Beruflich Dokumente

Kultur Dokumente

4-Vicksburg Rig Move Guidelines and Procedures

Hochgeladen von

Ridamrut0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

426 Ansichten19 SeitenOffshore

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenOffshore

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

426 Ansichten19 Seiten4-Vicksburg Rig Move Guidelines and Procedures

Hochgeladen von

RidamrutOffshore

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 19

1

Atwood Offshore Drilling Ltd

Safety Always

VICKSBURG RIG MOVE

GUIDELINES AND PROCEDURES

RIGMOVE # 129

From

Coastal Energy - Songkhla-G (Thailand)

To

Coastal Energy - Songkhla D (Thailand)

April 2011

DOCUMENT ISSUE RECORD

Rev. Date Status Author Signature Approved Signature

1 19

th

April

2012

Review Atwood

P. Roedgaard

Atwood

Tony

Wilson

2

TABLE OF CONTENTS

SUBJ ECT

1. INTRODUCTION

2. PERSONNEL RESPONSIBILITIES

3. PREAMBLE

4. PRE-MOVE PREPARATION

5. SUMMARY OF PLANNED ACTIVITY

6. DEPARTURE FROM SONGKHLA-E, LEG PULLING OPS, TOW

ROUTE

7. ARRIVAL, POSITIONING, PRELOADING AT SONGKHLA-G

8. TOWING READINESS

9. TOWING SAFETY

10. WEATHER AND OPERATIONAL LIMITS

11. TOW BRIDLE CONNECTION & DISCONNECTION

12. SUPPORT

13. EMERGENCY CONTACT NUMBERS / ROUTINE

COMMUNICATION

14. MEDIVAC PROCEDURES

15. MINIMUM MANNING CONSIDERATIONS

1.0 INTRODUCTION

1.1 The procedures contained within this document are designed to propose a suitable

methodology for the departure of Vicksburg from Songkhla-G and intended tow

route to Songkhla-D in Thailand. The procedures have been developed and

approved by Atwood and Coastal Energy Management.

1.2 These procedures assume the following:-

The reported water depth at Songkhla-G is: 56.4 ft

3

Three anchor-handling vessels (AHVS) will be utilized to move off the Songkhla-G

location.

AHVS will be manned to allow 16 hours continuous operation in all respects.

1.4 Three AHVs will proceed to the Songkhla-G location for utilization.

1.5 The details within this document are guidelines for the planning, preparation and

implementation of procedures associated with this particular VICKSBURG rig

move. For all issues associated with the move, all decisions and actions shall

adhere to Atwood accepted methodology and prudent marine practices.

2.0 PERSONNEL RESPONSIBILITIES

The following descriptions of responsibility refer to the key personnel who will be

involved in the VICKSBURG rig move from Songkhla-G location to Songkhla-D.

2.1 THE VICKSBURG OIM

Will have total responsibility for the safety of the rig and personnel at all times, as per

statutory requirements, and will decide when it is safe and practicable to commence

operations within the limitation of the units Operations Manual, having consulted with the

Warranty Surveyor.

The VICKSBURG BARGE MASTER will be responsible for the conduct and safe

operation during the moving off / jacking operations at Songkhla-G and positioning

operations at Songkhla-D

Will ensure the correct placement of competent Atwood personnel to ensure the safe

deployment, handling of vessel tow gear and leg jacking operations.

Will ensure the correct placement of competent Atwood personnel to ensure the safe

deployment, handling of vessel tow gear and leg jacking operations.

Will be responsible for the conduct and safety of the tow and will give instructions to the

towing vessels with regard to tow-wire deployment, passage planning, courses and speeds

after consultation with the Vessel Masters.

4

Will ensure the stability of the rig at all times, including making any required adjustments

to trim or heel, as necessary.

Will ensure that all relevant authorities are kept informed by e-mail of the rig move status.

Will ensure that a pre-rig move safety meeting is held onboard prior to commencement of

the tow.

2.2 THE COASTAL ENERGY DRILLING SUPERVISOR

A Coastal Energy drilling supervisor will be onboard the rig for the tow from Songkhla-G

to the Songkhla-DJ .

The Vicksburg will be responsible for figures for rig and tow boat vessel consumables at

relevant times required by Coastal Energy and document on the Vicksburg IADC.

2.3 RIG POSITIONING SURVEYORS

Will be required for the tow, also a monitor will be required in the Control room, under the

cantilever, the main tow boat and AHVs and equipment must be operational.

2.4 RIG MOVE VESSEL MASTERS

Will be responsible for the safety of their vessels and for the safety of the tow. Will be

responsible for ensuring that all towing operations are conducted in a safe manner with due

regard to safe working practices and the practices of good seamanship. Will ensure that all

crews are familiar with and towing operation.

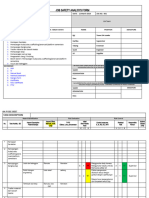

Will use the J SA as a tool for incident prevention and ensuring that all hazards have been

identified and communicated to the crew prior to each marine operation.

Will ensure that 'Clear Deck' Policy is adhered to during operations.

2.5 WARRANTY SURVEYOR

5

Shall confirm sea-fastenings prior to jacking into the water and watertight integrity prior to

putting the unit afloat. He will check stability information and confirm the unit has

sufficient reserves to complete the move.

He will issue a certificate of approval for the rig move and approve all towing vessels.

He will confirm weather forecast conditions meet with procedural criteria prior to

beginning the rig move and keep a detailed log of events.

He will be available to discuss and advise on all aspects of the rig move with the Barge

Master & OIM, if required.

He will ensure that all the Braemar Falconers recommendation and requirements have been

met prior to departing the Songkhla-G location and that all operations are in accordance

with Atwood policies and procedures including compliance with the Operations Manual.

2.6 RIG MOVER (BARGE MASTER)

The Rig Mover shall be responsible for the towing and positioning operations, otherwise

this responsibility will revert to the O.I.M.

Will be responsible for the conduct and safety of the tow and will give instructions to the

towing vessels with regard to tow-wire deployment, courses and speeds in consultation

with the Vessel Masters.

Will be responsible for the departure and approach from/ into the respective location and

soft pinning of the legs.

Will conduct pre-job safety meetings before the commencement of jacking down, jacking

up, pulling off, pulling into location and mooring operation detailing the work that is to be

carried out for the day. The Rig Mover shall be responsible for the towing and positioning

operation, otherwise these responsibilities will revert to the OIM.

The designated rig mover for this move shall be Barge Master Poul J. Roedgaard

6

For this move, a "pre-move" meeting will be conducted onboard the VICKSBURG in a

timely manner to clarify details and establish responsibilities with the following attendees.

O.I.M.

Rig crew with key responsibilities

Warranty Surveyor

Tow Vessel Captains

3.0 PREAMBLE

3.1 The purpose of this document is to ensure that the 'VICKSBURG' departure, and

approach to the location are conducted in a safe and efficient manner.

3.2 The safety of Personnel, Rig, Equipment and ATWOOD / COASTAL ENERGY assets

is of paramount importance and all parties involved in the operation will comply fully

with all safety procedures in place.

3.3 These approved procedures shall be followed as closely as circumstances permit,

having due regard for the limitations of the unit and its assisting vessels. Should any

deviations be necessary, the COASTAL ENERGY Superintendent / OIM and Barge

Master will be advised immediately. They shall initiate the Management of Change

Process (M.O.C.) and get the necessary approvals.

3.4 Due considerations must be given to any, and all, effects of such a deviation.

3.5 Prior to the commencement of jacking hull into water, leg freeing, pull off from

location, anchor deployment, pinning of legs, preloading and anchor recovery

operations, weather forecasts shall be obtained which show the operation can be safely

completed without interruption..

3.6 All rig move vessels will be issued with a copy of this rig move procedure prior to

departure from Songkhla-G. Vessel Masters will be required to review the procedure

and comment accordingly.

7

3.7 Prior to commencement of operations, the 'VICKSBURG' Barge Master and the

Masters of the AHVs are to confirm that all mechanical equipment and fittings to be

utilized in the pull off and move on operation are operable.

3.8 All key personnel shall be fully briefed by the VICKSBURG Barge Master prior to the

commencement of operations, to ensure a full understanding of these procedures. Key

personnel shall include Atwood ToolPusher, Rig Mover, Warranty Surveyor, Winch

Operators and Vessel Masters.

4.0 PRE-MOVE PREPARATION

4.1 Pre-move preparations will be made which includes the following as a minimum:

All non-essential personnel to be taken off the rig

Rig move checklist detailing pre-move tasks completed by designated parties and

approved by the Barge Master prior to jacking down.

Stability calculations completed and approved by the Barge Master

Watertight Integrity/ Openings Requiring Closure for unit to be watertight, all

hatches/doors, vents, confirmed watertight. The compartmentalization and watertight

integrity compliance, with specific mention of the closures involved, is addressed in the

Operations Manual.

Sea-fastenings/tie-down made in accordance with good Marine practice and Atwood

Offshore standards. The sea-fastenings will be approved by the O.I.M. and Warranty

Surveyor prior to jacking down. Safety Equipment will be re-verified to be in good

condition 12 hours prior to the rig move.

4.2 Towing Vessels Moving off SONGKHLA-G

Vessels

Lead Tug: Hawk K

Second Tug: Crest Ruby

Third Tug: TBN

All tugs to be provided by COASTAL ENERGY

Note: Atwood tow vessel requirements are For Ocean Tow an approved tow vessel of

minimum 120T bollard pull. For field move two approved tow vessel of minimum 70T bollard

pull. For stern positioning approved tow vessels of minimum 45t bollard pull.

8

All Tow Vessels are subject to approval by Atwood elected insurance surveyor.

4.22 The tugs contracted by Coastal Energy must have permission to enter 500m and

connect to the Vicksburg for the duration of move off and tow operations.

.23 The details for this move will be presented at the pre-move meeting and will cover the

following points:

Weather parameters for location departure

Weather Criteria (From Vicksburg MOM Section, 16.16)

a. The rigs hull should never enter the water or exit the water unless waves are less than three

(3) feet in height for hard bottom and five (5) feet in height for soft bottom.

Weather window for expected duration of the rig move jacking operations

Weather window of a minimum 72 hours will be required to do and complete the

move, jacking, stomping and preload operations

Lines of communication

Tow route

Safe shelters available along the tow route: None.

Soft Pin Positions

Piracy prevention measures to be taken and followed during the tow (24 hour watch

and other measures, as considered necessary.)

4.3 Procedures Undertow

4.31 All operating criteria and guidance for stability and watertight integrity contained in

the VICKSBURG Operation Manual will be complied with.

4.32 During the tow, routine checks for watertight integrity /tank soundings / draft marks/

towing gear condition / sea-fastenings as instructed by the Barge Master. will be

made and recorded.

4.33 Rig motion recorded and position reports can be obtained from the towing vessel, as

available to the rig.

4.34 Safe shelters (Thailand)

There are no safe shelters available along the tow route

4.35 Piracy prevention measures to be taken and followed during the tow (24 hour watch)

and other measures as considered necessary will be set out.

9

5.0 SUMMARY OF PLANNED ACTIVITIES

5.1 The VICKSBURG will be demobilized from Songkhla-G after the completion

scheduled work activities.

5.2 The lead tug Hawk K will be secured to the bow lead and the remaining boats to the

port/stbd aft as designated by the rig mover.

5.3 When pre-move preparations are complete the rig will jack down into the water and

attempt to pull legs, if no go then jetting legs will commence until free.

5.4 The rig will jack down to draught. Legs will be raised to towing position. Watertight

integrity of the hull shall be checked by the rig personnel and warranty surveyor.

Water Tower must be raised to full height also utilizing extension hoses.

Jetting

5.5 After confirmation of w/t integrity from warranty surveyor, the rig will

jack to 1-2 foot below floating draft and begin leg pulling operations. The

legs will be jetted, if the legs do not pull free immediately. Bow leg will be

freed first, then Starboard, Port leg last.

5.6 Upon completion of the leg pulling operations once the legs are free and clear of sea

bed, the rig will once clear of platform gradually turn to port to go on a northerly

heading ensure that passage will be minimum 500 meters east of SonghklaC thereafter

tow across to Songkhla-D soft pin position location. Final waypoints to be made up

once the position surveyors comes onboard

5.7 Once the rig is positioned it will be soft pinned 100m of Songhkla-D and anchors run.

Stomping

5.8 Procedure to follow

6.0 DEPARTURE FROM SONGKHLA-G

6.1 Location Details

Lat; 07 2606 N

Long; 100 3625 E

10

Water Depth: 56.4 ft

Vicksburg position heading 90.8

Leg penetrations: Bow: 35.0 ft Port: 35.0 ft Stbd: 35.0ft

6.2 Pull off from Songkhla-G

6.3 The rig will be slowly moved away from the location as the spud can tips clear the

bottom. The initial pull by the tow boats and tugs shall be as directed by the rig

mover.

6.4 Tow Passage

The tow passage will be altered to avoid the fishermans nets, all necessary steps and

precautions will be taken to minimize any possible property damage whilst also

ensuring the safety of all vessels and structures in the area.

6.41 The move from Songkhla-G will be in accordance with these guidelines and details

established in the pre-move meeting. Consumable quantities will be recorded for the

rig and tugs; this will be logged in IADC report.

6.42 Warranty Surveyor will prior to the move provide approval for the tow. Acceptable

weather conditions must be present to commence the tow and weather forecasts will

be received at a minimum of 72 hrs prior to jacking down with a 5 day outlook.

6.43 The passage from Songkhla-G to Songkhla-D shall be conducted with Haw K lead tug

(Connected to the VICKSBURG main towing wire). Assisted by another two

nominated tow vessels Crest Ruby and TBN connected to the quarters

6.44 The tow distance from Songkhla-G to Songkhla-D is 5.0 nautical miles. The duration

of tow shall be 3 hours at an anticipated tow speed of 1.7 knots.

6.45 The proposed tow route shall ensure that a maximum clearance is maintained from

any obstacles or structures. The tow vessels shall be provided with a copy of the

intended tow route and move procedure.

11

6.46 The Rig Mover shall discuss the procedures and plans with each boat Captain(s) and

shall include the following as a minimum:

Communications during towing operations.

Proposed tow route

Weather criteria and forecast information

Navigation procedures

Sufficient navigation equipment and updated charts

Facilities and capabilities of tow vessels

Towing arrangements.

Contingency plans and emergency procedures

6.48 Notification shall be transmitted to Coastal Energy, Atwood and the Helicopter

Operators at the following times:

Departure from Songkhla-G

If any problems or delays are encountered in route while in Thai territorial waters.

Arrival at Songkhla-D

Other appropriate authorities shall also be notified of VICKSBURG move progress,

as required.

6.49 It must be ensured that all rig and vessel anchors are racked and double secured. The

tow line length shall be adjusted by the respective vessels accordingly; take into

account towing wire centenary and water depth.

The BA charts used must be corrected to the latest Notices to Mariners.

All vessels shall exhibit the appropriate shapes and lights as required by the Rules of

the Road.

6.50 Tow Route

Below is the proposed tow route of the Vicksburg from Songkhla-G to Songkhla-D,

Thailand. TAS Helicopters requires this to determine the extent of chopper

12

requirement in the event of Medivac in Thai waters. TAS Helicopters will provide

emergency cover in Thailand. This will then be communicated to relevant

authorities.

The proposed tow route way points and coordinates

Description Latitude Longitude Course Distance

Songkhla-G 07 2606 N 100 3625 E

Songhkla D 07310 N 100 3645 E 002 5.0 NM

7.0 Arrival at Songkhla-D

This will be about 100m off final location at the rig movers discretion

7.1 Final Location Details

Lat; 07 30 59.6 N

Long; 100 36 45 E

Water Depth: 17.8 Mtr / 58.4 Ft ref. Braemar Falconer

Vicksburg to be positioned heading 90

The weather forecasts shall be used to assist in deciding course of action

7.3 Positioning

Positioning will take place by using four anchors and tug assistance

The rig will soft pin 100m off Songhkla-D platform at the rig movers

discretion enabling anchors to be run and connected, by AHVs. Once anchors

deployed and holding stomping will commence

Rig will move onto final position in daylight hours only

Rig must give Coastal Energy 12 hrs notice to enable them to shut in

production.

7.4 Preload

Sequence and holding time will be decided when stomping has been completed.

Awaiting stomping procedures

13

8.0 Anchoring Operations

Two AHVs will be utilized at Songhkla-D soft pin location; anchors will be

run as per the anchor spread diagram.

Port fwd anchor 040c/w 300 mtr wire

Stbd Fwd anchor 140 c/w 300 mtr wire

Stbd aft anchor 220 c/w 450 mtr wire

Port aft anchor 303 c/w 300 mtr wire and also

50 mtr of 70mm chain and one piggy back anchor.

8.1 Clear Deck Policy

8.11 "Clear Deck" Policy MUST be fully discussed and understood on VICKSBURG and

the designated AHVs.

8.12 Winch operators must understand that the load path is clear of personnel prior to

lowering and heaving in of any wires.

8.13 Deck crew handling wire must understand to keep away from the wire paths

whenever wire or chain is under tension. Essential personnel needed on deck must

be within safe haven during operations.

8.2 Communication

8.21 Establish direct VHF radio communication on designated frequency/ channel to link

VICKSBURG to all its support vessels.

8.22 Support Vessels are to ensure that they have direct radio communication between

bridge and deck operations. We will work on channel 72. In case of loss of

communications we will fall back to channel 9, the field channel. Also contact

Phone, fax and email numbers of the tow vessels will be given to the Vicksburg and

Coastal Energy offices before departing Songkhla-G location.

8.23 Communications will be done using the English language.

14

8.3 Tow Vessel Readiness

8.31 Tow vessel are to have a sufficient fuel on board for a minimum of 14 days tow

passage at 100% power plus consumables and provisions.

8.32 All towing, anchor handling wires and ancillaries must be certified by class and

maintenance log of same shall be updated and be readily available for inspection

prior to usage.

8.33 Towing trim and draught is to be suitable for anticipated weather.

8.4 Jack-Up Readiness

8.41 Towing winches and all associated equipment and instruments are verified functional.

8.42 API RP 21 Inspection of Mooring Equipment performed.

8.5 Survey Spread

Will be required for the tow, also a monitor will be required in the Control room, the main

tow boat and AHVs and equipment must be operational.

8.6 Weather Forecast

8.61 Weather forecasts for this move will be obtained on a two times / day arranged by

Atwood.

Weather reports will provide the following information as a minimum and meet the

following reporting criteria:

Early warning of typhoon development, then continuous monitoring / updates and actual

and predicted tracks.

Wind speed and direction.

Wave height, period and direction

Current speed and direction

Confidence of the forecast, (high, medium, low)

The information for waves should include the wind, wave and swell components, as well

as the maximum combined sea.

15

Both site and route specific forecasts.

Transmissions direct to the rig twice each 24 hours.

Each forecast to provide 3 day advance cover.

Immediate updates provided in the event of significant change in the forecast.

8.62 Receipt of the first forecast will be 48 hours prior to move commencement.

9.0 TOWING SAFETY

SAFETY IS COASTAL ENERGY AND ATWOODS NO.1

PRIORITY

9.1 Atwood & Coastal Energy expects that the pull off operations of the VICKSBURG

from Songkhla-G and the tow to Songkhla-D is carried out in a safe and efficient

manner.

9.2 J ob Safety Analysis (J SA) shall be carried out by the Master of each AHV before the

start of the positioning operations.

9.3 Daily Safety Meeting shall be held and the Master of each support vessel shall brief his

crew on all aspects of the work to be carried out.

9.4 Work Vests and personal safety equipment must be worn at all times when working on

deck.

9.5 Inspect tools and buoy catchers, test shark jaws/ kamforks, anchor handling winch,

tugger winches and capstans before commencing on operations. OIM / RIG MOVER

shall be kept informed of the status of equipment. Any malfunction shall be reported

immediately to the OIM / Rig Mover who will then advise all key personnel offshore.

9.6 Test communication system between the bridge, tow winch operator, rig mover and the

deck crew.

9.7 Pelican hooks shall not be used at any time during the operations.

9.8 Deck Crew shall stand clear of wires under tension and shall not be on the aft deck

during winch operations. This shall be in accordance with 'Clear Deck Policy' as

described in Section 8.1

9.9 Periodic (hourly) safety messages must be transmitted via all available means by the

lead tug warning traffic in the vicinity of the status of tow.

9.10 Working hours and rest periods onboard the towing vessels should be in compliance

with the STCW Convention (STCW95) and ILO Convention No. 180.

16

10.0 Final Positioning on Songkhla-D

Final positioning of the rig will be carried out after stomping operations are complete, refer

attached procedure

11. TOW BRIDLE CONNECTION & DISCONNECTION

11.1 The tow bridle connection to the two tugs shall be made when directed by the rig

mover.

11.2 Tow Line Connections at Songkhla-G

11.21 The designated lead tug Hawk K shall back up to the bow of the rig and take

position under the helideck of the rig.

11.22 The eye of the tow wire shall be lowered by rigs tugger winch until the tow

stringer is received and hauled in by the Hawk K. The tow wire will then be

secured on mechanical securing device.

11.23 Tow line connection shall then proceed with the stringer being secured by 100T

shackle to tow wire of Lead Tug.

11.24 The tug shall then pay out tow wire and adjust length for effective pull of rig when

legs are freed.

11.25 Second and third tugs will be connected to the port and stbd aft side of the rig by

aft tow wires.

11.26 The lead tug shall then pay out tow wire and adjust length for effective pull of rig

when legs are freed.

11.3 Tow Line Disconnection at Songkhla-D

11.31 The main tow line shall be shortened until the stinger is secured on the mechanical

securing device. The Lead Tug shall manoeuvre itself until the stern is under the

helideck whilst spooling in tow wire.

11.32 After the stinger has been disconnected, the weight on the air tugger wire

connected to the delta plate shall be taken up by the rig whilst the stinger remains

secured on mechanical securing device.

11.33 The stinger shall be released from the mechanical securing device of the tug

ONLY after receiving instructions from the rig mover.

11.34 The tugs on the quarters wire will come close to the side and within reach of

cranes.

11.35 The crane will bring down a pennant wire, which will be connected to the socket

of the tow wire when it is locked on the kamfork. When the crane is connected the

tow line can be released from the kamfork and brought back on board the

Vicksburg

17

12.0 SUPPORT

12.1 Survey Vessel

None

12.11 Security Vessel

None

12.2 Other Support

12.21 All vessels must be suitably manned and be capable of 24 hours continuous

operations.

12.22 Vessel Masters and their relief are required to have a good command of the English

language.

12.3 Navigation Package

All AHVs are required to have a navigation package onboard

13.0 EMERGENCY CONTACT NUMBERS / ROUTINE COMMUNICATION

13.1 Field Working VHF channels 72

SSB 5930.0 KHz

Proposed Rig working VHF channel 72 / 73

13.2 The following contact numbers are to be used during the tow as required. As a matter

of protocol, all initial communication whether of routine or emergency nature shall be

directed first to the ATWOOD office to Larry Holloway, Operations Manager

VICKSBURG. If Larry Holloway is not available, any of the following ATWOOD

personnel should be contacted.

ATWOOD OFFSHORE Offices Thailand ( Bangkok )

18

Office Home Mobile

Larry Holloway

+66 (0) 2-7457305

Houston, Ext. 8780

+66 (0) 2-300-2664 +66-(0) 87-984-9882

Tony Wilson +66 (0) 2- 7457305

Houston, Ext. 8781

+66-(0) 89-812-7224

Michael VanKeuren +66 (0) 2-7457305

Houston, Ext 8783 +662 911-6750 +66-(0)8-9529-0022

COASTAL ENERGY Offices ( Thailand )

Office Home Mobile

Tony Veerachai Marine Facilities

Manager

+662 6100594 +6621970031 +66817315090

Rapee Kudisri Drilling Manager +6626100591 +66854867458

Ken Hemmerich Operations Manager +66 2 6100577 +66 819211061

Soraya OIM OIM +662 6100580 +66824288250

Suwat (Base Manager) Songkhla Base Manager +6674 331031 +66815417476

Vicksburg

Office Home Mobile

Inmarsat +873- 350 302 310

V-Sat

19

Tow Boats Comms:

Contact Name Boat Mini Sat Boat Mini-M Sat Fax Hand Phone

Via Radio Room

14.0 MEDIVAC PROCEDURES

14.1 In the event a serious injury or sickness occurs during the tow, Atwood Medivac

Procedures shall apply while in Thai territorial waters.

Das könnte Ihnen auch gefallen

- Responsibilities During Offshore Rig MovesDokument2 SeitenResponsibilities During Offshore Rig MovesYougchu LuanNoch keine Bewertungen

- Measurement While Drilling: Signal Analysis, Optimization and DesignVon EverandMeasurement While Drilling: Signal Analysis, Optimization and DesignNoch keine Bewertungen

- Manta Rig Move 1 - Songkhla - E. PlatformDokument22 SeitenManta Rig Move 1 - Songkhla - E. PlatformCaptIsqanNoch keine Bewertungen

- Deepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationVon EverandDeepwater Drilling: Well Planning, Design, Engineering, Operations, and Technology ApplicationBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Jr2016 012 Rig Move Cop SowDokument22 SeitenJr2016 012 Rig Move Cop SowImran Siddiqui100% (1)

- ADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Dokument15 SeitenADMI Move 6procedure (Rig Move4) To Mozhel PFrev3Mohamed MostafaNoch keine Bewertungen

- Super m2 New Offshore RigDokument50 SeitenSuper m2 New Offshore RigAmanda MartinezNoch keine Bewertungen

- DNV RP C104Dokument86 SeitenDNV RP C104Maremagnum3Noch keine Bewertungen

- Heron Jack UpDokument128 SeitenHeron Jack UpSubhra S Sanyal100% (1)

- Punch-Through Analysis of Jack-Up Rig at A Site Off The East Coast of India - A Case StudyDokument4 SeitenPunch-Through Analysis of Jack-Up Rig at A Site Off The East Coast of India - A Case StudyAtul KumarNoch keine Bewertungen

- Rack Phase Difference - RPD - Practical ApplicationsDokument19 SeitenRack Phase Difference - RPD - Practical ApplicationsAyman64100% (1)

- Jack Ups in Operation - Types and DifferencesDokument16 SeitenJack Ups in Operation - Types and Differencesibnuhary100% (1)

- (IADC) JRC Rig Move Warranty Survey Revision 2.0 16 October 2014 Aligned With ISO SNAMEDokument20 Seiten(IADC) JRC Rig Move Warranty Survey Revision 2.0 16 October 2014 Aligned With ISO SNAMEpaoloNoch keine Bewertungen

- Dynamic Behavior of Jack-Up ISOPE10Dokument36 SeitenDynamic Behavior of Jack-Up ISOPE10Imran Siddiqui100% (1)

- Jackup Introduction - StructureDokument77 SeitenJackup Introduction - Structuretranhuy3110Noch keine Bewertungen

- Jack-Up Rigs Operational Aspects (Offshore Drilling)Dokument22 SeitenJack-Up Rigs Operational Aspects (Offshore Drilling)myusuf_engineer100% (8)

- Theroadtosaqqara 131105123308 Phpapp02 PDFDokument63 SeitenTheroadtosaqqara 131105123308 Phpapp02 PDFMILADNoch keine Bewertungen

- Rig Move ManualDokument45 SeitenRig Move Manualjrladdu100% (24)

- Department Pre Rig Move ChecklistsDokument11 SeitenDepartment Pre Rig Move ChecklistsNagendra Singh Ranawat100% (1)

- Jack Up RigDokument39 SeitenJack Up Rigaksasingh75% (8)

- 3 - Blowout PlanDokument9 Seiten3 - Blowout Planbilo1984Noch keine Bewertungen

- Offshore Rig Move PlanDokument2 SeitenOffshore Rig Move Planmendezfs100% (2)

- Guidelines For JACKUP RigsDokument6 SeitenGuidelines For JACKUP RigsSfiriac LauraNoch keine Bewertungen

- ND - Jack Up RulesDokument25 SeitenND - Jack Up RulesImran Siddiqui100% (1)

- Station KeepingDokument67 SeitenStation Keepingdriller22Noch keine Bewertungen

- SPE - Emerging Decommissioning Trends in South East Asia - Local Interpretation and Implementation of Recently Updated Legislative Framework and GuidelinesDokument23 SeitenSPE - Emerging Decommissioning Trends in South East Asia - Local Interpretation and Implementation of Recently Updated Legislative Framework and Guidelinesredevils86100% (1)

- 6-HSE OSD 21 - The Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsDokument9 Seiten6-HSE OSD 21 - The Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsRidamrutNoch keine Bewertungen

- Jack Up RigsDokument57 SeitenJack Up Rigsnehan245Noch keine Bewertungen

- Jack Up Rig PlatformDokument2 SeitenJack Up Rig PlatformAbam JoshuaNoch keine Bewertungen

- BV Class Jack UpDokument62 SeitenBV Class Jack Upjrladdu100% (1)

- Rig MoveDokument10 SeitenRig Movejosel321100% (1)

- Jacking SystemsDokument3 SeitenJacking Systemsjiokoijiko100% (1)

- Jack Up PrimerDokument24 SeitenJack Up Primerruzbeh449066100% (2)

- Analysis and Improvement of Jacking Systems For Jack-Up RigDokument57 SeitenAnalysis and Improvement of Jacking Systems For Jack-Up RigImran Siddiqui50% (2)

- V.002 Vryhof Manual For WebDokument170 SeitenV.002 Vryhof Manual For WebShubhrajit Maitra100% (1)

- Plug and Abandonment Solution For Oilfield Decommissioning in The North SeaDokument19 SeitenPlug and Abandonment Solution For Oilfield Decommissioning in The North Seaerdal aydinNoch keine Bewertungen

- Review of API RP 16QDokument83 SeitenReview of API RP 16QSusan Diana Badillo Trejo0% (1)

- 5-Guidelines For The Content of Rig Move ProceduresDokument8 Seiten5-Guidelines For The Content of Rig Move ProceduresRidamrutNoch keine Bewertungen

- Jack Up GuidelinesDokument89 SeitenJack Up Guidelinesmelody0422367% (3)

- Safe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsDokument3 SeitenSafe Approach, Set-Up and Departure of Jack Up Rigs To Fixed InstallationsanhlhNoch keine Bewertungen

- R P Jacking SystemDokument2 SeitenR P Jacking Systemgrupa2904Noch keine Bewertungen

- What Is Rack Chock SystemDokument7 SeitenWhat Is Rack Chock SystemSarah Perez100% (1)

- Best Drilling Practices HDDDokument13 SeitenBest Drilling Practices HDDAzra RasidNoch keine Bewertungen

- 2 Bonga Riser Installation2Dokument25 Seiten2 Bonga Riser Installation2Antonio Ribeiro0% (1)

- Offshore DrillingDokument22 SeitenOffshore DrillingTarun Agarwal100% (1)

- SPDC Standard Drilling Procedures Manual Site: CHA Pter 07Dokument39 SeitenSPDC Standard Drilling Procedures Manual Site: CHA Pter 07Agaba Idu100% (1)

- StructuralAnalysesOfJack upsInElevatedConditionDokument12 SeitenStructuralAnalysesOfJack upsInElevatedConditionNavalArchitectureNoch keine Bewertungen

- Jack Up Rig Design PDFDokument91 SeitenJack Up Rig Design PDFAhmed Rehim50% (2)

- Development of A Petroleum Contractual Strategy ModelDokument12 SeitenDevelopment of A Petroleum Contractual Strategy Modelmohamadi42100% (1)

- Drilling OffshoreDokument1.086 SeitenDrilling OffshoreVenky KelseyNoch keine Bewertungen

- Survey Report-Jack Up RigDokument67 SeitenSurvey Report-Jack Up Rigifebrian80% (5)

- Jack-Up Conference 2009Dokument3 SeitenJack-Up Conference 2009Saeed JabbariNoch keine Bewertungen

- Shell Ox Exploration PlanDokument182 SeitenShell Ox Exploration Planjdlouhy3911100% (1)

- Manta Rig Move 1 - Songkhla - E. PlatformDokument22 SeitenManta Rig Move 1 - Songkhla - E. PlatformCaptIsqan100% (1)

- Ship Towage Guidelines MedwayDokument17 SeitenShip Towage Guidelines MedwayMichael Pascual100% (2)

- Towage GuidelinesDokument22 SeitenTowage GuidelinesMichael Pascual100% (3)

- Safety Regulations: International Longshore & Warehouse Union CanadaDokument38 SeitenSafety Regulations: International Longshore & Warehouse Union CanadaSanjayNoch keine Bewertungen

- Msre - Anchoring Procedure Letter PDFDokument5 SeitenMsre - Anchoring Procedure Letter PDFanhlh100% (1)

- Course: MTEC 102 Period: PRELIM Week: 2 Session: 1 Topic: Procedures For Safe Mooring-Deployment and Monitoring of Moorings For Cargo ShipDokument14 SeitenCourse: MTEC 102 Period: PRELIM Week: 2 Session: 1 Topic: Procedures For Safe Mooring-Deployment and Monitoring of Moorings For Cargo ShipMeljorin LayeseNoch keine Bewertungen

- Characteristics: Our in Vitro IdentityDokument4 SeitenCharacteristics: Our in Vitro IdentityMohammed ArifNoch keine Bewertungen

- DOMESDokument23 SeitenDOMESMukthesh ErukullaNoch keine Bewertungen

- TSR 9440 - Ruined KingdomsDokument128 SeitenTSR 9440 - Ruined KingdomsJulien Noblet100% (15)

- English 6, Quarter 1, Week 7, Day 1Dokument32 SeitenEnglish 6, Quarter 1, Week 7, Day 1Rodel AgcaoiliNoch keine Bewertungen

- Theory of Construction of The Giza Plateau Pyramids (Original Title Hypothesis of Construction of The Pyramids of The Valley of Gizeh (Giza)Dokument15 SeitenTheory of Construction of The Giza Plateau Pyramids (Original Title Hypothesis of Construction of The Pyramids of The Valley of Gizeh (Giza)International Journal of Innovative Science and Research TechnologyNoch keine Bewertungen

- Creativity Triggers 2017Dokument43 SeitenCreativity Triggers 2017Seth Sulman77% (13)

- Week1 TutorialsDokument1 SeiteWeek1 TutorialsAhmet Bahadır ŞimşekNoch keine Bewertungen

- Corporate Members List Iei Mysore Local CentreDokument296 SeitenCorporate Members List Iei Mysore Local CentreNagarjun GowdaNoch keine Bewertungen

- Catalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDokument336 SeitenCatalog de Aparatura Si Instrumentar Veterinar Eikemeyer-GermaniaDr. Dragos CobzariuNoch keine Bewertungen

- EQUIP9-Operations-Use Case ChallengeDokument6 SeitenEQUIP9-Operations-Use Case ChallengeTushar ChaudhariNoch keine Bewertungen

- Comparison of Multi-Coil and Diaphragm Spring ClutchesDokument3 SeitenComparison of Multi-Coil and Diaphragm Spring Clutchesmasb_994077Noch keine Bewertungen

- Qualification of Class Y Flip Chip Cga Package Technology For SpaceDokument8 SeitenQualification of Class Y Flip Chip Cga Package Technology For SpacePepe ChorizoNoch keine Bewertungen

- Student Committee Sma Al Abidin Bilingual Boarding School: I. BackgroundDokument5 SeitenStudent Committee Sma Al Abidin Bilingual Boarding School: I. BackgroundAzizah Bilqis ArroyanNoch keine Bewertungen

- Internship (1) FinalDokument12 SeitenInternship (1) FinalManak Jain50% (2)

- Module 17 Building and Enhancing New Literacies Across The Curriculum BADARANDokument10 SeitenModule 17 Building and Enhancing New Literacies Across The Curriculum BADARANLance AustriaNoch keine Bewertungen

- Green ProtectDokument182 SeitenGreen ProtectLuka KosticNoch keine Bewertungen

- JSA FormDokument4 SeitenJSA Formfinjho839Noch keine Bewertungen

- Nodal Analysis Collection 2Dokument21 SeitenNodal Analysis Collection 2Manoj ManmathanNoch keine Bewertungen

- ASHRAE Final Operating Room 508 PDFDokument13 SeitenASHRAE Final Operating Room 508 PDFSilisteanu AndreiNoch keine Bewertungen

- Dekker V Weida Amicus Brief by 17 AGsDokument35 SeitenDekker V Weida Amicus Brief by 17 AGsSarah WeaverNoch keine Bewertungen

- 20150714rev1 ASPACC 2015Dokument22 Seiten20150714rev1 ASPACC 2015HERDI SUTANTONoch keine Bewertungen

- Venere Jeanne Kaufman: July 6 1947 November 5 2011Dokument7 SeitenVenere Jeanne Kaufman: July 6 1947 November 5 2011eastendedgeNoch keine Bewertungen

- CBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Dokument6 SeitenCBSE Class 12 Informatics Practices Marking Scheme Term 2 For 2021 22Aryan BhardwajNoch keine Bewertungen

- Brianna Pratt - l3stl1 - Dsu Lesson Plan TemplateDokument5 SeitenBrianna Pratt - l3stl1 - Dsu Lesson Plan Templateapi-593886164Noch keine Bewertungen

- GSP AllDokument8 SeitenGSP AllAleksandar DjordjevicNoch keine Bewertungen

- Industry GeneralDokument24 SeitenIndustry GeneralilieoniciucNoch keine Bewertungen

- 02 Laboratory Exercise 1Dokument2 Seiten02 Laboratory Exercise 1Mico Bryan BurgosNoch keine Bewertungen

- Clock of Destiny Book-1Dokument46 SeitenClock of Destiny Book-1Bass Mcm87% (15)

- Deictics and Stylistic Function in J.P. Clark-Bekederemo's PoetryDokument11 SeitenDeictics and Stylistic Function in J.P. Clark-Bekederemo's Poetryym_hNoch keine Bewertungen

- First Aid Transportation of The InjuredDokument30 SeitenFirst Aid Transportation of The InjuredMuhammad Naveed Akhtar100% (1)

- Well Integrity for Workovers and RecompletionsVon EverandWell Integrity for Workovers and RecompletionsBewertung: 5 von 5 Sternen5/5 (3)

- Flow Analysis for Hydrocarbon Pipeline EngineeringVon EverandFlow Analysis for Hydrocarbon Pipeline EngineeringNoch keine Bewertungen

- Pocket Guide to Flanges, Fittings, and Piping DataVon EverandPocket Guide to Flanges, Fittings, and Piping DataBewertung: 3.5 von 5 Sternen3.5/5 (22)

- Practical Reservoir Engineering and CharacterizationVon EverandPractical Reservoir Engineering and CharacterizationBewertung: 4.5 von 5 Sternen4.5/5 (3)

- Abrasive Water Jet Perforation and Multi-Stage FracturingVon EverandAbrasive Water Jet Perforation and Multi-Stage FracturingNoch keine Bewertungen

- Well Control for Completions and InterventionsVon EverandWell Control for Completions and InterventionsBewertung: 4 von 5 Sternen4/5 (10)

- Machine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsVon EverandMachine Learning Guide for Oil and Gas Using Python: A Step-by-Step Breakdown with Data, Algorithms, Codes, and ApplicationsBewertung: 4 von 5 Sternen4/5 (4)

- Internal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesVon EverandInternal Combustion: How Corporations and Governments Addicted the World to Oil and Subverted the AlternativesBewertung: 4 von 5 Sternen4/5 (2)

- Casing and Liners for Drilling and Completion: Design and ApplicationVon EverandCasing and Liners for Drilling and Completion: Design and ApplicationBewertung: 5 von 5 Sternen5/5 (3)

- Case Studies of Material Corrosion Prevention for Oil and Gas ValvesVon EverandCase Studies of Material Corrosion Prevention for Oil and Gas ValvesNoch keine Bewertungen

- Advanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityVon EverandAdvanced Biomass Gasification: New Concepts for Efficiency Increase and Product FlexibilityBewertung: 3 von 5 Sternen3/5 (2)

- Well Testing Project Management: Onshore and Offshore OperationsVon EverandWell Testing Project Management: Onshore and Offshore OperationsNoch keine Bewertungen

- Fundamentals and Applications of Bionic Drilling FluidsVon EverandFundamentals and Applications of Bionic Drilling FluidsNoch keine Bewertungen

- Guide to the Practical Use of Chemicals in Refineries and PipelinesVon EverandGuide to the Practical Use of Chemicals in Refineries and PipelinesBewertung: 5 von 5 Sternen5/5 (1)

- The Petroleum Engineering Handbook: Sustainable OperationsVon EverandThe Petroleum Engineering Handbook: Sustainable OperationsBewertung: 3.5 von 5 Sternen3.5/5 (5)

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsVon EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsBewertung: 4 von 5 Sternen4/5 (6)

- Advanced Production Decline Analysis and ApplicationVon EverandAdvanced Production Decline Analysis and ApplicationBewertung: 3.5 von 5 Sternen3.5/5 (4)

- Heavy and Extra-heavy Oil Upgrading TechnologiesVon EverandHeavy and Extra-heavy Oil Upgrading TechnologiesBewertung: 4 von 5 Sternen4/5 (2)

- Gas-Liquid And Liquid-Liquid SeparatorsVon EverandGas-Liquid And Liquid-Liquid SeparatorsBewertung: 3.5 von 5 Sternen3.5/5 (3)