Beruflich Dokumente

Kultur Dokumente

07 132

Hochgeladen von

Fernando SabinoOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

07 132

Hochgeladen von

Fernando SabinoCopyright:

Verfügbare Formate

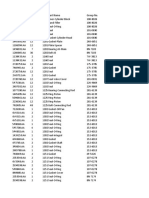

No.

7-132

October, 1997 Char-Lynn

Hydraulic Motor

10 000 Seri es

Gerol er

MotorTwo Speed 001

Repai r Informati on

2

Parts Drawi ng

27

49

36

35

36

35

36

35

18

19

17

15

16 3

7

13

14

11

38

5

37

9

8

2

8

8

2

8

34

34a

1c

1b

1bb

1bbb

1a

1aa

12a

12b 41 Bearingless Motor

50

Retainer inside bore of valve plate bearingless motors only

48

6

11

4

36

47

40

39

29

30

31

32

33

44

42

29

21

22

20

45

46

43

28

28

27

25

26

24

23

Ref.

No. Description

Ref.

No. Description

1a

1aa

1b

1bb

1bbb

1c Shaft S/A (2-1/8 in. 16T Involute Spline)

Shaft S/A (2-1/4 in. Tapered)

Shaft S/A (2-1/4 in. Str. w/o Thread)

Key (Str. Shaft)

Key (Tapered Shaft)

Nut (Tapered Shaft)

Thrust Washer, Rear

Whasher, Thrust

3

4

2 Spacer, Bearing

Whasher, Thrust

Thrust Bearing, Rear

Thrust Bearing, Front

Seal, Shaft

5

6

7

9

Bearing, Radial 8

Spacer, Front Bearing

Washer, Backup

Housing, Bearing (Whl. Mtr. Mtg. Flange)

Housing, Bearing (Std. Mtr. Mtg. Flange)

10

11

12a

12b

Plate, Wear

Flange, Mounting /Wear Plate

18

Plug/O-ring S/A 32

32a O-ring (Ref. No. 32)

Screw, Cap

16

Plate, Valve

17 Geroler

Plug/O-ring S/A Retainer, Front

Drive Plug/O-ring S/A

Ball

Spring

20 Valve

13

14

15

30

Balance Ring/Pin Assembly 22

Spring 21

31

19 Drive, Valve

33

33a

34

34a

Plug/O-ring S/A 42

42a O-ring (Ref. No. 42)

Plug/O-ring S/A 43

43a O-ring (Ref. No. 43)

Spool, Control 44

Spring, Compression 45

Spring, Compression 46

Plug/O-ring S/A 47

47a

O-ring (Ref. No. 33)

O-ring (Ref. No. 34)

41

Seal, Dust

Bolt (replaces and interchanges with studs)

O-ring 37

38

39

Bolt (replaces and interchanges with studs) 40

O-ring (Ref. No. 47)

O-ring 23

Ring, Back-up 24

Ring, Back-up 26

Valve Housing 29

Ring, Back-up 28

O-ring 25

O-ring 27

O-ring 49

Seal

Seal

35

36

Ref.

No. Description

Ring, Retaining 48

Plug, Pipe 50

See

Note 1

Note 1: Do Not

use spacer with

current replacement shafts

(Ref. No. 1). Motors with this

shaft spacer (6171-000) will still have

to be reassembled with spacer unless the

shaft was damaged and must be replaced.

3

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Fi gure 1

Tool s Requi red:

- Torque Wrench, 165 Nm [120 lb-ft] * capacity

- 15/16, 1, and 11/4 inch sockets

- 5/32, 3/16, 5/16, and 5/8 inch hex keys

- 300 mm to 450 mm [12 to 16 inch] breaker bar

- Small blade screwdriver, 150 to 200 mm [6 to 8 inch] long

- Plastic or rubber hammer

Speci al Tool s:

- Small internal bearing puller, sliding hammer type

- Output shaft sleeve

* Inch equivalents given in [brackets].

Di sassembl y

Cleanliness is extremely important when repairing hydraulic motors.

Work in a clean area. Before disconnecting the oil lines thoroughly

clean the port area of the motor. After the oil lines have been

disconnected, plug the motors ports to prevent dirt from entering.

Clean the exterior of the motor with a wire brush. Check the keyway

and chamfered area of the output shaft and remove any nicks, burrs,

or sharp edges that could damage the shaft seals during reassembly.

Drain the oil from the motor before beginning disassembly.

Note: On the standard and wheel motors the output shaft seal and dust

seal can be changed without completely disassembling the motor.

Steps 23 through 41 describe shaft and dust seal replacement. If

complete disassembly is planned, both the shaft seal kit and motor seal

kit will be needed. Refer to parts list 6-131 for seal kit part numbers.

1 Place the motor in a vise with the output shaft down. Clamp on the

motors mounting flange as shown in Figure 1. Protect the mounting

flange with soft vise jaws, wood, or hard rubber. Use just enough

clamping force to hold the motor securely during repairs. Excessive

force will distort the motor housing.

Note: Even though the motor i s not shown i n a vi se i n al l the

drawi ngs, i t i s recommended that the motor be kept cl amped i n a

vi se duri ng repai rs.

2 Remove the four hex head bolts from the motor.

4

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Valve

Housing

Valve

Valve

Plate

Fi gure 2

Spring (4)

Balance Ring/Pins (2)

A, C, E, Back-up Ring

B, C, F, O-ring

Fi gure 4

A

B

A

D

C

E

F

3 Carefully lift the valve housing straight up. The balance ring should

lift away with the valve housing. The valve will remain on the valve

plate.

4 Set the valve housing on a clean work bench. Be sure to protect its

machined surfaces. Remove the 108 mm [4.25 in.] seal and 9,5 mm

[.375 in.] o-ring.

5 Remove the plug and o-ring from the port face. Remove the case

drain plug and o-ring from the bottom of the valve housing (see Figure 3).

6 Remove the balance ring and four balance ring springs. The

balance ring fits into the valve housing tightly. A sliding hammer

bearing puller may be needed to loosen it.

7 Remove the o-rings and back-up rings from the balance ring.

Note: Compressed spri ngs under pl ugs, see step 8.

8 Carefully remove the two control spool plugs and o-rings.

9 Remove the control spool and springs.

10 Remove the two check ball plugs and o-rings. Remove the two

check balls and springs.

Di sassembl y

Valve

Housing

Plug/O-ring

Plug/O-ring

O-ring

Seal

Fi gure 3

Plug

Assembly

Plug with

Recess/

O-ring

Spring

Spool, Control

Plug/O-ring

Spring Spring

Ball, Check

Fi gure 5

5

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Valve

Valve

Plate

Valve

Drive

Fi gure 6

Seals

Valve

Plate

Seals

Fi gure 7

Splined

Drive

Thrust

Washer

Wear

Plate

Thrust

Bearing

Fi gure 8

11 Remove the valve.

12 Remove the valve plate.

13 Remove the valve drive.

14 Remove the Geroler. Be sure to keep the Geroler star and rollers

within the outer ring if they are loose.

15 Remove the 108 mm [4.25 in.] seal and 9,5 mm [.375 in.] o-ring

from each side of the Geroler.

16 Remove the splined drive.

17 Remove the wear plate.

18 Remove the rear thrust bearing and rear thrust washer. These parts

will either be on the wear plate or shaft bearings.

Di sassembl y

O-ring

Plug/O-ring

Plug/O-ring

Seal

Fi gure 9

6

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Drive Spacer

Fi gure 10

Fi gure 11

19 Remove the 108 mm [4.25 in.] seal and 9,5 mm [.375 in.] o-ring

from the bearing housing.

20 Remove the two case drain plugs and o-rings from the bearing

housing.

21 Remove the bearing housing from the vise and turn it over so the

output shaft is on top.

22 The drive spacer may fall out of the output shaft (see Figure 10).

Watch for it! This spacer must be reinstalled when the motor is

reassembled.

Note: Some motors do not use a dri ve spacer.

23 Clamp the bearing housing in a vise so the output shaft is on top

(see Figure 11). Protect the bearing housing with soft vise jaws, wood,

or hard rubber. Use just enough clamping force to hold the bearing

housing securely while the retainer is removed.

24 Remove the eight cap screws that hold the retainer to the bearing

housing.

25 Carefully pry the retainer loose with a small blade screwdriver.

Do not damage the mating surfaces of the retainer or bearing housing.

26 Remove the 89 mm [3.5 in.] o-ring from the retainer.

27 Use a small blade screwdriver to pry the quad ring seal and back-

up washer from the retainer. Be careful not to damage the seal seat.

28 Turn the retainer over and pry out the dust seal with a small blade

screwdriver. Be careful not to damage the seal seat (see Figure 12).

29 Remove the output shaft.

30 Remove the thrust bearing and two thrust washers from the output

shaft.

31 Remove the bearing spacer.

Note: The shaft bearings are pressed into the bearing housing and

should not be removed. If the housing or bearings are damaged the

complete assembly must be replaced.

Di sassembl y

Cap

Screw

Retainer O-ring Quad Ring Seal

Dust

Seal

Back-up

Washer

Fi gure 12

Thrust Bearing

Thickest Washer

Thrust

Washers

Bearing Spacer

Fi gure 13

7

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Thrust Bearing

Thickest Washer

Thrust

Washers

Fi gure 14

Dust Seal

O-ring

Back-up Washer

Retainer

Seal Replacement

Fi gure 15

Quad

Ring

Seal

Torquing Sequence

Fi gure 16

5

3

1

8

6

4

2

7

Check all mating surfaces and replace any parts with scratches or

burrs that could cause leakage. Wash all metal parts in clean solvent

and blow them dry with compressed air. Do not wipe parts dry with

paper towels or cloth as lint in a hydraulic system will cause damage.

Check the keyway and chamfered area of the output shaft and remove

any nicks, burrs, or sharp edges that could damage the shaft seals

during reassembly.

Note: Always use new seals when reassembling hydraulic motors.

Refer to parts list 6-131 for seal kit part numbers, replacement parts,

and ordering information.

Important: Duri ng reassembl y l ubri cate the new seal s wi th a

petrol eum j el l y such as Vasel i ne

. Al so l ubri cate al l machi ned

surfaces and beari ngs wi th cl ean hydraul i c fl ui d.

32 Re-clamp the bearing housing in a vise with the mounting flange

up (see Figure 11). Remember, use just enough clamping force to

hold the bearing housing securely while the output shaft and retainer

are reinstalled.

33 Install the bearing spacer.

34 Lubricate the output shaft with clean hydraulic fluid and insert it

into the bearing housing. Rotate it as it is inserted.

35 Install the thrust bearing and thrust washers. Install the thick

thrust washer first, then the thrust bearing, then the thin thrust washer.

36 Press the dust seal into the retainer. The metal side of the dust

seal must face the retainer (see Figure 15). If a press is not available

carefully tap the dust seal into the retainer with a plastic or rubber

hammer.

37 Install the quad ring seal and back-up washer as shown in

Figure15.

38 Apply petroleum jelly to the 89 mm [3.50 in.] 0-ring and install it in

the groove in the retainer.

39 Lubricate the inner edge of the dust seal and quad ring seal with

petroleum jelly.

40 Slide the retainer over the output shaft onto the bearing housing.

Important: Do not damage the seal s. Use an output shaft sl eeve to

protect the seal s i f avai l abl e.

41 Install the eight cap screws and tighten them to 34 Nm [300 lb-in].

Follow the screw torque sequence in Figure 16.

Reassembl y

8

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Fi gure 18

Case

Drain

Case

Drain

Wear

Plate

Thrust

Washer

Thrust

Bearing

Fi gure 19

Seals

Geroler

Seals

Case

Drain

Splined

Drive

Case

Drain

42 Reposition the bearing housing in the vise so the output shaft is in

the down position.

43 Install the two case drain plugs in the bearing housing drain holes.

Use new o-rings and tighten the plugs to 81-122 Nm [60-90 lb-ft].

44 Pour a small amount of clean hydraulic fluid into the bearing

housing and output shaft.

45 Reinstall the drive spacer* if it was dislodged during disassembly.

Use a long thin rod to guide the drive spacer into the output shaft.

* Note: Do not use spacer wi th current motors or repl acement shafts.

Motors wi th thi s shaft spacer wi l l sti l l have to be reassembl ed wi th

thi s spacer unl ess the shaft was damaged and must be repl aced.

46 Apply petroleum jelly to the 108 mm [4.25 in.] seal and 9,5 mm

[.375 in.] o-ring. Install each in the appropriate groove in the bearing

housing (see Figure 17).

47 Put the rear thrust washer and rear thrust bearing into the recess in

the wear plate. The rear thrust washer goes in first. Petroleum jelly

may be used to hold these parts in place while the wear plate is being

installed.

48 Install the wear plate so the rear thrust washer is against the shaft

bearings. Be sure to align the case drain holes.

Reassembl y

Fi gure 17

O-ring

Plug/O-ring

Plug/O-ring

Seal

Drive Spacer

*

9

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

49 Install the splined drive.

Note: On smal l er di spl acement motors the spl i ned ends of the dri ve

are di fferent l engths. If thi s i s the case the l onger spi nes go i nto the

beari ng housi ng.

50 Determine which side of the Geroler goes against the wear plate.

Install the 108 mm [4.25 in.] seal and 9,5 mm [.375 in.] o-ring in the

appropriate grooves in that side of the Geroler. Apply petroleum jelly

to the seal and o-ring before installation.

51 Install the Geroler on the wear plate. Be sure to align the case

drain holes.

52 Apply petroleum jelly to the 108 mm [4.25 in.] seal and 9,5 mm

[.375 in.] o-ring. Install each in the appropriate groove in the top side

of the Geroler.

53 Install the valve drive.

Motor Ti mi ng Timing a hydraulic motor involves three steps. The

direction the output shaft rotates is determined by timing.

Ti mi ng Step #1 Locate the largest open pocket in the Geroler and mark

its position.

54 Install the valve plate on the Geroler. Be sure to align the case

drain holes.

Ti mi ng Step #2 Locate the open slot in the valve plate that is in line

with the largest open pocket in the Geroler.

Ti mi ng Step #3 Align any one of the side openings in the valve with the

open slot in the valve plate that is over the largest open pocket in the

Geroler. Engage the valve with the valve drive by rotating it clockwise

until the spine teeth mesh (1/2 spIine tooth). This will provide standard

rotation when pressurized (see Figure 21).

To reverse rotation engage the valve with the valve drive by rotating it

counter clockwise until the spline teeth mesh (1/2 spine tooth).

55 Install the control spool and springs.

56 Install the control spool plugs with new o-rings. The springs will

need to be compressed to install the second plug.

57 Tighten the control spool plugs to 81 -122 Nm [60-90 lb-ft].

58 Install the plug in the port face. Use a new o-ring and tighten the

plug to 27-46 Nm [20-34 lb-ft] (see Figure 22).

Reassembl y

Fi gure 20

Rotate Valve

Clockwise

1/2 Tooth to

Engage Spline

Case

Drain

Alignment

Reference

Only

Valve

Plate

Valve

Drive

Largest

Open

Reference

Mark

Any One of

Eight Ports

Open to Outside

of Valve

Case

Drain

Geroler

Fi gure 22

Plug with

Recess/

O-ring

Plug/O-ring

Spool, Control

Plug/O-ring Plug/O-ring Spring Spring

Fi gure 21

Standard Timing

10

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Fi gure 23

Spring (4)

Balance Ring/Pins (2)

A, C, E, Back-up Ring

B, C, F, O-ring

A

B

A

D

C

E

F

O-ring

Seal

Fi gure 24

Small Gap

Plate,

Valve

Valve Housing

Fi gure 25

Bolt Torquing Sequence

Fi gure 26

4 1

2 3

59 Install the case drain plug in the bottom of the valve housing. Use

a new o-ring and tighten the plug to 81-122 Nm [60-90 lb-ft] (see

Figure 22).

60 Install the o-rings and back-up rings on the balance ring. Install

the o-rings first then the back-up rings.

61 The largest o-ring has two back-up rings, one on each side. The

two smaller o-rings each have one back-up ring. The two smaller

back-up rings are installed closest to the small end of the balance ring.

62 Put the four balance ring springs into their holes in the valve

housing.

63 To aid the installation of the balance ring lubricate its o-rings and

back-up rings with petroleum jelly. Align the balance ring index pins

with the index holes in the valve housing. Push the balance ring into

the valve housing until it just touches the springs.

Important: Do not push the balance ring all the way down into the

valve housing.

64 Apply petroleum jelly to the 108mm [4.25 in.] seal and 9,5 mm

[.375 in.] o-ring. Install each in the appropriate groove in the valve

housing.

65 Carefully position the valve housing on the valve plate. Be sure to

align the case drain holes. There should be a small gap between the

valve housing and valve plate. This gap will be closed when the hex

head bolts are tightened.

66 Install the four hex head bolts and tighten them to 129-149 Nm

[95-110 lb-ft]. Follow the torque sequence in Figure 26.

67 Install the two check balls and springs.

Reassembl y

11

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Plug

Assembly

Spring

Ball, Check

Ball, Check

Ball, Plug

Fi gure 27

Bearing Housing

Retainer

Seal

Back-up

Washer

Quad

Ring

Seal

Cap

Screw

Dust Seal

Fi gure 28

Mounting Flange/Wear Plate

Seal

Seal

Pipe Plug

Fi gure 29

Important: The motor shaft must be vertical when the check balls are

installed. This will insure that they seat properly (see Figure 27).

68 Install the two check ball plugs with new o-rings and tighten them

to 6,8-12 Nm [ 5-10 lb-ft].

Wheel Motor

A different bearing housing is used on wheel motors (see Figure 28).

Other than this the parts are the same and the same disassembly/

reassembly procedures apply.

Beari ngl ess Motor

Bearingless motors are the same as standard motors without the shaft/

bearing assembly, and thrust bearings. The mounting flange replaces

the bearing housing and wear plate (see Figure 29).

Reassembl y

Copyright Eaton Corporation, 1989, 1996, and 1997

All Rights Reserved

Printed in USA Form No. 7-132

Eaton Corporation

Hydraul i cs Di vi si on

15151 Hwy. 5

Eden Prairie, MN 55344

Telephone 612/937-9800

Fax 612/937-7130

Eaton Ltd.

Hydraul i cs Di vi si on

Glenrothes, Fife

Scotland, KY7 4NW

Telephone 01-592-771-771

Fax 01-592-773-184

Eaton GmbH

Hydraul i cs Products

Am Schimmersfeld 7

40880 Ratingen, Germany

Telephone 02102-406-830

Fax 02102-406-800

ISO-9001 CERTIFICATED FIRM

DET NORSKE VERITAS INDUSTRY BV, THE NETHERLANDS

ACCREDITED BY

THE DUTCH COUNCIL

FOR CERTIFICATION

Reg. No. 24

Qual i ty System Certi fi ed

Products i n thi s catal og are manufactured

i n an ISO-9001-certi fi ed si te.

Di sc Val ve Hydraul i c Motor

10 000 Seri es

Gerol er MotorsTwo Speed

Each Order Must Incl ude the Fol l owi ng:

How to Order Repl acement Parts

1. Product Number

2. Date Code

3. Part Name

4. Part Number

5. Quantity of Parts

For Additional Literature Contact Eaton Corp. Hydraulics

Division 15151 Highway 5 Eden Prairie, MN 55344.

Specifications and performance Data, Catalog No. 11-878

Replacement Part Numbers and Kit Information:

10 000 Series Motors Two Speed

Parts Information No. 6-131.

Char-Lynn

Product number

Eaton Corp. Hydraulics Div.

Eden Prairie, MN 55344

Product Number

119 0000 000

120 0000 000

121 0000 000

Product Line

Identification

Number

Product

Identification

Number

Engineering

Change

Code

Week of

Year 01

Thru 52

Last

Number

of Year

Date Code

00 0

Displ. cm

3

/r [in

3

/r] Product Number

Shaft Mounting

480

[29.3]

665

[40.6]

940

[57.4]

345

[21.0] Ports

2-1/4 Inch

Tapered

120-2013 -2014 -2015 -2016 1-5/16 O-ring

Wheel

Motor

119-2013 -2014 -2015 -2016

2-1/4 inch Straight

Standard

119-2001 -2002 -2003 -2004 1-1/4 Split Flange

1-5/16 O-ring

119-2021 -2022 -2023 -2024

119-2009 -2010 -2011 -2012 1-1/4 Split Flange

1-5/16 O-ring

2-1/8 Inch

16 T Splined

119-2017 -2018 -2019 -2020 1-5/16 O-ring

2-1/4 Inch

Tapered

119-2005 -2006 -2007 -2008 1-1/4 Split Flange

120-2005 -2006 -2007 -2008 1-1/4 Split Flange 2-1/4 inch Straight

121-2005 -2006 -2007 -2008 1-5/16 O-ring

Bearingless

121-2001 -2002 -2003 -2004 1-1/4 Split Flange

120-2009 -2010 -2011 -2012 1-1/4 Split Flange

2-1/8 Inch

16 T Splined

120-2001 -2002 -2003 -2004 1-1/4 Split Flange

Das könnte Ihnen auch gefallen

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- 3410 3411 H179Service TrainingDokument668 Seiten3410 3411 H179Service TrainingWilliam Giovanni Madariaga Malebrán97% (35)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- ZE205E/ZE230E Hydraulic Excavator Maintenance Manual: First Edition of January 2013Dokument73 SeitenZE205E/ZE230E Hydraulic Excavator Maintenance Manual: First Edition of January 2013nay hlaing Soe100% (4)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- 953D PDFDokument173 Seiten953D PDFstodzathegreat100% (2)

- Volvo BL71 A10vo74dflr31r-R902436775Dokument33 SeitenVolvo BL71 A10vo74dflr31r-R902436775Mark Dickason100% (1)

- 2ZZGE Engine PDFDokument46 Seiten2ZZGE Engine PDFDavide Faelli100% (1)

- Folding Stairway: Hitachi EX 1900-6 Excavator (4")Dokument39 SeitenFolding Stairway: Hitachi EX 1900-6 Excavator (4")pablo moraledaNoch keine Bewertungen

- 10 FIAT KOBELCO Ex255t Service Manual PDFDokument971 Seiten10 FIAT KOBELCO Ex255t Service Manual PDFnajafali100% (8)

- CH-47 Çekli̇stDokument120 SeitenCH-47 Çekli̇stYaren BekenNoch keine Bewertungen

- Yuchai YC4DDokument59 SeitenYuchai YC4DFerran Alfonso100% (13)

- CelerioDokument198 SeitenCelerioMecanica SeguraNoch keine Bewertungen

- A-761E Manual PDFDokument107 SeitenA-761E Manual PDFsergNoch keine Bewertungen

- DG L23-30H - Mk2 Operation ManualDokument928 SeitenDG L23-30H - Mk2 Operation Manualdionpanag100% (21)

- Finotek CatDokument1 SeiteFinotek CatFernando SabinoNoch keine Bewertungen

- New Holland D350 EN PDFDokument348 SeitenNew Holland D350 EN PDFChakrouneNoch keine Bewertungen

- Caseih Staiger PBDokument1.366 SeitenCaseih Staiger PBFernando SabinoNoch keine Bewertungen

- SD300E ZF TransmissionDokument29 SeitenSD300E ZF TransmissionAimHigh100% (1)

- S3000 H188-H189Dokument612 SeitenS3000 H188-H189Ingetest Diesel88% (17)

- 420 Mobile Piston Pump Design Code CDokument41 Seiten420 Mobile Piston Pump Design Code CFernando Sabino100% (1)

- Liebherr Technical Data DpvoDokument86 SeitenLiebherr Technical Data DpvoІгор Веселов100% (1)

- Series 40 M46 Pump Parts ManualDokument120 SeitenSeries 40 M46 Pump Parts ManualUmar Ikram100% (1)

- V90N DPDokument18 SeitenV90N DPFernando SabinoNoch keine Bewertungen

- New Holland D350 EN PDFDokument348 SeitenNew Holland D350 EN PDFChakrouneNoch keine Bewertungen

- Travel Motor: Main MenuDokument24 SeitenTravel Motor: Main MenuSavio Rodrigues100% (1)

- New Holland D350 EN PDFDokument348 SeitenNew Holland D350 EN PDFChakrouneNoch keine Bewertungen

- Workshop ManualDokument837 SeitenWorkshop ManualFernando Sabino100% (1)

- Finotek CatDokument1 SeiteFinotek CatFernando SabinoNoch keine Bewertungen

- Finotek KomatsuDokument1 SeiteFinotek KomatsuFernando SabinoNoch keine Bewertungen

- Finotek 3Dokument1 SeiteFinotek 3Fernando SabinoNoch keine Bewertungen

- ZE205E零件图册2013年1月版5 23 PDFDokument333 SeitenZE205E零件图册2013年1月版5 23 PDFnay hlaing Soe100% (3)

- Hydraulics Part 3Dokument24 SeitenHydraulics Part 3MACHINERY101GEAR100% (4)

- Finotek Komatsu 3Dokument1 SeiteFinotek Komatsu 3Fernando SabinoNoch keine Bewertungen

- Finotek Komatsu 1Dokument1 SeiteFinotek Komatsu 1Fernando SabinoNoch keine Bewertungen

- Finotek Doosan CatDokument1 SeiteFinotek Doosan CatFernando SabinoNoch keine Bewertungen

- Finotek KatoDokument1 SeiteFinotek KatoFernando SabinoNoch keine Bewertungen

- Finotek SolenoidDokument1 SeiteFinotek SolenoidFernando SabinoNoch keine Bewertungen

- Finotek 1Dokument1 SeiteFinotek 1Fernando SabinoNoch keine Bewertungen

- Cs533e Part ListDokument105 SeitenCs533e Part ListMohamed Bakheet100% (2)

- NCS Auto Mechanic RevisedDokument56 SeitenNCS Auto Mechanic RevisedmarranNoch keine Bewertungen

- Manual - Partes - CabezoteDokument4 SeitenManual - Partes - CabezoteTesla EcNoch keine Bewertungen

- Replace cavitation rotors and alternator partsDokument365 SeitenReplace cavitation rotors and alternator partsYulianto Gedibal PuolNoch keine Bewertungen

- Mab 206Dokument82 SeitenMab 206david100% (1)

- Yamaha - 125ccDokument5 SeitenYamaha - 125ccBaiss AvyalimanaNoch keine Bewertungen

- Harmonic DriveDokument3 SeitenHarmonic DriveDaniel AndoneguiNoch keine Bewertungen

- OJT2 - Steam Turbine Part & Components (Part 1)Dokument17 SeitenOJT2 - Steam Turbine Part & Components (Part 1)Azizul IshakNoch keine Bewertungen

- Replacement Parts for 876C Series 4-Inch Gravity CouplersDokument15 SeitenReplacement Parts for 876C Series 4-Inch Gravity CouplersDodik Novie PurwantoNoch keine Bewertungen

- kUBOTAv2003tb PDFDokument112 SeitenkUBOTAv2003tb PDFBobCavNoch keine Bewertungen

- ENGINE C15 (Torque de Bielas)Dokument4 SeitenENGINE C15 (Torque de Bielas)Maquinaria Pesada ServisNoch keine Bewertungen

- Part List Repair Engine 3512 Mha00109 PT Dowel AnadrillDokument8 SeitenPart List Repair Engine 3512 Mha00109 PT Dowel AnadrillIndra SetiawanNoch keine Bewertungen

- The Dry Double Clutch LukDokument40 SeitenThe Dry Double Clutch Luknicolae_popescu_18Noch keine Bewertungen

- Spare Parts List: Hand-Held Gas Saw DS KC80-12"Dokument20 SeitenSpare Parts List: Hand-Held Gas Saw DS KC80-12"mayoo1986Noch keine Bewertungen

- Cruze TimingDokument33 SeitenCruze TimingJose Luis LopezNoch keine Bewertungen

- Maryland Metrics Thread Data ChartsDokument9 SeitenMaryland Metrics Thread Data ChartsCarlos LopesNoch keine Bewertungen

- John Deere 4435 Parts CatalogDokument20 SeitenJohn Deere 4435 Parts Catalogmathew100% (50)

- 32-11-12 AssemblyDokument3 Seiten32-11-12 AssemblyJosua SilaenNoch keine Bewertungen

- Machine Design I Practical InstructionsDokument11 SeitenMachine Design I Practical InstructionsAlbatross BeastboyNoch keine Bewertungen

- Cobra: Spare Parts ListDokument32 SeitenCobra: Spare Parts ListGerwazy KufloweMocne MontanaNoch keine Bewertungen

- Ariel Build Book F-13989 PDFDokument133 SeitenAriel Build Book F-13989 PDFhugoheloNoch keine Bewertungen

- 4d94e17 Be2 PDFDokument160 Seiten4d94e17 Be2 PDFdend juandiNoch keine Bewertungen

- ABS Air Bag Guide - Comprehensive Car GlossaryDokument27 SeitenABS Air Bag Guide - Comprehensive Car GlossarySharizal SanikNoch keine Bewertungen

- Engine Cooling SystemDokument22 SeitenEngine Cooling SystemDidier ÁlvarezNoch keine Bewertungen