Beruflich Dokumente

Kultur Dokumente

Test Procedure To Evaluate Fluids in Open Loop Axial Piston Pumps

Hochgeladen von

Fernando SabinoOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Test Procedure To Evaluate Fluids in Open Loop Axial Piston Pumps

Hochgeladen von

Fernando SabinoCopyright:

Verfügbare Formate

Test Procedure to Evaluate Fluids in

Open Loop Axial Piston Pumps

Technical Data 03-06-0002-EN-0601

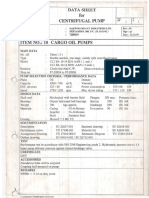

Pump Model

PVH57C-RF-2S-11-C25V-31

This test procedure is to evaluate fluids for use in

open loop axial piston pumps. It consists of 250 hours

of actual test time (not including break-in or per-

formance running). The operation temperature is

dependent upon the capability of the test fluid as

specified by the fluid manufacturer or the rated

temperature specified for the pump, whichever is

lower. Inlet fluid temperature must be maintained per

fluid/pump rating throughout the complete test.

The pump to be used is a PVH57 with a pressure

compensator and load sensing control, model code

PVH57C-RF-2S-11-C25V-31.

Table of Contents

Fluid Ratings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Pump Break-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Pump Performance Check Procedure . . . . . . . . . . . . . . . . . . . . . . 3

Disassembly and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Test Fluid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Fifty-Hour Pressure Cutoff Test . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Two Hundred-Hour Cyclic Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Final Fluid Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Fluid Pass/Fail Criteria . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Appendix A - Efficiency Formulas . . . . . . . . . . . . . . . . . . . . . . . . . 9

Appendix B - Control Pressure Hysteresis Test . . . . . . . . . . . . . . . 10

Pump Performance Check Record . . . . . . . . . . . . . . . . . . . . . . . 11

Fluid Properties Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Piston/Bore Record . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3 EATON CORPORATION Fluid Power Test Procedure to Evaluate Fluids in Piston Pumps Technical Data 03-06-0002-EN-0601 August 2001

Pump Break-In

Pump Performance

Check

Table 2 Pump Break-In Procedure

OUTLET PRESS

DURATION SPEED BAR (PSIG) INLET OIL TEMP

STEP MIN RPM 20 5 (72.5) C 5 (F 9)

1 5 600 50 (725) Ambient increase

2 5 1200 50 (725) to

3 10 1200 100 (1450)

4 10 1200 150 (2175)

5 10 1800 150 (2175)

6 10 1800 200 (2900)

7 10 2400 220 (3190) 95 (203)

Pump Break-In

Break in the pump using anti-

wear petroleum base hydraulic

fluid that complies with Vickers

Oil Recommendation Data Sheet

M-2950-S. Run the break-in

procedure step-by-step as listed

in Table 2. Inlet is to be at

atmospheric. No external leak-

age is allowed during the entire

test.

Overall Efficiency Percentage

Continue running the pump at

full stroke displacement using

the parameters in Table 2, Step

7 to determine its overall

efficiency.

The outlet flow must be

between 121 lpm (32 gpm) and

140 lpm (37 gpm).

If not, STOP THE TEST AND

CONTACT YOUR EATON

REPRESENTATIVE.

Record the output flow, input

torque, and case flow. Compute

the overall efficiency using the

formulas in Appendix A.

If the overall efficiency is less

than 85%, continue running the

pump (20 hours maximum)

using the parameters in Table 2,

Step 7 and re-check overall

efficiency using the formulas in

Appendix A.

If the overall efficiency is not

85% or greater, DISCONTINUE

TESTING AND NOTIFY YOUR

EATON REPRESENTATIVE.

Performance Baseline Test

Continue using petroleum-based

fluid, but at the conditions listed

in Table 1 for the test fluid. Set

the compensator at rated

pressure; adjust speed and

temperature per the ratings for

the test fluid.

Perform the pump performance

check procedure.

Sequence of Operations

1 Energize 15 while 16 is de-

energized. The pump is now

at full flow with pump outlet

pressure controlled by relief

valve 14.

2 Vary pump outlet pressure by

adjusting relief valve 14.

Performance Check Procedure

The pump performance check

must be at 14 bar (203 psi)

below the rated pressure

specified in Table 1.

Record the following parameters

on the blank Pump Performance

Check Record (page 11).

Input torque

Output pressure

Output flow

Case flow

Case temperature

Case pressure

Inlet temperature

Inlet pressure

Use the results to compute the

overall efficiency per the formu-

las in Appendix A.

Figure 2 shows an example of

test data obtained from the

pump performance check.

Company: ___________________________________

Technician: ___________________________________

Test: ________________________________________

Pump Serial No. ______________________________

Date: ________________________________________

Pump Assembly: _____________________________

Pump Model: ________________________________

Pump Inlet Fluid Temperature: _________________

Baseline Performance Check with Petroleum-Based Fluid

Fluid: ________________________________________________________________________________________

Pressure: ___________________________________ Speed (rpm): __________________________________

INPUT OUTPUT OUTPUT CASE CASE CASE INLET

TORQUE PRESSURE FLOW FLOW TEMP PRESSURE TEMP EFFICIENCY

| | | | | | |

| | | | | | |

| | | | | | |

Figure 2

Petro Oil Company 19 January 1999

Joe Technical 690825

Performance PVH57C-RF-2S-10-C25V-31

SC00002 120 F

Western AWHydraulic Fluid

1750

1365 lb.in 2294 psig 25 gpm .5 gpm 149 F 7 psig 120 F 88%

4 EATON CORPORATION Fluid Power Test Procedure to Evaluate Fluids in Piston Pumps Technical Data 03-06-0002-EN-0601 August 2001

Figure 3

Disassembly and

Inspection

Disassemble the pump per

Vickers Overhaul Manual

M-2210-S, Figure 3. Identify the

pistons and respective bores in

the cylinder barrel per Figure 4

for re-assembly into the same

location.

NOTE: In millimeters, measure cylinder barrel

bores and piston OD to three decimal places

(four decimal places if measuring in inches), and

dimensions A and B to two decimal places

(three decimal places if measuring in inches).

Record information on a blank Piston/Bore

Record (pages 14 and 15).

Figure 4

5 EATON CORPORATION Fluid Power Test Procedure to Evaluate Fluids in Piston Pumps Technical Data 03-06-0002-EN-0601 August 2001

Figure 6 Figure 5

Disassembly and

Inspection (continued)

Inspect its components as

follows:

1 Valve plate running-face

inspect surface finish visually

and take a photograph.

(Figure 5)

2 Cylinder barrel running face

inspect surface finish visually.

(Figure 5)

3 Swashplate (yoke) running

face inspect surface finish

visually. (Figure 5)

4 Swashplate (yoke) bearing

journals inspect visually.

(Figure 5)

5 Cradle (saddle) bearings

inspect visually. (Figure 5)

6 Bias and control piston/rod

inspect visually. (Figure 6)

7 Hold-down arms and shoe

face inspect visually.

8 Shaft and shaft bearings

inspect visually. (Figure 6)

9 Measure metering lands

diameters and widths on

both control spools (compen-

sator). (Figure 6)

10 Measure shoe thickness (B),

pocket depth (A), piston/

shoe endplay (maximum

allowable end play 0.13mm

[0.005]), piston diameter at

top, middle, and bottom of

piston and cylinder barrel

bores at top, middle, and

bottom. Record results on

the blank Piston/Bore Record

(page 14).

11 Shoe cage inspect visually.

12 Shaft seal and mating shaft

surface inspect visually.

13 Photograph visually worn

parts.

7 EATON CORPORATION Fluid Power Test Procedure to Evaluate Fluids in Piston Pumps Technical Data 03-06-0002-EN-0601 August 2001

Final Fluid Testing

Fluid Pass/Fail Criteria

Measure the following on the

test fluid after completion of

testing. Record the results on

the Test Fluid Record (page 13).

Viscosity cSt @ 40C

Water content wt % (0.03%

max. non-water based fluid)

Cleanliness level ISO Code

18/16/14 or better

Spectrographic analysis for at

least the following elements

(ppm): P, Zn, Ca, K, Ba, B, Si,

Fe, Cu, Pb, Sn

Total Acid Number (TAN)

mg/KOH (Report only for

vegetable and synthetic

environmentally acceptable

hydraulic fluids, and poly-

olester fire resistant hydraulic

fluids.)

The following are the criteria by

which the fluid is judged to have

passed or failed the test:

The overall efficiency of the

pump is equal to or greater

than 85%.

The volumetric efficiency of

the pump is not degraded by

more than 5% at the end of

the 200-hour cyclic test.

The control pressure hystere-

sis is less than or equal to 45

bar (652.5 psi) at the end of

the 200-hour cyclic test.

Figue 7

10 EATON CORPORATION Fluid Power Test Procedure to Evaluate Fluids in Piston Pumps Technical Data 03-06-0002-EN-0601 August 2001

Sequence of Operations

1 Energize 15 while 16 is de-

energized. Pump is now at

cut-off (pressure compensa-

tion mode, high pressure, no

flow).

2 Open variable orifice valve 22

to vary the pump outlet pres-

sure to run a control pressure

hysteresis check per Appendix

B.

3 Once the control pressure

hysteresis check has been

completed, close the variable

orifice valve 22 and resume

test.

Control Pressure Hysteresis

Check Procedure

Control pressure hysteresis is

calculated using a plot of outlet

flow versus control pressure.

To check control pressure

hysteresis, plot outlet flow (on

the y-axis) versus control piston

pressure while varying outlet

pressure from 500 psi (at full

flow) to the compensator setting

(high-pressure, no-flow

condition) and back to 500 psi

(at full flow).

An adapter block needs to be

assembled between the control

and the end cover (valve block)

to pick up control piston

pressure. Use a variable orifice

valve to vary the pumps outlet

pressure (refer to page 3 for

preparatory steps). It may take

1.5 to 2.0 minutes to run a

sweep from full flow to pressure

compensation and back again.

The majority of the sweep time

should be while the pump is

going into and out of the

compensator mode.

After generating a plot of outlet

flow vs. control piston pressure:

Determine the full flow value.

Draw horizontal lines on the

plot at 75%, 50% and 25% of

full flow.

Determine the pressure

values at which these lines

intersect the vertical sections

of the plot. (Note: There will

be two intersection points for

each horizontal line.)

Calculate the difference

between each pair of pressure

values (one p for 75% flow,

one p for 50% flow, and one

p for 25% flow).

Take the average of these

three p values.

This is considered the average

control pressure hysteresis. This

value should not exceed 45 bar

(652.5 psi).

A sample curve is shown in

Figure 8.

Appendix B

Control Pressure

Hysteresis Test

Figure 8

2001 Eaton Corporation

All Rights Reserved

Printed in USA

Form No. 03-06-0002-EN-0601

August 2001

ISO-9001 CERTIFICATED FIRM

DET NORSKE VERITAS INDUSTRY BV, THE NETHERLANDS

ACCREDITED BY

THE DUTCH COUNCIL

FOR CERTIFICATION

Reg. No. 24

Quality System Certified

Products in this catalog are manufactured in an

ISO-9001-certified site.

Eaton Fluid Power

Industrial & Mobile

14615 Lone Oak Road

Eden Prairie, MN 55344

Telephone: 952 937-7254

Fax: 952 974-7130

www.eatonhydraulics.com

Eaton Fluid Power

Industrial & Mobile

46 New Lane, Havant

Hampshire PO9 2NB

England

Telephone: (44) 23 92 486 451

Fax: (44) 23 92 487 110

Das könnte Ihnen auch gefallen

- 420 Mobile Piston Pump Design Code CDokument41 Seiten420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- Workshop ManualDokument837 SeitenWorkshop ManualFernando Sabino100% (1)

- Caseih Staiger PBDokument1.366 SeitenCaseih Staiger PBFernando SabinoNoch keine Bewertungen

- 3410 3411 H179Service TrainingDokument668 Seiten3410 3411 H179Service TrainingWilliam Giovanni Madariaga Malebrán97% (35)

- Finotek SolenoidDokument1 SeiteFinotek SolenoidFernando SabinoNoch keine Bewertungen

- Finotek 1Dokument1 SeiteFinotek 1Fernando SabinoNoch keine Bewertungen

- Finotek Komtasu 2Dokument1 SeiteFinotek Komtasu 2Fernando SabinoNoch keine Bewertungen

- Cat 350-375 TDokument60 SeitenCat 350-375 TFernando Sabino100% (1)

- Kawasaki K3VL Technical Brochure BlueDokument68 SeitenKawasaki K3VL Technical Brochure BlueFernando Sabino100% (1)

- EM140 Final Drive Layout PDFDokument1 SeiteEM140 Final Drive Layout PDFFernando SabinoNoch keine Bewertungen

- Caseih Serie 20Dokument1.267 SeitenCaseih Serie 20Fernando Sabino100% (2)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 7.1. FM Listing Approval of Amipox 2016Dokument8 Seiten7.1. FM Listing Approval of Amipox 2016minov minovitchNoch keine Bewertungen

- Garden Denver PET Reference Parts NumberDokument6 SeitenGarden Denver PET Reference Parts Numberdevilsharma100% (1)

- Mud Pump Spare Parts 6-8-22Dokument1 SeiteMud Pump Spare Parts 6-8-22Eden DavidsonNoch keine Bewertungen

- The Original Dome ValveDokument4 SeitenThe Original Dome ValveTan Nguyen Huu100% (2)

- Aplicaciones Valvulas de ControlDokument45 SeitenAplicaciones Valvulas de ControlLOPEZCRG100% (1)

- Q116 Hydrostatic Test ProcedureDokument18 SeitenQ116 Hydrostatic Test ProcedureParthiban NCNoch keine Bewertungen

- Steam Turbine FFCDokument31 SeitenSteam Turbine FFCTaha KhanNoch keine Bewertungen

- Critical Service Control Valve - DRAGDokument11 SeitenCritical Service Control Valve - DRAGamer_arauf75% (4)

- T Series Take ApartDokument4 SeitenT Series Take ApartJak JoniNoch keine Bewertungen

- Recommended Piping Practices For Steam Heating CoilsDokument1 SeiteRecommended Piping Practices For Steam Heating CoilsJam AvilésNoch keine Bewertungen

- Cargo Pump Curve - MT BourneDokument2 SeitenCargo Pump Curve - MT Bournetimayaa1000100% (1)

- Evaporator AccessoriesDokument21 SeitenEvaporator AccessoriesgrittyptNoch keine Bewertungen

- 6-1. Work EquipmentDokument87 Seiten6-1. Work EquipmentSaidi JalelNoch keine Bewertungen

- Cleancut R-Valve PDFDokument2 SeitenCleancut R-Valve PDFbruce lianNoch keine Bewertungen

- PUMPS Part 2Dokument11 SeitenPUMPS Part 2Kaiser CarloNoch keine Bewertungen

- BAC Evaporative CondensersDokument12 SeitenBAC Evaporative CondensersKONARASKI1982Noch keine Bewertungen

- 05pages From Code-291Dokument1 Seite05pages From Code-291Maged BesharaNoch keine Bewertungen

- 1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeDokument3 Seiten1 Gala Rubber Flexible Connector Flange Double Bellows GFLEX-F2 FlangeNon Etabas GadnatamNoch keine Bewertungen

- Siglas de Las ConexionesDokument16 SeitenSiglas de Las ConexionesHunab379Noch keine Bewertungen

- Arenado: Equipment DescriptionDokument5 SeitenArenado: Equipment DescriptionDiego GuajardoNoch keine Bewertungen

- Fire Pump TestingDokument2 SeitenFire Pump TestingAshraf Adel Nashed ZakiNoch keine Bewertungen

- L4 Screw Pump PDFDokument11 SeitenL4 Screw Pump PDFrizairawan09Noch keine Bewertungen

- CCW Pump First Trial Run Check ListDokument8 SeitenCCW Pump First Trial Run Check ListA.PRABHAKARANNoch keine Bewertungen

- DXR 145 Spare Part ListDokument47 SeitenDXR 145 Spare Part ListColin LeeNoch keine Bewertungen

- Brayton CycleDokument6 SeitenBrayton CycleNavnina Bhatia100% (1)

- Leser Compact Performance CatalogDokument28 SeitenLeser Compact Performance CatalogLudi D. LunarNoch keine Bewertungen

- Kitz DJ E-234-03 PDFDokument16 SeitenKitz DJ E-234-03 PDFYudi KurniawanNoch keine Bewertungen

- Accumulator (Pilot) : Systems OperationDokument3 SeitenAccumulator (Pilot) : Systems Operationallan lariosaNoch keine Bewertungen

- Line Sizing For Systems PDFDokument13 SeitenLine Sizing For Systems PDFCua TranNoch keine Bewertungen

- FWDS 0236 ADokument2 SeitenFWDS 0236 AAlanka PrasadNoch keine Bewertungen