Beruflich Dokumente

Kultur Dokumente

Allison WTEC

Hochgeladen von

Ed CalheOriginalbeschreibung:

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Allison WTEC

Hochgeladen von

Ed CalheCopyright:

Verfügbare Formate

Pro-Link/MPC

Allison Transmissions

Users Manual

Pro-Link

/MPC Allison Transmissions

NNT, Inc., retains all ownership rights to the Pro-Link

/MPC and its documentation. The Pro-Link

/MPC source

code is a confidential trade secret of NNT, Inc.. You may not decipher or de-compile the Pro-Link

/MPC

applications, develop source code for the Pro-Link

/MPC, or knowingly allow others to do so. The Pro-Link

/MPC

and its documentation may not be sublicensed or transferred without the prior written consent of NNT, Inc..

This manual, as well as the software it describes, is furnished under license and may only be used or copied in

accordance with the terms of such license. The content of this manual is furnished for informational use only, is

subject to change without notice, and should not be construed as a commitment by NNT, Inc. NNT, Inc. assumes no

responsibility or liability for any errors or inaccuracies that may appear in this book.

Except as permitted by such license, no part of this publication may be reproduced, or transmitted, in any form or by

any means, electronic, mechanical, or otherwise, without the prior written permission of NNT, Inc..

NEXIQ Technologies is a trademark of NNT, Inc.

2005 NNT, Inc. All rights reserved. All other marks are trademarks or registered trademarks of the respective

holders. Pictures for illustration purposes only. Specifications are subject to change without notice.

www.nexiq.com

Rev: 12/05/2005

Pro-Link

/MPC Allison Transmissions Users Manual iii

Chapter 1:

Using This Manual ................................................. 1

Manual Overview........................................................................... 2

Conventions................................................................................... 3

Special Messages ................................................................................ 3

Specialized Text ................................................................................... 5

Chapter 2:

Getting Started..................................................... 7

Navigating Pro-Link

Menus and Screens .................................... 9

Connecting to a Transmission Application .................................. 10

Allison World Transmission ................................................................ 13

Allison CEC Transmission.................................................................. 14

Chapter 3:

Using the WTEC Diagnostics Menu........................ 15

Diagnostics Menu........................................................................ 16

Diagnostic Data.................................................................................. 17

Diagnostic Codes ............................................................................... 27

Shift Inhibits........................................................................................ 29

I/O Wire States ................................................................................... 32

Clear Active Indicators........................................................................ 34

Clear Inactive Codes .......................................................................... 35

Action Requests ................................................................................. 36

Trigger/Snapshot ................................................................................ 44

Chapter 4:

Using the WTEC ECU/EEPROM Setup Menu............ 53

The Setup Menu.......................................................................... 54

ECU Calibration.................................................................................. 55

View Customer Modifiable Constants................................................. 57

iv Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 5:

Using the WTEC Printout Option ........................... 61

Using the Printout Option ............................................................ 62

Chapter 6:

Using the Allison CEC Application.......................... 65

Diagnostic Data........................................................................... 66

Diagnostic Codes ........................................................................ 67

Snapshot ..................................................................................... 73

Trigger On Specific............................................................................. 73

Trigger On Any Code ......................................................................... 74

Appendix A:

PID Fault Code Descriptions ................................. 75

Appendix B:

SID Fault Code Descriptions................................. 87

Appendix C:

MID Fault Code Descriptions ................................ 93

Appendix D:

FMI Fault Code Descriptions................................. 99

Pro-Link

/MPC Allison Transmissions Users Manual v

Appendix E:

Warranty & Service ........................................... 101

Exclusive Warranty.................................................................... 102

Exclusive Remedy..................................................................... 102

Return Materials Authorization (RMA)....................................... 103

Return of Goods Policy.............................................................. 104

Return Goods Authorization (RGA) Procedure ................................ 105

vi Pro-Link

/MPC Allison Transmissions Users Manual

Pro-Link

/MPC Allison Transmissions Users Manual 1

1

Using This Manual

u

Manual Overview, page 2

u

Conventions, page 3

This chapter provides an overview of this manuals organization and the conventions

used thought out.

2 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 1 Using This Manual

Manual Overview

This manual provides basic and detailed information to support you in using the

Pro-Link

/MPC Allison Transmissions application.

The manual is comprised of the following sections:

Table of Contentshelps you to find the information you are looking for

quickly and easily.

Using This Manualprovides an overview of this users manual.

Getting Startedprovides instructions on loading the Allison Transmis-

sions applications (i.e., WTEC and CEC).

Using the WTEC Diagnostics Menuprovides detailed instructions for

accessing and using each of the Diagnostics menu options.

Using the WTEC ECU/EEPROM Setup Menuprovides detailed in-

structions for accessing and using each of the Setup menu options.

Using the WTEC Printout Optionprovides detailed instructions for ac-

cessing and using the Printout option.

Using the Allison CEC Applicationprovides detailed instructions for ac-

cessing and using each of the applications menu options.

PID Fault Code Descriptions (Appendix) provides a table that com-

pares SAE and ATA Parameter Identification (PID) descriptions with

Pro-Link

PID descriptions.

SID Fault Code Descriptions (Appendix)provides a table that com-

pares SAE and ATA System Identification (SID) descriptions with Pro-

Link

SID descriptions used for MID 128.

MID Fault Code Descriptions (Appendix)provides a table that com-

pares SAE Microprocessor Identification (MID) descriptions with Pro-

Link

MID descriptions.

FMI Fault Code Descriptions (Appendix)provides a table that com-

pares SAE Failure Mode Identifier (FMI) descriptions with Pro-Link

FMI

descriptions.

Warranty and Service (Appendix)provides warranty and service

information.

Each chapter is introduced by an at-a-glance list of the chapters contents, along

with corresponding page numbers.

- Conventions

Pro-Link

/MPC Allison Transmissions Users Manual 3

Conventions

Different conventions are used in this users manual to draw your attention to

certain types of information. This section provides an overview of these

conventions.

Special Messages

Notes

NOTE provides explanations, comments, or tips related to the subject matter that

is being discussed.

Example:

NOTE:

iRefer to the page number provided for each described component for fur-

ther details.

Important

IMPORTANT indicates a situation which, if not avoided, may result in damage to

the test equipment or vehicle.

Example:

IMPORTANT:

Keep all cables clear of moving or hot engine parts.

Cautions

CAUTION indicates a potentially hazardous situation which, if not avoided, may

result in moderate or minor injury to the operator or to bystanders.

Example:

CAUTION:

Do not use the unit to perform tests on household or industrial sources.

Warnings

WARNING indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury to the operator or bystanders.

4 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 1 Using This Manual

Example:

WARNING:

Wear gloves when handling hot engine components.

Stop

Information that needs to be considered before proceeding is presented in the fol-

lowing manner:

Troubleshooting

Information intended to help you to address or anticipate potential issues are pre-

sented in the following manner:

Before using this application, be sure to read the Pro-Link

Users Manual

for:

Important safety information

Instructions on connecting the device to a vehicle

Instructions on properly inserting an application card

If the Loading Application message continuously appears, check the label

on the card to verify you are using the appropriate card for the given manu-

facturer/ECU.

- Conventions

Pro-Link

/MPC Allison Transmissions Users Manual 5

Specialized Text

The following specially formatted text is used to help you to differentiate certain

elements discussed within this manual:

Emphasis: Used to draw your attention to particularly important

information.

Field/Line: Used to highlight the name of a field or a line of text from a

display.

Example: The Request Lamp line updates to reflect the current

request.

Menu items: Used to highlight a series of menu selections.

Example: From the Main Menu, select MPC UTILITIES

4

RS-232

SERIAL PORT

4

TERMINAL SETUP....

Screen titles: Used to highlight the title of a screen showing on the de-

vicess readout window.

Example: The display shows the Review Snapshot menu, which lists

the event captures at the bottom of the screen.

Selection: Used to highlight a selectable item, such as a menu option.

Example: From the Main Menu, select View Calibrations.

6 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 1 Using This Manual

Pro-Link

/MPC Allison Transmissions Users Manual 7

2

Getting Started

u

Navigating Pro-Link

Menus and Screens, page 9

u

Connecting to a Transmission Application, page 10

u

Allison World Transmission, page 13

u

Allison CEC Transmission, page 14

The Allison Transmission applications consist of two diagnostic tools that provide the

capability to reprogram and diagnose Allison transmissions using the Pro-Link

/MPC.

There are four applications:

Allison WTEC

Allison CEC

Heavy Duty Systems (not covered in this manual)

MPC Utilities (not covered in this manual)

NOTE:

iSince these applications are supported by both the Pro-Link GRAPHIQ and the Pro-

Link Plus, this manual uses Pro-Link

to refer to both products.

This chapter provides instructions on connecting to the Allison Transmissions applications

(i.e., Allison WTEC and Allison CEC) and navigating through their menu hierarchies (refer

to Figure 2.1 Application Flow Chart, next).

8 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 2 Getting Started

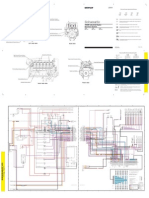

Figure 2.1 Application Flow Chart

Allison World

Transmission

Allison CEC

Printout

Diagnostic

ECU/EEPROM Setup

Diagnostic Data

Diagnostic Codes

Snapshot

Trigger On Specific

Trigger On Any Code

Diagnostic Data

Diagnostic Codes

Shift Inhibts

I/O Wire States

Clear Active Indicators

Clear Inactive Codes

Action Requests Enable Clutch Test

Disable Clutch Test

Active Fast Adaptive

Reset Unadaptive

Shifts

Reset Throttle

Calibration

Reset Autodetect

Trigger On Any Code

Trigger On Specific

Trigger Manually

Clear Trigger

Print Snapshot

Trigger/Snapshot

ECU Calibration

Information

View CMCs

I/O Wire States

I/O Assignment

Autodetect Information

- Navigating Pro-Link

Menus and Screens

Pro-Link

/MPC Allison Transmissions Users Manual 9

Navigating Pro-Link

Menus and Screens

To use the features provided with this application, you will need to select from

various menus presented on the Pro-Link

/MPC screen. Making selections typi-

cally involves using the arrow keys ( and ) to navigate to a desired

option, then pressing the key.

The following convention is used throughout this manual to provide abbreviated

instructions on making on-screen selections.

Example instruction sheet:

1 From the WTEC main menu, select Diagnostics.

What this means:

1 From the WTEC main menu, use the and keys to select Diag-

nostics, then press .

10 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 2 Getting Started

Connecting to a Transmission Application

Use the following procedure to connect to an Allison Transmission application.

To connect to a transmission application:

1 Connect the Pro-Link

/MPC to the diagnostic connector on the vehicle, and

turn the key to the on position.

The following copyright screen appears and is displayed for approximately

one second:

The Pro-Link

/MPC Start New Session screen appears:

NOTE:

iif you select YES, you will start a new session. If you select NO, the Pro-

Link

/MPC displays data from a previous session.

2 Select YES.

Before using this application, be sure to read the Pro-Link

Users Manual

for the following:

Important safety information

Instructions on connecting the device to a vehicle

Instructions on properly inserting an application card

MPC BIOS

2005 NNT, INC.

PRO-LINK 9000/MPC

START NEW SESSION?

[YES] NO

- Connecting to a Transmission Application

Pro-Link

/MPC Allison Transmissions Users Manual 11

The system selection screen appears.

3 Select the correct transmission type (either Allison WTEC or Allison CEC).

4 Press .

The Pro-Link

/MPC attempts to establish communication with the vehicles

on-board electronic control unit (ECU).

NOTE:

iIf you select Allison WTEC, the cartridge automatically selects the proper

World Transmission type.

If the Pro-Link

/MPC is successful in establishing communication with the

ECU, the following screen is displayed.

If the Pro-Link

/MPC is connected to a World Transmission, refer to

Allison World Transmission (WTEC), next in this chapter.

If the Pro-Link

/MPC is connected to an Allison CEC transmission, refer to

Allison CEC, later in this chapter.

PRO-LINK MPC

VERSION X.XX

----Selections----

ALLISON WTEC

LOADING

ALLISON WTEC

[FUNC] TO CANCEL

12 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 2 Getting Started

If the Pro-Link

/MPC is unsuccessful in establishing communication with the

ECU, the following message is displayed:

5 Press to continue.

If the Pro-Link

/MPC is still unable to establish communication with the

ECU, the following message is displayed:

NOTE:

iPlease refer to the Multi-Protocol Cartridge (MPC) Utilities Manual for trou-

bleshooting recommendations.

ALLISON WORLD

TRANSMISSIONS

LOOKING FOR WTEC

[FUNC] TO CANCEL

NO TRANSMISSION SEEN

ON 1708 BUS

[ENTER] TO CONTINUE

- Connecting to a Transmission Application

Pro-Link

/MPC Allison Transmissions Users Manual 13

Allison World Transmission

After communication has been established, the WTEC main menu appears:.

The following choices are available:

Diagnostics (Refer to Chapter 3, later in this manual.)

ECU/EEPROM Setup (Refer to Chapter 4, later in this manual.)

Printout (Refer to Chapter 5, later in this manual.)

WTEC II

VERSION X.XX

----Selections----

DIAGNOSTICS

14 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 2 Getting Started

Allison CEC Transmission

You access the Allison CEC Transmission application from the main system se-

lection screen.

1 Use the and keys to make your selection, and press .

The following menu choices are available:

MTB600 CLBT,V,HT700

CLBT5/6/9000 DP8000

2 When you see the proper transmission type on the display, select it and press

.

A screen similar to the following is displayed:

The following choices are available:

Diagnostic Data (Refer to Diagnostic Data, page 66, of this

manual.)

Diagnostic Codes (Refer to Diagnostic Codes, page 67, of this

manual.)

Snapshot (Refer to Snapshot, page 73, of this manual.)

NNT PRO-LINK/MPC

VERSION X.XX

----Selections----

ALLISON CEC

MTB600 CLBT,V,HT700

----Selections----

DIAGNOSTIC DATA

Pro-Link

/MPC Allison Transmissions Users Manual 15

3

Using the WTEC

Diagnostics Menu

u

Diagnostics Menu, page 16

u

Diagnostic Data, page 17

u

Diagnostic Codes, page 27

u

Shift Inhibits, page 29

u

I/O Wire States, page 32

u

Clear Active Indicators, page 34

u

Clear Inactive Codes, page 35

u

Action Requests, page 36

u

Trigger/Snapshot, page 44

This chapter provides detailed information on Allison World Transmission (WTEC)

diagnostics. Options on the Diagnostics menu are covered, as are the options available

through the submenus.

NOTE:

iFor information on connecting to WTEC and using the main menu, refer to the previous

chapter of this manual.

16 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Diagnostics Menu

1 Select DIAGNOSTICS from the WTEC main menu using the and

keys.

2 Press .

The DIAGNOSTICS menu displays:

The following menu choices are available:

Diagnostic Data

Diagnostic Codes

Shift Inhibits

I/o Wire States

Clear Active Indicators

Clear Inactive Codes

Action Requests

Trigger/snapshot

3 Use the and keys to scroll through the Diagnostics menu. Press

to select menu choice.

WTEC II

VERSION X.XX

----Selections----

DIAGNOSTICS

DIAGNOSTICS

----Selections----

DIAGNOSTIC DATA

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 17

Diagnostic Data

After selecting Diagnostic Data from the Diagnostics menu, a screen similar to

the following screen appears:

Use the and keys to scroll through the diagnostic data list.

The following tables show the WTEC II and WTEC III diagnostic data covered by

this application. The Diagnostic Data List Definitions describe the parameters

used in the diagnostic application. The list is in the approximate order displayed

by Pro-Link

/MPC but will vary based on the transmission system being diag-

nosed. Parameters not available will be indicated on the right hand side of the

screen by a N/A symbol.

NOTE:

iDetailed diagnostic and repair procedures as well as specifications may be

found in the system manufacturers shop manual.

# ACTIVE CODES 5

IGN STATUS ON

SOL APPLY VOLTS 11.6V

SUMP 50F

TABLE 1. WTEC II Data List

Parameter

Sample

Value Diagnostic Data List Definition

#ACTIVE CODES 0 Indicates the number of currently active codes (up to

five) in the diagnostic codes data list. Placing the

cursor on this line and pressing provides a

shortcut to the diagnostic codes data list to view all

diagnostic codes, active or inactive. To return to the

diagnostic data list, press the key.

IGN STATUS ON Ignition StatusThe ECU interpretation of ignition

voltage. When voltage is below a calibration value, the

ignition is considered to be off.

18 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

IGN VOLTS

(WTEC II only)

11.1V Ignition VoltsThis voltage is used to determine if the

vehicle ignition is turned on. The ECU shuts off when

ignition is turned off and output speed is too low to

measure.

SOL APPLY VOLTS 11.1V Solenoid Apply VoltsThis voltage is measured inside

the ECU, downstream of some power supply compo-

nents. It is used for controlling the solenoid currents,

and for detecting ECU supply voltage that is either too

high or too low for normal operation.

DIMMER VOLTS

(WTEC II only)

11.8V This voltage is used to control the display intensity.

When it is zero, the ECU assumes that the headlights

are off and sets the display to full intensity. When the

dimmer voltage rises above a calibration level, the

display is set to minimum intensity. As the dimmer

voltage rises up to the same level as ignition voltage,

the display intensity also rises.

SUMP 161 F Sump temperature is measured by a thermistor located

in t he transmission sump. The function of the ther-

mistor is to detect cold oil temperature and limit

transmission operation until sump oil has reached a

minimum recommended temperature. It also serves to

limit transmission operation when the oil has reached

too high of a temperature. The ECU uses the sump

temperature information to assist in estimating clutch

fill times (affects smoothness of shifting) and to

estimate solenoid resistance (for current control). In

addition, the sump temperature is used as a variable to

permit oil level readings when the sump... and to limit

those readings to a range of between 140F and 220F.

OIL LVL AVAIL NO

SENSOR

Oil Level AvailableThis is a YES or NO response to

Autodetect.

OIL LVL +0QT Oil LevelThe volume of oil that needs to be added or

removed from the transmission to get the correct oil

level.

OIL LVL CNTS 155 Oil Level CountsSlight fluctuations in the counts

indicate proper function of the sensor as it responds to

variations caused by oil flow within the transmission.

TABLE 1. WTEC II Data List

Parameter

Sample

Value Diagnostic Data List Definition

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 19

SELECTED N This shows the actual gear selected by the operator.

The transmission will automatically shift from its

starting gear up to the gear range selected. Actual

means that the gears are displayed in the ECUs

internal naming scheme, L-6, N, and R.

ATTAINED N1 This shows the actual gear that is commanded by the

ECU at the moment. Actual means that the gears are

displayed in the ECUs internal naming scheme, L-6

with all the different neutral gears, and showing C or

L for converter or lock-up operation. Actual range

will always be the same for a given gear, while dis-

played ranges, described next in this table, can be

calibrated to display anything for a given gear.

DISPLAYED N This is the gear selected by the operator as shown on

the shift selector display. The ECU calibration deter-

mines what number is displayed for any given gear.

DISP ATTAINED N This is the actual gear that is commanded by the ECU

at the moment.

TPS PERCENT 0.0% This is the ECUs calculation of throttle opening, 0 to

100 percent. It can be used to troubleshoot problems

with the throttle linkage/TPS system, or SAE J-1939 or

SAE J-1587 link to electronic engines.

TPS CNTS 55 TPS CountsThis is the raw voltage signal as read

from the TPS. The ECU calculates the throttle percent

from this value, then voltage at closed throttle, and the

voltage at WOT. This value can be used to troubleshoot

problems with the throttle linkage/TPS system. It is not

applicable to vehicles that use the SAE J-1587 or J-

1939 link to electronic engines instead of a TPS. A

steady, low number of counts or zero counts will always

be displayed when the transmission is communicating

with an electronic engine on the serial communication

interface lines.

INPUT SPEED 705 RPM The same as engine speed when the engine is directly

connected to the transmission. This value may not be

reasonable if there is a problem anywhere in the speed

system (i.e., broken wire, runout on speed gear, or

ECU calibration with wrong number of teeth).

TABLE 1. WTEC II Data List

Parameter

Sample

Value Diagnostic Data List Definition

20 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

TURBIN SPEED 685 RPM Turbine SPD RPMThe same as input speed when

the converter lockup clutch is applied. It can be

compared to output speed to check gear ratios. This

value may not be reasonable if there is a problem

anywhere in the speed system (i.e., broken wire,

runout on speed gear, or ECU calibration with wrong

number of teeth).

OUTPUT SPEED 1 RPM Output SPD RPMOutput speed is used to determine

shift points. The service tool can be used to verify that

the transmission shifts when it is supposed to. It can

also be compared to turbine speed to check gear

ratios. This value may not be reasonable if there is a

problem anywhere in the speed system (i.e., broken

wire, runout on speed gear, or ECU calibration with

wrong number of teeth).

LOCKUP 0 RPM This is the ouput speed when the last shift into, or out

of lockup occurred.

RNG SHIFT 0 RPM Range ShiftThis is the output speed when the last

range shift occurred. A shift from one gear range to

another is a range shift.

NEXT UP SHFT 0 RPM This is the output shift at which the next upshift will

occur. Its value depends on throttle position and the

range attained.

NEXT DOWN SHFT 0 RPM This is the output speed at which the next downshift will

occur. Its value depends on throttle position and the

range attained.

DO NOT SHIFT

(WTEC II only)

OFF Status of the Do Not Shift output from the ECU to the

Do Not Shift light on the dashboard.

REVERSE

WARNING

OFF A command from the ECU to the reverse warning relay

to activate the audible warning device which indicates

that the vehicle is in reverse gear.

NEUTRAL START ON A command from the ECU to relay which allows the

engine to be started in neutral only.

RTDR REQ 0.0% Retarder Request%This is the ECUs calculation of

the retarder request, 0 to 100 percent.

TABLE 1. WTEC II Data List

Parameter

Sample

Value Diagnostic Data List Definition

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 21

RTDR REQ CNTS 85 Retarder Request CountsThis is the raw voltage as

read from the retarder modulation sensor. The ECU

calculates the retarder request percent from this value.

This value can be used to troubleshoot problems with

the retarder modulation sensor.

RTDR TEMP 195 F Retarder TemperatureThis is the temperature of the

oil in the retarder cavity.

C3 PRESSURE SW OFF The C3 Pressure Switch closes when the C3 clutch is

applied. (Example, Reverse, 3rd, or, 5th gears)

A SOLENOID ON This is the commanded state (ON or OFF) of solenoids

A through N.

B SOLENOID ON This is the commanded state (ON or OFF) of solenoids

A through N.

C SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

D SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

E SOLENOID ON This is the commanded state (ON or OFF) of solenoids

A through N.

F SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

G SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

H SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

J SOLENOID N/A This is the commanded state (ON or OFF) of solenoids

A through N.

K SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

N SOLENOID N/A This is the commanded state (ON or OFF) of solenoids

A through N.

CLTCH TST ENABL OFF Clutch Test EnabledThe state (ON or OFF) of the

Clutch Test Mode. See Enable Clutch Test, page 38,

later in this chapter.

TABLE 1. WTEC II Data List

Parameter

Sample

Value Diagnostic Data List Definition

22 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

TABLE 2. WTEC III Data List

Parameter

Sample

Value Diagnostic Data List Definition

#ACTIVE CODES 5 Indicates the number of currently active codes (up to

five) in the diagnostic codes data list. Placing the

cursor on this line and pressing provides a

shortcut to the diagnostic codes data list to view all

diagnostic codes, active or inactive. To return to the

diagnostic data list, press the key.

IGN STATUS ON Ignition StatusThe ECU interpretation of ignition

voltage. When voltage is below a calibration value, the

ignition is considered to be off.

SOL APPLY VOLTS 11.4V Solenoid Apply VoltsThis voltage is measured inside

the ECU, downstream of some power supply compo-

nents. It is used for controlling the solenoid currents,

and for detecting ECU supply voltage that is either too

high or too low for normal operation.

SUMP 147 F Sump temperature is measured by a thermistor located

in t he transmission sump. The function of the ther-

mistor is to detect cold oil temperature and limit

transmission operation until sump oil has reached a

minimum recommended temperature. It also serves to

limit transmission operation when the oil has reached

too high of a temperature. The ECU uses the sump

temperature information to assist in estimating clutch

fill times (affects smoothness of shifting) and to

estimate solenoid resistance (for current control). In

addition, the sump temperature is used as a variable to

permit oil level readings when the sump... and to limit

those readings to a range of between 140F and 220F.

OIL LVL AVAIL NO Oil Level AvailableThis is a YES or NO response to

Autodetect.

OIL NO

SENSOR

Oil LevelThe volume of oil that needs to be added or

removed from the transmission to get the correct oil

level.

OIL LVL CNTS 178 Oil Level CountsSlight fluctuations in the counts

indicate proper function of the sensor as it responds to

variations caused by oil flow within the transmission.

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 23

SELECTED N This shows the actual gear selected by the operator.

The transmission will automatically shift from its

starting gear up to the gear range selected. Actual

means that the gears are displayed in the ECUs

internal naming scheme, L-6, N, and R.

ATTAINED N1 This shows the actual gear that is commanded by the

ECU at the moment. Actual means that the gears are

displayed in the ECUs internal naming scheme, L-6

with all the different neutral gears, and showing C or

L for converter or lock-up operation. Actual range

will always be the same for a given gear, while dis-

played ranges, described next in this table, can be

calibrated to display anything for a given gear.

DISPLAYED N This is the gear selected by the operator as shown on

the shift selector display. The ECU calibration deter-

mines what number is displayed for any given gear.

PRI SEL OUT

(WTEC III only)

NEUTRAL Primary selector OutputRaw shift selector, data

based on five secondary selector input wires. Invalid

data displayed as FAULT.

SEC SEL OUT

(WTEC III only)

FAULT Secondary Selector OutputRaw shift selector, data

based on five secondary selector input wires. Invalid

data displayed as FAULT.

MODE ICON OFF Indicates the mode button has been activated and the

input function assigned to the mode button has been

regulated.

THROT SRC UNKNOWN Throttle SourceThis is detected by Autodetect,

Analog, J-1587, or J-1939. PWM can be manually

selected from the reprogramming section of this

manual.

TPS PERCENT 0.0% This is the ECUs calculation of throttle opening, 0 to

100 percent. It can be used to troubleshoot problems

with the throttle linkage/TPS system, or SAE J-1939 or

SAE J-1587 link to electronic engines.

TABLE 2. WTEC III Data List

Parameter

Sample

Value Diagnostic Data List Definition

24 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

TPS CNTS 27 TPS CountsThis is the raw voltage signal as read

from the TPS. The ECU calculates the throttle percent

from this value, then voltage at closed throttle, and the

voltage at WOT. This value can be used to troubleshoot

problems with the throttle linkage/TPS system. It is not

applicable to vehicles that use the SAE J-1587 or J-

1939 link to electronic engines instead of a TPS. A

steady, low number of counts or zero counts will always

be displayed when the transmission is communicating

with an electronic engine on the serial communication

interface lines.

INPUT SPEED 700 RPM The same as engine speed when the engine is directly

connected to the transmission. This value may not be

reasonable if there is a problem anywhere in the speed

system (i.e., broken wire, runout on speed gear, or

ECU calibration with wrong number of teeth).

TURBIN SPEED 692 RPM Turbine SPD RPMThe same as input speed when

the converter lockup clutch is applied. It can be

compared to output speed to check gear ratios. This

value may not be reasonable if there is a problem

anywhere in the speed system (i.e., broken wire,

runout on speed gear, or ECU calibration with wrong

number of teeth).

OUTPUT SPEED 1 RPM Output SPD RPMOutput speed is used to determine

shift points. The service tool can be used to verify that

the transmission shifts when it is supposed to. It can

also be compared to turbine speed to check gear

ratios. This value may not be reasonable if there is a

problem anywhere in the speed system (i.e., broken

wire, runout on speed gear, or ECU calibration with

wrong number of teeth).

LOCKUP 0 RPM This is the ouput speed when the last shift into, or out

of lockup occurred.

RNG SHIFT 0 RPM Range ShiftThis is the output speed when the last

range shift occurred. A shift from one gear range to

another is a range shift.

NEXT UP SHFT 0 RPM This is the output shift at which the next upshift will

occur. Its value depends on throttle position and the

range attained.

TABLE 2. WTEC III Data List

Parameter

Sample

Value Diagnostic Data List Definition

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 25

NEXT DN SHFT 0 RPM This is the output speed at which the next downshift will

occur. Its value depends on throttle position and the

range attained.

C3 PRESSURE SW OFF The C3 Pressure Switch closes when the C3 clutch is

applied. (Example, Reverse, 3rd, or, 5th gears)

CHECK TRANS

(WTEC III only)

ON Check TransmissionStatus of CHECKTRANS output

from ECU to CHECKTRANS light on the dashboard.

REVERSE

WARNING

ON A command from the ECU to the reverse warning relay

to activate the audible warning device which indicates

that the vehicle is in reverse gear.

NEUTRAL START ON A command from the ECU to relay which allows the

engine to be started in neutral only.

RETARD AVAIL NO Retarder AvailableThis is the response from Autode-

tect (YES or NO).

RTDR REQ 0.0% Retarder Request%This is the ECUs calculation of

the retarder request, 0 to 100 percent.

RTDR REQ CNTS 231 Retarder Request CountsThis is the raw voltage as

read from the retarder modulation sensor. The ECU

calculates the retarder request percent from this value.

This value can be used to troubleshoot problems with

the retarder modulation sensor.

RTDR TEMP 185 F Retarder TemperatureThis is the temperature of the

oil in the retarder cavity.

ENG COOL CNTS 110 Engine Coolant CounterThis gives the direct voltage

measurement in counts of Engine Coolant Tempera-

ture Sensor.

ENG COOL 85 F Engine CoolantTemperature detected or broadcast

of the engine coolant. This is used to restrict retarder

operation at higher temperatures.

ENG COOL SRC ANALOG Engine Coolant SourceThis is the source of the

Engine Coolant Temperature signal (Analog, J-1587, or

J-1939).

A SOLENOID ON This is the commanded state (ON or OFF) of solenoids

A through N.

B SOLENOID ON This is the commanded state (ON or OFF) of solenoids

A through N.

TABLE 2. WTEC III Data List

Parameter

Sample

Value Diagnostic Data List Definition

26 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

C SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

D SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

E SOLENOID ON This is the commanded state (ON or OFF) of solenoids

A through N.

F SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

G SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

H SOLENOID OFF This is the commanded state (ON or OFF) of solenoids

A through N.

J SOLENOID N/A This is the commanded state (ON or OFF) of solenoids

A through N.

N SOLENOID N/A This is the commanded state (ON or OFF) of solenoids

A through N.

J1939 ABS ACTIVE NO This is the current ABS Active state (YES or NO) on the

J1939 bus.

J1939 KICK ACTIVE NO This is the current Kickdown Active state (YES or NO)

on the J1939 bus.

J1939 ENG BRK LV N/A This is the current Engine Brake Level (OFF, LO, MED,

HI) on the J1939 bus.

CLTCH TST ENABL OFF Clutch Test EnabledThe state (ON or OFF) of the

Clutch Test Mode. See Enable Clutch Test, page 38,

later in this chapter.

PERCENT LOAD 0 - 100% This is the current Percent Load.

TABLE 2. WTEC III Data List

Parameter

Sample

Value Diagnostic Data List Definition

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 27

Diagnostic Codes

1 Use the and keys to locate Diagnostic Codes from the Diag-

nostics menu. Press .

If no diagnostic codes are present, the following screen appears:

2 Press to return to the Diagnostics menu.

If diagnostic codes are present, a screen similar to the following appears:

3 Use the and keys to scroll through the available active codes.

The first line on this screen is the Header Line. The Header Line defines

each of the five fields.

The following table describes each symbol displayed on the Header Line.

---EMPTY---

CODE d1 ACTV CTR IGN

23 12 YES 60

PRI SHIFT SELECTOR

OR RSI LINK FAULT

Code Description

Code The code is a four-digit number. The first two digits

represent main code (e.g., 23 in the above screen),

while the second two digits represent sub code (e.g.,

12 in the above screen).

d The field d stands for Diagnostic Code List. Possible

displays for d are the numbers 1 through 5. The d

number relates to the single code you are viewing of

the five possible.

28 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

4 Use the and keys to scroll through the active codes.

5 Press to return to the main menu.

ACTV ACTV indicates if the code is Active Indicator of not.

The display shows either YES or NO. Active Indicator

indicates a code which is currently active or which

conditions for clearing the code have not been met.

Restrictions to operation may or may not occur and

vary by code.

CTR CTR is the Event Counter. The Event Counter tells

you how many times this event or condition occurred.

IGN IGN is the Ignition Cycle Counter, telling you how

many times the ignition switch was cycled since this

code was detected.

Lines three and four are a plain English description of

the code meaning. The two lines are different for each

code.

Code Description

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 29

Shift Inhibits

Shift inhibits are conditions present in the transmission that prevent shifting from

taking place because of the state of the transmission. This information is used to

determine what condition, if any, is inhibiting normal transmission operation. Shift

Inhibits do not generate diagnostic codes as there is no malfunction occurring in

the system.

1 Using the and keys, scroll through the Diagnostics menu until

SHIFT INHIBITS appears.

2 Press .

The following screen appears:

3 Use the and keys to scroll through the Shift Inhibits list.

Each inhibitor will have one of the following designations:

Y = inhibitor active; shifting is not permitted

N = inhibitor inactive; transmission shifting is permitted

DIAGNOSTICS

----Selections----

SHIFT INHIBITS

INPUT SPD N

SPL FUNC RNG N

MED COLD OIL N

WHELL LOCK N

30 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

The Pro-Link

/MPC displays a Y for Yes and an N for No when the following

inhibits are active or inactive respectively:

Shift Inhibit Description

INPUT SPEED If input (engine) speed is above a calibration

value, and the splogic output speed is LO,

then neutral to drive and neutral to reverse

shifts are not allowed. The display updates

instantly from N to Y but will only update from Y

to N after a range selection.

SPECIAL FUNCTION

RANGE (SPL FUNC

RNG)

This inhibit is active when an I/O function input

wire (using the direction change enable func-

tion) disables the following shifts:

Neutral to Drive

Neutral to Reverse

Drive to Reverse

Reverse to Drive

This display will only update when a range is

selected.

MEDIUM COLD OIL When the transmission oil is cold, this inhibit

limits operation to reverse, neutral, and second

and higher forward ranges. This display

updates instantly.

WHEEL LOCK When rapid deceleration of the output shaft is

detected, this inhibit will prevent downshifts.

This condition only lasts for a few seconds.

SPLOGIC THROTTLE

and SPLOGIC OUT SPD

SPLOGIC THROTTLE and SPLOGIC OUT

SPD inhibitors list the LO and HI state condi-

tions. SPLOG=INHIB WARN is not followed by

a state condition indicator. This parameter is a

special pattern logic action code and can be

different at various times.

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 31

SPECIAL PATTERN

LOGIC

Special Pattern Logic will do one of the follow-

ing (depending on the status of splogic

throttle (HI/LO) and splogic output speed (HI/

LO), which updates instantly):

Inhibit WarningDirection change shifts

are inhibited and the select digit flashes

with a continuous warning tone.

CFNFRThis response pre-selects down

to a calibration gear ratio, and then shifts to

neutral. There is no warning tone and the

select digit will not flash.

Neutral WarningThe transmission will

shift to neutral, and the select digit will flash

with a continuous warning tone.

Enable ShiftsThis allows normal trans-

mission operation.

SP LOGWill only update as ranges are

selected by the operator.

I/O WIRE STATES I/O Wire States shows the status of each avail-

able input and output wire for the ECU in the

configuration selected. It also indicates if the

wire is in use and what function the input or

output serves. Each wire is described as

follows:

WIRE XXX IN X OFFThis is the pro-

grammed input function, giving the wire

circuit number, the input function number,

and the ON or OFF state of that function on

the first line. The second line in the data

display is an English description of that

function.

WIRE XXX OUT # OFFThis is pro-

grammed output function, giving the wire

circuit number, the input function number,

and the ON or OFF state of that function on

the first line. The second line in the data

display is an English description of that

function.

Shift Inhibit Description

32 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

I/O Wire States

1 Use the and keys to scroll through the DIAGNOSTICS menu

until I/O WIRE STATES appears.

2 Press .

A screen similar to the following appears:

3 Use the and keys to scroll through the available wire states.

The following tables describe sample WTEC and WTEC III/IV wire states;

actual values change based on the calibration:

WIRE 119 IN#19 OFF

ENG BRAKE REQUEST

TABLE 3. WTEC II I/O Sample Wire States

Wire #

Sample

Function

Sample

State Sample Defintion

117 IN#00 OFF INPUT NOT USED

118 IN#00 OFF PTO ENABLE

119 IN#19 OFF ENG BRAKE REQUEST

137 IN#40 OFF SERVICE BRK STATUS

153 IN#18 OFF AUX FUNC INHB SPL1

154 IN#20 OFF ANTI-LOCK BRAKE

155 IN#38 OFF AUX FUNC INHB SPL2

163 IN#00 OFF INPUT NOT USED

MODE IN#01 OFF SECOND SHIFT SCHED

105 OUT#00 OFF OUTPUT NOT USED

112 OUT#00 OFF OUTPUT NOT USED

114 OUT#22 OFF NEUT INDICATOR PTO

125 OUT#00 OFF OUTPUT NOT USED

132 OUT#02 OFF ENGINE BRAKE ENABLE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 33

4 Press to return to the DIAGNOTICS menu.

TABLE 4. WTEC III I/O Wire States

Wire #

Sample

Function

Sample

State Sample Description

117 IN#00 OFF INPUT NOT USED

118 IN#00 OFF INPUT NOT USED

119 IN#19 OFF ENG BRAKE REQUEST

126 IN#00 OFF INPUT NOT USED

137 IN#40 OFF SERVICE BRK STATUS

153 IN#01 OFF SECOND SHIFT SCHED

154 IN#00 OFF INPUT NOT USED

155 IN#17 ON AUX FUNC INHB STD

163 IN#54 OFF RETARDER ENABLE

169 IN#45 OFF ENG BRAKE REQUEST #2

177 IN#00 OFF INPUT NOT USED

178 IN#00 OFF INPUT NOT USED

MODE IN#15 OFF PTO ENABLE

105 OUT#10 OFF SUMP/RTDE TEMP IND

112 OUT#12 OFF PTO ENABLE 1

114 OUT#04 ON RANGE INDICATOR

125 OUT#09 OFF RETARDER INDICATOR

132 OUT#02 OFF ENGINE BRAKE ENABLE

166 OUT#00 OFF OUTPUT NOT USED

167 OUT#05 OFF OUTPUT SPD INLK A

176 OUT#00 OFF OUTPUT NOT USED

34 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Clear Active Indicators

1 Use the and keys to scroll through the DIAGNOSTICS menu

until CLEAR ACT INDICATORS appears.

2 Press .

The following screen appears:

3 Press .

The following screen appears:

The Pro-Link

/MPC displays the DIAGNOSTICS menu.

If the vehicle is still in motion, the following screen appears:

When all Active Indicators have been cleared, the following screen appears:

4 Press to return to the DIAGNOSTICS menu.

DIAGNOSTICS

----Selections----

CLEAR ACT INDICATORS

CONTINUING WILL

CLEAR ACTIVE

INDICATORS

[CONTINUE] CANCEL

OUTPUT SPEED TOO HI

[ENTER] TO CONTINUE

ACTIVE INDICATORS

HAVE BEEN CLEARED

[ENTER] TO CONTINUE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 35

Clear Inactive Codes

1 Use the and keys to scroll through the DIAGNOSTICS menu

until CLEAR INACTIVE CODES appears.

2 Press .

The following screen appears:

3 Press to continue.

The following two screens appear:

4 Press to return to the DIAGNOSTICS menu.

If you do not wish to erase the Inactive Codes, press the key to select

CANCEL. Then press to return to the DIAGNOSTICS menu. The

Inactive Codes will remain in the system memory.

CONTINUING WILL

CLEAR INACTIVE CODES

[CONTINUE] CANCEL

CLEARING INACTIVE

CODES

PLEASE WAIT

[FUNC] TO CANCEL

INACTIVE CODES

HAVE BEEN CLEARED

[ENTER] TO CONTINUE

36 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Action Requests

1 Use the and keys to scroll through the DIAGNOSTICS menu

until ACTION REQUESTS appears.

2 Press .

The following menu options appear:

Enable Clutch Test

Disable Clutch Test

Activate Fast Adaptive

Reset Unadaptive Shifts

Reset Throttle Calibration

Reset Autodetect

Certain conditions must be met for these actions to be performed. You may

receive the following message while attempting to perform these actions:

This message occurs if the vehicle is moving. Stop the vehicle in a safe

place and set the parking brake so the vehicle will not move. Shift the trans-

mission into Neutral. Press .

OUTPUT SPEED TOO HI

[ENTER] TO CONTINUE

VEHICLE MUST BE

STOPPED AND NEUTRAL

SELECTED TO CONTINUE

[ENTER] TO CONTINUE

NOT IN NEUTRAL

[ENTER] TO CONTINUE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 37

This message occurs when you are stopped but the transmission is in any

other position besides Neutral. Set the parking brake and shift the transmis-

sion into Neutral. Press .

The ECU transmitted a code the Pro-Link

/MPC did not understand. Press

. The Pro-Link

/MPC will repeat the requested action.

ECU RESPONSED

UNDEFINED

[ENTER] TO CONTINUE

38 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Enable Clutch Test

To run the Enable Clutch test:

1 From the Action Requests menu, select Enable Clutch Test, and press

.

The following screen appears.

2 Press .

The following screens appear:

3 Use the and keys to scroll through the list of Diagnostic Data.

4 Press to return to the Action Requests menu.

5 Do one of the following:

Continue to make selections from the Action Requests menu.

or

Press to return to the Diagnostics menu.

CONTINUING WILL

ENABLE CLUTCH TEST

[CONTINUE] TO CANCEL

ENABLING CLUTCH TEST

PLEASE WAIT...

[FUNC] TO CANCEL

J1939 ABS ACTIVE NO

J1939 KICK ACTIVE NO

J1939 ENG BRK LV N/A

CLTCH TST ENABL ON

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 39

Disable Clutch Test

To run the Disable Clutch test:

1 From the Action Requests menu, select Disable Clutch Test.

2 Press .

The following screen appears:

3 Press to return to the Action Requests menu.

4 Do one of the following:

Continue to make selections from the Action Requests menu.

or

Press to return to the Diagnostics menu.

CONTINUING WILL

DISABLE CLUTCH TEST

[CONTINUE] CANCEL

40 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Activate Fast Adaptive

Use the Activate Fast Adaptive option if you want the shifts to have a faster con-

vergence. A faster convergence leads to a smoother shifting condition.

To use the Activate Fast Adaptive option:

1 From the Action Requests menu, select Activate Fast Adaptive.

2 Press .

The following screen appears.

3 Press .

4 Press to return to the Action Requests menu.

5 Do one of the following:

Continue to make selections from the Action Requests menu.

or

Press to return to the Diagnostics menu.

CONTINUING WILL

ACTIVATE FAST

ADAPTIVE

[CONTINUE] TO CANCEL

FAST ADAPTIVE HAS

BEEN ACTIVATED

[ENTER] TO CONTINUE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 41

Reset Unadapted Shifts

To use the Reset Unadapted Shifts option:

1 From the Action Requests menu, select Reset Unadapted Shifts.

2 Press .

The following screen appears:

3 Press enter.

The following screen appears:

4 Press enter to return to the Action Requests menu.

5 Do one of the following:

Continue to make selections from the Action Requests menu.

or

Press to return to the Diagnostics menu.

CONTINUING WILL

RESET UNADAPTED

SHIFTS

[CONTINUE] CANCEL

SHIFTS HAVE BEEN

RESET TO UNADAPTED

CYCLE IGNITION POWER

[ENTER] TO CONTINUE

42 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Reset Throttle Calibration

To use the Reset Throttle Calibration option:

1 From the Action Requests menu, select Reset Throttle Calibration.

The following screen appears:

2 Press .

The following screen appears:

3 Press to return to the Action Requests menu.

4 Do one of the following:

Continue to make selections from the Action Requests menu.

or

Press to return to the Diagnostics menu.

CONTINUING WILL

RESET THROTTLE

CALIBRATION

[CONTINUE] CANCEL

THROTTLE CALIBRATION

HAS BEEN RESET

[ENTER] TO CONTINUE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 43

Reset Autodetect

Use this option to reset all Customer Modifiable Constants (CMCs) that have been

set to Autodetect. CMCs that can be reset include, but are not limited to the

following:

Retarder

Oil Level

TPS Source

Engine Coolant Source

To use the Reset Autodetect option:

1 From the Action Requests menu, select Reset Autodetect.

2 Press .

The following screen appears:

3 Press .

The following screen appears:

4 Press to return to the Action Requests menu.

5 Do one of the following:

Continue to make selections from the Action Requests menu.

or

Press to return to the Diagnostics menu.

CONTINUING WILL

RESET AUTODETECT

PARAMETERS

[CONTINUE] CANCEL

AUTODETECT WILL

RESTART AT NEXT

ENGINE START

[ENTER] TO CONTINUE

44 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Trigger/Snapshot

Trigger/Snapshot enables the Pro-Link

/MPC to record data from the vehicle

while it is being driven. Data can then be played back when you return to the shop.

You can use this feature to identify intermittent problems that would be difficult to

locate by any other method. Depending on the data update rate selected, the Pro-

Link

/MPC can record up to 30 minutes of data.

When using the Trigger/Snapshot option, the Pro-Link

/MPC continuously

records data. When the memory is full, the oldest data is dropped and new data

is added. You choose what will trigger data recording. The trigger is a mark in

the recording so you can find that exact spot later during playback. You choose

what to use as a trigger. Because driveability problems are often related to active

codes, you can have the Pro-Link

/MPC trigger when an active code is set. You

can choose a specific code, or have the trigger set if any code is stored while

Trigger/Snapshot is enabled.

You decide how much data will be stored before or after a trigger has been set. It

is sometimes useful to record data that was stored before a trigger was set,

looking for a trend that led up to setting the trigger. It can also be helpful to look at

data that was recorded after a trigger was set. You decide ahead of time how

much data will be recorded before and after the trigger point.

You can also review Snapshot data captured once the trigger has activated by se-

lecting a data list. For more information on how to review Snapshot data, refer to

Reviewing Snapshot Data later in this chapter.

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 45

You access Trigger/Snapshot functions from the MPC Utilities menu or the

WTEC Diagnostics menu.

The Pro-Link

/MPC uses a fault code (specific or any) as the trigger. You specify

the trigger point by choosing from the following:

Trigger on Any Code

Trigger on Specific

Trigger Manually

Clear Trigger

Print Snapshot

To use the Trigger/Snapshot option and set the trigger point:

1 From the Diagnostics menu, select Trigger/Snapshot.

2 Press .

The following screen appears:

3 Use the and keys to make your selection.

TRIGGER/SNAPSHOT

----Selections----

TRIGGER ON ANY CODE

46 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Trigger on Any Code

If you select Trigger on Any Code as your trigger point, the Pro-Link

/MPC

triggers on any fault code when an active fault occurs.

To use the Trigger on Any Code option:

1 From the Trigger/Snapshot menu, select Trigger on Any Code.

2 Press .

The following screen appears:.

3 Press to continue.

When an active fault occurs, the following screen appears:

4 Press to return to the previous screen.

TRIGGER/SNAPSHOT

----Selections----

TRIGGER ON ANY CODE

TRIGGER IS SET TO

ANY CODE

[ENTER] TO CONTINUE

TRIGGER OCCURRED AT

XX-XX-XX

[ENTER] TO CONTINUE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 47

Trigger on Specific

If you select Trigger on Specific as your trigger point, the Pro-Link

/MPC triggers

only on the specific code you designate.

To use the Trigger on Specific option:

1 From the Trigger/Snapshot menu, select Trigger on Specific.

2 Press .

The following screen appears:

3 Use the and keys to scroll through the specific WTEC codes until

the appropriate code is displayed.

4 Press .

The following confirmation screen appears:

The trigger is activated when the selected code has an active fault.

TRIGGER/SNAPSHOT

----Selections----

TRIGGER ON SPECIFIC

SELECT TRIGGER CODE

12 12

TRIGGER SET TO 21 12

21 THROTTLE SENSOR

FAILED LOW

[CONTINUE] CANCEL

48 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Trigger Manually

If you select Trigger Manually, you determine the trigger point by pressing any

numeric key on the Pro-Link

/MPC. Keep the Press Any Numeric Key to Fire

Trigger screen active while driving the vehicle, then set the trigger point at your

discretion.

To use the Trigger Manually option:

1 From the Trigger/Snapshot menu, select Trigger Manually.

2 Press .

The following screen appears:

3 While driving the vehicle, press any numeric key to manually set the trigger

point.

The following screen appears:

Line two is the length of time the Pro-Link

/MPC has been on before the

trigger point was set.

TRIGGER/SNAPSHOT

----Selections----

TRIGGER MANUALLY

PRESS ANY NUMERIC

KEY TO

FIRE TRIGGER

[FUNC] TO CANCEL

TRIGGER OCCURRED AT

XX-XX-XX

[ENTER] TO CONTINUE

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 49

Clear Trigger

Use the Clear Trigger option to erase the data that is being stored at the time the

trigger is activated. The only information retained will be the current information

from the vehicle.

To use Clear Trigger option:

1 From the Trigger/Snapshot menu, select Clear Trigger.

2 Press .

A Trigger Cleared message appears.

3 Press to return to the Trigger/Snapshot menu.

Print Snapshot

Use Print Snapshot to print the data that was stored in the Custom Data List

when Snapshot was activated. Each piece of Snapshot data is stored in a frame.

You select the number of frames you want to print. You access the Print

Snapshot option from the Trigger/Snapshot menu.

Note: You must set up a custom data list prior to printing Snapshot data. If you

have not set up a custom data list, you may encounter the following

message:

TRIGGER/SNAPSHOT

----Selections----

CLEAR TRIGGER

SNAPSHOT PRINTOUT

ONLY AVAILABLE FOR

CUSTOM DATA LIST

[ENTER] TO CONTINUE

50 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

Refer to the Custom Data List section of the Multi-Protocol Utilities Manual

for details on setting up a custom data list. You may create a custom data

list to print Snapshot data before or after Snapshot data is captured. The

custom data list may also be altered and Snapshot data printed again.

Snapshot data will only be deleted when the Pro-Link

/MPC is turned off

or when a new Snapshot request is activated.

To use the Print Shapshot option:

1 From the Trigger/Snapshot menu, select Print Snapshot.

2 Press .

The following screen appears:

Selecting the number of frames you want to print allows for the adjustment

of the data window to print.

3 Using the numeric keypad, enter the number of frames desired.

4 Press .

The following screen appears:

TRIGGER/SNAPSHOT

----Selections----

PRINT SNAPSHOT

ENTER TOTAL SNAPSHOT

FRAMES TO PRINT

100

ENTER MSECS PER

FRAME

500

- Diagnostics Menu

Pro-Link

/MPC Allison Transmissions Users Manual 51

The time duration of each frame is in milliseconds (1000 milliseconds equals

1 second, 500 milliseconds equals second, etc.). Adjusting the number of

frames and the time or each frame gives the technician the capability to alter

the amount of data printed.

5 Using the numeric keypad, enter the number of milliseconds for each frame.

6 Press .

Snapshot prints five items at a time. If you have more than five items in a

Custom Data List, Snapshot prints five items and the starts over with the

next five items until all Custom Data List selections are printed. You will

receive a printed message.

7 To cancel printing, Press .

Reviewing Snapshot Data

Once the trigger has been activated, you can review the data captured by select-

ing a data list. This list is either a standard data list such as Diagnostics Codes

from the Diagnostics menu, or it could be a custom data list.

To review Snapshot data:

1 Select the data list you wish to review.

2 On the numeric keypad, press 7.

The MPC Info screen appears.

The time should reflect the time the trigger was activated. This indicates that

the Pro-Link

/MPC is in Snapshot Review Mode. The flashing cursor should

be two vertical lines rather than the solid cursor normally seen.

3 Press 7 again to put the Pro-Link

/MPC into Real-time Mode (all data

reviewed will be real time).

NOTE:

iFor detailed explanation of cursors, please refer to the keyboard section of

the Multi-Protocol Cartridge (MPC) Utilities Manual.

4 To view captured data, press the key.

You are returned to the data list you for review.

5 Use the and keys to select the parameter you want to view.

52 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 3 Using the WTEC Diagnostics Menu

6 Place the blinking cursor on the desired parameter.

7 To view changes to the information for that specific parameter during the data

capture time frame, hold in the red, side button located on the left side of the

Pro-Link

/MPC and simultaneously press the or right key.

If you receive an empty message, you have exceeded the time frame of

data captured and must restart the Pro-Link

/MPC.

8 If you wish to continue to review Snapshot data, restart the Pro-Link

/MPC.

9 When prompted to start a new session, select NO.

The data captured during the Snapshot session will be restored for viewing.

IMPORTANT:

If the trigger is activated more than once during a session, only the last

trigger event will be used as a time mark. Earlier triggers will not be

retained as a reference point.

10 Press to return to the Allison WTEC main menu.

Pro-Link

/MPC Allison Transmissions Users Manual 53

4

Using the WTEC

ECU/EEPROM

Setup Menu

u

The Setup Menu, page 54

u

View Customer Modifiable Constants, page 57

u

I/O Wires States, page 59

u

I/O Assignments, page 59

u

Autodetect INFO, page 60

This chapter provides detailed information on using the ECU/EEPROM Setup Menu.

54 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 4 Using the WTEC ECU/EEPROM Setup Menu

The Setup Menu

The ECU/EEPROM Setup menu provides information on the transmission ECU.

The functions of this section of the application will vary based on the version of the

software you have. Not all functionality may be available in your system.

From the WTEC main menu, use the and keys to select ECU/

EEPROM Setup.

Press .

The ECU/EEPROM Setup menu appears:

The following menu selections are available (depending on which version of the

software you have):

ECU Calibration

View CMCs

I/O Wire States

I/O Assignments

Autodetect Info

WTEC II

VERSION XX.XX

----Selections----

ECU/EEPROM SETUP

ECU/EEPROM SETUP

----Selections----

ECU Calibration

- The Setup Menu

Pro-Link

/MPC Allison Transmissions Users Manual 55

ECU Calibration

To use the ECU Calibration option:

1 From the ECU/EEPROM Setup menu, use the and keys to select

ECU Calibration.

2 Press .

A scrollable data list similar to the following appears:

3 Use the and keys to scroll through the parameter list.

ECU/EEPROM SETUP

----Selections----

ECU Calibration

CIN 08002RQ006N

SW Level P02

ECU S/N M-03166498

ECU P/N 29524775

ECU M/D 03-11-1996

HCN 6

CCN D70

TRANS CONFIG

CONFIG AVAIL

CONFIG USED

TOOL S/N 11420

LAST S/N 11420

I/O PACKAGE #00114

56 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 4 Using the WTEC ECU/EEPROM Setup Menu

The following parameters may be viewed:

4 Press to return to the ECU/EEPROM Setup menu.

Parameter Description

CIN Calibration Identification number (11 characters)

SW LEVEL Identifies the software level of the transmission ECU

ECU S/N Identifies ECU serial number (eight characters; an M, B,

or a 3 prior to the number indicates the ECU as a MAX

feature, a Basic, or a WTEC III unit)

ECU P/N Identifies ECU part number without a cover or shifter (up

to ten characters; ECUs manufactured prior to 09/92

may not display a part number)

ECU M/D ECU manufacture date

HCN Hardware compatibility number

CCN Calibration compatibility number

TRANS

CONFIG

Level of transmission detected TRANS ID

CONFIG AVAIL Level of TRANS ID in ECU Calibration

- The Setup Menu

Pro-Link

/MPC Allison Transmissions Users Manual 57

View Customer Modifiable Constants

You use the View CMCs option to view Customer Modifiable Constants (CMCs)

for the selected I/O Package.

The calibration of the transmissions electronic control unit (ECU) is programmed

with one of six possible I/O function packages. The I/O Packages are based on

vehicle use, and contain the appropriate I/O functions and the appropriate settings

for the Customer Modifiable Constants (CMCs) for the stated use of the vehicle.

CMCs vary by I/O Package.

The Pro-Link

/MPC will only display those I/O functions and CMCs that are

enabled by the current ECU programming. Not all of the CMCs in the following list

are available in your specific package.

Customer Modifiable Constant

D1 Select Position (Primary) Eng Brake Preselect Shift

Position

D1 Select Position (Secondary) Maximum Output Speed Auto-

matic Neutral

Maximum Engine Speed for

PTO Engagement

Maximum Output Speed Low

Axle Select

Maximum Engine Speed for

PTO Operation

Range Indicator Low Gear

Maximum Output Speed for

PTO Engagement

Range Indicator First Gear

Maximum Output Speed for

PTO Operation

Range Indicator Second Gear

Range Indicator Third Gear Override Engine Coolant Source

Autodetect

Range Indicator Fourth Gear Override Oil Level Sensor Auto

Detect

Range Indicator Fifth Gear Override Retarder Autodetect

Range Indicator Sixth Gear Eng Coolant Temp To Start

Retarder Capacity Reduction

Range Indicator Neutral Gear Eng Coolant Temp To Start Pre-

select Shifts

Range Indicator Reverse Gear Eng Brake Preselect Shift Sched

Select

58 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 4 Using the WTEC ECU/EEPROM Setup Menu

To view CMCs:

1 From the ECU/EEPROM Setup menu, use the and keys to select

View CMCs.

2 Press .

Speed to Turn On Output Speed

Interlock

Flash If Hot Oil - Retarder

Capacity Reduction

Speed to Turn Off Output Speed

Interlock

Flash If Hot Oil - Preselected

Shifts

Eng Speed to Turn On PTO

Overspeed Ind

Flash if Hot Coolant - Retarder

Capacity Reduction

Eng SPD to Turn Off PTO Over-

speed Ind

Flash if Hot Coolant - Reselected

Shifts

Eng Speed to Turn On Eng

Overspeed Ind

Retarder Capacity Reduction-

Hot Coolant

Eng Speed to Turn Off Eng

Overspeed Ind

Override Throttle Source Auto

Detect

ECU/EEPROM SETUP

----Selections----

VIEW CMCs

Customer Modifiable Constant

- The Setup Menu

Pro-Link

/MPC Allison Transmissions Users Manual 59

The following is a representative screen, displaying the first CMC for the

current I/O Package:

3 Use the and keys to scroll through the list of available CMCs.

4 When you are finished viewing CMCs, press to return to the ECU/

EEPROM Setup menu.

I/O Wires States

The I/O Wire States function provides you with the capability to view the I/O wires

that are enabled.

1 From the ECU/EEPROM Setup menu, select I/O Wire States and press

.

The first I/O Wire is displayed. The ON/OFF indicator on the right-hand side

of the Pro-Link

/MPC display indicates the status of the wire.

2 Use the and keys to scroll through the wire status display.

3 To return to the ECU/EEPROM Setup menu, press .

I/O Assignments

The I/O Assignments function displays the enabled/disabled status of the input

and output wire assignment.

1 From the ECU/EEPROM Setup menu, select I/O Assignments and press

.

2 Use the and keys to scroll through the wire I/O assignments list.

3 To return to the ECU/EEPROM Setup menu, press .

RANGE INDICATOR

SECOND GEAR

NO

60 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 4 Using the WTEC ECU/EEPROM Setup Menu

Autodetect INFO

The Autodetect INFO function displays parameters that are configured for auto-

matic detection.

1 From the ECU/EEPROM Setup menu, select Autodetect INFO and press

.

2 Use the and keys to scroll through the parameter list.

3 A screen similar to the following is displayed:

The following table shows the Allison response to the Throttle Source Avail-

able Signal and the corresponding Autodetect response to the type of

throttle source detected:

The following table shows the Allison response to the Engine Coolant Avail-

able Signal, and the corresponding Autodetect response to the type of

engine coolant source detected:

OIL LEVEL AVAIL NO

RETARD AVAIL NO

ENG COOL SRC ANALOG

ANALOG COOL AVAIL YES

Allison Response Autodetect Response

Analog (ANALG THR AVAIL) Analog (YES or NO)

J-1587 (J1587 THR AVAIL) J-1587 (YES or NO)

J-1939 (J1939 THR AVAIL) J-1939 (YES or NO)

Allison Response Autodetect Response

Analog (ANALG COOL AVAIL) Analog (YES or NO)

J-1587 (J1587 COOL AVAIL) J-1587 (YES or NO)

J-1939 (J1939 COOL AVAIL) J-1939 (YES or NO)

Pro-Link

/MPC Allison Transmissions Users Manual 61

5

Using the WTEC

Printout Option

u

Using the Printout Option, page 62

This chapter provides a quick overview of the Printout option available with Allison

World Transmissions (WTEC). You access the Printout option from the WTEC main menu.

For information on the WTEC main menu, refer to Chapter 2 of this manual.

62 Pro-Link

/MPC Allison Transmissions Users Manual

Chapter 5 Using the WTEC Printout Option

Using the Printout Option

The Printout option provides you with the capability to obtain printed information

on several from several areas within the diagnostic program.

To use the Printout option:

1 From the WTEC main menu select Printout.

2 Press .

The following items (varies by diagnostic application) may be available to

print:

3 Use the and keys to scroll through the menu and select the items

you wish to print

4 Press .

WTEC II

Version X.XX

----Selections----

PRINTOUT

ECU Calibration Info Diagnostic Codes

I/O Wire States AutoDetect Info

Modifiable Constants I/O Assignments

Shift Inhibits Custom Data List

Diagnostic Data MPC Info

- Using the Printout Option

Pro-Link

/MPC Allison Transmissions Users Manual 63