Beruflich Dokumente

Kultur Dokumente

Horizontal Boilers Make 700C Steam Economic

Hochgeladen von

Krishnan Santhanaraj100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

91 Ansichten5 SeitenHORIZONTAL BOILERS

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenHORIZONTAL BOILERS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

91 Ansichten5 SeitenHorizontal Boilers Make 700C Steam Economic

Hochgeladen von

Krishnan SanthanarajHORIZONTAL BOILERS

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

Operating_Experience.fh8 09.04.

2001 8:17 Uhr Seite 1

Probedruck

C M Y CM MY CY CMY K

Coal Fi red Pl ant s:

Hori zont al Boi l ers Make 70 0C St eam Economi c

COMMUNICATING POWER TECHNOLOGY WORLDWIDE

Reprint from

ModernPowerSystems

Power for Generations Siemens Power Generation

Author:

David Smith

I

n a world of rapidly advancing deregu-

lation, it has become increasingly diffi-

cult for coal fired power generation to

compete. Now the pendulum may be

beginning to swing back.

It is not just the forecast of a doubling in

natural gas prices in the next three years that

is driving this trend. Under the influence of

stringent political regulatory regimes, unsta-

ble gas prices, the prospect of heavy emissions

trading costs, carbon taxes and the response

to Kyoto, interest in advanced coal fired gen-

eration technology is enjoying a resurgence.

Often dismissed by many senior pundits as

having little prospect of economic viability in

the foreseeable future, ultra supercritical coal

fired utility boilers to generate steam at over

700C and 350 bar is beginning to be more

vigorously pursued, particularly in Europe,

and in Germany and Denmark in particular.

The main hurdle in the past has been the

horrendously high cost of the high nickel al-

loys needed to withstand these temperatures

and pressures. However, new designs of boil-

er using a horizontal furnace configuration

have now been developed by Benson licensor

Siemens that greatly reduce the impact of the

cost of high nickel alloys (see Figure 1). The

concept has been developed in the context of

a study of future advanced coal fired plants

with ultracritical steam conditions.

Development work has been underway on

horizontal furnace boiler technology for some

years. In the medium term, a demonstration

plant incorporating the new boiler, working

at current state of the art conditions, could

prove the viability of the design. A fully de-

veloped ultra supercritical version could start

operation in 2010.

Horizontal vertical tube boilers

There is nothing new about vertical tube

Benson boilers from as early as 1930 up to

the mid 1960s the use of vertical tubes with

refractory linings was the popular design ap-

proach. Since then the furnace tubing has gen-

erally been configured in a spiral

configuration with the tubes welded togeth-

er to form membrane walls.

Various concepts for using vertical tubes in

the form of membrane walls were developed

in the USA in the late 1950s. The main prob-

lem with this arrangement was achieving ad-

equate cooling of all of the tubes under a wide

range of load conditions. The use of high mass

flow densities was the generally adopted so-

lution.

In the 1980s Sulzer developed a concept

that used internally ribbed tubing which has

been used in the 2 x 700 MWe gas fired power

plant at the Kawagoe site and the Matsuura

700 MWe coal fired plant in Japan.

Full load mass flow density in the tubes for

this design of boiler is in the range 16002000

kg/m

2

s.

To accommodate temperature

variations that would occur at the

evaporator outlet due to differ-

ences in heat input conditions,

tubes expected to be subject to

insufficient heat input are fitted

with flow restrictors. But rather

than assume complete evapora-

tion in the furnace, a convection

evaporator section is added for

completion of the evaporation process.

Siemens has been conducting experimen-

tal research into heat transfer and flow con-

ditions in such tubes for some years in a high

pressure test loop in Erlangen, and many re-

ports have been published by Joachim Franke,

Rudolf Kral and his colleagues over the last

decade. They have produced an extensive

database which shows that the heat transfer

is highly sensitive to changes in internal rifling

rib geometry.

Heat transfer in a rifled (also called ribbed)

tube (Figure 2) is exceptionally good, espe-

cially during evaporation. This is because cen-

trifugal force transports the water fraction of

the wet steam to the tube wall. The resulting

A novel design of Benson boiler with horizontal furnace and internally rifled vertical tubes has been developed by

Siemens. In association with the EU-funded Thermie advanced 700C PF power plant programme it has been

designed for steam conditions of 350 bar/700C/720C. The reduced height of the boiler minimises the amount of

expensive high nickel alloys required for the steam lines to a point where the economics are competitive. Mounting

the steam turbine at the level of the boiler steam outlet headers results in further cost reductions.

Horizontal boilers make

700C steam economic

Figure 1. Layout of the

new horizontal furnace

boiler, with vertical tubes.

Note the vortex burners

located on the front of the

furnace

Figure 2. Internally

rifled tube

David Smith

1000

980

960

940

920

900

880

860

840

820

800

0.40

0.38

0.36

0.34

0.32

0.30

0.28

0.26

0.24

0.22

0.20

Middle tube

(with burner)

Middle tube

(without burner)

Corner tube

Mass flux m (kg/m

2

s) Relative heat input (q

n

/q

o

)

q

n

/q

o = 1

.

.

m

q

1

/q

o

q

2

/q

o

q

3

/q

o

Figure 3. Typical measurements on a supercritical

boiler with vertical rifled-tube water walls, showing

the relatiuonship between heat input and mass flux.

May 2000 Modern Power Systems 37

May 2000 Modern Power Systems 39

wall wetting causes excellent heat transfer

from the wall to the fluid. This has the fol-

lowing advantages over smooth tubes:

G No deterioration of heat transfer even in

the range of high steam quality

G Very good heat transfer even at low mass

flux

G Only slight increase in wall temperature in

case of film boiling near critical pressure

(interval from about 200 bar to critical

pressure)

G Potential for increased heat transfer by op-

timisation of rifling geometry.

The low mass flux design not only enables

downward extension of the output limits for

vertical tubes to 300 or 200 MW and use of

large-diameter tubes, but in particular it also

changes the flow characteristic of a once-

through system: with increased heating of an

individual tube, the throughput of that tube

increases instead of decreasing.

In a rifled tube, the boiling crisis does not

take place until steam quality is less than 0.9

shortly before the end of evaporation due to

the swirl flow generated by the spiral ribs in-

side the tubes. Differences in centrifugal force

separate the water from the steam fraction and

force the water towards the tube wall. This

maintains wetting up to high steam quality lev-

els, resulting in high flow velocities even at

the boiling crisis location.

The main advantages of vertical internally

rifled tubes in a Benson boiler can be sum-

marised as:

G Reduced mass flow, from 2000 to 1000

kg/s, with flow characteristics as in drum

boilers, ie increased heat input to an indi

vidual tube increases throughput in that

tube (as shown in Figure 3).

G Cost effective fabrication and assembly

G Minimum Benson output can be as low as

20 per cent.

G Simple start up system for 20 per cent

evaporator throughput

G Reduced slagging on combustion chamber

walls.

Siemens, Babcock Lentjes

Kraftwerkstechnik and Steinmller carried

out large scale testing in a rig installed in

PreussenElektras supercritical 320 MWe

Farge coal fired power plant in 1993 which

served to verify the experimental results and

yield input to design codes for a new vertical

tube Benson boiler concept.

The theoretical conclusions for this con-

cept regarding pressure drop and thus for flow

distribution with non-uniform heating were

tested in practice in the Farge plant. It was im-

portant to achieve the physical height which

is significant for a natural circulation charac-

teristic but which cannot be attained in labo-

ratory operation. A furnace heat exchange

surface with the low mass flux design was in

trouble-free operation at the Farge plant for

more than 10 000 hours. This confirmed the

calculation fundamentals and at the end of

trial operation the tubes were still practically

as good as new, the rib profile not smoothed

by deposits.

Heat transfer measurements were not per-

formed in Farge, as important factors such as

heating and the thickness of the insulating ash

layer on the tubes vary constantly, preventing

reliable, reproducible measurement results.

But the low mass flux design with its opti-

mised internally rifles tubes has even greater

benefits when applied to the low profile hor-

izontal furnace boiler configuration.

The thermohydraulic principles of low

mass flux design have already been proven in

commercial operation in the horizontal

Benson heat recovery steam generator used in

Siemens most advanced V94.3A gas turbine

combined cycle field development plant, at

Cottam, UK (see MPS, September 1999, pp

40-43), shown in Figure 4.

The parallel tubes of the evaporator for the

HP and IP stages arranged sequentially in the

exhaust flow path are characterised by ex-

tremely different heat uptakes. In the select-

ed concept, mass flows automatically adjust

to the heat input ie all parallel tubes of the HP

evaporator show saturation temperature at

first pass outlet and low temperature differ-

ences between the rows of the second pass

(Figure 5). The thermoelastic construction of

the Benson boiler significantly increases flex-

ibility of the com-

bined-cycle power

plant over that of a

drum boiler, espe-

cially during start-

up.

One third of

the height

Figures 1 and 6

show the schemat-

ic layout of the hor-

izontal coal fired

boiler for which

very considerable

cost reductions are

claimed, particular-

31m

63m

91m

Tower Two pass Horizontal

Figure 5. Mass flow distribution, steam quality and temperatures in the HRSG for the Cottam combined cycle plant

Figure 6. Size comparison

of coal fired boilers for

550 MW output

Figure 7. The modular design of the boiler lends itself to variations in output rating

Figure 4. Cottam, UK, uses a horizontal HRSG

ly for the most highly supercritical power

plants. Such boilers will have a height of little

more than 30 m.

Typical turbine plinth levels today are

around 16 m high. But with the new hori-

zontal furnace there is the possibility of rais-

ing the turbine floor level to the boiler main

steam outlet pipe level, ie to about about 30

m above datum, to minimise superheated

steam pipe length and complexity. Power

plant designs being developed with the hori-

zontal furnace boiler combined with

Siemens new four-stage turbine have this con-

figuration.

The main advantages of the low-profile boil-

er configuration are obvious:

G Reduced structural steelwork costs.

G Simplified installation.

G Installation time is reduced as the furnace,

lateral pass and vertical pass can be in-

stalled in parallel, which also reduces in-

terest during construction.

G The steam lines between the boiler and

turbine are shorter and more direct.

G All of the burners are mounted on one

side of the combustion chamber.

G The modular design of the boiler lends it-

self to variations in output rating a 700

MWe version can be put together with

dual furnace sections to make a 700 MWe

unit with twice the width but the same

height as a 350 MWe unit (see Figure 7).

Whereas with more conventional steam

conditions the superheated steam lines ac-

count for some 3 per cent of the power plant

costs (see Figure 8), this number increases to

about 15 per cent in plants with steam tem-

peratures of 700 C (using Ni base alloys and

state of the art power block design). But with

the compact horizontal furnace boiler the fig-

ure decreases once again to around 3 per cent.

This is because with the horizontal furnace

boiler the length of pipes is reduced to 20 per

cent of that in the conventional design.

Also, in the horizontal furnace boiler, the

convection section with the horizontal and

vertical passes is located downstream of the

horizontal furnace, and is largely identical

with proven two-pass boilers (see Figures 1

and 6).

Materials

Increasingly purposeful negotiations have re-

cently been held between nickel alloy suppli-

er Inco and the 40 strong members of the

Thermie 700 project, which include all of the

boiler makers in Europe, many utilities and

manufacturing concerns.

Significantly, other German

utilities and the power plant

operators association VGB

are expecting to join the

group before long.

It seems that the projected

cost of the high nickel alloys needed to han-

dle the 700 C steam is now down to around

10 x the cost of present P91 and P92 materi-

als instead of the 40 x figure recently mooted.

The new boiler layout clearly reduces the

amount of High Nickel Alloy 617 in the su-

perheated steam pipes, but thick castings in

this material are still needed for the high pres-

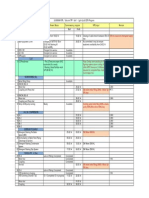

sure turbine casings. Table 1 indicates the pro-

gression of high temperature steam system

alloy applications to date.

Four-stage turbine

As already mentioned, the turbine envisaged

for use with the horizontal furnace boiler has

four stages: HP1, HP2, IP and LP (see Figure

9). The design takes into account the high

costs of nickel-based alloys and the need to re-

strict component weights. Accordingly, the

HP cylinder is split into separate HP1 and HP2

cylinders. The HP1 cylinder includes parts

made of nickel-based alloys and is designed to

be very compact. The HP1 exhaust steam

flows directly into the HP2 cylinder, which

can be designed for moderate steam condi-

tions and thus manufactured from conven-

tional materials, eg cost effective 9 ... 12 per

cent chromium steels. Reheat steam enters the

IP cylinder, in which the hot areas will be man-

ufactured from nickel-based materials, while

conventional materials will be used for the

colder areas (Figure 10).

Reference

J. Franke and R. Kral, Advanced boiler design for

high efficiency power plants, to be presented at

Parsons 2000, Cambridge, 3-7 July 2000. These au-

thors acknowledge participants in the advanced

700C PF power plant project carried out under the

EU funded Thermie programme and the financial

contributions from the European Commission and

the Swiss government.

Figure 10. Materials for the IP and HP2 stages of

the 700C steam turbine, 400 MWe single reheat

power plant

Figure 8. Reductions in costs gained by horizontal

furnace (HF) boiler design for the highest steam

temperatures

Rotor nickel based alloy

Inner casing

nickel based alloy

Casing G17CrMoV5-10

Outlet casing 9...12% Cr steel

Inlet casing 9...12% Cr steel

Inner casing nickel based alloy

Rotor nickel based alloy

Table 1.

Materials for steam generators

with high steam temperatures

Components Material Temperature for

105h creep at 100

N/mm2 (C)

Membrane wall 13CrMo44 515

7CrMoVTiB910 580

HCM12 600

NF12/SAVE12 640

Superheater tubes X3CrNiMoN1713 630

Esshete 1250 640

TP347HFG 655

Alloy 617 ~690

Alloy 625 ~740

Headers P91 590

E911/NF616 615

NF12 640

TP347HFG 655

Modified 617 ~700

160

140

120

100

80

60

40

20

0

540C

Conventional

design

700C

Conventional

design

700C

Conventional design

with HF boiler

100%

120%

107%

Steam

piping

Boiler

Turboset

Other

Relative power plant

investment costs (%)

IP HP1

Figure 9. Siemens has designed

a new four-stage steam turbine

generator set for highly

supercritical power plants

HP1

HP

Old design

New design

IP LP LP

HP1 HP2 IP LP LP

HP2

May 2000 Modern Power Systems 41

2_r ckseite 09.04.2001 8:21 Uhr Seite 1

Probedruck

C M Y CM MY CY CMY K

s

This article appeared in:

Modern Power Systems

May 2000, page 37-41

Published by and copyright 2000

Siemens AG

Power Generation Group (KWU)

Freyeslebenstrae 1

91058 Erlangen, Germany

Phone: +49 913118-3787

E-mail: contact

@

erl11.siemens.de

http:www.siemens.de/kwu

Siemens Westinghouse

Power Corporation

The Quadrangle

4400 Alafaya Trail

Orlando, FL 32826-2399 (USA)

Phone: +001407736-2000

http://www.siemenswestinghouse.com

Two n a me s o n e g l o b a l c o mp a n y

S i e me n s A k t i e n g e s e l l s c h a f t

Subject to change without prior notice

Printed on paper treated with chlorine-free bleach

Order No. A96001-S90-A703-X-7600

Printed in Germany

101830M SD 09001.

SEK 22209

Das könnte Ihnen auch gefallen

- Scientific American Supplement, No. 303, October 22, 1881Von EverandScientific American Supplement, No. 303, October 22, 1881Noch keine Bewertungen

- Encyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Von EverandEncyclopaedia Britannica, 11th Edition, Volume 8, Slice 3 "Destructors" to "Diameter"Noch keine Bewertungen

- Posiflow Technology of Doosan Babcock For Supercritical BoilersDokument12 SeitenPosiflow Technology of Doosan Babcock For Supercritical BoilersKarthick VelayuthamNoch keine Bewertungen

- Posiflow Benson BoilerDokument8 SeitenPosiflow Benson BoilerKarthick VelayuthamNoch keine Bewertungen

- Tech Paper - Super Critical Boiler With Low Mass Flux, Vertical Wall DesignDokument6 SeitenTech Paper - Super Critical Boiler With Low Mass Flux, Vertical Wall Designsbala_810Noch keine Bewertungen

- Benson BoilersDokument20 SeitenBenson BoilersPrasanna Kumar100% (1)

- Abma 9 00Dokument11 SeitenAbma 9 00Matias MancillaNoch keine Bewertungen

- Use of Vacuum Furnaces in Heat Treatment: J. OleinikDokument5 SeitenUse of Vacuum Furnaces in Heat Treatment: J. OleinikhasanNoch keine Bewertungen

- Best Choice: Benson BoilerDokument5 SeitenBest Choice: Benson BoilerVaibhav SarinNoch keine Bewertungen

- The Advantages of Supercritical Circulating Fluidized Bed Boiler (Posted by P.Muthu, DGM-TSX) PDFDokument19 SeitenThe Advantages of Supercritical Circulating Fluidized Bed Boiler (Posted by P.Muthu, DGM-TSX) PDFRKVSK1Noch keine Bewertungen

- Progress of The Weston Unit 4 Supercritical Project in Wisconsin PDFDokument6 SeitenProgress of The Weston Unit 4 Supercritical Project in Wisconsin PDFktsnlNoch keine Bewertungen

- Vertical Tube, Variable Pressure Furnace For Supercritical Steam BoilersDokument7 SeitenVertical Tube, Variable Pressure Furnace For Supercritical Steam BoilersSamNoch keine Bewertungen

- Alstom CFBDokument7 SeitenAlstom CFBCoalhouse Walker JuniorNoch keine Bewertungen

- Research and Development at The BENSON Test RigDokument20 SeitenResearch and Development at The BENSON Test RigsbktceNoch keine Bewertungen

- 2.10. Furnace Design Considerations: Fig. 2.5 Fig. 2.6Dokument8 Seiten2.10. Furnace Design Considerations: Fig. 2.5 Fig. 2.6vatsal07Noch keine Bewertungen

- Fuel Efficient Burner SystemDokument4 SeitenFuel Efficient Burner SystemGilang SeptianNoch keine Bewertungen

- Topsoe High Flux Steam ReformDokument6 SeitenTopsoe High Flux Steam ReformAnissa Nurul BadriyahNoch keine Bewertungen

- Alstom Process Gas CoolerDokument12 SeitenAlstom Process Gas Coolerrajaramc100% (1)

- Advantages of Ultra Super - FINALDokument6 SeitenAdvantages of Ultra Super - FINALAmar N. MauryaNoch keine Bewertungen

- Boiler of 500 MWDokument8 SeitenBoiler of 500 MWHKVMVPVPV021511Noch keine Bewertungen

- Shell BoilerDokument12 SeitenShell BoilerMochamad Fajar RamdaniNoch keine Bewertungen

- Fire Tube BoilerDokument21 SeitenFire Tube Boiler声原Noch keine Bewertungen

- SuperCritical Boiler 1Dokument45 SeitenSuperCritical Boiler 1swatantar17100% (1)

- How To Increase The Efficiency of Commercial BoilersDokument48 SeitenHow To Increase The Efficiency of Commercial BoilersAnas AsifNoch keine Bewertungen

- 1991 - Test Loop For Research On Direct Steam Generation in Parabolic Trough Power Plants - MullerDokument9 Seiten1991 - Test Loop For Research On Direct Steam Generation in Parabolic Trough Power Plants - MullerhakeemniyasNoch keine Bewertungen

- Convection Section CleaningDokument10 SeitenConvection Section CleaningSuresh RamakrishnanNoch keine Bewertungen

- EPSRC Thermal Management Sheffield Progress Report July 2010Dokument76 SeitenEPSRC Thermal Management Sheffield Progress Report July 2010Junaid MugholNoch keine Bewertungen

- Chapter 4 BoilerDokument66 SeitenChapter 4 BoilerAnonymous YSdtimxAbNoch keine Bewertungen

- Modeling of Fire Tube BoilerDokument16 SeitenModeling of Fire Tube BoilerVignesh AlagesanNoch keine Bewertungen

- Recover Heat From Waste Inciniration PDFDokument4 SeitenRecover Heat From Waste Inciniration PDFcvolkan1100% (1)

- The Boiler HouseDokument12 SeitenThe Boiler Housemeijon pelayerNoch keine Bewertungen

- Chapter - IIIDokument20 SeitenChapter - IIIRajeshNoch keine Bewertungen

- BoilerDokument29 SeitenBoilerMadhan RajNoch keine Bewertungen

- Ganapathy PDFDokument90 SeitenGanapathy PDFpinenamuNoch keine Bewertungen

- A Coupled Combustion and Hydrodynamic Model For The Prediction ofDokument11 SeitenA Coupled Combustion and Hydrodynamic Model For The Prediction ofFaridNoch keine Bewertungen

- Fire Tube BoilerDokument14 SeitenFire Tube BoilersadvdsNoch keine Bewertungen

- Coeficien Heat Tranfer Boiler Fire Tube1Dokument8 SeitenCoeficien Heat Tranfer Boiler Fire Tube1กี๋ แต่งงาม100% (1)

- CFCB Bed Ash CoolerDokument11 SeitenCFCB Bed Ash CoolerUdhayakumar VenkataramanNoch keine Bewertungen

- Boiler Pressure PartsDokument3 SeitenBoiler Pressure PartsBedabyas DehuryNoch keine Bewertungen

- Boiler Design AspectsDokument43 SeitenBoiler Design AspectsAashish PalNoch keine Bewertungen

- 460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolandDokument8 Seiten460 Mwe Supercritical Otu CFB Boiler: Łagisza Power Plant PolanddhmbasNoch keine Bewertungen

- BLR - Operation & Maintenance Q&A - 2017Dokument50 SeitenBLR - Operation & Maintenance Q&A - 2017RAJKUMARNoch keine Bewertungen

- 12-Design Fundamentals of BoilerDokument12 Seiten12-Design Fundamentals of BoilerVishalVaishNoch keine Bewertungen

- Boiler Tube Failure and ImpactsDokument8 SeitenBoiler Tube Failure and ImpactsUdhayakumar VenkataramanNoch keine Bewertungen

- A Study On The Design of Recuperative Burner (1998)Dokument12 SeitenA Study On The Design of Recuperative Burner (1998)Ricardo AlanisNoch keine Bewertungen

- Numerical and Experimental Study On Biased Tube Temperature Problem in Tangential Firing BoilerDokument22 SeitenNumerical and Experimental Study On Biased Tube Temperature Problem in Tangential Firing BoilerraitoNoch keine Bewertungen

- BoilerDokument48 SeitenBoilerSubramanian Ravishankar100% (1)

- Recovering Heat When Generating PowerDokument8 SeitenRecovering Heat When Generating Poweraliscribd46Noch keine Bewertungen

- Waste Boilers: Problems & SolutionsDokument8 SeitenWaste Boilers: Problems & SolutionsHsein WangNoch keine Bewertungen

- Trends in Packaged Boiler Design PDFDokument10 SeitenTrends in Packaged Boiler Design PDFpertspyNoch keine Bewertungen

- High Intensity Slag Resistance Furnace DesignDokument10 SeitenHigh Intensity Slag Resistance Furnace DesignBrian Andres Madariaga MuñozNoch keine Bewertungen

- Metallurgical Industrial Furnaces 3Dokument6 SeitenMetallurgical Industrial Furnaces 3Mining ReviewNoch keine Bewertungen

- Angelo MantelliDokument6 SeitenAngelo MantelliNatarajan RavisankarNoch keine Bewertungen

- Boiler EfficiencyDokument2 SeitenBoiler EfficiencycyruskuleiNoch keine Bewertungen

- THERMAL-1 Experiment 1 Part ADokument7 SeitenTHERMAL-1 Experiment 1 Part Anishith ranaNoch keine Bewertungen

- Scientific American Supplement, No. 633, February 18, 1888Von EverandScientific American Supplement, No. 633, February 18, 1888Noch keine Bewertungen

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesVon EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNoch keine Bewertungen

- Process Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersVon EverandProcess Steam Systems: A Practical Guide for Operators, Maintainers, and DesignersNoch keine Bewertungen

- Us5282442 PDFDokument6 SeitenUs5282442 PDFKrishnan SanthanarajNoch keine Bewertungen

- 212292Dokument91 Seiten212292Jaime BerryNoch keine Bewertungen

- Instant Up Right Cat 2015Dokument40 SeitenInstant Up Right Cat 2015Krishnan SanthanarajNoch keine Bewertungen

- Rim and Face Shaft AlignmentDokument38 SeitenRim and Face Shaft AlignmentJaime Berry100% (2)

- Pulverizer Fire and ExplosionDokument4 SeitenPulverizer Fire and ExplosionKrishnan SanthanarajNoch keine Bewertungen

- Review of Type IV Cracking of Weldments in 9Dokument64 SeitenReview of Type IV Cracking of Weldments in 9Krishnan SanthanarajNoch keine Bewertungen

- Sag ChartDokument1 SeiteSag ChartKrishnan SanthanarajNoch keine Bewertungen

- Tri Sec AphDokument36 SeitenTri Sec AphKrishnan Santhanaraj100% (1)

- Thrust Bearing End PlayDokument3 SeitenThrust Bearing End PlayKrishnan SanthanarajNoch keine Bewertungen

- Turbine Operational ProblemsDokument35 SeitenTurbine Operational Problemsna2011100% (1)

- Presentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Dokument74 SeitenPresentation ON Cerc Discussion Paper On Terms & Conditions of Tariff Applicable FROM 01.04.2004Krishnan SanthanarajNoch keine Bewertungen

- NTPL U1 Edta Prog 200214Dokument2 SeitenNTPL U1 Edta Prog 200214SethuRamalingamNoch keine Bewertungen

- Operators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineDokument8 SeitenOperators of Coal-Fired Power Plants Decide How To Meet MATS 2015 DeadlineKrishnan SanthanarajNoch keine Bewertungen

- Supercritical Power Generation-Experiences, Issues & ChallengesDokument85 SeitenSupercritical Power Generation-Experiences, Issues & ChallengesVeda SiddharthNoch keine Bewertungen

- 1.best Erection and Commg Practice Product APHDokument13 Seiten1.best Erection and Commg Practice Product APHKrishnan Santhanaraj100% (1)

- Lubrication. BasicsDokument127 SeitenLubrication. BasicsKrishnan SanthanarajNoch keine Bewertungen

- Energy Audit Methodology For FOR Turbine Cycle: M.V.Pande Dy - Director NPTI, NagpurDokument33 SeitenEnergy Audit Methodology For FOR Turbine Cycle: M.V.Pande Dy - Director NPTI, NagpurKrishnan Santhanaraj100% (1)

- BCP Installation & CommissioningDokument18 SeitenBCP Installation & CommissioningKrishnan SanthanarajNoch keine Bewertungen

- Bowl Mill-Feb 2009Dokument12 SeitenBowl Mill-Feb 2009Krishnan SanthanarajNoch keine Bewertungen

- BCP Dismantling & OH With Trouble ShootingDokument24 SeitenBCP Dismantling & OH With Trouble ShootingKrishnan SanthanarajNoch keine Bewertungen

- BCP Technical & Operating DataDokument24 SeitenBCP Technical & Operating DataKrishnan SanthanarajNoch keine Bewertungen

- Boiler Feed Water Pump Inspection at Jubail TM.P. Workshop PDFDokument17 SeitenBoiler Feed Water Pump Inspection at Jubail TM.P. Workshop PDFAlaina Hood100% (1)

- Safety Precautions For Home UPS - InverterDokument2 SeitenSafety Precautions For Home UPS - Inverterakbisoi1100% (1)

- R2SDokument31 SeitenR2SdhruvaklNoch keine Bewertungen

- Effects of Variable Load On Power StationDokument3 SeitenEffects of Variable Load On Power StationRasel Islam100% (1)

- Atx 060Dokument2 SeitenAtx 060TimmyJuriNoch keine Bewertungen

- Coal Gasification - EastmanDokument44 SeitenCoal Gasification - Eastmanstavros7Noch keine Bewertungen

- T-Bat-Sys-Hv-3.0 (T30) V2.2Dokument2 SeitenT-Bat-Sys-Hv-3.0 (T30) V2.2Sampath HemasingheNoch keine Bewertungen

- Datasheet PDG5Dokument2 SeitenDatasheet PDG5SolarCollabNoch keine Bewertungen

- Presentation On Heat EXchanger1Dokument51 SeitenPresentation On Heat EXchanger1BaqirMuhammadNoch keine Bewertungen

- 2020124-OPE-Operator Logbook v01Dokument2 Seiten2020124-OPE-Operator Logbook v01Love Buddha's WordsNoch keine Bewertungen

- Datasheet - VertexS - NEG9R.28 - EN - 2023 - B - Web - NEG9R.28 - 2022PA2 - EN - 20230505Dokument2 SeitenDatasheet - VertexS - NEG9R.28 - EN - 2023 - B - Web - NEG9R.28 - 2022PA2 - EN - 20230505Marian FlorescuNoch keine Bewertungen

- Me309 2015 11 PDFDokument4 SeitenMe309 2015 11 PDFgift mudimuNoch keine Bewertungen

- Boiler SafetyDokument24 SeitenBoiler SafetynagarajsumaNoch keine Bewertungen

- R Series 10691 Series BackPressureReliefValveDokument3 SeitenR Series 10691 Series BackPressureReliefValveCristobal HernandezNoch keine Bewertungen

- Presentaton: On Bhel BhopalDokument25 SeitenPresentaton: On Bhel BhopalGauriNoch keine Bewertungen

- Flameless CombustionDokument8 SeitenFlameless CombustionHasan Kayhan KayadelenNoch keine Bewertungen

- List of Existing Power Plants (Grid-Connected) As of December 2019Dokument7 SeitenList of Existing Power Plants (Grid-Connected) As of December 2019PH GAMINGNoch keine Bewertungen

- Piston PumpsDokument33 SeitenPiston PumpsPridhar Thiagarajan100% (1)

- Air Blowing: Method Statement FORDokument6 SeitenAir Blowing: Method Statement FORrvsreddysenaNoch keine Bewertungen

- Simops MatrixDokument17 SeitenSimops MatrixthinkpadNoch keine Bewertungen

- BE-WI-248-01-F07 Datasheet Turbine FlowmeterDokument3 SeitenBE-WI-248-01-F07 Datasheet Turbine Flowmetermika cabelloNoch keine Bewertungen

- The Spanish Electricity System 2014 0 PDFDokument150 SeitenThe Spanish Electricity System 2014 0 PDFCristóbal KettererNoch keine Bewertungen

- CURRICULUM VITAE Evan BARUDokument2 SeitenCURRICULUM VITAE Evan BARUsyauqiNoch keine Bewertungen

- Seminar Report Solar TowerDokument24 SeitenSeminar Report Solar TowerPatricia Joseph100% (1)

- Sme - Unit - 1 - MCQ: More Than Diesel Power StationDokument5 SeitenSme - Unit - 1 - MCQ: More Than Diesel Power StationDhawal DhurveNoch keine Bewertungen

- A1 Poster TemplateDokument1 SeiteA1 Poster TemplateIntan ShafinazNoch keine Bewertungen

- Prepared JHA: Attachment V: The Following Samples/pre-Prepared JHA Are Available For Download atDokument4 SeitenPrepared JHA: Attachment V: The Following Samples/pre-Prepared JHA Are Available For Download atprinceoceanNoch keine Bewertungen

- Incubadora Ref 3990ltDokument2 SeitenIncubadora Ref 3990ltKarynaHernandezMonarrezNoch keine Bewertungen

- Diesel Progress Sourcing Guide 2021Dokument367 SeitenDiesel Progress Sourcing Guide 2021Mamta RaybageNoch keine Bewertungen

- Fire Tube Boilers - (21.07.2020)Dokument131 SeitenFire Tube Boilers - (21.07.2020)Dr. BIBIN CHIDAMBARANATHANNoch keine Bewertungen