. However, accuracy is limited by

the difficulty in establishing the relative

contribution of various factors that interrelate in

plant operation.

Faced with these doubts, contactor designers

have chosen to provide for lEG circulation rates

that are overly high so as to insure more than

adequate water removal. Such a practice is

undesirable, however, where space and power are

at a premium, as on offshore production platforms.

Thus, the range of this investigation was governed

by the need to extend equilibrium information to the

contact temperatures

and TEG concentrations

necessary to optimize glycol contractors on offshore

production platforms.

New procedures were developed for sampling and

analyzing very small concentrations of water in gas

and in TEG. To avoid experimental difficulties

encountered by previous authors, equilibrium was

reached and samples were takml under dynamic

conditions.

Experimental equilibrium results were smoothed

and correlated by several methods. Thermodynamic

equations were used to check on the internal

consistency of data and to calculate equilibrium

constants at conditions outside the range of the

investigation itself. The White expression, l fitted

to the COFRC experimental data, adequately

describes the results within the range of

temperatures and concentrations studied.

DEFINITIONS AND METHODS

At water dewpoint temperature, the water

contained in a natural gas reaches saturation. Part

of that water will condense if the gas is brought

to a lower temperature or to a higher pressure.

Thus, the dewpoint temperature describes the

water content of the gas.

When dewpoint gas contacts TEG, the water

content of the gas decreases. The lower water

content corresponds to saturation water at a lower

temperature; that is, the dew point will be lower.

The initial dewpcint temperature is the contacting

temperature. The temperature corresponding to the

lowered water content is the equilibrium dewpoint

temperature, and the difference between the two

temperatures is the dewpoint depression.

297

The above definitions apply to a system at any

pressure. The effect of pressure on the dewpoint

data was not studied, since most authors agree that

data obtained at atmospheric pressure are valid

for the design of glycol contractors operating at

higher pressures. For instance, Scauzi110,2 who

made a study of the TEG-water-gas equilibrium data

up to 1961, found that dewpoint values for any one

contact temperature agree within 1F throughout

pressures ranging from 14.7 to 2,500 psia.

Assuming that

equilibrium dew points are

independent of pressure, data obtained at

atmospheric pressure can be used to forecast the

dewpoint depression attainable in a glycol contactor

operating at a higher pressure. Although the amount

of water in gas will be lower at the higher pressure,

the equilibrium dew point will still be the same if

the saturation temperature and the TEG concentration

remain the same.

Any serious attempt to optimize contactor design

must make use of gas-liquid equilibrium ratios,

Ku, as defined by Eq. 1:

Y

Kw=#oo..osoos..(l)

w

Although the equilibrium investigated is for a

two-phase, three-component system, the study was

limited to the distribution of one component, water,

between two mutual Iy noninteracting phases. This

is justified by the very low TEG vapor pressure in

the temperature range considered here and by the

negligible methane solubi]ity at atmospheric

pressure. Water concentrations were determined

experimentally in the gas and liquid phases.

Because the approach to equilibrium in the

recirculating system is essentially asymptotic, gas

equilibration was approached from two directions at

every selected temperature to make sure that

equilibrium had been reached. This was achieved

(1) by using overly dry gas so that water would

shift from the liquid TEG to the gas and (2) by

contacting the TEG with gas containing excess

moisture, thereby reversing the driving force.

For the first approach, the gas was previously

dried at a lower temperature with glycol of about

the same concentration as that used for the point

studied. To reach equilibrium from the opposite

direction, we used gas from a higher contacting

temperature, Experimental results from the two

approaches were usually closer than the expected

analytical variation at the corresponding concen-

tration level. Where a larger discrepancy was

observed, the steps for a point were repeated.

This equilibration method is amenable to

conducting experimental determinations at several

temperatures using essentially the same TEG-water

solution and the same gas.

experimental sequence for any

would involve determinations

temperatures:

Schematically, the

TEG concentration

at the following

40 +600+800+ 1005+1200+1400+(1500)

400<.600,-800,- 1000.- 1200.1400 4-J

The 150F temperature gives an intermediate

(and usually incomplete) equilibration that shifts

enough moisture into the gas to insure the desired

approachto the 140 equilibrium point.

A knowledge of the amount of water contained

in the gas at saturation is fundamental for the

interpretation of water. in-gas experimental data.

VoIes percent of water were converted to pounds

per MMscf according the equivalence

I mol percent water = 474.71 lb water/\fMscf.

The latter units are used in the industry for dewpoint

measurements. After a survey of the literature on

moisture content of natural gases had been

conducted, dewpoint values were taken from the

charts published by the Institute of Gas

Technology. 3 Points below the minimum chart

temperature were extrapolated from published IGT

relationships.

Research grade T17G and distilled water were

used to prepare the various mixtures used in the

liqui 1 phase. .Methane was used as tht. gas phase.

Although a natural gas would be likely to contain

very slightly less water than would pure methane,

the difference does not appear significant. For

instance, Sharma 4114reports that ethane in amounts

up to 20 percent did not appreciably affect the

equilibrium water content of methane.

ANALYTICAL METHODS AND

EXPERIMENTAL APPARATUS

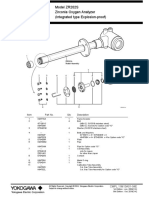

As shown schematically on Fig. 1, the equilibrium

measurement apparatus was built around three

interrelating systems.

1. r/ JF rwrlarl?rrg syslrm, where equilibrium

between water in gas and in TEG is reached at

constant temperature and atmospheric pressure;

2. The sampling system, whic!r makes it possible

to sample the gas and liquid streams without

disturbing the equilibrium;

3. Tbe ana)y[icnl system, basically a chromato-

graphy with recording and integrating facilities.

THE CONTACTING SYSTEM

This system consisted of a glass TEG-gas

contactor where the methane was bubbled through a

gravimetrically prepared solution of TEG and

water, a gas chamber, and circulating apparatus.

The desired equilibrium temperature was kept

constant in the contactor within f.0,05 F. Other

parts of the system were maintained at a higher

temperature to make sure that no condensation

occurred elsewhere. Gas, circulated by means of a

diaphragm pump, went through the sampling syringe,

was brought to equilibrium temperature as it passed

through a coil in the constant temperature bath,

bubbled through the TEG, and returned to the gas

container. Stratification in the container was

avoided by means of a small but powerful fan that

SOCIETY OF PETROLEUM ENGINEERS JOURNAL

mixed the incoming gas with the bulk.

THE SAMPLING SYSTEM

The sampling system consisted of two subsystems,

one for liquid and one for gas.

To sample the TEG prior to water analysis, the

contactor was pressurized with equilibrium gas,

which forced the liquid through an enclosed rubber

tube mounted over the injecting system. To reach

the sample, the syringe needle went through an

outer septum, and once the liquid was sampled the

needle was pushed further through the injection

port septum. Thus, the sample was injected without

allowing the TEG to come in contact with the

humidity in the air.

To sample the equilibrium gas, a large sample

(up to 55 cc) was passed from the equilibrated

syringe into a freezing coil, where the water in gas

accumulated as ice. As too large an amount of

methane would have flooded the chromatographic

column, the volume of the gas sample was measured

by mercury displacement in a twin burette that

could be read to fO.01 cc. The water was then

released from its frozen state by heating and

routed to the gas chromatography. The resulting

peak was measured against an absolute water

response standard.

THE ANALYTICAL SYSTEM

The analytical system consisted of a chromato-

graphy with thermal conductivity detector, a

multirange recorder, andan Instron electromechanical

integrator. The recorder permitted the development

of large peaks by switching from the standard I-rev

range to a range of 0.1 mv. Both the liquid and the

gas samples were separated in columns packed

with Porapak Q.

PRECISION OF THE EXPERIMENTAL DATA

A common difficulty of previous work in this area

is the inability to reproduce analytical data

reliably. Consequently, investigators must adopt

self-imposed constraints as precision criteria for

experimental repeatability. Examples of the

precision achieved are presented in Table 1.

Experiments where repeatability was exceptionally

good were not considered for inclusion in the table.

Good precision is more significant for the analysis

of low concentration components, since any

deviation apparent there will have more relative

impor~ than if applied to the abundant component.

Different sample sizes could reproduce relative

concentrations well. However, efforts were made to

maintain constant sample volume. As the volume

of the liquid sample was only 2 microliters,

maintaining constant sample size was difficult. In

the example on Table 1, assuming that the counts

per microliter are constant throughout the series of

runs, a maximum deviation of

3.3 percent

corresponds to an absolute sample-size variation

of 0.000066 cc. In many runs, the count variation

was less than 3.3 percent.

Because Kw is the ratio of two concentrations,

analytical accurac, and precision cannot exceed

the worst of the two analyses involved. The gas

~ __, ~____

. . .

i r

,

!m

i-

l _

_p

I

TO ::

II ~ CONSTANT TEMP BATH

I I

WITH TEG-GAS CONTACTOR

r [

MANOMETER

c

I

I

I

I

1-

J

T,

[T, >TIJ

1

1

CIRCULATING

PUMP

t

)

GAS

SPACE

II

1

I

3

1;

Ill

SEBLED SYRINGE

I

II

SEPTUM SYSTEM

20CC 1

I

SYRINGE

1, I I PORAPAK O

!? % !!F d

COLUMNS

I I

I I

, 1

D;

I I

I I

I

I I

. _ . J

II

I I

I I

!@

FREEZING

1 I SAMPLE LOOP

~1

1!

o

Q

- .

GAS

BURETTE

J

IL_

I

I

_ .

CHROMATOGRAPHY

lL _. ___ J--J

I

SAMPLI NGSYSTEM

I

I

CONTACTI NG SYSTEM

FIG. 1 SCHEMATIC OF TEG-WATER-GAS EQUILIBRIUM MEASUREMENT APPARAT\JS,

OCTOBER, 1973

analyses at-e likely to show the larger variations

because of the small amount of water present.

Thus the most severe analytical limitations on the

study of equilibria exist at high TEG concentrations

and low temperatures, where water concentrations

are in the ppm range.

Experimental Run 65, listed in Table 1, illustrates

some of the least favorable conditions encountered

in our work, That run studied water distribution

between gas and 99.95 weight percent TEG at

60 F. Water in the gas phase was analyzed four

times, The results averaged 0.0034 mol percent

with a standard deviation of 0.00029. Water in the

liquid phase was analyzed three times. Results

(not shown in Table 1) averaged 0.4314 mol percent,

with a standard deviation of 0.01087. The range of

water equilibrium constant values spreads from a

minimum Kw of 0.007032 to a maximum K w of

0.008775. Average K is 0.00790420.000872,

How much of an achievement is a variation of

311 percent in the calculated K-value? While not

directly comparable, many studies were made on

the precision of hydrocarbon analysis by

chromatography. One study S shows that relative

variation between consecutive runs performed by

the same operator on the chromatography, increases

for any one component with its decreasing

concentration in the sample. Accordingly, the

relative deviation expected at a true concentration

of 0.003 percent is f35 to 70 percent. This work

reports water concentrations of 0.003 mol percent

(30 ppm) with a deviation of t8.5 percent.

Analytical accuracy is harder to demonstrate

since an analysis might be repeatable but wrong.

When data were suspect, a decision was made on

the basis of consistency checks. A study was

conducted to establish possible sources of

experimental error, and where consistency checks

were inconclusive the experiments were pursued

further.

EXPERIMENTAL RESULTS

EQUILIBRIUM DEWPOINT DEPRESS1ON

Water equilibrium dew points were established

for TEG concentrations ranging from a nominal 94

to 99.95 weight percent and equilibrium temperatures

of 40, 600, 80, 100, 120 and 140 F. Fig, 2 shows

the relationship between dewpoint depression and

TEG concentration at 80 F equilibrium temperature.

-. ...

TABLE 1 - PRECISION OF THE EXPERl!d ENTAL DATA

Percent

Fxneriment Stondfird Standard -. .-. . .

Number Type of Dots RUI-I 1 Run 2 Run 3 Run 4 Average - - Deviation Deviation Observations

.

Mol %H. O in aas 0.0030 0.0034 0.0035 0.0037 0.0034 0.00029

.-

Mol % CH4 in gas

Wt %H20 in liquid

Wt %TEG in liquid

Sample size, ml gos

Water counts, gas

TEG counts, liquid

Water counts, liquid

Mo] % HaO In gas

Mol % CH4 in gas

Wt %H20 in liquid

Wt %TEGin liquid

Sample size, ml 90s

Water counts, gas

TEG counts, liquid

water counts, liquid

Mol % HZO in gas

Mol % CH4 in gas

Wt % H20 in liquid

Wt % TEG in liquid

Sample size, ml gas

Water counts, gas

TEG counts, liquid

Water counts, liquid

Mol % H20 in gas

Mol % CH4 in gos

Wt % H20 in Iiqujd

Wt % TEG in liquid

Sample size, ml gas

Water counts, gas

TEG counts, liquid

Water counts, liquid

99.9970

0.0.533

99.9A67

18.7

43.4

185,681,

212.0

0.0145

99,985S

0.0633

99.9367

19.32

249,

194,853.

264.1

0,0902

99.9098

fl.0712

99.9288

18.

1,477.

190,621.

291.

0.3083

99,6917

5.5S66

94.4434

3.54

99Q

160,33%

17,383.

99,9966

0.0519

99.9481

54.38

143.4

192,043.

213,5

0.0140

99.9860

0.0601

99.9399

19.32

239,5

189,118,

243.7

0,0822

99.9178

0.0790

99.9210

17.86

1,329.

186,618.

316,

0.2949

99.7051

5.7813

94.2167

3,72

997.

152,487.

17,242.

99.9965 99.9963

0.0507

99,9493

54,9 36.52

150,2 108.

189,313.

205.5

0.014LI 0.0144

99.9855 99.9856

0.0588

99.9412

19.2 19.26

246. !3 245,5

189,852. (197,988. )

239.2 (212.0 )

0.0852 0.0882

99.9148 99.9118

0.1838 0.0837

999162 99.9)63

18. 18.

1,391. 1,434,

189,262. 189,003.

340. 339.

0.2825 0.2986

99.7175 99.7014

5,5119

94.4881

4.08 3.50

1,050. 951.

152,761.

16,421.

99.9966 0,072

0.0520 0.0013

99.9480 0.088

189,012. 3,192.

210.3 4,25

0.01435 0.00024

99.9856 0.072

0.0607 0.0023

99.9393 0.063

19.275 0,057

245.1 4,03

191,274. 3,114,

249. 13.3

0.0864 0.0035

99.9136 0.11

0.0794 0.0059

99.9205 0.063

17.965 0.07

1,407,8 63.2

188,876. 1,659,

321.5 23.16

0.2961 0.0107

99.7039 0.130

5,6166 0.144

94.3834 0.165

3.71 0.265

999.3 40.45

155,194. 4,456.

17,015, 519.4

65

67

70

101

8,5

0.07

2.5

0.09

(1) (2)

(1)

1.7 (4)

2.0 (4)

1.7

0.07

3.8

0.06

0.3 (2)

l,rj

1.6 (3)

5.3 (3)

4.0

0.11

7.4

0.06

0.4 (2)

4,5

0.9

7.2

3.6

0.13

2.5

0.17

7.1 (2)

4,0

2.9

3.1

(1)

(2)

(3)

(4)

300

No direc+ comparison because of different sample sizes.

Before calculation volume is corrected for barometric pressure and ombient temperature.

Figures in parentheses not used for calculation.

Sample size: 2 microliters = 0.002 cc.

SOCIETY OF PETROLEUM ENGINEERS JOURNAL

Similar plots can be drawn for other equilibrium

temperatures. Dewpoint depression, measured in

equivalent degrees F, decreases with decreasing

contacting temperature. The rate of the decrease

appears to be a function of the equilibrium

temperature. Everything else being equal, the

higher the contacting temperature (i.e., water

saturation) of a gas, the larger the amount of water

removed at equilibrium. The amount of water removed

from the gas decreases with increasing dilution of

the contacting TEG. Presumably, the TEG-water

solution ceases to be very effective as a dehydrating

agent once it reaches a certain composition. By

extrapolation on Fig. 2, that composition is found

at approximately 60 weight percent water.

The semiIogarithmic relationship between dewpoint

160

MO-

K%

120-

100-

\

%

80 -

$

60 -

\

\%

40 -

\

\

*oo~%!84q

10 50 ;

CONcEN(RA1lON 0S I+ZOIN T~G ~ %

2 DEWPOINT DEPRESS1ON VS TEG CONCEN-

TRATION, 80% EQUILIBRIUM TEMPERATURE.

110

100 -

90 -

80 -

70 -

:

# 60

g 50 -

~ 40

r

~ 30

1-

= 20

: 10 -

Ho

~ -,0 .

>

~-zo

+

s -30

-40

-5 o

-6o

-7o

WI % TEG

/

90

x?:

-80

t

-90 - ~.

60 80 100 120 I40 160

EQUILIBRIUMTEMPERATURE. t.F

FJIG. 3 WATER DEWPOINT TEMPERATURE OF

METHANE IN EQUILIBRIUM WITH TEG. LEAST-

SQUARES FIT OF EXPERIMENTAL DATA (LINEAR).

6)CTO~ER, 1973

depression and TEG concentration points up the

fact that small increments in TEG concentration

correspond to increasingly larger dewpoint

depressions and significant gains in absorber

performance.

Values interpolated from plots like Fig, 2

were used to present the experimental data as

Equilibrium Dew Point vs Equilibrium Temper-

ature on Fig. 3, and as Equilibrium Dew Point

vs Water Concentration in TEG on Fig. 4. They

also form the basis for an empirical correlation

that will be further discussed in the section on

Data Interpretation.

Experimental data on Fig. 3 confirm that the

equilibrium water dew point of a natural gas

decreases with increasing concentration of the

contacting TEG, and with decreasing contacting

temperature. The family of concentration isograms

was extended below the lowest TEG concentration

actually studied (94 weight percent). However,

data are not shown beyond the highest experimental

concentration of 99.97 weight percent.

Fig. 4 is useful as a consistency check for data

generated experimentally. The equilibrium temper-

atures are operating parameters, so Fig. 4 is

expected to show a family of isotherms where

equilibrium dew point at 100 percent water is the

equilibrium temperature itself. In effect, the

isotherms may be drawn as straight lines up to

approximately 60 percent water, after which they

curve slightly toward the expected temperature.

Water Distribution Between TEG and Methnne

Fig. 5 presents a plot of gas-liquid equilibrium

ratios, Kw, as a function of TEG concentration, for

the temperature range 40 F to 140 F and atmospheric

pressure. Logarithmic coordinates were chosen as

a matter of convenience because they compress a

wide range of data into one figure. To emphasize

the important role of even small amounts of liquid

water, the abscissa shows weight percent water in

the contacting TEG rather than the concentration

of TEG itself.

On first approximation, K-values show little

-:70., ;2 ~5 ,0 ~.

I

$0 IN 200 50Q {000 20 50 10004

W1H3MT % WATt R IN1t G

FIG. 4 WATER VAPOR DEW POINT VS WEIGHT

PERCENT WATER IN EQUILIBRIUM TEG (NON-

SMOOTHED EXPERIMENTAL DATA).

301

dependency on contacting TEG concentration,

throughout the concentration range of this study.

Horizontal isotherms, drawn through the average

value of all K-data at ~ne temperature, present a

reasonable fit. However, a statistical analysis of

the data, confirmed by thermodynamic fitting,

indicated that K increases slightly with increasing

TEG concentration.

Equilibrium values roughly doubled for every

20F increase in equilibrium temperature. Fig. 6,

which shows a plot of K vs equilibrium temperature

for a contacting 99.0 weight percent TEG is typical.

Regardless of the method used to smooth the data,

the relationship is quasilinear within the studied

range of TEG-water compositions. If the relatively

small effect of TEG concentration is ignored, one

single line applies to the temperature range 400 to

140 F. Its empirical equation offers an easy-to-use

first approximation of water equilibrium values at

atmospheric pressure:

Kw=e

0. 035129 L23. 082f 55. . (2)

For more accurate calculations, the curvature of

the plots (Fig. > and 6) cannot be ignored, however.

Comparison wltb Pub Iisbed Data

The Chevron Oil Field Research Co. (COFRC)

results reveal some general similarities in shape

with published data. However, differences in value

are significant. Closest to our observations are

data published by Union CarbideG and by Worley,7

Fig. 7 presents several typical isograms of

equilibrium dew points vs equilibrium temperatures

from the two sources mentioned above. Generally,

COFRC equilibrium dewpoint temperatures are

lower than Union Carbides for corresponding TEG

concentrations. On the other hand, both sets of data

show a very similar dependence on the contact

temperature. The similarity is particularly apparent

for TEG concentrations around 99 weight percent.

The equilibrium dew points in Ref. 7, which

?0

1, , ,

I

,

I

1

001 I

, [ , ,(#i 1 ! , , J

01 L% *O .$ 10 60 10

WATCR W+4CLNTRA110N IN TCO. !MIG.T %

FIG. 5 WATER EQUILIBRIUM CONSTANTS IN

THE TEG-GAS-WATER SYSTEM; 14.7 PSIA

EXPERIMENTAL,

were obtained from operating glycol contractors

and extrapolated to an infinite number of trays and

glycol rates, coincide very well with COFRC values

at the extremes of the concentration range. The

similarity does not hold true for intermediate

concentrations, where differences in dewpoint

temperature range up to 16 F, the COFRC data

being the more conservative.

I

1

w

.

J

01

00

x

/

COFRC ExPERIMENTAL

oAT A 990wT%ltG

$

/

e

/

/

/

+

~ , ~ 0035129 1 - 2308265

Tm OR

)0) (520) (540) (5601 (580) (600) R

40 bb 8( Icc ,X 4 F

61)un,,I+K: R). 11,p! IIAIIJR~ p v

FIG. 6 VARIATION OF WATER EQUILIBRIUM

CONSTANT WITH TEMPERATURE.

110[-

wEIGI+T %TEC

100

[

90 -

80

101- /

, . .. .. -w

/

/

/

/

/

/--71

/

/

/ -

/

/ //

/

A

/

/

/

/

/

//-

/

/

.-

.

/

:=

40 60 80 [M 120 140 160

ECIUILKIRIUM TEMPERA1uR6. t F

FIG. 7 WATER DEWPOINT TEMPERATURE OF

NATURAL GAS IN EQUILIBRIUM WITH TEG.

aoz SOCIETY OF PETROLEUM E~Cl~EE~S JouR~~L

Comparisons of COFRC equilibrium dew points

with other values in the literature, for example

those published by Dingman and LeBas,8 or Dow

Chemical Co.,g~10 are much less satisfactory.

Data published in 1961 by Scauzillo2 deserve

special mention since they are calculated on the

basis of older experimental fugacity values rather

than determined experimentally. Scauzillos data

are very similar to Worley s, which they precede by

5 years.

Few papers on the subject allow a direct

comparison with the gas-liquid equilibrium values,

K, originated in this investigation, In most

instances, K-values must be calculated indirectly,

from equilib~ium dewpoint data for natural gas or

from vapor pressure over aqueous TEG solutions.

Calculations are limited by some implied

assumptions: in the case of dewpoint data we need

to know what moisttire charts, if any, were used

by the author in translating water content of gas

into equilibrium dewpoint temperatures.

TEG-water so]utions have two partial vapor

pressure components. TEG vapor pressure is very

low at experimental temperatures. Townsends 11

estimated value, 0.01 mm Hg at 68 F, is in line.

with the Union Carbide and Dow Chemical published

data. Wise etal.~2 indicated that TEG vapor pressure

(PTEG) between 69 and 84F obeys the relationship

log PTEG = ~; f i + 7. 758 s (3)

In either case we conclude that, within our

experimental range, errors that result from neglecting

the TEG vapor pressure would not be significant.

Despite differences in value, most shapes of

K-vs-TEG concentration plots obtained from

published data are similar to those found in our

investigation. However, some isograms have more

pronounced curvatures and exhibit a minimum for

certain TEG concentrations.

In conclusion, water equilibrium constants are

virtually independent of TEG concentrations at the

high TEG concentrations required in gas dehydration

(98 to 99.5 weight percent TEG). With increasing

concentrations of water in TEG (95 percent TEG),

equilibrium constants do increase. The difference

in K-values between the conditions at the top and

at the bottom of a glycol contactor could therefore

be significant.

INTERPRETATION OF DATA

DATA SMOOTHING AND CORRELATION

Least-squares smoothing methods were applied

where data appeared to be in a linear or

sernilogarithmic relationship. In most of the data

sets the correlation coefficient was very close to

unity. The smoothed data were then correlated by

an empirical equation, based on the variation of

the equilibrium dewpoint depression with TEG

concentration, at various temperatures. Given two

variables within our range of investigation, the

third can be calculated.

WATER VAPOR DEWPOINT DEPRESSION

The variation of dewpoint depression with glycol

concentration and temperature, one example of

which is shown on Fig. 2, can be fitted to an

equation of the type

W=aebD) . . . oo( 4) 4)

where a is the intercept on the water concentration

coordinate and b is the slope of dewpoint depression

variation with weight percent water in TEG. In

physical terms , a is the weight percent of water in

an aqueous glycol solution where the glycol is too

diluted to remove water from natural gas. Both a

and b are temperature dependent and can be

correlated by semilogarithmic exponential equations.

Eq. 4 can then be rewritten in a generalized form:

w=

( o0074f1

I n T- 6. 7932

G

)

exp

[(

6)]

i n T- 6. B7! 36~D . . . . .(5)

11. 364

When TEG concentration and equilibrium temperature

are known, dewpoint depression can be calculated

from the following form of Eq. 4:

D=

in W- I n a

77- - ( 6)

where all terms are either known or can be

calculated.

Eq. 4 is not amenable to an explicit solution for

the contacting temperature, T, even if both ~~and

D are known. However, T can be easily calculated

with a computer by trial and error.

EQUILIBRIUM DEWPOINT CALCULATION

Water vapor dewpoint temperature, TD(OF) can

be calculated from the following equation:

D

=T - (D + 459. 7). . . . . . (7)

Within the range of concentrations and temperatures

investigated, the equations above permit a quick

evaluation of attainable water dew points, provided

the natural gas and TEG come close tc equilibrium.

Since the attainable dew point is assumed to be

independent of pressure, the above equations can

be applied to real systems.

Fig. 8 is a plot of the equilibrium dewpoint

temperatures calculated from Eqs. 6 and 7. TEG

concentrations were extended below experimental

range to account for the lowest iikely composition

at the bottom of a glycol contactor. The resulting

concentration isograms exhibit a slight curvature

that becomes more pronounced as the equilibrium

temperature increases.

To test the validity of the generalized dewpoint

equation, data calculated from individually smoothed

dewpoint depression plots (Fig. 2, for instance)

were plotted for comparison along the 90.0, 99.0

and 99.9 weight percent TEG lines, With one

oCTOBER, 1973

.903

exception at 40 F, the individual data points fall

within 3F of the predicted dewpoint temperature.

The fit is even better in the high-temperature,

high-concentration range where exact data are

scarce.

Another validity test is to check how well the

curves on Fig. 8 can predict values beyond the

range of this ifivestigation. An equilibrium dew

point was originated experiment~lly at 1600F and

99.906 weight percent TEG. Tht solid circle shows

the experimental results, the open circle the

predicted dewpoint temperature. The difference of

1.44 F is only 0.9 percent of the 159.1F total

dewpoint depression.

BASIC EQUILIBRIUM RELATIONSHIPS

FOR THE SYSTEM TRIETHYLENE

GLYCOL-WATER-NATURAL GAS

Several previous attempts to describe the

TEG-water-gas system by means of an equation of

state were limited by the disparity in the nature of

the components and the uncertainty of the

experimental data. The thermodynamic approach

was used by Wise et al.lzto measure equilibria in

the binary system TEG-water. Townsendl 1 and

later Scauzillo2 considered TEG-water-nattual gas

systems from a thermodynamic point of view.

Results were not too satisfactory, however.

To extend correlating applications, various

thermodynamic equations were fitted to the COFRC

experimental data. Among them, the White equationl

110

100

90

[ /

80

G

70

:

n 60

1-

g 50 -

~ G

a 40

u

~ 20 - EG

2 l o

-1

s 90.

80

/%

/

/

&

g -30

-40

-60 gg~

-80 ~%

-90-

1 1

40 60 60 100 120 140 160

EWILIBRIUM TEMPERATuRE.f F

FIG. 8 WATER DEWPOINT TEMPERATURE OF

METHANE IN EQUILIBRIUM WITH TEG (EXPONENTIAL

LEAST-SQUARES FIT OF EXPERIMENTAL DATA).

sol

was chosen because of its successful application

. .

to binary systems of widely different boiling

points. 13 The equation calculates water activity

coefficients, which in turn can be defined in terms

of the equilibrium constant.

APPLICATION OF THE WHITE EXPRESSION

TO THE EXPERIMENTAL DATA

The White equation describes vapor-liquid

equilibria in terms of temperature, pressure, liquid

composition, and two independent constants. Similar

to the Van Laar equation, the expression includes

a temperature factor and possesses other correlating

advantages that will be discussed later. For a

binary system the equation takes the following form:

()

b,

1. 5

1

[ T l o9 yl l - 0*5 = ~ $

( )0

1. 5

bl be, . . . . . . . .

+

a21

q

()

1. 5

b2 2

CT l og y2] - 05 = ~ ~

( )()

1. 5

b2

+

bl . . . . . . ..(8b)

a12

q

The ratios of constants in Eq. 8a are also constants:

()

b 1, 5

~

=m= constant . . . .(9)

G

b2 n

=

= constant . ( 10)

bl

Their values can be calculated from the slope and

intercept of the linear plot:

[ T log yl]-05 VS X, 1X2

This is a significant advantage when experimental

values for the equilibrium of the second component

(TEG) are very difficult to evaluate. A numerical

solution of the expression (T log yl )-05 is likely

to be imaginary, but that fact appears to have no

effect upon the applicability of Eq. 8a, provided

that xl/x2 <2.

In this work, the White equation was used both

as a means of smoothing experimental data and as

a correlating instrument. The correlation had the

form

SOCIETY OF PET ROLEIIM ENGINEERS JO UR31AL

Xw

(T I n ~w) - o. 5

= 0000g2 XTEG

+0. 0535 ( 11)

when fitted to nonsmoothed experimental data, and

Xw

( T I n ~w) - 005

= o*0063 xTEf j

+0. 05449 ( 12)

when fitted to data smoothed by the least-squares

method.

Small differences in the constants obtained for

the two cases do not amount to a significant

difference in the calculated values.

AS xw/xTEG

<<1.0 over most of the concentration range studied,

the two equations give practically equivalent

results. We believe that Whites expression, in the

form of Eq. 12, is the best correlating instrument

for the present investigation. The various aspects

of the calculated values are considered below.

CALCULATION OF WATER EQUILIBRIUM

CONSTANT, K

The activity coefficient is related to the

equilibrium constant, K, as follows.

Yi p

P

Yi =~V=K

. (13)

i Pi

I wo

To calculate K at other pressures and

temperatures, Eqs. 12 and 13 are combined into the

following expression:

K=

r

1

( ) 1

p, ..

exp -

~+l n

.(14)

~

~nLT

where

n E 0. 0063

(

w

FE G

+ 0. 05449 ( 5)

Fig. 9 is a plot of calculated K-values for various

equilibrium temperatures as a function of water

concentration in the contacting TEG. The calculated

values exhibit the same features as the equilibrium

constants shown on Fig. 5. However, trends in the

results are easier to distinguish from experimental

scatter. The apparent independence of the equilibrium

constants from contacting TEG concentration is

confirmed by the flat equilibrium isotherms at

concentrations over 98 weight percent. However,

equilibrium constants are increasingly larger for

more dilute TEG as would be found at the bottom

of a conta ctor.

Fig. 10 shows the variation of the equilibrium

constant with equilibrium temperature. The plots

exhibit a slight curvature and are very close

together and parallel for TEG concentrations of

OCTOBER, 1973

95.0, 98.0 and 99.9 percent. The experimental

values on Fig. 6 compare reasonably well with

those calculated.

Equilibrium water-vapor dew points can be

derived from the calculated equilibrium constants.

Water concentration in :he gas phase is translated

into dewpoint temperatures by means of a suitable

natural gas moisture chart. For higher TEG

concentrations, calculated dew points are slightly

higher than the experimental data at the lower

equilibrium temperatures, but coincide well or are

slightly higher at temperatures in the range of 120

to 140 F. The 160 F experimental check of the

correlations extended vaIues shows a difference of

only 1.7 F, or 1.1 percent of the total dewpoint

depression.

r

t ,..

,.

.

v

.

.

i:l:~

. .

.

.

.

. . .

.

. d

.W

I

40,6

:

:

%

ml

,,, , I I I I

0! C6 10 5 10 50 10

WATER CONCi Ni RA7(0N IN 7[0 w1kG T %

FIG. 9 WATER EQUILIBRIUM CONSTANTS IN

THE TEG-GAS-WATER SYSTEM; 14.7 PSIA WHITE

I

1

31X*

X3

01

001

EQUATION.

W %TEG

/%

WHITEEOUATIONFITTEOTO

COFRCEXPERIMtNTALOAIA

98

999

.

40 60 80 100 1?0 140

EOWIIBRIUMIE?APERATuRE F 7

FIG, 10 VARIATION OF WATER EQUILIBRIUM

CONSTANT WITH TEMPERATURE; 14.7 PSIA.

30s

CONCLUSIONS

Water-vapor dewpoint temperatures can be lowered

to a greater extent than predicted by most published

glycol equilibrium data.

Experimental dew points are dependent 0~

equilibrium TEG concentration and temperature and

can be described by means of a thermodynamic

relationship. Close first approximations may be

obtained from an exponential least-squares

correlation that allows calculation of either dew

point, TEG concentration, or equilibrium temperature

if the two other quantities are known.

Water equilibrium constants are virtually

independent of TEG concentration in the high

con centration range required for advanced gas

dehydration. If TEG contains more than a nominal

3 weight percent water, equilibrium constants

increase significantly with increasing concentrations

of water. The difference in TEG concentrations

between the top and the bottom of a glycol contactor

could therefore be significant.

The dependence of the equilibrium constant on

contact temperature is exponential. The equilibrium

water content of the natural gas roughly doubles for

every 20 F increase in temperature. The relationship

provides a useful first approximation for all TEG

concentrations studied.

The effect of contacting pressure on water vapor

dewpoint temperature and water distribution constant

was not investigated. A consensus of published data

indicates that equilibrium dewpoint depression is

independent of pressure and that the water

equilibrium constant decreases with increasing

pressure. The thermodynamic expression of White,

found valid for our data, indicates that the latter

assertion is correct.

The White correlation fitted to our smoothed

experimental data (Eq. 12) is recommended as the

preferred method for obtaining design data on

triethylene

D=

P=

PTEG =

T=

TD .

w=

a12 =

61,62 =

p. =

p; =

glycol contractors.

NOMENCLATURE

dewpoint depression = saturation temper-

ature - equilibrium dewpoint tempera-

ture, F

system pressure, psia

TEG vapor pressure, mm Hg

equilibrium temperature, R

water-vapor dewpoint temperature, F

weight percent water in equilibrium TEG

- a21 = constants

constants in White equation

partial pressure of pure water

vapor pressure of the pure component i

at system temperature

Xw =

mole fraction of water at equilibrium in

the liquid phase

yi =

yw .

y.

mole fraction of component i in vapor

phase

mole fraction of water at equilibrium in

the gas phase

activity coefficient

SUBSCRIPTS

w = water

TEG = triethylene gIycol

ACKNOWLEDGMENTS

I wish to express my thanks to Chevron Oil Field

Research Co. for permission to publish this paper

and to C. A. Johnson for his competent and

meticulous handling of the demanding experimental

program.

I.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11,

12.

13.

14.

REFERENCES

White, R, R.: Vapor-Liquid Equilibria in Non-Ideal

Solutions, Trans., AIChE (1945) Vol. 41, 539.

Scauzillo, F, R.: Equilibrium Ratios of Water in

the Water-Triethylene Glycol-Natutal Gas System,})

J, Pel. Tech. (July 1961) 697-702; Trans., AIME,

vol. 222.

Bukacek, k, F.: Equilibrium Moisture Content of

Natural Gases, IGT Research Bull. 8, Chicago

(1955); Charts of the Equilibrium Moisture Content

of Natural Gases, $J Supplement to IGT Research

Bull. 8 and ASTM Method D 1142-58, Chicago (1959),

Sharma, S. C.: Equilibrium Water Content of Gaseous

Mixturea, PhD thesis, U. of Oklahoma, Norman

(1969),

Millhone, R, S. and Fett, E. R.: Chromatographic

Analysis of Natural Gas Liquids, Ptoc,, 41st

Annual Fall Meeting of WGP and ORA, Anaheim,

Calif. (Oct. 1966) 91-109.

GIYCOIS, Bull. F-4763H, Union Carbide Corp.

(1964) Table 29, (Page 46).

Worley, M. S.: TEG Still the Least Expensive

Route, Cdn, Petroleum (June 1967) 34.

Dingman, J, C. and LeBas, C. L.: NOW New

Dew Point Data for Triethylene Glycol Solutions,

Oil and Gas ]. (Feb. 3, 1964) 7.5.

Gas Conditioning Fact Book, Dow Chemical Co.,

Midland, Mich, (1962).

GIYcoIs, Properties and Uses, Form No. 125-285-

61, Dow Chemical Co., Midland, Mich. (1961).

Townsend, F, M.:

~~Equilibrium Water Content S of

Natural Gas Dehydrated by Aqueous Diethylene and

Triethylene Glycol Solutions at Varioua Temperatures

and Press ures, PhD thesis, U. of Oklahoma, Norman

(1955).

Wise, H., Puck, T. T. and Failey, C. F,: Studies

in Vapor-Liquid Equilibria: The Binary System

Triethylene Glycol-Water, j, Pbys. Chern, (1950)

vol. 54, 734.

Ha-la, E., Pick, J., Fried, V, and Vil~m, O.: Vapour-

Liquid Equilibrium, 2nd English Ed., trans. by G.

Standart, Pergamon Press, Oxford (1967).

Sharma, S. C, and Campbell, J. M.: Water Content

of Natural Gas, paper presented at 1969 NGPA

National Convention.

***

S06 SOCIETY OF PETROLEUM ENGINEERS JO CRNAL

Das könnte Ihnen auch gefallen

- Dictionary For The Petroleum Industry.Dokument242 SeitenDictionary For The Petroleum Industry.Clarissa100% (5)

- Dictionary For The Petroleum Industry.Dokument242 SeitenDictionary For The Petroleum Industry.Clarissa100% (5)

- Instrument For Benzene and Toluene Emission Measurements of Glycol RegeneratorsDokument7 SeitenInstrument For Benzene and Toluene Emission Measurements of Glycol Regeneratorssejerson07Noch keine Bewertungen

- Twenty Years of Progress with TEG DehydrationDokument5 SeitenTwenty Years of Progress with TEG Dehydrationsejerson07Noch keine Bewertungen

- Contenth ServerDokument9 SeitenContenth Serversejerson07Noch keine Bewertungen

- Composicon Con c7+Dokument7 SeitenComposicon Con c7+sejerson07Noch keine Bewertungen

- Teg HysysDokument11 SeitenTeg Hysyschemeng2004100% (1)

- Boggs Principles of Sedimentology and StratigraphyDokument796 SeitenBoggs Principles of Sedimentology and Stratigraphysejerson07100% (1)

- Glycol Dehydrators - Rev 0Dokument10 SeitenGlycol Dehydrators - Rev 0Suleman TariqNoch keine Bewertungen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Motion in Multiple DimensionsDokument26 SeitenMotion in Multiple Dimensionsa5759761Noch keine Bewertungen

- List of Baryons - WikipediaDokument8 SeitenList of Baryons - WikipediaSallyy SpitownNoch keine Bewertungen

- Sheet - 01 - Real GasDokument41 SeitenSheet - 01 - Real GasSushant VermaNoch keine Bewertungen

- Catalysts 04 00397 v2Dokument17 SeitenCatalysts 04 00397 v2Anonymous Wcj4C3jNoch keine Bewertungen

- Anatomy and Physiology With Integrated Study Guide 5th Edition Gunstream Solution ManualDokument7 SeitenAnatomy and Physiology With Integrated Study Guide 5th Edition Gunstream Solution Manualelizabeth100% (25)

- Intermolecular ForcesDokument29 SeitenIntermolecular ForcesemilyNoch keine Bewertungen

- Test Questions in Engineering MechanicsDokument2 SeitenTest Questions in Engineering Mechanicsbasanth babuNoch keine Bewertungen

- Sesame ProteinDokument10 SeitenSesame ProteinJulius BudiNoch keine Bewertungen

- ESAS-Lindeburg Terms (Dreamforce)Dokument14 SeitenESAS-Lindeburg Terms (Dreamforce)e5865domingoascotbaguioNoch keine Bewertungen

- Discharge Coefficients for Compressible Flow Through Small DiametersDokument15 SeitenDischarge Coefficients for Compressible Flow Through Small DiametersProcess LibraryNoch keine Bewertungen

- Game PhysicsDokument31 SeitenGame Physicscabella_pasaporteNoch keine Bewertungen

- TRANSIENT HEAT TRANSFER CALCULATIONSDokument3 SeitenTRANSIENT HEAT TRANSFER CALCULATIONSSanith RenjalNoch keine Bewertungen

- Sensors 3Dokument59 SeitenSensors 3zubairawNoch keine Bewertungen

- Austenitic Cast Iron Welding Detailsfrequently Aske-WPS OfficeDokument17 SeitenAustenitic Cast Iron Welding Detailsfrequently Aske-WPS Officearjun prajapatiNoch keine Bewertungen

- Spec Potassium SorbateDokument2 SeitenSpec Potassium SorbateFerdian Iwank IriyantoNoch keine Bewertungen

- CELL OxigenoDokument1 SeiteCELL OxigenopedrogutizNoch keine Bewertungen

- BurnerDokument33 SeitenBurnertoficNoch keine Bewertungen

- Euterpe Oleracea, Matricaria Chamomilla, and Camellia Sinensis AsDokument10 SeitenEuterpe Oleracea, Matricaria Chamomilla, and Camellia Sinensis AsAlejandra Maria Monroy EspejoNoch keine Bewertungen

- Pogil Photosynthesis and Respiration-SDokument6 SeitenPogil Photosynthesis and Respiration-Sapi-2623786400% (1)

- Zumdahl Chapter 9Dokument24 SeitenZumdahl Chapter 9Master NistroNoch keine Bewertungen

- Water Purification Experiment Dissolved OxygenDokument2 SeitenWater Purification Experiment Dissolved OxygenJunNoch keine Bewertungen

- 10biology Practical - StomataDokument2 Seiten10biology Practical - StomataHridaan SherawatNoch keine Bewertungen

- Solution To Problem 4.5, Mandl-ShawDokument4 SeitenSolution To Problem 4.5, Mandl-ShawMikael Souto MaiorNoch keine Bewertungen

- Tutorial 2 ProblemsDokument2 SeitenTutorial 2 Problemsneji hyuugaNoch keine Bewertungen

- 2020 - Skema Bab 3 Konsep Mol, Formula Dan Persamaan Kimia Editted PDFDokument36 Seiten2020 - Skema Bab 3 Konsep Mol, Formula Dan Persamaan Kimia Editted PDFsyed ali0% (3)

- Circularmotion 120902002951 Phpapp02Dokument82 SeitenCircularmotion 120902002951 Phpapp02Victor OkosunNoch keine Bewertungen

- Copernican PrincipleDokument7 SeitenCopernican Principlemaddy555Noch keine Bewertungen

- Condensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsDokument9 SeitenCondensation of Acetophenone To (Dypnone) Over Solid Acid CatalystsLutfiah Nur HidayatiNoch keine Bewertungen

- ADA214144Dokument384 SeitenADA214144shawn AkersNoch keine Bewertungen