Beruflich Dokumente

Kultur Dokumente

Stress Residual en Vigas Armadas

Hochgeladen von

victor.melgarejo19085Originalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Stress Residual en Vigas Armadas

Hochgeladen von

victor.melgarejo19085Copyright:

Verfügbare Formate

Residual St r esses in Heavy Welded Shapes

G e o m e t r y o f p l a t e s a nd s h a p e s is a n im p o r t a nt v a r ia b l e a ffe c t in g

r e s idu a l s t r e s s m a g nit u de a nd dis t r ib u t io n, a nd init ia l r e s idu a l s t r e s s e s du e t o r o l l ing

c a n b e a h ig h e r m a g nit u de t h a n t h o s e du e t o w e l ding

BY G. A. AL P S T E N AND L T AL L

A B S T R A C T . R esidual stresses can have a

significant influence on the load-carrying

behavior of structural steel members sub-

jected to compressive loads. Previous ex-

perimental research on residual stresses

and the strength of columns was related

to small and medium-size shapes. In

today's large structures, increasingly

heavy shapes are employed. While heavy

column shapes are being used extensive-

ly, very little information has been avail-

able on the residual stresses and strength

of such members.

T his paper presents the results of the

first phase of a major investigation into

the residual stresses in, and the behavior

of, thick plates and heavy shapes used in

compression members. T he shapes con-

sidered in this initial study are a 15H290

shape and a 23H681 shape, as well as

two loose component plates, PL 16x2 and

PL24x3V. ,. For the smaller shape, com-

parative tests were carried out for differ-

ent manufacturing conditions of the com-

ponent plates (universal-mill and flame-

cut plates), different weld type (penetra-

tion) and different yield strengths of the

material.

T he results of residual stress measure-

ments carried out in this first phase of

the study indicate the following for

heavy fabricated members:

1. All phases of the manufacture and

fabrication procedure generally affect the

formation of residual stresses.

2. T he weld type (penetration) and

the yield strength of the steel are not

major factors in the formation of residu-

al stresses.

3. T he geometry of the plates and

shapes is one of the important variables

affecting the residual stress magnitude

and distribution.

4. T he variation of residual stress

across the thickness of plates more than

G. A. A LPS T EN is A ssociate Director.

S wedish Institute tor S teel C onstruction

and was formerly with Lehigh University:

L. T A LL is Director, Division for Fatigue

and Fracture. Fritz Engineering Labora-

tory. Lehigh University, B ethlehem, Pa.

Paper presented at the AWS 50th A nnual

Meeting held in Philadelphia, Pa. , during

A pril 28 to May 2, 1969.

1 in. thick can be considerable.

5. T he welding residual stresses in

portions of the cross section other than

the weld area tend to decrease with

increasing size of the member, probably

because the weld area, and consequently,

the heat input, is relatively smaller in

heavy plates and shapes as compared to

light members.

6. T he initial stresses can be of a

higher magnitude than the welding resid-

ual stresses.

T he relationship between initial resid-

ual stresses in ccmponent plates and

welding residual stresses implies that

efforts to limit the magnitude of residual

stresses in heavy welded shapes should be

directed towards the manufacture of the

component plates. T hus, by using flame-

cut plates in heavy welded shapes, there

is a prospect for an increase in strength

when compared with lighter members at

the same slenderness ratio. T here is

even a possibility that such welded

shapes may be stronger than their rolled

counterparts.

Intr o du c tio n

Only in the past t wo decades was

it experi ment al l y and theoretically

verified t hat residual stresses are a

maj or influence on t he st rengt h of

steel member s in compressi on. It was

shown t hat t hey have a significant

effect on col umn st rengt h ' -

2

and on

the buckl i ng of plates.

3

-

4

It is also

known t hat residual stresses can be of

great i mpor t ance in fatigue, brittle

fract ure, and stress cor r osi on.

T he previ ous experi ment al research

on residual stress and the st rengt h of

welded steel member s was related to

small and medi um-si ze shapest hat

is, shapes of component s with a thick-

ness equal to or less t han 1 in. ~

rl

In

t oday' s large st ruct ures, increasingly

heavy shapes are used. Very little

i nformat i on has been available on the

residual stresses and st rengt h of heavy

col umns, yet t hey are used extensively

in Nor t h A mer i ca and el sewhere. A p-

plications i ncl ude the l ower stories of

multi-story buildings, maj or bridges,

and l aunchi ng gantries for rocket s and

space vehicles. S imilar st ruct ural ele-

ment s are used in ship and submar i ne

hulls, and in vessels for at omi c reac-

t ors.

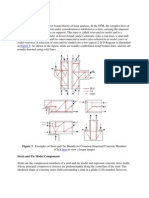

S ome heavy col umn shapes used in

existing st ruct ures are shown in Fig.

1, whi ch also illustrates the different

ways of designing a heavy col umn

shape. R olled shapes can be used and

are available in sizes up to t he

14WF730 " j umbo" shape of Fi g. l a.

If the st rengt h of t he available rolled

shape is insufficient for a part i cul ar

appl i cat i on, plates can be welded t o a

rolled shape as shown in Fi gs, l b and

c. A heavy shape can also be built up

from welding t oget her t hree plates to

form an H-shape, as illustrated in Fig.

l d. Fi nal l y, a box-shape can be made

from wel di ng t oget her four pl at es

Fi g. l e. T he plates used in a welded

shape can be manuf act ur ed ei t her as

universal-mill plates ( t hat is, rolled to

exact wi dt h and used with as-rolled

edges) or as flame-cut * plates (t hat

is, flame-cut from a larger base

pl at e) .

A t present , t he design of heavy

col umns does not differ from t hat of

small and medi um-si ze col umns. T he

design cri t eri a previously developed

for small and medi um-si ze rolled

col umns

2

have been ext rapol at ed t o

include heavy member s. Whi l e experi -

ence has i ndi cat ed t hat this l eads t o

safe design, it may not be a compl et e-

ly rational design met hod.

A n extensive research pr ogr am is

current l y under way at Lehi gh Uni ver-

sity to st udy residual stresses in heavy

welded plates and shapes. ( Heavy

plates and shapes are defined here as

member s with a t hi ckness exceedi ng 1

i n. ) . T he specific objectives of t he

* Or oxygen-cut (from oxygen cutting as

defined by AWS in Terms and Definitions,

AWS A3. 0-69).

W E L D I N G R E S E A R C H S U P P L E M E N T | 93-s

730 l b /ft

(a )

130 l b /ft

(b )

2690 l b /ft

(C)

1

Scale (i nch e s ):

10 20 30

1610 Ib /ff 1190 l b/ft

(d ) (e )

Fi g. 1Heavy col u mn shapes i n e xi s t i ng s t r u ct u r e s

X" I

8W 40

(a )

I I H 66

(b)

I 4H 202

(O

1

1 1

I5H290

(d )

23H 68I

(e )

3

24D774

( f )

24H I I 22

(g)

Scale (i nch e s ):

i 1 1 i

0 10 20 30

Fi g. 2Test col u mns

study are to determine the magnitude

and distribution of residual stresses in

thick welded plates by both experi-

mental and theoretical means, and to

relate this to the stability under com-

pressive loads of structural members.

Prior to the initiation of the current

study, critical information was lacking

on the behavior of heavy columns.

T he present status is illustrated in Fig.

2 (a-d) which shows:

a. T he largest test shape so far used

in a multi-story frame test.

b. T he largest welded shape in a

beam-column test.

c. T he largest column shape.

d. T he largest stub column shape.

T he shapes in Figs. 2e through 2g

are examples of the specimens in the

current research program. T hese shapes

compare to the heavy column shapes

used in construction (see Fig. 1).

T he paper presents some experi-

mental results obtained in the first

phase of the investigation. While the

specimens in the overall program cov-

er the complete range of dimensions

which are practical in construction,

that is, plates ranging in size from 9 x

V

2

up to 24 x 6 in. and welded

H-shapes and a box-shape ranging

from a 7H28 to a 24H1122 shape, the

specimens considered in this paper are

the 15H290 and 23H681 shapes (see

Figs. 2d and e) as well as two as-man-

ufactured plates, 1 6 x2 and 24 x 3

1

/?

in. Figure 3 shows a comparison be-

tween the 23H681 shape and the

7H28 shape, corresponding to the

heaviest and lightest welded specimens

tested so far in the Lehigh program.

T he results of the overall study will

allow the prediction of residual

stresses in any plate and any welded

shape used in construction. T he plates

and shapes in the investigation will

serve as reference data, and by know-

ing the dimensions of components and

the manufacturing and fabrication de-

tails of a practical column, the dis-

tribution of residual stress can be pre-

dicted. T he column strength can then

be determined, including the effect of

residual stresses.

T he study is of a fundamental

nature and of considerable importance

in many areas; however, the present

Fi g. 3Largest (23H681) a nd s ma l l e s t

(7H28) col u mn shapes t e s t e d so fa r i n

t h e r esear ch program

Fi g. 4Fa br i ca t i on of t h e we l d e d H-

shape 23H681 (cou r t e s y Be t h l e h e m

St e e l Corp.)

application is the development of in-

formation which will be useful in

preparing design criteria for heavy

column members as are used in con-

struction. T he findings obtained for

the basic welded plates will be appli-

cable also to other types of structures

for instance, ship and submarine

hulls, and atomic reactor vessels.

Fa br i ca t i on of Test Specimens

T he test specimens were fabricated

by steel fabricators according to nor-

mal practices and procedures. A WS

specifications were followed in the

fabrication. S ubmerged-arc welding

method was used for all specimens.

Pertinent welding data have been

summarized in T able 1.

T he first four specimens were fabri-

cated from universal-mill platesthat

is, the component plates in the welded

shapes were used with as-rolled edges.

T he remaining specimens were fabri-

cated from flame-cut plates, obtained

by flame-cutting the component plates

from larger base metal plates. S peci-

mens of the 15H290 shape were fabri-

cated in both A S T M A 36 and A 441

steel for comparative tests. In addi-

tion, both a fillet weld (partial pene-

tration) and a groove weld (full pene-

tration) were used. For the heavy

shape 23H681, only one specimen of

A 36 steel with fillet welds was fabri-

cated.

T he welds in the 15H290 shapes

were deposited in a symmetrical pat-

tern as indicated in T able 1, to mini-

mize the distortion of the members.

T wo passes were used for the 15H290

shapes with fillet welds, but seven

passes were required for the groove

welds.

94-s M AR C H 1 9 7 0

Ta b l e 1 -

Te s t

s p e ci me

no.

1

2

3

4

5

6

7

8

9

10

11

-We l d in g Da t a fo r Fa b

n S h a p e

d e s i gna t i on

15H290

15H290

15H290

15H290

15H290

15H290

15H290

15H290

PL16 X 2

PL24 X 3Vs

23H 681

Ma t e r i a

A36

A36

A441

A441

A36

A36

A441

A441

A36

A36

A36

r ic a t io n

S t a t i c

y i e l d

s t r e s s ,

ks i

33.7

36.0

46.7

45.2

35.9

35.9

44.6

42.0

32.5

32.1

32.2

o f Te s t Sp e c im e n s

Ma nu -

f a ct u r e

of p l a t e s

UM

UM

UM

UM

FC

FC

FC

FC

FC

FC

FC

S i ze of

f l a nge

p l a t e ,

b

i n.

14 X 2>A

14 X 2/a

14 X 2>/,

14 X 2

1

/.,

14 X 2 7,

14 X 27

2

14 X 2' /.,

14 X 27,

24 X 37,

S i ze of

we b

p l a t e ,

i n.

10 x 172

10 x 172

10 X i y *

10 x 172

10 X 17-j

10 x iy

s

10 x 172

10 x 172

16 X 2

Ty p e

s u b-

me r ge d -

a r c

we l d

Fi l l e t

Gr oov e

Fi l l e t

Gr oov e

Fi l l e t

Gr oov e

Fi l l e t

Gr oov e

Fi l l e t

De t a i l

of

we l d ' '

A-

B"

c<-

No. of

p a s s e s S e - . W e l d i ng

for qu e nce

e a ch of we l d Pa s s

we l d p a s s e s

0

no.

2 D 1-4

5-8

7 E" 1-2

3-4

5-28

S e e t e s t s p e ci me n no.

S e e t e s t s p e ci me n no.

S e e t e s t s p e ci me n no.

S e e t e s t s p e ci me n no.

S e e t e s t s p e ci me n no.

S e e t e s t s p e ci me n no.

1 F= 1s t DC

FI. AC

2nd DC

FI. AC

Vol t -

a ge ,

V

33

33

32

33

33

1

2

1

2

1

2

26

31

26

30

d a t a -

Cu r - '

r e nt ,

a mp

650

650

500

650

650

700

530

710

530

.

S p e e d

i p m

26

14

24

18

16

15

15

18

18

W e i gh t e d a v e r a ge .

' UMu ni v e r s a l mi l l e d ; FCfl a me cu t .

See s ke t ch op p os i t e l e t t e r d e s i gna t i on be l ow:

A

SAW>"f>/

Ft t

SAW>l

II

TS

6 0 * ^ "

T he 23H681 shape was welded

using an automatic beam welding ma-

chine with two tandem electrodes.

T hus, it was possible to weld simul-

taneously on both the left and the

right side of the shape, each weld

being deposited in one pass from one

d-c electrode and one a-c electrode

spaced 4

1

/

2

in. apart. A fter the first

flange and the web were joined to-

gether, the T -shape was turned over

and the second flange was welded to

the T to form the final H-shape. Fig-

ure 4 shows the 23H681 specimen and

the beam welding machine used for

the fabrication. A more detailed ac-

count of the fabrication of the

23H681 shape can be found in the

literature.

s

It was specified that no straighten-

ing operations in any form should be

used after the welding. In practice,

such operations may become neces-

sary to fulfill straightness require-

ments. T he common methods used

for straightening heavy welded shapes

that is, gagging or local heating by

a flamewill change the residual

stress distribution locally at the straight-

ened section. T he residual stresses in

the unstraightened parts of the col-

umn will remain unchanged.

Pro c e du re fo r Me a s u r e m e nt of

Re s idu a l Stre s s

T he residual stress distribution in a

thick plate is generally three-di-

u

S AW >J

rl

8, 4

6. 2

1.5

3,7

mensional with stresses in the longi-

tudinal as well as the transverse direc-

tions. While the transverse stresses

will affect the yielding behavior of the

different fibers of the cross section, the

longitudinal stresses are of primary

interest for column strength. T hus, the

theoretical methods normally em-

ployed for the prediction of column

behavior and maximum strength of

columns consider the longitudinal re-

16,9,8,2,

25,24,17

27,22,19,

14,11.6,3

4.5.I 2A

20,21,28

18,23,26,

1.7,10,15

sidual stresses only.

When only longitudinal stresses are

taken into account in the theories for

column strength prediction, it is in

fact more relevant in the residual

stress measurement to consider the

apparent longitudinal stresses as ob-

tained directly from the measured re-

leased strain in the longitudinal direc-

tion, rather than to separate the influ-

ence of the stresses in all three direc-

SECTIQNING

-Top Surface Reading

Straight Line

Approximation

SLICING

Straight Line

Approximation

From Sectioning

-Shaded Area Equals Final

Residual Stress Distribution

Fi g. 5Pr i nci p l e of t h e s e ct i oni ng me t h od for r e s i d u a l s t r e s s measur e-

me nt s

Bottom Surface Reading

Additional Stress

From Slicing

W E L D I N G R E S E A R C H S U P P L E M E N T ! 95-s

- 40

- 2 0

KSI 0

20

40

60

k f,

\ \ rr*>^/ /

\ t

- \ \

KSI

60 40 20 0 - 20 - 40

KSI

60 40 20 0 - 20 - 40

I i I i I ' I i I ' I

60

40

20

KSI 0

-20

- 40

- \ \

~ J \

/ V

^

Near Surface

Far S u r fa ce

Fi g. 6Resi dual st resses i n a we l d e d shape 15H290univer-

s a l -mi l l p l a t e s , A36 S t e e l , y , i n. fi l l e t we l d s

Ne a r Su r fa c e

Fa r Su r fa c e

Fi g. 7Residual st resses

s a l -mi l l p l a t e s , A36 S t e e l ,

i n a we l d e d shape 15H290-

"/m i n. groove we l d s

-Univer-

tions.

0

T his is because the effect of

transverse stresses on the measured

released strain in a sectioning

procedure is somewhat similar to that

on the yielding behavior of a column

under load. T hus, there are two ap-

proximations, the error of which tend

to cancel each other. " With this

procedure of treating the measure-

ments as one-dimensional, and when

the transverse stresses are reasonably

smallthat is, less than 50% of the

longitudinal stressthe relative error

in the applied stress to cause yield in a

fiber is less than 20%. For the behav-

ior of the complete cross section, the

relative error will be considerably less.

A nother important feature of the

residual stress distribution in thick

components is that the longitudinal

stresses can be expected to vary sig-

nificantly through the thickness of the

components. T he method for meas-

urement of residual stresses must

take into account this variation.

T he procedure used for the meas-

urements was a sectioning method,

involving longitudinal saw cuts both

across the width and through the

thickness of the components. T he

method is basically similar to the sec-

tioning method used by Kalakoutsky

in 1888 for the measurement of resid-

ual stresses in steel cylinders.

10

T he

technique of the sectioning method as

applied to heavy welded shapes was

developed in the Lehigh research pro-

gram.

11

Gage points were first laid out

around the specimen (Fig. 5) , and

readings were obtained using a 10 in.

Whittemore mechanical extensometer.

T he specimen was then cut into ele-

ments containing one or more gage

points on each surface ("sectioning"),

and new measurements were made.

T he released strains at both surfaces

of the elements could be evaluated

from these measurements. If the ratio

of width to length and width to thick-

ness of the elements is such that

beam-type action will occur, the

through-thickness variation of strains

released in the sectioning (

s(

,,.

t

.) will

approximate a straight line going

through the data points obtained on

the surfaces. Measurements have indi-

cated that the straight-line assumption

is reasonable for the geometry of ele-

ments used, and this assumption is the

basis for the evaluation procedure.

T he sectioning was then continued

to obtain the actual variation of resid-

ual stress through thickness. A fter the

first set of saw cuts were made ("sec-

tioning"), additional gage points were

laid out along the sides of the ele-

ments. New readings were taken by

the extensometer, followed by sawing

the elements into strips across the

thickness ("slicing"). From exten-

someter readings before and after the

slicing, additional strains, e

sli(

. , were

obtained. T hese strains are superim-

posed upon the strains from the sec-

tioning to furnish the total strain vari-

ation (see Fig. 5) . A ssuming that all

residual strains have been released,

the residual stress may be obtained

from the relationship:

E (**,<(. + Eslic. ) (1)

T he residual stresses released in the

slicing procedure must be in equilibri-

um for each sectional element. T hus,

there is no contribution to the average

stress through thickness from these

stresses. C onsequently, the average

residual stress obtained as the mean

value of readings from both surfaces

in the sectioning procedure is equal to

the actual average stress through the

thickness.

T he accuracy in the stress measure-

ment is of the order of 1 ksi. An

extensive study of the accuracy and

9B-s I M AR C H 1 9 7 0

KS I

60 40 20 0

I ' I

KS I

fl

u.

6 0 -

Near Surface

Far Surface

4 0

20

KS I 0

Fi g. 8Resi dual st resses i n a we l d e d shape 15H290univer-

s a l -mi l l p l a t e s , A441 S t e e l , */, i n. fi l l e t we l d s

- 20

- 4 0 -

Near Surface

Far S u r fa ce

Fi g. 9Resi dual s t r e s s e s i n a we l d e d shape 15H290univer-

s a l -mi l l p l a t e s , A441 S t e e l ,

U

/

M

i n. groove we l d s

the error sources in the measurements

was carried out in connection with the

investigation.

12

T he experimental work involved in

the method is enormous, both with

respect to the required number of

gage point readings and the necessary

sawing operations. For example, the

number of gage readings involved in

the measurements on a 24 x 3

1

/: ; in.

plate (see Figs. 17 and 19) is more

than 5000; the sawing was done on a

band saw and required a net machine

time of the order of 100 hr.

Te s t Re s u lts

T he residual stress distributions ob-

tained from sectioning of the four

15H290 specimens fabricated from

universal-mill plates are given in Figs.

6 through 9. T he curves shown refer

to the results obtained on both sur-

faces of the shape components in the

sectioningthat is, before slicing. T he

Fi g. 10Two-d i me ns i ona l v a r i a t i on of

r e s i d u a l s t r e s s i n a we l d e d shape 15H290

u ni v e r s a l -mi l l p l a t e s , A36 S t e e l , Va i n.

fi l l e t we l d s

W E L D I N G R E S E A R C H S U P P L E M E N T 97-s

- 40

-20

KSI 0<

20

40

60

-

__y v ^~x

H r* - * > X

n n

- r

- w

T T

4-4

KSI

6 0 40 20 0 -20 -40

I ' I ' I ' I ' I ' i

KSI

60 40 20 20 -40

Ne a r Su r fa c e

Fa r Su r fa c e

Fi g. 11Residual st resses i n a we l d e d shape 15H290-

cu t p l a t e s , A36 S t e e l , 7 i n. fi l l e t we l d s

-fl ame-

Ne a r Su r fa c e

Fa r Su r fa c e

- 4 0

L

Fi g. 12Residual st resses i n a we l d e d shape 15H290flame-

cu t p l a t e s , A36 S t e e l , "/, i n. groove we l d s

shapes in Figs. 6 and 7 are of A 36

steel, differing only in the type of

weld. Figures 8 and 9 show a similar

comparison for A 441 steel.

T he results of a complete sectioning

and slicing procedure from one of the

specimens is given in Fig. 10. T he

residual stress distribution is rep-

resented in the form of an iso-stress

diagram, that is, contour lines for

constant stress.

For all four shapes of universal-mill

plates, the stresses at the flange tips

are in compression, and of a relatively

high magnitude. T he average stress at

the flange tip varies between 16 and

24 ksi for the four shapes.

Figures 11 through 14 show the

residual stresses as measured in the

four 15H290 specimens fabricated

from flame-cut plates. A gain, the

curves in the diagrams correspond to

the measurements obtained on both

surfaces of the components in the sec-

tioning test. Each specimen made of

flame-cut plates in Figs. 11 through 14

corresponds to a similar specimen

made of universal-mill plates (Figs. 6

through 9) so the distributions may be

compared directly. Instead of relative-

ly high compressive stresses as in the

universal-mill plates, there are very

high tensile stresses at the flange tips

of the shapes made of flame-cut

plates.

Figure 15 gives the results obtained

from sectioning and slicing of the

15H290 specimen made of A 36 steel,

and with fillet welds. A s may be seen

from the contour lines, there are steep

gradients in the weld region and at the

flame-cut edges.

As will be discussed further in the

next section, it is obvious from the

results on the 15H290 specimens that

the initial stresses existing in the com-

ponent plates prior to welding are of

great importance. T herefore, meas-

urements on the component plates,

before welding, were included in the

study of the 23H681 shape. Figures

16 and 17 give the average residual

stress through the thickness for a 16 x

2 in. plate, taken from the same base

metal as the web plate of the shape,

and a 24 x 3

1

/. , in. plate, correspond-

ing to the flange plates of the shape.

T he stresses at the plate edges are in

tension with a maximum of approx-

imately 50 ksi at the flame-cut sur-

face. T he tensile stresses are balanced

by compressive stresses in the center

of the plates.

A complete picture of the actual

distribution of longitudinal residual

stresses in the thick plates can be

obtained only from a study of the

two-dimensional variation of residual

stresses over the cross section. Figures

18 and 19 show iso-stress diagrams as

obtained from sectioning and slicing

of the 1 6 x2 in. and the 24 x 3

1

/, , in.

plates, respectively. T he variation

through the thickness amounts to ap-

proximately 12 ksi for the 16 x 2 in.

plate and 15 ksi for the 24 x 3V

2

in.

plate. T hus, although the average

stress in the center part of the plates is

compressive (see Figs. 16 and 17),

the actual stress in the interior is

tensile. S imilarly, while the maximum

compressive stress in the average di-

agram of the 24 x 3

1

/. , in. plate is

11 ksi, and true maximum compres-

sion at any measured point through

the cross section is actually 22 ksi.

Figure 20 shows schematically the

addition of stresses during welding of

the 23H681 shape. T he distributions

shown are those measured in separate

specimens of loose plates and shapes,

so there is no true algebraic addition

in the diagrams. T he additional resid-

ual stresses resulting from the welding

98-s M AR C H 1 9 7 0

KSI

60 40 20 0 -20 - 40

T T

4-4-

- 4 0

- 20

KSI 0

20

40

S*

r

/

I

r \

* J \

~l r n

/ i

i

/ r

6 0 h

Ne a r Su r fa c e

Fa r Su r fa c e

Fi g. 13Residual stresses i n a we l d e d shape 15H290-

cu t p l a t e s , A441 S t e e l , Va i n. fi l l e t we l d s

-fl ame-

60

i

40

20

KSI 0

- 2 0

. - 4 0

-

9

r \

\ /

\j \i

y~-sjj

Ne a r Su r fa c e

Fa r Su r fa c e

Fi g. 14Residual s t r e s s e s i n a we l d e d shape 15H290-

fl a me cu t p l a t e s , A441 S t e e l , "/

v

. i n. groove we l d s

were obtained from gage readings on

the plates before and after welding.

T hese welding residual stresses add to

the initial stresses existing prior to

welding. It should be noted that the

welding stresses could be measured

only in the regions which remain elas-

tic throughout the welding and cooling

after welding. In the parts of the cross

section where plastic deformations oc-

curred at any stage of the process, the

measured strain will contain a plastic

component and cannot directly be

coverted to stress.

While the initial stresses in the

flange plates vary between approx-

imately 11 ksi and 50 ksi, the addi-

tional stresses as measured in the elas-

tic part of the flanges nowhere exceed

2 ksi (Fig. 20b). For the web the

comparison between initial stresses

and welding stresses is similar, al-

though the welding stresses are of a

somewhat larger magnitude than en-

countered in the flangesthat is, up

to 13 ksi. Measured welding stresses

in most points were in compression.

Naturally, the stress in the weld region

must be in high tension, but this could

not be meastired directly as explained

above.

B ecause of the small residual

stresses due to welding of this heavy

shape, the distribution of the initial

stresses is retained in the welded

shape, only with some modifications in

the magnitude of stress. Figure 21

shows the stresses as measured on

both surfaces of the components of

the welded shape 23H681. T he di-

agram can be compared directly with

those in Figs. 6-9 and 11-14 for the

15H290 shape.

A full understanding of the distribu-

tion of the residual stresses in the

23H681 shape can be gained only

from the results of complete section-

ing and slicing, shown in Fig. 22. T he

diagram indicates that not only is the

variation of stress across the width

retained in the welded shape but also

the variation across the thickness is

similar to that in the loose component

plates. (C ompare the diagram in Fig.

22 with those in Figs. 18 and 19).

Major changes have occurred only in

the weld area.

Discussion of Results

From the results obtained on thick-

plates and heavy shapes in the investi-

gation it is clear that the welding

residual stresses in areas of the cross

section away from the weld are far

smaller in heavy welded shapes than

found in the earlier investigations

3

-"

for small plates and shapes. Figure 23

shows a comparison between the ini-

tial residual stresses in a universal-mill

plate 10 x V

2

in. and the residual

stresses after applying welds in the

center of the plate."' While the max-

imum compressive stress in the as-

rolled plate is 6 ksi, the maximum

compressive stress in the welded plate

is 26 ksi, indicating a contribution

from the welding of 20 ksi at this

point. T hus, for this plate, which is

representative of small and medium-

sized plates, the residual stresses from

welding constitute the major part of

the residual stress distribution.

C omparing these results with those

summarized in Fig. 20, it is noted that

the situation in the heavy material is

quite different; the major portion of

the residual stresses in the 23H681

shape are those originating from the

initial plates. T he maximum compres-

sive welding stress in the flange plate

is 2 ksi. T he flange plate is basically

a center-welded plate and may, there-

fore, be compared directly with the

center-welded plate in Fig. 23. T he

comparison exemplifies the observa-

tion that the welding residual stresses

W E L D I N G R E S E A R C H S U P P L E M E N T 99-s

Fi g. 15Two-d i me ns i ona l v a r i a t i on, of r e s i d u a l s t r e s s i n a we l d e d shape

15H290flame-cut p l a t e s , A36 S t e e l , /, i n. fi l l e t we l d s

are of a smaller absolute and relative

magnitude in heavy plates and shapes.

T his could also be predicted since the

ratio of weld area to that of base

metal is smaller for heavy practical

shapes. T hus, proportionately, there is

a smaller heat input for shapes of

thick plates than there is for light

plates, and so heavy shapes would be

expected to contain compressive weld-

ing residual stresses of a smaller mag-

nitude.

T he above finding also means that

the initial residual stresses existing in

KSI 0

KSI 0

PL 2 4 x 3 ^ (FC)

Fi g. 17Residual st resses i n a 24 x 3 , i n. fl a me -cu t p l a t e

PLI6x2(FC)

Fi g. 16Resi dual stresses i n a 16 x 2 i n.

fl a me -cu t p l a t e

the component plates before welding

are of greater importance for heavy

shapes. T his conclusion is obvious

from the results obtained on the

15H290 when comparing the residual

stresses in the shapes made from uni-

versal-mill plates (Figs. 6-9) and

from flame-cut plates (Figs. 11-14).

T he only difference between the two

sets of specimens is in the manufac-

turing procedure for the plates, so the

comparison reflects the effect of this

variable only.

All flanges of the 15H290 shapes

made of universal-mill plates show a

similar kind of distribution with high

compressive stresses at the flange tips.

A s can be seen in Fig. 10, the com-

pressive stresses are at the yield point

level in the flange tip corners. T his is

in accordance with theoretical predic-

tions of residual stresses in universal-

mill plates based upon the heat flow in

cooling.

,:t

A ccording to the predic-

tions, the residual stresses tend to

increase with increasing size of the

member. For heavy plates subjected

to free cooling, the cooling residual

stresses as predicted are in high com-

pression at the plate edges and may

approach the yield point for some

plates.

Flame-cut plates show a reversed

distribution with high tensile stresses

at the flame-cut edge, balanced by

compressive stresses in the center of

the plate. T he stress at the flame-cut

surface is larger than the yield point

of the parent material. T his is possible

because the mechanical properties of

the material close to the flame-cut

surface have been increased from the

rapid cooling after cutting. A nother

factor which influences the conditions

is the three-dimensional stress state.

Since the local stresses in the heated

material normally are in high tension

100-s M AR C H 1 9 7 0

that is, of equal sign in all three di-

rectionsthe material can sustain a

higher stress than the yield point in a

uni-axial tension test.

B asically, these conditions prevail

also in the weld regions in the welded

shapes; this can explain the high ten-

sion stresses invariably experienced in

the welds. For the weld, however, the

weld area contains a mixture of elec-

trode and base metal. T he mechanical

properties of electrodes used for weld-

ing structural carbon steels normally

have a higher strength than the base

metal. T hus, there are three effects

o

1

o

CO

o o

6

0

K

S

I

2

0

0

-

2

0

o

O J

o

O J

o

o

O J

1

o

co

o

CM

O

*

o

CD

(/>

(/)

<D

-t- .

OO

UD

i

75 CM

1 / 1

Ql

Q.

r o

o-Sj

! "

=?

r o

il. E

ll LU-

o

ID

O O

CM

O

o j

t o

tn

co

or.

co

<

o

co

UJ

a :

1

o

l>

1

O

<*

1

o

CM

'

i

1

o

CO

1

o

O J

1

CO

UI

8

UJ

CO

CD

z

a

i

u i

S

i

<

>-

o

t -

Q

n

<

CO

co

UI

cc

<

o

CO

UJ

a'

W E L DI N G R E S E AR CH S U P P L E ME N T 101-s

which explain the occurrance of high

stresses in the weld areas:

1. Increased strength of material

due to the electrode material.

2. Increased strength due to the

cooling rate.

3. T hree-dimensional stresses.

T ension tests of specimens contain-

ing weld metal have indicated a yield

strength of 50-55 ksi for A 7 steel

that is, about 50% higher than the

yield strength of the base metal."' T he

residual stresses measured in the weld

area of the heavy shapes are all of this

order of magnitude.

T he weld type is not a major factor

in the formation of residual stresses in

thick plates and shapes. A comparison

of the distributions in Figs. 6 and 13.

for fillet welds, and the corresponding

diagrams in Figs. 7, 9, 12, and 14 for

groove welds, indicates no significant

difference. T his is probably because

the heat input in each weld pass is of

the same order of magnitude for the

fillet weld and the groove weld (see

T able 1). S imilar results were ob-

tained previously for small and medi-

-40h -

um-size plates. "'

T he residual stress distributions as

measured in the shapes of A 36 steel

and of A 441 steel are similar, indicat-

ing that the type of steel has no great

influence on residual stress. Since the

effect of residual stress on column

strength is dependent on the ratio of

residual stress to yield stress while at

the same time the magnitude of the

residual stresses are not much affected

by the type of material, it can be

expected that columns made of high-

strength steels are stronger than those

made of A 36 steel, also when com-

pared on a non-dimensional basis.

T his has been confirmed previously by

residual stress measurements and

column tests on small and medium-

size welded shapes.

14

T he geometry of the plates and

shapes is one of the major variables

affecting the residual stress distribu-

tion. A s discussed above, the contribu-

tion of residual stress due to welding is

greatly dependent on the size of the

componentsthat is, whether the

shape is light, medium-size, or heavy.

KSI

60 4 0 2 0 20 - 4 0

Ne a r Su r fa c e

Far Su r fa c e

Fi g. 21Re s i d u a l s t r e s s e s i n a we l d e d shape 23H681flame-cut p l a t e s ,

A36 S t e e l , '

s

i n. fi l l e t we l d s

Figure 24 summarizes the results of

residual stress measurements made on

a number of welded shapes using

flame-cut plates, ranging from the

7H28 shape to the 23H681 shape.

Generally, the residual stresses due to

welding decrease with increasing size

of the member.

A nother feature of residual stresses

in thick plates is the variation through

the thickness of the components. R e-

sults of measurements including both

sectioning and slicing have shown that

the variation in thick plates is consid-

eiable. For instance, the nonsymmet-

rical application of welds on a flange

plate results in high tensile stresses on

the welded side, whereas the stress at

the opposite side often is compressive.

It is believed that the large varia-

tion of stress across the thickness for

the component plates 24 x 3

1

/. , in.

and 16 x 2 in. (Figs. 18 and 19)

remains from the cooling after rolling

of the base metal. T heoretical predic-

tions of cooling stresses in rolled

plates of a similar size show a dis-

tribution of stress through thickness of

the plate very close to that measured

in the center of these flame-cut

plates.

1:i

A lso, the variation across the

width for the center portion of the

plates appears to be influenced by the

initial stresses from the cooling after

rolling of the base metal plates.

If there were no initial stresses be-

fore flame-cutting of the plates, the

stress distribution in the center por-

tions of the plates would approximate

a plane, except for the heated and

yielded regions at the flame-cut edges,

where tensile stresses are introduced.

T he measured distributions, however,

show a variation across the plate

width of 10 ksi and 13 ksi for the

center portions of the 16 x 2 in. and

24 x V/., in. plates, respectively. T he

actual type of distribution in the cen-

ter of the plates, with higher compres-

sive stresses towards the edges, is con-

sistent with predictions of cooling

stresses in similar rolled plates.

VA

T his

means that the stresses in thick flame-

cut plates result from both the cooling

after rolling of the base metal and the

local heat input in the flame-cutting

process.

T hus, the residual stress distribution

in a fabricated member of thick com-

ponent plates generally is a complex

superimposed pattern resulting from

the different stages of manufacture

and fabrication procedures. T his is to

say that cooling residual stresses after

rolling, residual stresses from flame-

cutting as well as the welding residual

stress and any other procedure em-

ployed in the manufacture and fabri-

cation will influence the final residual

stress distribution in a heavy welded

.shape. However, since the welding

102-s MAR CH 1970

residual stresses in heavy welded

shapes are small, except in the weld

region, residual stresses in such shapes

may be predicted by determining the

initial stresses in the component plates

from existing data or from measure-

ments and estimating the additional

residual stresses due to welding. T his

is a further simplification of the

finding obtained previously for smaller

shapes that the residual stresses in a

welded shape can be predicted from a

knowledge of the residual stress dis-

tribution in the separate component

plates with simulated weld beads.

7

T he relationship between initial re-

sidual stresses in component plates and

welding residual stresses implies that

efforts to limit residual stresses in

heavy welded shapes should be direct-

ed towards the manufacture of the

component plates. T hus, by using

flame-cut plates in heavy welded

shapes, there is a prospect for an

increase in strength when compared

with lighter members at the same

slenderness ratio. On the other hand,

the column strength of heavy columns

made of universal-mill plates with as-

rolled edges may be lower, in particu-

lar for A 36 steel and at higher slen-

derness ratios.

16

For heavy welded columns made of

flame-cut plates, there is even a possi-

bility that such welded shapes may be

stronger than their rolled counter-

parts. Figure 25 shows the measured

distribution of residual stress in a

rolled shape 14W

r

426.

17

T he nomi-

nal strength characteristics of this

shape fall in between those of the two

welded shapes 15H290 and 23H681

studied here. T he stresses are very

high, of a similar distribution and

order of magnitude as in the welded

shape 15H290 made of universal-mill

plates.

T he favorable indications for the

strength of heavy welded columns

made of flame-cut plates is in contrast

with previously published results for

small and medium-size welded shapes

of universal-mill plates which proved

to be weaker than their rolled coun-

terparts.

6

However, since the present

basis for the implications on heavy

column strength is limited to the few

specimens studied, the statements are

preliminary; the general conclusions

will be developed further when the

current research program is com-

pleted.

Co nc l u s io ns

T he purpose of this study was to

investigate experimentally the magni-

tude and distribution of residual stress

in heavy column shapes built up by

welding plates with thickness in the

range of 1V

2

to 3V

2

in. T wo shapes

were investigateda 15H290 shape

and a 23H681 shape. For the smaller

shape comparative tests were conduct-

ed to study the influence of the manu-

facture of plates, weld type, and yield

strength of the material. T he speci-

mens referred to in this paper consti-

tute the first phase of a major re-

search program concerning residual

stresses in thick welded plates.

B ased on the results of this first

phase of the program, the following

conclusions can be stated:

Fi g. 22Two-d i me ns i ona l v a r i a t i on of r e s i d u a l s t r e s s i n a we l d e d shape 23H681flame-cut p l a t e s , A36 S t e e l ,

Va i n. fi l l e t we l d s

W E L DI N G R ES EAR CH S U P P L E M E N T ' 103-s

-20

KSI 0-

2 0 -

PLI0x' / 2 (UM)

- 4 0

-20'

KSI 0

20

40

60

-

^ ^ ^ ^ 5 ^ M*^ ^ D

- \ /

6 0 Gr oov e W e l d

- 40

- 2 0

KSI 0

20

40

60

-

Do u b l e V We l d

Fi g. 23R e s i d u a l s t r e s s e s i n a 10 x

1

/,

i n. u ni v e r s a l - mi l l p l a t e

1. T he residual stress distribution in

a fabricated member of thick com-

ponent plates generally is a complex

superimposed pattern resulting from

the different stages of manufacture

and fabrication proceduresthat is,

cooling residual stresses from the roll-

ing of the base plates, residual

stresses from flame-cutting the plates,

as well as the residual stresses from the

welding process, all influence the final

residual stress distribution in a welded

shape.

2. T he welding residual stresses in

portions of the cross section other

than the weld area tend to decrease

with increasing size of the member,

probably because the weld area, and

consequently, the heat input, is rela-

tively smaller in heavy plates and

shapes as compared to lighter mem-

bers.

3. T he results of comparative meas-

surements on 15H290 shapes indicate

that the weld type (penetration) is

not a major factor in the formation of

residual stresses in heavy plates and

shapes, as long as the heat input is not

drastically changed.

4. T he residual stress distributions

as measured in shapes of A S T M A 36

steel and of A 441 steel are similar,

indicating that the yield strength of

7H28

I0H 62

I2H79

I4H202

I5H290

23H68I

Stress Scale(ksi):

60 40 20 0 -20 -40

23H68I I5H290 I4H202

I2H79 I0H 62 7H28

Fi g. 24R e s i d u a l s t r e s s e s i n we l d e d H -s h a p e s of d i f f e r e nt ge ome t r y . Fl a me -cu t

p l a t e s , A36 S t e e l , f i l l e t we l d s . (R e s u l t s f or 12H 79 a nd 14H 202 s h a p e s f r om

McFa l l s a nd Ta l l

1

")

the steel has no great influence on

residual stresses in heavy shapes.

5. T he magnitude and distribution

of initial residual stresses depends

greatly on the manufacturing pro-

cedurethat is, universal-mill plates

or flame-cut plates.

6. T he geometry of the plates and

shapes is one of the major variables

affecting the residual stress distribu-

tion. More specifically, the residual

stresses will depend upon whether the

shape is light, medium-sized or heavy

(effect of size of cross section) or

whether the plates are narrow, medi-

um or wide (effect of width to thick-

ness ratio).

7. R esidual stresses due to cooling

after rolling of a plate normally are

compressive at the edges, balanced by

tension stresses in the center portion

of the plate. Measurements on four

welded H-shapes, 15H290, containing

universal-mill plates indicate that the

initial stresses in the flange plates are

very high. T his conforms to the obser-

vation made previously from the re-

sults of theoretical predictions that the

cooling residual stresses in rolled

plates tend to increase with increasing

size of the plate.

8. R esidual stresses due to flame-

cutting are in high tension at the

flame-cut edge due to the local heat

input. For the flame-cut plates

studied, the stress at the burned sur-

face is about 50% above the yield

point of the base metal. T he tensile

stresses are balanced by compression

in the center part of the plate; the

distribution of residual stresses in the

center of a heavy flame-cut plate is

dependent also on the initial stresses

due to rolling.

9. T he variation of residual stress

across the thickness of plates more

than 1 in. thick can be considerable.

S uch variation will result in a plate

with welds deposited on one side of

the plate; also, a significant difference

can be expected between stresses in

the surface and the interior of heavy

rolled plate components.

10. T he relationship between the

initial residual stresses in component

plates and the welding residual stresses

implies that the welding stresses in

thick welded plates and shapes are of

less importance than the initial stresses

existing prior to welding. Efforts to

limit residual stresses in heavy welded

shapes should be directed towards the

manufacture of the component plates.

11. S ince the welding residual

stresses in heavy welded shapes are

small, except in the weld region, resid-

ual stresses in such shapes may be

predicted by determining the initial

stresses in the component plates from

existing data or from measurements,

and estimating the additional residual

stresses due to welding. T his is a

further simplification of the finding

obtained previously for smaller shapes

that the residual stresses in a welded

shape can be predicted from a knowl-

edge of the residual stress distribution

in the separate component plates with

simulated weld beads.

7

Th e e f f e ct of r e s i d u a l s t r e s s e s on t h e

104-s M AR C H 19 70

load-carrying behavior and strength of

heavy columns will be discussed fur-

ther in the future paper.

16

Briefly, by

using flame-cut plates in heavy welded

shapes, there is a prospect for an

increase in strength when compared

with lighter members at the same

slenderness ratio. Under certain cir-

cumstances, there is even a possibility

that such welded shapes may be strong-

er than their rolled counterparts; this

is the opposite relationship as com-

pared to the situation for small and

medium-sized shapes. On the other

hand, heavy welded columns of uni-

versal-mill plates and A 36 steel are

expected to show a lower column

strength, especially for columns of a

medium to high slenderness ratio.

Acknowledgments

T his paper presents the results of an

experimental study of residual stresses

in heavy welded shapes. T he investiga-

tion is the first phase of a major

research program designed to deter-

mine the residual stresses in thick

welded plates and shapes and to relate

this to the stability under load of

compression members.

T he investigation was conducted at

Fritz Engineering Laboratory, Lehigh

University, B ethlehem, Pa. T he Na-

tional S cience Foundation sponsors

the current research program. A pilot

study, included in this paper, was part

of a project sponsored jointly by the

Pennsylvania Department of High-

ways, the B ureau of Public R oads of

the U. S. Department of C ommerce,

the C olumn R esearch C ouncil, the

A merican Institute of S teel C onstruc-

tion, and the A merican Iron and Steel

Institute. T he specimens were fabri-

cated by the B ethlehem S teel C orp. ,

and thanks are due to that corpora-

tion and its personnel who assisted in

the design and fabrication of the spec-

imens. T he guidance of T ask Group

1 of the C olumn R esearch C ouncil,

under the chairmanship of John A .

Gilligan, is gratefully acknowledged.

S pecial thanks are due to Lynn S.

B eedle, Director of Fritz Engineering

Laboratory, for his advice and en-

couragement throughout the program.

Fiorello R . Estuar and William C .

C ranston carried out the experiments

on the 15H290 shape and C harles R.

Nordquist assisted in the measure-

ments on the 23H681 shape and its

component plates. T heir assistance is

sincerely appreciated.

T hanks are also due to Kenneth R.

Harpel, laboratory foreman, and his

staff for the preparation of the test

specimens, to Mrs. S haron B alogh for

the preparation of the drawings, and

l 4W

r

426

.

) V

KSI

20 10 0 10 - 20 - 30

T T

Ne a r Su r fa c e

Far Su r fa c e

Fi g. 25Resi dual s t r e s s e s i n a h ot -r ol l e d shape 14\AF426, A7 s t e e l

to Miss Joanne Mies and Mrs. Linda

Welsch for their care in typing the

manuscript.

References

1. Huber . A . W. . and B eedle, L. S . .

"R esi dual S t resses and t he C ompressi ve

Pr oper t i es of S t eel , " WELDING JOUR NA L, 33

(12), R esearch S uppl . . 589-s to 614-s, (1954).

2. B eedle. L. S . , and T al l . L. . "B asi c

C ol umn S t r e ngt h, " T r ans . A S C E, Vol. 127,

Pa r t II, pp. 138 to 179, 1962.

3. Ni shi no, F. , Ueda. Y. , and T al l . L. ,

Exper i ment al Invest i gat i on of t he B uckl i ng

of Pl at es wi t h R esi dual S t resses, A S T M

S T P No. 419. " T e s t Met hods for C om-

pressi on T es t i ng, " A ugust 1967.

4. Ueda, Y. , and T al l , L. , "Inel ast i c

B uckl i ng of Pl at es wi t h R esi dual S t r es s es , "

Publ i cat i ons, Int er nat i onal A ssociation for

B r i dge and S t r uct ur al Engi neer i ng, Vol.

27. 1967.

5. Nagar aj aR ao. N. R . . and T all. L. .

"R esi dual S t r esses in Wel ded Pl at es . "

WELDING JOUR NA L, 40 (10), R esearch S uppl . ,

468-s to 480-s (1961).

6. Est uar , F. R . . and T al l . L. . "Exper i -

ment al Invest i gat i on of B ui l t -Up C ol umns. "

WELDING JOUR NA L. 42 (4), Ibid., 164-s to

176-s (1963).

7. Nagar aj aR ao, N. R . , Est uar , F. R . ,

and T al l , L. , "R esi dual S t resses in Wel ded

S hapes. WELDING JOUR NA L, 43 (7), Ibid.,

295-s to 396-s (1964).

8. A l pst en, G. A . , "R esi dual S t resses in

a Heavy Wel ded S hape 23H681, " Fr i t z

Labor at or y R epor t No. 337. 9, in pr epar a-

tion.

9. A l pst en. G. A . . "T hr ee- Di mensi onal

R esi dual S t resses and C ol umn S t r engt h, "

Fr i t z Labor at or y R epor t No. 337. 20, in

pr epar at i on.

10. Kal akout sky, N. , T he S t udy of In-

t ernal S t r esses in C ast Iron and S teel,

London. 1888.

11. Est uar , F. R . . "Wel di ng R esi dual

S t resses and t he S t r engt h of Heavy C ol umn

S hapes , " Ph. D. Di ssert at i on. Lehi gh Uni-

versi t y, A ug. 1966. (Uni versi t y Microfilms,

Inc. . A nn A rbor, Mi chi gan).

12. B rozzet t i . J. . and A l pst en. G. A . .

"A ccuracy of t he S ect i oni ng Met hod for

R esi dual S t ress Meas ur ement s , " Fr i t z Lab-

or at or y R epor t No. 337. 11. in pr epar at i on.

13. A l pst en, G. A . . " T her mal R esi dual

S t resses in Hot -R ol l ed S teel Member s. "

Fr i t z Labor at or y R epor t No. 337. 3, Decem-

ber, 1968.

14. Ki shi ma. Y. . A l pst en, G. A . , and

T al l , L. , "C ol umn S t r engt h of Wel ded

S hapes Usi ng Fl ame- C ut Pl at es . " Fr i t z Lab-

or at or y R epor t No. 321. 4. in pr epar at i on.

15. McFal l s, R . K. , and T al l , L. , "A

S t udv of Wel ded C ol umns Manufact ured

from" Fl ame- C ut Pl at es . " WELDING JOUR NA L,

48 (4), R esearch S uppl . , 141-s to 151-s

(1969).

16. A l pst en. G. A . , and T al l , L. , "C ol -

umn S t r engt h of Heavy S h a p e s - A Pr og-

r ess R epor t , " Fr i t z Labor at or y R epor t No.

337. 16. in pr epar at i on.

17. Fuj i t a, Y. , " T he Magni t ude and Dis-

t r i but i on of R esi dual S t r esses, " Fr i t z Lab-

or at or y R epor t No. 220A . 20, May, 1955.

W E L DI N G R ES EAR CH S U P P L E ME N T | 105-s

Das könnte Ihnen auch gefallen

- Fillet Weld Research Paper - For UndercuttingDokument7 SeitenFillet Weld Research Paper - For UndercuttingHemantNoch keine Bewertungen

- Residual Stresses in Thick Welded PlatesDokument14 SeitenResidual Stresses in Thick Welded Platesbhanu.kiranNoch keine Bewertungen

- CivilBay Steel Connection Brace ConnectionDokument12 SeitenCivilBay Steel Connection Brace ConnectionMichenerparkNoch keine Bewertungen

- 1 s2.0 S0143974X1730562X MainDokument19 Seiten1 s2.0 S0143974X1730562X MainMassimo LatourNoch keine Bewertungen

- A Fresh Look at Bolted End-Plate Behavior and Design - Krishnamurthy1978q2Dokument11 SeitenA Fresh Look at Bolted End-Plate Behavior and Design - Krishnamurthy1978q2mert_atasoyNoch keine Bewertungen

- Stress Intensifiyer in Tanks 01Dokument22 SeitenStress Intensifiyer in Tanks 01gechaves1Noch keine Bewertungen

- A Fresh Look at Bolted End Plate Behaviour and DesignDokument11 SeitenA Fresh Look at Bolted End Plate Behaviour and DesignSulaim Al KautsarNoch keine Bewertungen

- 34.sp1 02Dokument12 Seiten34.sp1 02Oraib AljaafrehNoch keine Bewertungen

- Design of Tension Circular Flange Joints in Tubular StructuresDokument9 SeitenDesign of Tension Circular Flange Joints in Tubular StructuresAnonymous tmRaHhNoch keine Bewertungen

- Test and Analysis of Reinforced Concrete Columns Strengthened With Polyester SheetDokument14 SeitenTest and Analysis of Reinforced Concrete Columns Strengthened With Polyester SheetRakesh Narayan SharmaNoch keine Bewertungen

- A Parametric Study On Inelastic Buckling in Steel Cylindrical Shells With Circular CutoutsDokument12 SeitenA Parametric Study On Inelastic Buckling in Steel Cylindrical Shells With Circular CutoutsChirag N PatelNoch keine Bewertungen

- Residual Stress of Cold Formed Thick Walled SteelDokument18 SeitenResidual Stress of Cold Formed Thick Walled SteelGhina UtamiNoch keine Bewertungen

- Welded Built-Up Columns, April 1966: Lehigh PreserveDokument95 SeitenWelded Built-Up Columns, April 1966: Lehigh PreservemohanNoch keine Bewertungen

- A Fresh Look at Bolted End - Plate Behavior and DesignDokument11 SeitenA Fresh Look at Bolted End - Plate Behavior and DesignBilly BobNoch keine Bewertungen

- Balser Thurlimann Plate Girder Part Literature ReviewDokument19 SeitenBalser Thurlimann Plate Girder Part Literature ReviewTAIYONG GUONoch keine Bewertungen

- Effects of patch loads on thin-walled steel silosDokument18 SeitenEffects of patch loads on thin-walled steel silosAnonymous wWOWz9UnWNoch keine Bewertungen

- Bryan : England. Printed in Great BritainDokument24 SeitenBryan : England. Printed in Great BritainSohini MishraNoch keine Bewertungen

- Local and Global Instabilities of Rolled T-Section Columns Under Axial CompressionDokument42 SeitenLocal and Global Instabilities of Rolled T-Section Columns Under Axial CompressionDavyNoch keine Bewertungen

- Imperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Dokument17 SeitenImperfection, Residual Stress and Yield Slenderness Limit of Very High Strength (VHS) Circular Steel Tubes, 2003 (H Jiao, X.-L Zhao)Phan Đào Hoàng HiệpNoch keine Bewertungen

- Numerical Estimation and Analysis of Effective Width of Composite Beams With Ribbed SlabDokument15 SeitenNumerical Estimation and Analysis of Effective Width of Composite Beams With Ribbed SlabInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Reinforced Concrete Curved Beams Literature ReviewDokument11 SeitenReinforced Concrete Curved Beams Literature ReviewDam HoangNoch keine Bewertungen

- Design Procedures For Extended Shear TabsDokument14 SeitenDesign Procedures For Extended Shear TabsCésar AlvaradoNoch keine Bewertungen

- Tests On Ultimate Strength of Hull Box Girders Made of High Tensile SteelDokument21 SeitenTests On Ultimate Strength of Hull Box Girders Made of High Tensile SteelvunhNoch keine Bewertungen

- Cracks As Important Constituents of Strut and Tie ModelsDokument20 SeitenCracks As Important Constituents of Strut and Tie ModelsBrandon LevineNoch keine Bewertungen

- Dented BeamDokument15 SeitenDented BeamjeacovjeceNoch keine Bewertungen

- Vol 1Dokument18 SeitenVol 1KmrnKhnNoch keine Bewertungen

- Augustin - A Contribution To The Design of Ribbed PlatesDokument10 SeitenAugustin - A Contribution To The Design of Ribbed Platesm2auNoch keine Bewertungen

- Residual Stresses in Welded Shapes of Flame-Cut Plates in Astm A5Dokument52 SeitenResidual Stresses in Welded Shapes of Flame-Cut Plates in Astm A5zhangjlNoch keine Bewertungen

- Design Criteria For Unified Strut and Tie Models: R.K.L.Su and A.M.ChandlerDokument31 SeitenDesign Criteria For Unified Strut and Tie Models: R.K.L.Su and A.M.ChandlerDereje bedoreNoch keine Bewertungen

- Stiffened Plates PDFDokument16 SeitenStiffened Plates PDFfarhadmrt6923Noch keine Bewertungen

- Behaviour and Strength of Composite Slabs With Ribbed DeckingDokument19 SeitenBehaviour and Strength of Composite Slabs With Ribbed DeckingRoberval PimentaNoch keine Bewertungen

- PAIK SNAME 2005 AM Paper by Paik Et Al, and Discussion (Rigo)Dokument41 SeitenPAIK SNAME 2005 AM Paper by Paik Et Al, and Discussion (Rigo)Kristopher OrlowskiNoch keine Bewertungen

- Holst 2000Dokument18 SeitenHolst 2000Thiago Lins CostaNoch keine Bewertungen

- Vailada Vinay 2015Dokument17 SeitenVailada Vinay 2015Rami Alraof AlaydiNoch keine Bewertungen

- 1 s2.0 S0143974X05000763 Main PDFDokument22 Seiten1 s2.0 S0143974X05000763 Main PDFMilmxmenNoch keine Bewertungen

- AISI Steel Plate Engineering Data-Volume 2-1992Dokument94 SeitenAISI Steel Plate Engineering Data-Volume 2-1992jcarbajal2013Noch keine Bewertungen

- Limit Analysi of Reinforced Concrete SlabsDokument122 SeitenLimit Analysi of Reinforced Concrete Slabssebastian9033100% (1)

- StressinCurvedCircularThinWallTubes PDFDokument2 SeitenStressinCurvedCircularThinWallTubes PDFskyerfreeNoch keine Bewertungen

- Nodal Regions) - A Selection of Strut-And-Tie Models For A Few Typical 2-D D-Regions Is IllustratedDokument9 SeitenNodal Regions) - A Selection of Strut-And-Tie Models For A Few Typical 2-D D-Regions Is IllustratedPrasanth NairNoch keine Bewertungen

- Member Stiffness and Contact Pressure Distribution of Bolted JointsDokument8 SeitenMember Stiffness and Contact Pressure Distribution of Bolted JointsreaderScribd9100% (1)

- Gusset StressDokument21 SeitenGusset StressSameera RaoNoch keine Bewertungen

- To Base Plates of Hollow Sections Columns: Conference PaperDokument9 SeitenTo Base Plates of Hollow Sections Columns: Conference PaperMisgun SamuelNoch keine Bewertungen

- Axial compression of metallic spherical shellsDokument21 SeitenAxial compression of metallic spherical shellsCuong NguyenNoch keine Bewertungen

- 10 1016@j Ijpvp 2005 10 003Dokument14 Seiten10 1016@j Ijpvp 2005 10 003Thiago Lins CostaNoch keine Bewertungen

- Punching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFDokument16 SeitenPunching Shear Strength of Reinforced Concrete Slabs Without Transverse Reinforcement by Aurelio Muttoni PDFNuttawuit BigGyNoch keine Bewertungen

- Plastic Buckling of Cylindrical Shells With CutoutDokument18 SeitenPlastic Buckling of Cylindrical Shells With CutoutVPN NetworkNoch keine Bewertungen

- Analysis of Compression of Hollow Circular Elastomeric Bearings 1992Dokument9 SeitenAnalysis of Compression of Hollow Circular Elastomeric Bearings 1992ciscoNoch keine Bewertungen

- 15-Performance of Concrete-Filled Thin-Walled Steel Tubes Under Pure Torsion 2007 PDFDokument13 Seiten15-Performance of Concrete-Filled Thin-Walled Steel Tubes Under Pure Torsion 2007 PDFHendrik TaupanNoch keine Bewertungen

- The Performance of A New Blind Bolt For Moment-Resisting ConnectionsDokument7 SeitenThe Performance of A New Blind Bolt For Moment-Resisting ConnectionsnurhishammNoch keine Bewertungen

- Dynamic Compression of Square Tube Cellular Structures: YAN Olloman Arthikeyan Andan Ikram Eshpande and Aydn AdleyDokument36 SeitenDynamic Compression of Square Tube Cellular Structures: YAN Olloman Arthikeyan Andan Ikram Eshpande and Aydn AdleyHaidarDiwantaraNoch keine Bewertungen

- Buckling of Stiffened Steel Plates - A Parametric Study: ArticleDokument26 SeitenBuckling of Stiffened Steel Plates - A Parametric Study: Articlekhudhayer1970Noch keine Bewertungen

- Flexibility Analysis of The Vessel-Piping Interface: Martin M. SchwarzDokument9 SeitenFlexibility Analysis of The Vessel-Piping Interface: Martin M. Schwarzgpskumar22Noch keine Bewertungen

- Bar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsDokument11 SeitenBar Pullout Tests and Seismic Tests of Small-Headed Barsin Beam-Column JointsProfessor Dr. Nabeel Al-Bayati-Consultant EngineerNoch keine Bewertungen

- CFT Subjected To Pure Bending, Elchalakani, 2001Dokument28 SeitenCFT Subjected To Pure Bending, Elchalakani, 2001Ryan FenyvesNoch keine Bewertungen

- Behavior and Analysis of Inverted T-Shaped RC Beams Under Shear and Torsion PDFDokument14 SeitenBehavior and Analysis of Inverted T-Shaped RC Beams Under Shear and Torsion PDFmfhfhfNoch keine Bewertungen

- Dimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyVon EverandDimensions, Weights and Properties of Special and Standard Structural Steel Shapes Manufactured by Bethlehem Steel CompanyNoch keine Bewertungen

- Mechanics of Sheet Metal FormingVon EverandMechanics of Sheet Metal FormingJack HuBewertung: 5 von 5 Sternen5/5 (3)

- Mechanics of Materials 2: The Mechanics of Elastic and Plastic Deformation of Solids and Structural MaterialsVon EverandMechanics of Materials 2: The Mechanics of Elastic and Plastic Deformation of Solids and Structural MaterialsBewertung: 4 von 5 Sternen4/5 (14)

- Composite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Von EverandComposite Steel and Concrete Structural Members: Composite Steel and Concrete Structures: Fundamental Behaviour (Second Edition)Bewertung: 4 von 5 Sternen4/5 (10)

- Measuring Boiler Efficiency - ASMEDokument8 SeitenMeasuring Boiler Efficiency - ASMEyvesdepermentier4622Noch keine Bewertungen

- CFBC Vs Pulverrised Coal Boilers - Good ArticleDokument7 SeitenCFBC Vs Pulverrised Coal Boilers - Good ArticleJeffrey MuellerNoch keine Bewertungen

- P&IDsDokument4 SeitenP&IDsRamadhan PrasetyaNoch keine Bewertungen

- CFBC Vs Pulverrised Coal Boilers - Good ArticleDokument7 SeitenCFBC Vs Pulverrised Coal Boilers - Good ArticleJeffrey MuellerNoch keine Bewertungen

- Research Article: Structural Strength and Reliability Analysis of Important Parts of Marine Diesel Engine TurbochargerDokument20 SeitenResearch Article: Structural Strength and Reliability Analysis of Important Parts of Marine Diesel Engine TurbochargerELIZA MARIA POPANoch keine Bewertungen

- Physics For Scientists and Engineers 6th Edition: CHAPTER 12Dokument22 SeitenPhysics For Scientists and Engineers 6th Edition: CHAPTER 12Fredy Arana Rodríguez100% (1)

- Accounting For Ductility and Overstrength in Seismic Design of Reinforced Concrete StructuresDokument4 SeitenAccounting For Ductility and Overstrength in Seismic Design of Reinforced Concrete StructuresHectoreRodriguezlNoch keine Bewertungen

- Ficha Técnica Conectores de TornilloDokument6 SeitenFicha Técnica Conectores de TornilloFernando Castillo HerreraNoch keine Bewertungen

- Mineral Wool Compressive PropertiesDokument10 SeitenMineral Wool Compressive Propertiespturner890Noch keine Bewertungen

- EC Kart Brake Mechanism DescriptionDokument19 SeitenEC Kart Brake Mechanism DescriptionUpender Rawat50% (2)

- Cesario Bacosa PDFDokument7 SeitenCesario Bacosa PDFAmanda SmithNoch keine Bewertungen

- Advance Staad by SarojDokument90 SeitenAdvance Staad by SarojSAROJ BISWAS100% (3)

- Rag H Vendra Paper VJ ItDokument16 SeitenRag H Vendra Paper VJ ItJollibee McdoNoch keine Bewertungen

- Visual Inspection of Main BearingDokument74 SeitenVisual Inspection of Main BearingDaniel AmanorNoch keine Bewertungen

- Strength of Material SugDokument8 SeitenStrength of Material Sugspraveen123Noch keine Bewertungen

- Hyper Static EffectsDokument13 SeitenHyper Static EffectsaiyubpatniNoch keine Bewertungen

- Series 2400 Fiberglass Pipe and Fittings: Using Key-Lock Mechanical Joint or Taper/ Taper Adhesive JointDokument7 SeitenSeries 2400 Fiberglass Pipe and Fittings: Using Key-Lock Mechanical Joint or Taper/ Taper Adhesive JointChristian UhreNoch keine Bewertungen

- Petrobras N-2409-A2Dokument88 SeitenPetrobras N-2409-A2traveller_16812847100% (4)

- ME010 701 Design of Machine Elements: Lecture NotesDokument37 SeitenME010 701 Design of Machine Elements: Lecture NotesDhanesh EswarNoch keine Bewertungen

- Bamboo Fibre Reinforced ConcreteDokument5 SeitenBamboo Fibre Reinforced ConcreteHaider KhanNoch keine Bewertungen

- (Alexander Mendelson) Plasticity Theory and ApplicationDokument183 Seiten(Alexander Mendelson) Plasticity Theory and ApplicationHariharan Krishnaswamy100% (1)

- PartB Vol2 2017Dokument192 SeitenPartB Vol2 2017djodje1Noch keine Bewertungen

- C CFS08Dokument68 SeitenC CFS08isaaaNoch keine Bewertungen

- Utilization of Water Hyacinth Ash in Creating Bio-TilesDokument41 SeitenUtilization of Water Hyacinth Ash in Creating Bio-TilesAdonah Mica ObenzaNoch keine Bewertungen

- Ada261900 1Dokument42 SeitenAda261900 1ksshashidharNoch keine Bewertungen

- Concrete 1 November 2022Dokument4 SeitenConcrete 1 November 2022Meverlyn Roquero100% (1)

- GSPC Gas Company Ball Valve Technical SpecificationDokument16 SeitenGSPC Gas Company Ball Valve Technical SpecificationAbhijit TumbreNoch keine Bewertungen

- High Strength ConcreteDokument6 SeitenHigh Strength ConcreteOnline AdoroNoch keine Bewertungen

- Bridge Repair by External Prestress: The Gibe Crossing in EthiopiaDokument6 SeitenBridge Repair by External Prestress: The Gibe Crossing in EthiopiaNasibSimamoraNoch keine Bewertungen

- International Journal of Mining Science and Technology: Jhon Silva, Tristan Worsey, Braden LuskDokument7 SeitenInternational Journal of Mining Science and Technology: Jhon Silva, Tristan Worsey, Braden LuskAshanti UtahelNoch keine Bewertungen

- POSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Dokument1 SeitePOSTER Characteristics Clay Brick Masonry Malang Indonesia 2009Murti WisnuNoch keine Bewertungen

- Chapter 6 - Fatigue FailuresDokument70 SeitenChapter 6 - Fatigue FailuresKanakNoch keine Bewertungen

- Data Collection and Rock Mass ClassificationDokument7 SeitenData Collection and Rock Mass ClassificationScott FosterNoch keine Bewertungen

- Campus Data BaseDokument77 SeitenCampus Data BaseFERNANDO JOSE NOVAESNoch keine Bewertungen