Beruflich Dokumente

Kultur Dokumente

Panel Wall - Retaining Wall - Confinement Wall - Geogrid Reinforced Soil Wall

Hochgeladen von

jeanfatOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Panel Wall - Retaining Wall - Confinement Wall - Geogrid Reinforced Soil Wall

Hochgeladen von

jeanfatCopyright:

Verfügbare Formate

16/7/2014 Panel wall | Retaining wall | Confinement wall | Geogrid reinforced soil wall

http://www.tenax.net/geosynthetics/products/tenax-equiter-panel-wall-system-for-earth-walls.htm 1/4

International web site

change

International web site Geosynthetics Soil reinforcement PANEL WALL FOR CONFINEMENT WALL WITH GEOGRIDS REINFORCED SOIL

sitemap contact us

site search

Soil reinforcement TENAX Geosynthetics products

Panel wall for confinement wall with geogrids reinforced soil

TENAX-EQUITER

Panel Wall System

The Panel Wall System is an innovative method for the construction of confinement walls with a

reinforced soil structure through the application of geogrids.

The Panel Wall System is unique and can be considered as a state of the art system, developed from

the joint cooperation between two of the most experienced and qualified companies in the market:

TENAX and EQUITER.

The cooperation between the two companies has allowed the development of a unique patented system

by EQUITER that delivers the maximum possible benefits and advantages when combining the use of

TENAX extruded geogrids reinforcement.

The Panel Wall system offers the best panel, the best geogrid and the best connection system, fully

supported by a comprehensive professional design approach.

The system components consist of:

EQUITER PRECAST REINFORCED CONCRETE PANELS

These are prefabricated concrete panels reinforced with welded wire mesh and having a constant

thickness of 140 mm. They are essentially classified in several types, but the standard panel size of 2.0

x 1.6 m allows making a broad surface extension (3.2m

2

/ panel) which is a guarantee of optimal

performance during the application and mounting of the system while preserving an excellent flexibility

in adapting to different geometric shapes in the project.

TENAX GEOGRID SOIL REINFORCEMENT

Placed behind the wall surface, these are integrated mono-oriented geogrids that are manufactured in a

continuous process with cross directional bars homogeneously connected to the high tensile longitudinal

strands to form a monolithic structure. The geogrids perforated continuous sheet structure performs

two critical functions. They allow for the secure anchorage of panels at the face of the structure as well as

ensuring that the soil behind the panelled wall is sufficiently reinforced to reduce the impact of any

horizontal forces onto the face.

Unlike other anchoring systems consisting of discrete strips or bars, Tenax geogrids provide a 100%

reinforcement coverage behind the concrete panels that are applied in such a way as to create a

longitunal UNIFORM reinforcement mechanism across the back of the vertical panels resulting in cost

effective and safe designs.

The benefits

The Panel Wall System offers many advantages to clients, specifiers and contractors when compared

with traditional methods such as gravity or reinforced concrete walls in retaining wall applications:

Cost savings when compared with concrete-reinforced retaining solutions or stone-clad walls;

The external wall face can be constructed with a variety of architectural designs through the

application of different finishing details and the composition of coloured construction elements as a

mosaic;

No practical height limitations;

The entire system is extremely durable, with possibility to use water-repellent wall coating,

antifreezing, and fire-resistant on demand;

Better resistance to dynamic effects arising from seismic activity;

100% reinforcement coverage is provided behind the panels thereby providing the crucial uniform

connection system required to maintain anchorage at the face.

No need for maintenance.

Better connection detail between panels: the geogrids provide an additional connection across panels

further strengthening the system.

The construction of the Panel Wall System is fast and easy due to the simplification of the anchoring

system allowing for a rapid and simple execution.

PANEL WALL - Applications

Construction of retaining walls

Slope crest enlargement

Construction of road and railway

embankments

PANEL WALL - Installations

Installation guidelines

Southern Ring Road near Verona,

new rest areas - Retaining walls with

heights varying from 1.4 to 4.0 m.

Montorsina (VI)

Intersection S.P. n. 31/43 Valdichiampo

with S.P. n. 33

San Don di Piave (VE)

Slip road linking Toll Gate Noventa di

16/7/2014 Panel wall | Retaining wall | Confinement wall | Geogrid reinforced soil wall

http://www.tenax.net/geosynthetics/products/tenax-equiter-panel-wall-system-for-earth-walls.htm 2/4

Piave to state highway S.S.14

S.S.9 Emilia

Cycling lane connection with bridge

over river Po

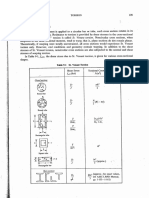

TENSILE STRENGTH OF TENAX TT GEOGRIDS (Certificate ITC DVT-0001 of 14.03.2011)

Characteristics u.m. TT 045 TT 060 TT 090 TT 120 TT 160

Junction strength kN/m 36 50 80 110 130

Long-term strength

(LTDS) at 120 years

kN/m 18.5 24.6 36.9 49.2 65.6

Strength at

2% elongation

kN/m 11.0 17.0 26.0 36.0 45.0

WALL COMPONENTS

The Panel Wall System consists of prefabricated concrete wall facing elements, geogrid reinforcement

layers made of high density polyethylene and a PVC-coated metal connection bar.

The reinforcing element

TENAX TT mono-oriented geogrids

TENAX geogrids are two-dimensional structures made of high-density polyethylene (HDPE) manufactured

by extrusion and mono-directional drawing of the material. This technology produces reinforcing elements

with excellent technical properties which make their application for innovative solutions possible. TENAX

geogrids are chemically inert with a high tensile strength and modulus and are specifically produced for

the reinforcement of soils. The particles of soil or aggregate partially enter the geogrid openings creating

a complete intelocking effect, limiting relative movements and increasing the overall shear strength of the

soil/grid composite. The application of normal stress on the particles, produces soil compaction and an

interlocking effect between the two faces of the geogrid layers ensuring a highly effective level of

interlocking.

The composite soil-geogrid structure behaves like a single reinforced monolithic block where the insertion

of the geogrid provides the element an increased tensile strength in a material (backfill soil) that without

reinforcement would resist only compression. As a consequence the soil-geogrid structure combines the

high compression strength of the granular fill soil with the high tensile strength of the geogrids thus

creating a material with a higher rigidity and stability than the aggregate alone. The geogrids stress

absorbing capability, through re-distribution, further improves the resistance to static and dynamic loads in

the layer. TENAX geogrids are therefore an innovative and cost effective solution from both a technical and

economic viewpoint in all applications that require improved properties of granular, cohesive, loose or

conglomerate materials.

TENAX geogrids are manufactured and tested according to the procedures contained in the TENAX Quality

System put into effect and certified in conformity with the ISO 9001:2000 standard. Close control over

each stage of the production, storage, delivery and support process guarantees adherence and conformity

of the provided standards.

Construction Examples

Curves

Bridge abutment

16/7/2014 Panel wall | Retaining wall | Confinement wall | Geogrid reinforced soil wall

http://www.tenax.net/geosynthetics/products/tenax-equiter-panel-wall-system-for-earth-walls.htm 3/4

Precast concrete panel

The precast reinforced concrete panels - are pre-fabricated

concrete panels (minimum class Rck 350) reinforced with a

welded wire mesh (diameter of 6-10 mm) and having a

constant thickness of 140 mm. There are essentially three

panel types:

1. the base panel measures maximum 2.0 x 0.8 m;

2. the standard panel that has a size of 2.0 x 1.6 m and the

3. top panel with variable dimensions to adapt to the profile

of the embankment project up to a maximum 2 x 2.4 m.

Dinamic interlocking

The element of transverse wires tested for pull-out resistance of the reinforcement geogrid has been

evaluated experimentally, and it was observed an increase in the range of five to six times compared to a

reinforcement test specimen of exclusively linear development with the same contact surface.

Moreover, the increase in pull-out resistance has been raised by the capacity of the grid elements to bring

about a dynamic interlock phenomenon inside the backfill soil, while the openings in the geogrid

structure cause soil grains to get stuck inside as, during compaction operations, these particles are forced

into the openings of the mesh dilating the polymer substance of the reinforcement mesh. When, at the

end of the compacting action, the mesh openings tend to turn back to their original state, the internal

stress created envelops the granular ground particles and reduces the horizontal thrust of the backfill on

the face wall.

Backfill material

Typically constructed using compacted granular backfill, selected site-won or imported material. There is

also the opportunity to use carefully selected recycled or stabilized backfills within the reinforced soil mass

thereby dealing with environmental pressures concerning the use of natural resources.

Dolo (VE) Highway Road Link of Mestre

Bridge abutment

Panel facing

www.equiter.com

16/7/2014 Panel wall | Retaining wall | Confinement wall | Geogrid reinforced soil wall

http://www.tenax.net/geosynthetics/products/tenax-equiter-panel-wall-system-for-earth-walls.htm 4/4

TENAX 1995-2014 All rights reserved

Das könnte Ihnen auch gefallen

- Stability of Geosynthetic Reinforced Soil Structures PDFDokument20 SeitenStability of Geosynthetic Reinforced Soil Structures PDFMed El Hadi Abidi100% (2)

- Soil C and Phi ValuesDokument3 SeitenSoil C and Phi ValuesthamiradNoch keine Bewertungen

- Measuring Propeller Drop With The Help of Poker GaugeDokument2 SeitenMeasuring Propeller Drop With The Help of Poker Gaugeas100% (1)

- Basal Reinforced Embankments over Soft FoundationsDokument66 SeitenBasal Reinforced Embankments over Soft FoundationskahgeapNoch keine Bewertungen

- Moment Connections to Column WebsDokument3 SeitenMoment Connections to Column WebsAmro Ahmad AliNoch keine Bewertungen

- Fuel Tank Ring Beam Design CalculationDokument11 SeitenFuel Tank Ring Beam Design CalculationDawson Preethi EA94% (16)

- Structural Design of Swimming PoolsDokument12 SeitenStructural Design of Swimming Poolsale hopeju200975% (20)

- ANSYS earthquake analysis tutorial: Response spectrum vs transientDokument14 SeitenANSYS earthquake analysis tutorial: Response spectrum vs transientIgor GjorgjievNoch keine Bewertungen

- Technical Paper On Plate Load Test PDFDokument138 SeitenTechnical Paper On Plate Load Test PDFPushpendra ChouhanNoch keine Bewertungen

- Seismic Load AnalysisDokument99 SeitenSeismic Load AnalysisMANDARAW100% (1)

- Seismic Load AnalysisDokument99 SeitenSeismic Load AnalysisMANDARAW100% (1)

- Ijggi-July 2014Dokument46 SeitenIjggi-July 2014Rajashekar.PNoch keine Bewertungen

- CE649 GeosyntheticsDokument46 SeitenCE649 Geosyntheticsjsd sspwdNoch keine Bewertungen

- Tutorial 14 Cofferdam SeepageDokument12 SeitenTutorial 14 Cofferdam SeepageCarlos Eduardo TorresNoch keine Bewertungen

- Determination of Radial Coefficient of Consolidation Using Log I T I MethodDokument10 SeitenDetermination of Radial Coefficient of Consolidation Using Log I T I MethodKlaus HenriqueNoch keine Bewertungen

- Bearing Capacity of Geosynthetic Reinforced Sand Bed On Problematic SoilDokument9 SeitenBearing Capacity of Geosynthetic Reinforced Sand Bed On Problematic SoilJEETENDRA PRAKASHNoch keine Bewertungen

- Igs July 2021Dokument64 SeitenIgs July 2021Rajashekar.PNoch keine Bewertungen

- Geogrid Reinforced Soil Slope With Tenax RivelDokument16 SeitenGeogrid Reinforced Soil Slope With Tenax RivelKhumairaNisaNoch keine Bewertungen

- Reinforced Earth Retaining Wall Design and Case StudiesDokument28 SeitenReinforced Earth Retaining Wall Design and Case StudiesKumar RavishankerNoch keine Bewertungen

- PreviewpdfDokument90 SeitenPreviewpdfSheeraz AhmedNoch keine Bewertungen

- CRRI Presentation On GeosyntheticsDokument51 SeitenCRRI Presentation On GeosyntheticsGautam RaiNoch keine Bewertungen

- The Design of Reinforced Earth Walls DGS 28-11Dokument32 SeitenThe Design of Reinforced Earth Walls DGS 28-11paulombatista100% (1)

- Soil Investigation Report (Package-3)Dokument59 SeitenSoil Investigation Report (Package-3)Vashav Pandey0% (1)

- Mse WallDokument10 SeitenMse Wallপ্রিয়দীপ প্রিয়মNoch keine Bewertungen

- Basic Soil MechanicsDokument104 SeitenBasic Soil MechanicsJorisGirdzijauskasNoch keine Bewertungen

- Rehabilitation of National Highway Damaged by Rain Using Geosynthetics in Hilly Terrain - A Case StudyDokument10 SeitenRehabilitation of National Highway Damaged by Rain Using Geosynthetics in Hilly Terrain - A Case StudyAdarsh VaishyaNoch keine Bewertungen

- Yokogawa 2015 Centum VP For Batch ControlDokument9 SeitenYokogawa 2015 Centum VP For Batch ControlArzymanNoch keine Bewertungen

- Info Iec62271-1Dokument28 SeitenInfo Iec62271-1RichardLemusNoch keine Bewertungen

- Design of Crane Steel BeamsDokument134 SeitenDesign of Crane Steel Beamsshak54383% (6)

- RE wall review checklistDokument21 SeitenRE wall review checklistGDRPL NHAINoch keine Bewertungen

- PW232 KMV Nakrekal RS Wall Design Report - MacLoopDokument98 SeitenPW232 KMV Nakrekal RS Wall Design Report - MacLoopAnde Bhanu100% (1)

- Geosynthetic Reinforced WallsDokument18 SeitenGeosynthetic Reinforced WallsYohannes GirmaNoch keine Bewertungen

- 04 Chapter 5 - Shallow Foundations-Allowable Bearing Capacity and Settlement-MDokument68 Seiten04 Chapter 5 - Shallow Foundations-Allowable Bearing Capacity and Settlement-MWaqas Sadiq100% (2)

- Class XII Computer Project - Hotel ManagementDokument29 SeitenClass XII Computer Project - Hotel ManagementLakshmi Puthiyedath71% (7)

- State of The Practice of Rigid Inclusions - 3-17-2021Dokument11 SeitenState of The Practice of Rigid Inclusions - 3-17-2021Tanju Tahir Ökten100% (1)

- Calcs HETPDokument50 SeitenCalcs HETPChemEngGirl89Noch keine Bewertungen

- 14 - Installation Effects in Geotechnical Engineering PDFDokument279 Seiten14 - Installation Effects in Geotechnical Engineering PDFilkayNoch keine Bewertungen

- Complete WorkDokument51 SeitenComplete WorkOdell Arome Darian100% (3)

- Structural Dynamics of Linear Elastic Multiple-Degrees-Of-Freedom ...Dokument125 SeitenStructural Dynamics of Linear Elastic Multiple-Degrees-Of-Freedom ...Guzalg100% (1)

- ACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev01 - 04-Nov-2014Dokument13 SeitenACI 350.3-06 Appendix B Seismic Loads For Liquid-Containing Rectangular RC Tank - Rev01 - 04-Nov-2014jeanfatNoch keine Bewertungen

- Pile Cap DesignDokument12 SeitenPile Cap DesignBhaskar Jyoti Das100% (2)

- Design Procedures For Gabion and Mattress Structures PDFDokument4 SeitenDesign Procedures For Gabion and Mattress Structures PDFrajaanwarNoch keine Bewertungen

- Interim Report Soil NailDokument11 SeitenInterim Report Soil Nailalex_rav17Noch keine Bewertungen

- Prefabricated Vertical DrainsDokument26 SeitenPrefabricated Vertical DrainsMayank Prakash100% (1)

- Design of Geosynthetic Reinforced Soil EmbankmentDokument9 SeitenDesign of Geosynthetic Reinforced Soil EmbankmentsankhaginNoch keine Bewertungen

- GT Report Open Cutting at Ch. 34 KM MizoramDokument15 SeitenGT Report Open Cutting at Ch. 34 KM MizoramAnil kumarNoch keine Bewertungen

- 07-02-157 Practical Soil Nail Wall Design and Constructability IssuesDokument11 Seiten07-02-157 Practical Soil Nail Wall Design and Constructability Issuesben indrawanNoch keine Bewertungen

- Stone Column 123Dokument34 SeitenStone Column 123Nilesh0% (1)

- PVD PreloadingDokument104 SeitenPVD PreloadingAkriti Kothiala100% (1)

- Cochin College: Soil Reinforcement Using ParawebDokument30 SeitenCochin College: Soil Reinforcement Using ParawebRowbina Machinchery100% (1)

- Container Yard Geocell Design PDFDokument9 SeitenContainer Yard Geocell Design PDFfemiNoch keine Bewertungen

- 2 - Design of Geocell Foundation For Embankment - Sitharam - 2013Dokument9 Seiten2 - Design of Geocell Foundation For Embankment - Sitharam - 2013Vetriselvan ArumugamNoch keine Bewertungen

- Design of Mechanically Stabilzed Earth Walls (Msew)Dokument22 SeitenDesign of Mechanically Stabilzed Earth Walls (Msew)SUNDARAVELNoch keine Bewertungen

- Functions of GeosyntheticsDokument24 SeitenFunctions of GeosyntheticsAzaz AhmedNoch keine Bewertungen

- Technical Data Sheet TECHSTRAP 2020Dokument1 SeiteTechnical Data Sheet TECHSTRAP 2020BalrajNoch keine Bewertungen

- Effect of Placement Depth of Geocell Reinforcement in Sand Deposit: A ReviewDokument12 SeitenEffect of Placement Depth of Geocell Reinforcement in Sand Deposit: A ReviewChaitali patilNoch keine Bewertungen

- Types of Earth Retaining Systems For Deep ExcavationsDokument16 SeitenTypes of Earth Retaining Systems For Deep ExcavationsRajesh KhadkaNoch keine Bewertungen

- Rock Bolting Techniques and ApplicationsDokument17 SeitenRock Bolting Techniques and ApplicationsMarkusMakuAldoNoch keine Bewertungen

- Ground Improvement TechniqueDokument3 SeitenGround Improvement TechniqueAlex Crispim Fortunato0% (1)

- Geogrid Reinforced Base Course For Flexible Pavements For Light Aircraft Literature Review and Test Section DesignDokument40 SeitenGeogrid Reinforced Base Course For Flexible Pavements For Light Aircraft Literature Review and Test Section Designbkollarou9632100% (1)

- Reshma Paper PDFDokument12 SeitenReshma Paper PDFJPDGLNoch keine Bewertungen

- Large-Scale Direct Shear Testing of Geocell Reinforced SoilDokument6 SeitenLarge-Scale Direct Shear Testing of Geocell Reinforced SoilnarutowhatsupNoch keine Bewertungen

- Design of Soil Nail HeadsDokument8 SeitenDesign of Soil Nail HeadsHuy Le QuangNoch keine Bewertungen

- Microsoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3Dokument9 SeitenMicrosoft Word - 20080820 Overview of Vibro Compaction and Dynamic Compaction - 3nn-85614Noch keine Bewertungen

- Unsaturated PDFDokument1.425 SeitenUnsaturated PDFChristian ValerioNoch keine Bewertungen

- MIHIR 7th Sem. Civil ProjectDokument19 SeitenMIHIR 7th Sem. Civil ProjectKUNAL SHAHNoch keine Bewertungen

- Identifying Dispersive Clays Using Pinhole Erosion TestsDokument28 SeitenIdentifying Dispersive Clays Using Pinhole Erosion TestsAndyra Jaiz Baddu100% (1)

- SCH-B Pragatipath Navsari DTP80 CRDokument100 SeitenSCH-B Pragatipath Navsari DTP80 CRKETANNoch keine Bewertungen

- Unit7 SKP PDFDokument36 SeitenUnit7 SKP PDFAGT 6BNoch keine Bewertungen

- Application of GeosyntheticsDokument30 SeitenApplication of GeosyntheticsKiprono VincentNoch keine Bewertungen

- Morth Section 700Dokument3 SeitenMorth Section 700Psrawat RawatNoch keine Bewertungen

- Construction of Slurry WallsDokument22 SeitenConstruction of Slurry WallsJOE G PHILIP CENoch keine Bewertungen

- Stone Column 123Dokument34 SeitenStone Column 123NileshNoch keine Bewertungen

- Problem 6 009Dokument9 SeitenProblem 6 009Jos Elito Van BuurenNoch keine Bewertungen

- Vibrating Machinery Steel Skid On PilesDokument30 SeitenVibrating Machinery Steel Skid On PilesAnonymous OnzJpzNoch keine Bewertungen

- Overview of Soil-Structure Interaction PrinciplesDokument58 SeitenOverview of Soil-Structure Interaction PrinciplesVasco AmaralNoch keine Bewertungen

- 16 SsiDokument17 Seiten16 Ssirajamanickam_007Noch keine Bewertungen

- PushoverDokument2 SeitenPushover1361rahmanNoch keine Bewertungen

- Prequalified Seismic Moment ConnectionsDokument2 SeitenPrequalified Seismic Moment Connectionssymon ellimacNoch keine Bewertungen

- En016 Icet 09 CarrolDokument5 SeitenEn016 Icet 09 CarrolIsmail Syafiq IbramshahNoch keine Bewertungen

- We Support You EnglishDokument4 SeitenWe Support You EnglishSrini VasuluNoch keine Bewertungen

- Torsión de Saint-VenantDokument1 SeiteTorsión de Saint-VenantChristian Daniel TranceVoyagerNoch keine Bewertungen

- MB Green Guide FinalDokument11 SeitenMB Green Guide FinaljeanfatNoch keine Bewertungen

- MB Green Guide FinalDokument11 SeitenMB Green Guide FinaljeanfatNoch keine Bewertungen

- Progressive Collapse Resistance of Axially-RestrainedDokument8 SeitenProgressive Collapse Resistance of Axially-RestrainedjeanfatNoch keine Bewertungen

- Da Pped BeamsDokument31 SeitenDa Pped BeamsjeanfatNoch keine Bewertungen

- Vibrating Machinery Steel Skid On PilesDokument30 SeitenVibrating Machinery Steel Skid On PilesAnonymous OnzJpzNoch keine Bewertungen

- The Direct Analysis Method Made Simple: CSC IncDokument73 SeitenThe Direct Analysis Method Made Simple: CSC IncgayalamNoch keine Bewertungen

- Span-Depth Ratios For One-Way Members Based OnDokument10 SeitenSpan-Depth Ratios For One-Way Members Based OntrabajosicNoch keine Bewertungen

- Engineer Columns and Secant FormulaDokument15 SeitenEngineer Columns and Secant FormulaBoppineti Naga Raju33% (3)

- Da Pped BeamsDokument31 SeitenDa Pped BeamsjeanfatNoch keine Bewertungen

- Ahmed Abdel Fat Tah 2012Dokument2 SeitenAhmed Abdel Fat Tah 2012jeanfatNoch keine Bewertungen

- Heat Exchanger FoundationDokument3 SeitenHeat Exchanger FoundationYash PaulNoch keine Bewertungen

- CSEC® Chemistry Past Papers January 2015Dokument20 SeitenCSEC® Chemistry Past Papers January 2015Jonathan RamsundarNoch keine Bewertungen

- The Use and Misuse of SEMDokument30 SeitenThe Use and Misuse of SEMPPDTBM renNoch keine Bewertungen

- Weld-Ing On in Inservice Pipelines - tcm153574190Dokument7 SeitenWeld-Ing On in Inservice Pipelines - tcm153574190Freddy Rondonil SNoch keine Bewertungen

- Class - 8 PT3 - Portion 2023 24 - 1Dokument5 SeitenClass - 8 PT3 - Portion 2023 24 - 1gurdeepbeniwal97Noch keine Bewertungen

- Lecture - 12 - Project EvaluationDokument68 SeitenLecture - 12 - Project EvaluationEngr. Md. Ashraful AlamNoch keine Bewertungen

- Homework Lesson 6-10Dokument9 SeitenHomework Lesson 6-10Valerie YenshawNoch keine Bewertungen

- Simulation and Implementation of Servo Motor Control With Sliding Mode Control (SMC) Using Matlab and LabviewDokument30 SeitenSimulation and Implementation of Servo Motor Control With Sliding Mode Control (SMC) Using Matlab and Labviewmjohn87Noch keine Bewertungen

- Process Bus and Sampled Values Based ApplicationsDokument49 SeitenProcess Bus and Sampled Values Based ApplicationsMarco TrovóNoch keine Bewertungen

- GU - Cabine MT BT (EN) - 1VCP000591 1511Dokument88 SeitenGU - Cabine MT BT (EN) - 1VCP000591 1511Fatmir JashariNoch keine Bewertungen

- Control of Multiple-Input, Multiple-Output ProcessesDokument27 SeitenControl of Multiple-Input, Multiple-Output Processesmeseret sisayNoch keine Bewertungen

- Recurrent Neural Network-Based Robust NonsingularDokument13 SeitenRecurrent Neural Network-Based Robust NonsingularDong HoangNoch keine Bewertungen

- ACI229Dokument18 SeitenACI229Francisco CalderónNoch keine Bewertungen

- Basic Probability and Reliability Concepts: Roy Billinton Power System Research Group University of Saskatchewan CanadaDokument248 SeitenBasic Probability and Reliability Concepts: Roy Billinton Power System Research Group University of Saskatchewan CanadaSimon van BentenNoch keine Bewertungen

- Electrical Circuit Analysis ProblemsDokument14 SeitenElectrical Circuit Analysis ProblemsMd Rafiqul IslamNoch keine Bewertungen

- Student's Error Analysis in Finishing Mathematic Word Problem Based Newman AnalysisDokument11 SeitenStudent's Error Analysis in Finishing Mathematic Word Problem Based Newman AnalysisguanyitorNoch keine Bewertungen

- Nptel: System Analysis and Design - Video CourseDokument2 SeitenNptel: System Analysis and Design - Video CourseAnu PriyaNoch keine Bewertungen

- Add Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDokument32 SeitenAdd Nordic Semiconductor DFU To SDK Example: Bluetooth Low EnergyDaniel Ernesto EspitiaNoch keine Bewertungen

- Atlas Copco Compressed Air Manual: 8 EditionDokument25 SeitenAtlas Copco Compressed Air Manual: 8 EditionRajNoch keine Bewertungen

- NCERT Solutions For Class 8 Maths Chapter 14 - FactorizationDokument25 SeitenNCERT Solutions For Class 8 Maths Chapter 14 - FactorizationSATAMANYU BHOLNoch keine Bewertungen

- Manual Hawk 4000 PDFDokument158 SeitenManual Hawk 4000 PDFNebur MtzaNoch keine Bewertungen

- Glass Transition Temperature: IntroductionDokument7 SeitenGlass Transition Temperature: IntroductionBarkha RaniNoch keine Bewertungen

- PLC Introduction: Programmable Logic Controller BasicsDokument3 SeitenPLC Introduction: Programmable Logic Controller Basicssreekanthtg007Noch keine Bewertungen

- Notes On Continuum MechanicsDokument13 SeitenNotes On Continuum Mechanicsdalves31503Noch keine Bewertungen

- Document: NO.:: Ultrasonic ExaminationDokument41 SeitenDocument: NO.:: Ultrasonic ExaminationDamar WardhanaNoch keine Bewertungen

- openPDC DM-Tools Usage Examples GuideDokument5 SeitenopenPDC DM-Tools Usage Examples GuidealantmurrayNoch keine Bewertungen