Beruflich Dokumente

Kultur Dokumente

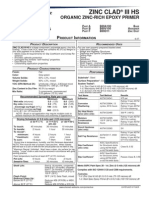

Description Packaging Product Data Sheet

Hochgeladen von

Ronald Fernandez Manubulu0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten2 SeitenARC 10

Originaltitel

ARC 10

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenARC 10

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten2 SeitenDescription Packaging Product Data Sheet

Hochgeladen von

Ronald Fernandez ManubuluARC 10

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Description

A reinforced composite for the repair and protection of metal surfaces. It is

machinable with excellent compressive strength, chemical resistance and

corrosion resistance. It is non-sagging, non-shrinking, and 100% solids.

Color is Grey.

The ARC 10 is formulated for applications where machining to exact

tolerances is required or desired. It is frequently used as an alternative to

resurfacing by welding or flame spraying.

ARC 10 is easily mixed and applied and cures without the need of heat or

pressure.

Composition - Polymer/Alloy Composite

Matrix - A two component, modified epoxy resin structure reacted with an

aliphatic curing agent.

Reinforcement - A proprietary blend of fine alloy particles and fibers

designed to achieve a machinable, corrosion resistant surface.

Suggested Uses

Condensers Bearing Housings

Cooling Water Pumps Shafts

Flange Faces Spline Repairs

Hydraulic Rams Pitted Castings

Keyways Heat Exchangers

Valve Bodies Pump Volutes

Benefits

High build characteristic allows for single coat applications

Tough resin structure resists thermal-mechanical shock.

Outstanding adhesion insures reliable performance.

Can be easily machined to exact tolerances.

Convenient 4-1 mix ratio and verification of mix by color change.

Performs well under fluctuating chemical environments.

Resists compression setting.

Packaging

Material is available in two package sizes: 250 g and 1 kg.

Each package contains pre-measured containers (Part A and Part B).

A mixing tool, applicator and application instructions are also included.

Chemical Resistance

Tested at 21C (70F). Samples cured 5 days at 25C (77F).

1 = Continuous long term immersion

2 = Short term/intermittent immersion

3 = Splash and spills with immediate cleanup, vapors

4 = Not recommended for direct contact

Acids

10%Hydrochloric 1

20%Hydrochloric 3

37%Hydrochloric 4

5%Nitric 3

10%Nitric 4

5%Phosphoric 1

20%Phosphoric 2

10%Sulfuric 1

20%Sulfuric 2

Alkalies & Bleaches

28%Ammonium Hydroxide 1

10%Potassium Hydroxide 1

50%Potassium Hydroxide 1

50%Sodium Hydroxide 1

10%Sodium Hydroxide 1

6%Sodium Hypochlorite 1

PRODUCT DATA SHEET

ARC 10

Technical Data

Cured Density ----------------- 2,0 g/cc 125 lb/ cu. ft.

Compressive Strength (ASTM D 695) 930 kg/cm

2

13,000 psi

Flexural Strength (ASTM D 790) 710 kg/cm

2

10,000 psi

Flexural Modulus (ASTM D 790) 3,6 x 10

4

kg/cm

2

5.1 x 10

5

psi

Tensile Strength (ASTM D 638) 280 kg/cm

2

4,000 psi

Taber Wear Weight Loss (ASTM D 4060) (H-18/250 g/1000 cycles) 275 mg

Composite Rockwell Hardness (ASTM D 785) R105

Composite Shore D Durometer Hardness (ASTM D 2240) 86

Vertical Sag Resistance

at 21C (70F) and 6 mm (1/4") ----------------- No sag

Maximum Temperature ----------------- Wet Service 66C 150F

(Dependent on service) ----------------- Dry Service 93C 200F

Other Compounds

Bunker C 1

Diesel Fuel 1

Isopropyl Alcohol 1

Kerosene 1

Naphtha 2

Salt Water 1

Sewage 1

Xylene 1

Toluene 1

Surface Preparation

Proper surface preparation is critical to the long term performance of this

product. The exact requirements for surface preparation will vary with the

severity of the application, expected service life, and the initial substrate

conditions.

Optimum preparation will provide a surface cleaned of all contaminants

and roughened to an angular profile between 75-125 microns (3 to 5 mils).

This is normally achieved by initial cleaning, abrasive blasting to a

cleanliness of White Metal (SA3/SSPC - SP5) or Near White Metal

(SA 2 1/2/SSPC SP10) followed by rinsing with an organic solvent which

evaporates leaving no film residue. Grinding to a rough surface profile, or

machining to a rough gramaphone cut, followed by rinsing with solvent is

acceptable although a subsequent lowering in adhesion may result.

Mixing

To facilitate mixing and application material temperatures should be

between 21-32C (70 - 90F). Each kit is packaged to the proper mix ratio.

If further proportioning is required the kit should be divided to the correct

mix ratio.

Mix Ratio By Weight

A:B 4:1

With the enclosed mixing tool, add Part B to Part A. Mix for 1 minute. Shift

a small portion of this mix back to Part B container and scrape the walls of

this container to remove all traces of residue. Transfer all material back to

Part A container and mix until the material is uniform in color and free of

streaks. Immediately apply.

Working Time - Minutes

10C 25C 43C

50F 77F 110F

250 g 75 40 25

1 kg 60 30 20

The chart above defines the practical working time of ARC 10, starting from when mixing begins.

Application

The ARC 10 is normally applied at a thickness between 3 mm - 9,5 mm

(1/8"- 3/8"), however it may be applied at a minimum thickness of 1,5 mm

(1/16"). Minimum application temperature is 10C (50F). Using a plastic

applicator or trowel press the material into the surface profile to completely

wet out the surface and build to the required thickness. Once the material

is placed it may be smoothed using a variety of methods. Always apply

and finish to desired contour within listed working times.

If required ARC 10 can be machined using a carbide tool bit once the

product has cured to Light Load as described below. In certain

applications requiring additional support where machining is not required it

may be advantageous to either weld expanded metal onto the surface

prior to preparing the surface or to impregnate nylon reinforcing mesh into

the composite while still wet.

The material may be overcoated with any of the ARC Polymer Composites.

If it has cured to the point of Light Load as described below, the surface

should be roughened and rinsed with an organic solvent prior to

topcoating. Prior to this point no additional surface preparation is required

provided that the surface has not been contaminated.

Coverage

Based on a 3 mm (1/8") thickness:

250 g kit will cover 417 cm

2

(61 in.

2

)

1 kg kit will cover 1667 cm

2

(244 in.

2

)

To calculate the kilograms required for a given application use the

appropriate formula below:

2,0 x Area (m

2

) x Average Thickness (mm) = kg or

4.7 x Area (ft

2

) x Average Thickness (inches) = kg

Curing Schedule

10C 16C 25C 32C

50F 60F 77F 90F

Tack Free 5 hrs 3 hrs 2 hrs 1 hr

Light Load 9 hrs 7 hrs 3.5 hrs 2.5 hrs

Full Load 48 hrs 36 hrs 20 hrs 16 hrs

Full Chemical 96 hrs 72 hrs 36 hrs 30 hrs

Clean Up

ARC 10 cures to a solid mass in a short period of time. All clean up

activities must be carried out as soon as possible to prevent material

hardening onto the tools. Use commercial solvents (Acetone, Xylene,

Alcohol, Methyl Ethyl Ketone) to clean tools immediately after use. Once

cured, the material would have to be abraded off.

Storage

Store between 10C (50F) and 32C (90F). Excursions beyond this range

which may occur during shipping, are acceptable. The shelf life is two

years in unopened containers.

Safety

Before using any product, review the appropriate Material Safety Data

Sheet (MSDS) or Safety Sheet for your area. Follow standard confined

space entry and work procedures, if appropriate.

Technical Data reflects results of laboratory tests and is intended to indicate general characteristics only. A.W. CHESTERTON CO. DISCLAIMS ALL WARRANTIES EXPRESSED, OR IMPLIED,

INCLUDING WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE OR USE . LIABILITY, IF ANY, IS LIMITED TO PRODUCT REPLACEMENT ONLY.

MIDDLESEX INDUSTRIAL PARK, 225 FALLON ROAD

STONEHAM, MASSACHUSETTS 02180-9101 USA

TEL: (617) 438-7000 FAX: (617) 438-8971 TELEX: 94-9417

CABLE: CHESTERTON STONEHAM, MASS.

A.W.CHESTERTON CO., 1996. All rights reserved.

Registered trademark owned and licensed by

A.W.CHESTERTON CO. in USA and other countries. FORM NO. E77011 REV. 5/96

Das könnte Ihnen auch gefallen

- Corrosion and Fouling Control in Desalination IndustryVon EverandCorrosion and Fouling Control in Desalination IndustryNoch keine Bewertungen

- Packaging Product Data Sheet DescriptionDokument2 SeitenPackaging Product Data Sheet DescriptionRonald Fernandez ManubuluNoch keine Bewertungen

- Devcon Plastic Steel Putty (A) - TDSDokument3 SeitenDevcon Plastic Steel Putty (A) - TDSsibi_s_raj100% (2)

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesVon EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNoch keine Bewertungen

- 201 Ceramic Paste Tds rv1 PDFDokument3 Seiten201 Ceramic Paste Tds rv1 PDFAzril DahariNoch keine Bewertungen

- Plastic Steel Putty - Materijal Za IspunuDokument2 SeitenPlastic Steel Putty - Materijal Za Ispunudavorp1402Noch keine Bewertungen

- Carbo Guard 893 SGDokument2 SeitenCarbo Guard 893 SGsuzilamatsallehNoch keine Bewertungen

- Plastic Steel Putty (A) : Technical Data SheetDokument3 SeitenPlastic Steel Putty (A) : Technical Data SheetsanjayNoch keine Bewertungen

- 3M2216Dokument8 Seiten3M2216pat_kunal1601Noch keine Bewertungen

- Devcon Plastic Putty A PDFDokument2 SeitenDevcon Plastic Putty A PDFbollidNoch keine Bewertungen

- Plastic Steel 5 Minute PuttyDokument3 SeitenPlastic Steel 5 Minute PuttyDivyanshu GuptaNoch keine Bewertungen

- Plasite 7159 PDS 1-07 PDFDokument2 SeitenPlasite 7159 PDS 1-07 PDFFabricio Jiménez TNoch keine Bewertungen

- Coal Tar PDFDokument4 SeitenCoal Tar PDFMohammadreza AsheghNoch keine Bewertungen

- Carbo Zinc 11 HsDokument2 SeitenCarbo Zinc 11 Hstyto_rmzNoch keine Bewertungen

- Amercoat 68sDokument3 SeitenAmercoat 68smevansmetreelNoch keine Bewertungen

- Carboguard 890 PDSDokument2 SeitenCarboguard 890 PDSLinnie McleodNoch keine Bewertungen

- Plasite 9133 Product Data SheetDokument3 SeitenPlasite 9133 Product Data SheetChris StroudNoch keine Bewertungen

- Carbothane+134+HG+PDS+3 11Dokument2 SeitenCarbothane+134+HG+PDS+3 11James Everett AbdulNoch keine Bewertungen

- Interseal 670 HSDokument4 SeitenInterseal 670 HSSyawaluddin Fitri AwangNoch keine Bewertungen

- Titanium Putty HPDokument2 SeitenTitanium Putty HPDivyanshu GuptaNoch keine Bewertungen

- Devoe Coatings - Bar Rust 231 - Data SheetDokument4 SeitenDevoe Coatings - Bar Rust 231 - Data SheetAnonymous rKklA4yNoch keine Bewertungen

- 7) PPG Amercoat 385 - Pds - AiDokument4 Seiten7) PPG Amercoat 385 - Pds - AididbeauNoch keine Bewertungen

- Interplus 1180: Protective CoatingsDokument4 SeitenInterplus 1180: Protective CoatingsAnindya Aulia PratiwiNoch keine Bewertungen

- Acrolon 218 HSDokument4 SeitenAcrolon 218 HSAndres MoralesNoch keine Bewertungen

- Interseal 670 HS EN O-FDokument4 SeitenInterseal 670 HS EN O-Fapde06Noch keine Bewertungen

- TL425Dokument2 SeitenTL425Sajeesh KrishnanNoch keine Bewertungen

- Chersterton Arc 982 PDFDokument2 SeitenChersterton Arc 982 PDFMohamed Nouzer100% (1)

- Carbomastic 15 PDS 2013Dokument2 SeitenCarbomastic 15 PDS 20134508366279Noch keine Bewertungen

- Ceramic Repair Putty: Technical Data SheetDokument2 SeitenCeramic Repair Putty: Technical Data SheetNiku SamarthNoch keine Bewertungen

- Plastic Steel Putty A v3Dokument2 SeitenPlastic Steel Putty A v3feri.ferdianto02Noch keine Bewertungen

- 323 Data Sheet and Application GuideDokument4 Seiten323 Data Sheet and Application Guidejast111Noch keine Bewertungen

- Physical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRDokument1 SeitePhysical Properties: % of Initial Strength Environment °C 100 HR 500 HR 1000 HRAlberto GutierrezNoch keine Bewertungen

- Amercoat® 385: Product Data SheetDokument8 SeitenAmercoat® 385: Product Data SheetSampath GaneshNoch keine Bewertungen

- X-Roc Epoxybond: Technical Data SheetDokument2 SeitenX-Roc Epoxybond: Technical Data SheetJanaka Dinesh100% (1)

- Carboguard 635 Thinned 50% - Sealer PDSDokument5 SeitenCarboguard 635 Thinned 50% - Sealer PDSjakeNoch keine Bewertungen

- Interline 850Dokument4 SeitenInterline 850shameelNoch keine Bewertungen

- Technical Data Sheet: Resichem 506 AluprimeDokument2 SeitenTechnical Data Sheet: Resichem 506 AluprimeTechnicalproducts 02 Indo Riau PerkasaNoch keine Bewertungen

- Stainless Steel Putty (ST) : Technical Data SheetDokument2 SeitenStainless Steel Putty (ST) : Technical Data SheetSreenivasNoch keine Bewertungen

- Floor Patch Fast CureDokument2 SeitenFloor Patch Fast CureStevenFerrelNoch keine Bewertungen

- Sonocrete - Gel PatchDokument4 SeitenSonocrete - Gel PatchOgbedande Awo OrunmilaNoch keine Bewertungen

- CLADLINER TDS October 2017Dokument2 SeitenCLADLINER TDS October 2017LuisSantiagoNoch keine Bewertungen

- Carboguard 89dfsfs0 PDSDokument2 SeitenCarboguard 89dfsfs0 PDSMayur PatelNoch keine Bewertungen

- Amercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsDokument4 SeitenAmercoat 391PC: Solvent Free Epoxy Product Data/ Application InstructionsAchraf BoudayaNoch keine Bewertungen

- Duraplate Uhs EnglishDokument4 SeitenDuraplate Uhs EnglishLuis JaraNoch keine Bewertungen

- Pds Ipd Sikafast3121 Us MW 3.22.12Dokument4 SeitenPds Ipd Sikafast3121 Us MW 3.22.12robox514Noch keine Bewertungen

- Araldite 2011Dokument2 SeitenAraldite 2011nrd9771Noch keine Bewertungen

- Chembloc Series 239Sc: Product ProfileDokument2 SeitenChembloc Series 239Sc: Product ProfileSky MoonNoch keine Bewertungen

- Flexane 80 CompoundDokument3 SeitenFlexane 80 Compoundabh_omegaNoch keine Bewertungen

- Interbond 808Dokument4 SeitenInterbond 808shameelNoch keine Bewertungen

- Carboguard 635: Selection & Specification DataDokument5 SeitenCarboguard 635: Selection & Specification DataPrakashNoch keine Bewertungen

- Zinc Clad IIIDokument4 SeitenZinc Clad IIIScott Van PeltNoch keine Bewertungen

- Brushable Ceramic Red BlueDokument2 SeitenBrushable Ceramic Red BlueWildor Cordova SanchezNoch keine Bewertungen

- Ceram Kote 54 SF - ARAMCO ApprovedDokument1 SeiteCeram Kote 54 SF - ARAMCO ApprovedSherif AbdelhameedNoch keine Bewertungen

- Icosit KC 330-2MDokument4 SeitenIcosit KC 330-2MNelu IvascuNoch keine Bewertungen

- Bronze Putty: Technical Data SheetDokument2 SeitenBronze Putty: Technical Data SheetSharad ShahNoch keine Bewertungen

- Carbocoat 8215 PDS 6-10Dokument2 SeitenCarbocoat 8215 PDS 6-10Mayur PatelNoch keine Bewertungen

- Amercoat 370Dokument3 SeitenAmercoat 370Victor Hugo Bustos Beltran100% (1)

- Carbozinc 11 PDS-MarineDokument2 SeitenCarbozinc 11 PDS-MarineJulie WillisNoch keine Bewertungen

- Amercoat® 385: Product Data SheetDokument8 SeitenAmercoat® 385: Product Data SheetNizar BouchaalaNoch keine Bewertungen

- Plate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumDokument1 SeitePlate Heat Exchanger Model M15-MFG - ASTM B265 Gr1 TitaniumCardoso MalacaoNoch keine Bewertungen

- FastenersDokument178 SeitenFastenersthulasi_krishna100% (6)

- TB 74CalculatingK 61d7cfd881b4c0.61d7cfdacfb339.69790737Dokument15 SeitenTB 74CalculatingK 61d7cfd881b4c0.61d7cfdacfb339.69790737任思诗Noch keine Bewertungen

- Solubility CurveDokument2 SeitenSolubility CurveDanni SulaimanNoch keine Bewertungen

- Fire HazardDokument65 SeitenFire HazardRohit Sharma75% (4)

- Doosan Mitsubishi 2.4L - Product Overview Training PDFDokument105 SeitenDoosan Mitsubishi 2.4L - Product Overview Training PDFkhairul100% (1)

- Fuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andDokument44 SeitenFuels and Combustion: - Calorific Value - Significance and Comparison Between LCV andanurag prernaNoch keine Bewertungen

- CO Storage: 20 ASCO ISO Tank ContainersDokument5 SeitenCO Storage: 20 ASCO ISO Tank ContainersMB ManyauNoch keine Bewertungen

- Microencapsulation by Spray Drying of Lannea Microcarpa Extract: Technological Characteristics and Antioxidant ActivityDokument10 SeitenMicroencapsulation by Spray Drying of Lannea Microcarpa Extract: Technological Characteristics and Antioxidant ActivityJournal of Pharmacy & Pharmacognosy ResearchNoch keine Bewertungen

- Periodic Classification of ElementsDokument101 SeitenPeriodic Classification of Elementsmrpulkit20Noch keine Bewertungen

- NSS Chemistry Part 2 The Microscopic World HKCEE Past Paper Question The Microscopic World I Ns - Multiple Choice QuestionsDokument32 SeitenNSS Chemistry Part 2 The Microscopic World HKCEE Past Paper Question The Microscopic World I Ns - Multiple Choice QuestionsミーチェルNoch keine Bewertungen

- Welding SymbolsDokument53 SeitenWelding SymbolsLâm Thanh100% (9)

- Fertilizer Subsidieswhich Way Forward 2 21 2017 PDFDokument327 SeitenFertilizer Subsidieswhich Way Forward 2 21 2017 PDFsharemwNoch keine Bewertungen

- AlkalinityDokument33 SeitenAlkalinityAinunNoch keine Bewertungen

- Final Key WednesdayDokument7 SeitenFinal Key WednesdayThanh LêNoch keine Bewertungen

- MRU Optima 7 BrochuresDokument3 SeitenMRU Optima 7 BrochureshaizriNoch keine Bewertungen

- Active Matter in Anionic Surfactants by Potentiometric TitrationDokument4 SeitenActive Matter in Anionic Surfactants by Potentiometric Titrationmkaseem74Noch keine Bewertungen

- Design and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsDokument5 SeitenDesign and Analysis of Gas Turbine Combustion Chamber For Producer Gas AsPhạm Công ÁnhNoch keine Bewertungen

- Activated Carbon From Corn CobDokument7 SeitenActivated Carbon From Corn CobJhen DangatNoch keine Bewertungen

- Project Report On Wire RodDokument9 SeitenProject Report On Wire RodEIRI Board of Consultants and Publishers100% (1)

- Mitsubishi Forklift 2020 Fd25 Operation Maintenance Service Manual enDokument23 SeitenMitsubishi Forklift 2020 Fd25 Operation Maintenance Service Manual enteresataylor130203xqo100% (31)

- Engineering ChemistryDokument60 SeitenEngineering ChemistryAditya ShindeNoch keine Bewertungen

- Pompa WarmanDokument2 SeitenPompa WarmanRahmad Saleh SiregarNoch keine Bewertungen

- MasoneilanDokument20 SeitenMasoneilanJohn MarshalNoch keine Bewertungen

- Molecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineDokument7 SeitenMolecules: Synthesis and Bioactivity of A-Aminophosphonates Containing FluorineThomas CharmNoch keine Bewertungen

- BIOCHEMDokument3 SeitenBIOCHEMLeighRence BaltazarNoch keine Bewertungen

- Igat6 D PL Me SPC 0007 01 Spec For Barred TeeDokument9 SeitenIgat6 D PL Me SPC 0007 01 Spec For Barred Teeamini_mohi100% (1)

- Home Made Soap: Using Glitz Caustic SodaDokument1 SeiteHome Made Soap: Using Glitz Caustic Sodaabeiasa_biomedNoch keine Bewertungen

- (Lertffi Y: (Typ - I) Iffi "Eq0Dokument6 Seiten(Lertffi Y: (Typ - I) Iffi "Eq0supremeNoch keine Bewertungen

- CorrosionDokument9 SeitenCorrosionhesampirNoch keine Bewertungen

- Periodic Tales: A Cultural History of the Elements, from Arsenic to ZincVon EverandPeriodic Tales: A Cultural History of the Elements, from Arsenic to ZincBewertung: 3.5 von 5 Sternen3.5/5 (137)

- The Rise and Fall of the Dinosaurs: A New History of a Lost WorldVon EverandThe Rise and Fall of the Dinosaurs: A New History of a Lost WorldBewertung: 4 von 5 Sternen4/5 (597)

- Alex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessVon EverandAlex & Me: How a Scientist and a Parrot Discovered a Hidden World of Animal Intelligence—and Formed a Deep Bond in the ProcessNoch keine Bewertungen

- Dark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseVon EverandDark Matter and the Dinosaurs: The Astounding Interconnectedness of the UniverseBewertung: 3.5 von 5 Sternen3.5/5 (69)

- The Best American Science And Nature Writing 2021Von EverandThe Best American Science And Nature Writing 2021Bewertung: 4 von 5 Sternen4/5 (8)

- Fire Season: Field Notes from a Wilderness LookoutVon EverandFire Season: Field Notes from a Wilderness LookoutBewertung: 4 von 5 Sternen4/5 (142)

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingVon EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingBewertung: 5 von 5 Sternen5/5 (5)

- The Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionVon EverandThe Ancestor's Tale: A Pilgrimage to the Dawn of EvolutionBewertung: 4 von 5 Sternen4/5 (812)

- When You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsVon EverandWhen You Find Out the World Is Against You: And Other Funny Memories About Awful MomentsBewertung: 3.5 von 5 Sternen3.5/5 (13)

- Remnants of Ancient Life: The New Science of Old FossilsVon EverandRemnants of Ancient Life: The New Science of Old FossilsBewertung: 3 von 5 Sternen3/5 (3)

- The Lives of Bees: The Untold Story of the Honey Bee in the WildVon EverandThe Lives of Bees: The Untold Story of the Honey Bee in the WildBewertung: 4.5 von 5 Sternen4.5/5 (44)

- The Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorVon EverandThe Revolutionary Genius of Plants: A New Understanding of Plant Intelligence and BehaviorBewertung: 4.5 von 5 Sternen4.5/5 (137)

- The Other End of the Leash: Why We Do What We Do Around DogsVon EverandThe Other End of the Leash: Why We Do What We Do Around DogsBewertung: 5 von 5 Sternen5/5 (65)

- Come Back, Como: Winning the Heart of a Reluctant DogVon EverandCome Back, Como: Winning the Heart of a Reluctant DogBewertung: 3.5 von 5 Sternen3.5/5 (10)

- World of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsVon EverandWorld of Wonders: In Praise of Fireflies, Whale Sharks, and Other AstonishmentsBewertung: 4 von 5 Sternen4/5 (223)

- The Hidden Life of Trees: What They Feel, How They CommunicateVon EverandThe Hidden Life of Trees: What They Feel, How They CommunicateBewertung: 4 von 5 Sternen4/5 (1003)

- The Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessVon EverandThe Soul of an Octopus: A Surprising Exploration into the Wonder of ConsciousnessBewertung: 4.5 von 5 Sternen4.5/5 (254)

- Spoiled Rotten America: Outrages of Everyday LifeVon EverandSpoiled Rotten America: Outrages of Everyday LifeBewertung: 3 von 5 Sternen3/5 (19)

- Darwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignVon EverandDarwin's Doubt: The Explosive Origin of Animal Life and the Case for Intelligent DesignBewertung: 4 von 5 Sternen4/5 (19)

- Ernst Haeckel's Art Forms in Nature: A Visual Masterpiece of the Natural WorldVon EverandErnst Haeckel's Art Forms in Nature: A Visual Masterpiece of the Natural WorldNoch keine Bewertungen

- Roxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingVon EverandRoxane Gay & Everand Originals: My Year of Psychedelics: Lessons on Better LivingBewertung: 3.5 von 5 Sternen3.5/5 (35)

- Microscopy of Numerology: Numerology SimplifiedVon EverandMicroscopy of Numerology: Numerology SimplifiedBewertung: 5 von 5 Sternen5/5 (2)