Beruflich Dokumente

Kultur Dokumente

Imer Cement Mixer Workmanii250

Hochgeladen von

Douglas Allen Hughes Sr0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

276 Ansichten14 SeitenImer Cement Mixer Workmanii250

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenImer Cement Mixer Workmanii250

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

276 Ansichten14 SeitenImer Cement Mixer Workmanii250

Hochgeladen von

Douglas Allen Hughes SrImer Cement Mixer Workmanii250

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 14

Machine serial N

Manual Part. number 3209290_R04 - 2003/10

U.S.A. inc.

WORKMAN II 250 MULTIMIXER

R

MANUAL INSTRUCTION

and

PARTS LIST

Model - 1105850

Write in the serial nof your machine here

IMER U.S.A. Inc.

- 2 -

WORKMAN 250 II Multimixer

Thank-you for purchasing a Workman 250 II from an Imer U.S.A. dealer. Your decision is an

intelligent one.

There is no other concrete mixer in the world which delivers the benefits and features of the

Workman 250 II:

- Extremely rigid, mig welded bar steel frame.

- 5.5 H.P. Honda with low oil alert.

.

- Full width fenders.

- Torsion Bar suspension.

- Advance drum and paddle design, excellent mixing and discharge action.

- Telescopic foot stands which provide additional stability during operation.

At IMER U.S.A. we continually search for ways to better serve our customers. Should you have

an idea or thought to share with us regarding this product we would appreciate hearing from

you. Our motto is "Tools and Services for the 21st Century" .

We look forward to delivering

the goods.

Thank you again for your purchase.

Mace T. Coleman, Jr.

President, Imer U.S.A, Inc.

IMER WEST

207 Lawrence Avenue

So. San Francisco, CA 94080

Tel 650 - 872 - 2200

Fax 650 - 873 - 6482

IMER EAST

221 Westhampton Place

Capitol Heights, MD 20743

Tel 301 - 336 - 3700

Fax 301 - 336 - 6681

IMER U.S.A. Inc.

- 3 -

WORKMAN 250 II Multimixer

IMER U.S.A., INC.

WORKMAN 250 II MULTIMIXER

INSTRUCTION MANUAL

NOTE:

Please read this manual before beginning to

assemble or operate this piece of equipment.

ASSEMBLY ........................................................................................ 4

IMPORTANT NOTES AND ADVICE.................................................. 5

OPERATING INSTRUCTIONS ........................................................... 7

MAINTENANCE.................................................................................. 8

BASIC TROUBLE SHOOTING - TECHNICAL SPECIFICATIONS... 10

SPARE PARTS ................................................................................... 11

IMER U.S.A. Inc.

- 4 -

WORKMAN 250 II Multimixer

ASSEMBLY

+

TOWING

Essentially the Workman 250 II is fully assembled and ready to operate when it leaves the assembly

facility here at Imer U.S.A. However, there are a couple items which should always be checked before

towing the Workman 250 II.

1. Make sure each tire is inflated to 50 PSI (cold), and check the oil level of the Honda motor.

2. Make certain the retractable stability legs are raised up fully and locked in place with the anchor

pin provided.

3. Make certain that the tow bar is properly anchored and its tow chain is in place. It is also important

to loop the tow chain around the tow bar several times before connecting it to a vehicle.

4. Make sure the engine canopy door is latched shut.

5. Make certain that the hitch system on your car or truck is compatible to the tow bar tongue.

6. Finally, local laws and ordinances vary from state to state regarding the registration of towable

construction equipment, check and see if a license plate is required. Call your local Department of

Motor Vehicles for the proper procedure to follow.

NOTE

State law may also require a tail light assembly.

Check with your local Department of Motor Vehicles for the proper procedure to follow.

IMER U.S.A. Inc.

- 5 -

WORKMAN 250 II Multimixer

IMPORTANT NOTES AND ADVICE

Do's and Don'ts on the Safe Use

of the Workman 250 II

In the interest of safety, whoever uses the Workman 250 II should first read this manual and become

familiar with all of the important safety notes. Failure to follow this advice may result in injury to

yourself and others.

WHAT TO DO !

- Carefully read and understand these instructions before operating the mixer. Read the Honda manual too.

- Always turn off the engine and disconnect the spark plug wire before cleaning or maintaining the mixer.

Mixers powered by electric motors should be unplugged from their power source before servicing is

performed.

- Make sure the safety guards are always in place.

- When using the machine always wear safety boots with reinforced toe-caps, safety glasses, gloves,

hard hat, and clothing with the appropriate fit. Loose clothing can cause injury should it become entangled

with the mixer.

- Practice starting and stopping the machine.

- Keep the mixer clean and free of debris build-up.

- Periodically inspect your mixer for abnormal wear or damage.

- Always stop the engine before adding fuel.

- Do not operate the mixer while under the influence of drugs or alcohol.

-Alwais operate the mixer on a level surface

-When loading the Workman it is the best to pour your bagged material into a 5 gallon buket then pour it

into the drum

- It is much easyier on your body and safer to load the drum in this manner.

IMER U.S.A. Inc.

- 6 -

WORKMAN 250 II Multimixer

IMPORTANT NOTES AND ADVICE

WHAT NOT TO DO !

DO NOT

Place your hands or any other object inside the mixer drum while it is running.

DO NOT

Place any tools or other objects in or around the mixer drum while it is running .

DO NOT

Operate the mixer on a surface that is UNEVEN.... if the Workman is placed on an incline, it can fall over

or roll away.

DO NOT

Clean, assemble or work on the mixer while it is plugged in !

DO NOT

Operate the mixer in or around water puddles !

DO NOT

Leave the mixer unattended !

DO NOT

Allow other persons around the mixer while it is operating

DO NOT

Operate the Workman II 250 if you are uncertain as to how to run the machine.... Contact your local Imer

Distributor or call Imer U.S.A. at 800 - 275 - 5463.

DO NOT

Operate the mixer while under the influence of drugs or alcohol !

WE WANT SAFE AND EFFICIENT

PRODUCTION/OPERATION

FOR ALL OUR CUSTOMERS !

IMER U.S.A. Inc.

- 7 -

WORKMAN 250 II Multimixer

OPERATING INSTRUCTIONS

1. Before starting the engine read the Honda manual provided and become familiar with the GX160

powerplant. Especially important is to check the oil daily and change it monthly. Additionally, cleaning

the air filter weekly ensures consistently good performance.

2. Operate the the Workman II 250 on a level surface. For additional stability the telescopic foot stands

can be lowered and locked into place.

3. To put the drum in the loading position rotate the dump wheel until the desired drum position is

achieved.

4. Start the engine and set the throttle at 3/4 to full on.

5. Now add 1/2 of the water which will be required and then begin to add the cement and aggregates.

Additional water can be added as the cement and aggregates mix together.

BE CAREFUL ! Do Not put your shovel or your hands inside the drum !

6. To put the drum in the discharge position rotate the dump wheel untill the desired drum position

is achieved.

7. During the loading, mixing, and discharge cycle it is important to keep the mixer running at all times.

8. Always prepare your work site to have a level ground surface, the mixer must be stable as you load and discharge

the drum.

IMER U.S.A. Inc.

- 8 -

WORKMAN 250 II Multimixer

MAINTENANCE

Lubrication

1. All the other components on the mixer which engage or move back and forth should be lubricated with a

light aerosol type lubricant on a weekly basis. WD- 40 works well for this application.

2. Essentially the gearbox is sealed for life.The quality of the gears and the lubricant are such that changing

the oil is not necessary. If you want to change the oil,see your dealer or call IMER U.S.A directly for

instruction.

3. One a year remove the cast cap from the top half of the dump gear assembly and grease it up good.

(Part #36, page 12)

Belt Tension

1. The mixer has two belts: one in the canopy and the other in the arm. The belts are properly adjusted

before leaving our factory, however, it is a good idea to check their tension before operating the mixer.

Then, when one belt becomes loose, tighten it back to this original condition.

NOTE

The belts will stretch the most during the first few

hours of operation .... check them frequently, and

always kill the motor and disconnect the spark plug

wire before touching the belts. Or, if your machine has

an electric motor, unplug it from the power source

before adjusting the behs.

2. To tighten the belt inside the canopy loosen the bolts which anchor the motor mount plate to

the mixer frame. This allows the motor mount plate to slide down the frame, which in turn

tightens the belt.The belt should have 1/4" to 3/8" of play.Now re-tighten the bolts which

anchor the motor mount plate.

3. To tighten the belt inside the arm loosen the 4 nuts which anchor the gearbox on the arm.

Tighten the belt by turning the adjustment bolt. The belt should have 1/4" to 3/8" of play, do

not over tighten as this shorter their drive life. Now re-tighten the gearbox anchor bolts.

IMER U.S.A. Inc.

- 9 -

WORKMAN 250 II Multimixer

NOTE

It is very important to keep the engine pulley and the

drive pulley in line with one another. Failure to

maintain this alignment will cause the belt to twist and

then break.

Wheel Bearings

1. The wheel bearings should be cleaned and repacked every 6 months to 1 year. The interval being

dependant upon the amount of time the machine is towed, and under what conditions. This maintenance

procedure is the same as that for automotive wheel bearings.

Engine

Read the Honda manual carefully ... and follow their instructions.

Changing the oil and cleaning the air filter frequently ensure a reliable and long lasting motor.

When you may need Honda Engine Service or Warranty Assistance, take the machine to your local Honda

power equipment dealer, they will honor the Warranty throughout America.

NOTE

It is always a good idea to check the oil level in the

engine crankcase at the start of each working day.

Clean oil at the correct level makes for a engine that

will last and last.

Mixer s drum disassembly and re-assembly

In case it s necessary to remove the drum, to reset it it s necessary.

- to clean carefully the gear shaft cone and the drum cone.

- to place the drum on the shaft cone, making sure that shaft shear pin is inside its seat in the drum cone.

- to block drum tighting screw with washer by following tighting torques:

Workman 250 II: 220 20 Nm.

MISC.

Every month check all the mixer's mounting hardware to

ensure all the nuts and bolts are properly tightened.

IMER U.S.A. Inc.

- 10 -

WORKMAN 250 II Multimixer

TECHNICAL

SPECIFICATIONS

WORKMAN II 250

*Capacity based upon usable volume

Due to Imer U.S.A. 's commitment to

Reasearch and Development,

specifications are subject

to change without notice.

Drum capacity 9 CU. FT.

Batch Output 6 CU. FT. (1 bag)*

Drum Diameter 27.5 Inches

Discharge Outlet Height 27.5 Inches

Pneumatic Wheels 4.50-10 Inches ( 50 PSI )

Power plants

5.5 HP Honda GX160

1.5 HP electric

Overall Operating Dimensions 76" x 49" x 57"

Overall Storage Dimensions 76" x 49" x 57"

Weight 450 LBS (206 Kg)

IMER U.S.A. Inc.

- 11 -

WORKMAN 250 II Multimixer

SPARE PARTS

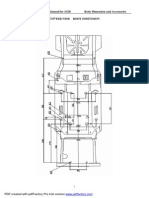

DRAWING 1.3 (WORKMAN II 250 CONCRETE MIXER - 1105850)

Ref. P.n. Main Description NOTES

1 3209287 MAIN FRAME

2 3209294 TOW BAR

3 3208906 ARM

4 3208811 DRUM ASS'Y

5 3206690 T-BOLT

6 3207225 T-BOLT WASHER

7 3209953 STABILIZING FOOT

8 3208792 NYLON FIBER BUSHING

9 2227205 CIRCLIP E 50

10 3209032 PLASTIC PLUG

11 3209298 HONDA MOTOR HONDA G 150

12 3209052 MOTOR PULLEY

13 3206322 WASHER 8X30X5

14 2210950 MOTOR BELT

15 3209524 BELT GUARD

16 2248216 TORSION BAR AXLE

17 3209293 LEG FRAME

18 3209250 REAR LEG FRAME

19 3208924 GEAR BOX

20 2223980 WHEEL NUT S 190 TT

21 2223923 SELF LOCKING NUT M 8 Z

22 2222114 BOLT M8X90 Z

23 2227320 CIRCLIP E 20

24 3208925 GEAR BOX BELT COVER

25 2222420 BOLT 4,8X13

26 3209134 BOLT M10X140Z

27 3208776 KEY WAY 14X9X25

28 3208770 BUSHING

29 3208773 DUMP GEAR Z 32

30 2211407 TIRE + WHEEL

31 3206704 ANCHOR PIN

32 3208944 BUMPER PAD

33 3208790 BUMPER PAD

34 2224220 WASHER D10X40

35 2223920 SELF LOCKING NUT M10 Z

36 3213876 CAST CAP

37 2222181 BOLT

38 2223921 SELF LOCKING NUT

39 3209786 DUMP GEAR CASTING

40 2229300 KEY WAY 6X6X20

41 2224204 WASHER D.8X24

42 3205545 RUBBER SWITCH CUP E 20

43 3208777 DUMP WHEEL

44 3206748 DUMP HANDEL

45 2223923 SELF LOCKING NUT M8 Z

46 2222077 BOLT M8X20 Z

47 3209049 BELT - GEAR BOX DRIVE 530 J6

48 3209289 SAFETY LABEL S 190 TT

49 3208916 ROLLER SHAFT

51 3203917 WASHER D8X25X4 Z

52 3201015 LEG CAP

53 3209467 ANCHOR PIN

54 2226700 SPLIT PIN

55 3210560 ENGINE MOUNTING FRAME

56 3209119 ENGINE MOUNTING PLATE

57 2222148 BOLT M10X65 Z

58 3208915 ROLLER GUIDE

59 2204421 ROLLER BEARING 6201 2RS

60 1227330 CIRCLIP E 15

61 2204438 DRIVE SHAFT BEARINGS 6004 2RS

62 3208919 GEAR BOX DRIVE PULLEY

63 3209055 SPACER

64 3203117 KEY WAY 5X5X20

65 3209054 SHAFT

67 3209053 ENGINE PULLEY

68 3208935 CANOPY DOOR

69 3209459 CANOPY REAR

70 3209120 MOUNTING BRACKET

71 2221994 PULLEY BOLT 5/16"X25 Z

72 3209136 ENGINE PULLEY GUARD

73 3209111 LOCK LEVER ROD

74 2222190 BOLT M8X40 Z

77 3209133 DUMP ARM PLUG

78 2222091 BOLT M8X70 Z

79 3205544 KILL BUTTON

80 3206011 FENDER

81 2222146 BOLT

82 3207782 FENDER ARM

83 2222060 BOLT M8X20 Z

84 2235452 PLUG

85 3206855 BOLT

87 3206861 AXLE MOUNTING SPACER

88 2223929 NUT

89 2234861 TOW CHAIN

90 2292298 QUICK CLIP

91 3208921 SHORT SPACER

92 3208923 LONG SPACER

IMER U.S.A. Inc.

- 12 -

WORKMAN 250 II Multimixer

DRAWING 1.3 WORKMAN II 250 CONCRETE MIXER

IMER U.S.A. Inc.

- 13 -

WORKMAN 250 II Multimixer

TABLE 2 - GEAR BOX : WORKAM II 250 (COD. 3208746)

RIF. COD. GB NOTE

1 2222018 BOLT M8 X 35 Z

2 3213896 OIL SEAL 72X52X8

3 2222112 BOLT M8 X 100 Z

4 3209681 GEAR BOX CASE

5 3213887 GEAR BOX GASKET

6 2228360 SHEAR PIN 8 X 16

7 3213897 KEY WAY 10X8X15

8 3209679 BEARING 6301

9 2202493 GEAR WHEEL Z.79

10 2229249 KEY 5X5X12

11 3208754 PINION GEAR Z9 M 1,75

12 3209680 GEAR BOX CASE

13 3200094 OIL SEAL 35X20X7

14 2229250 KEY 5X5X15

15 2204440 BEARING 6004

16 3209770 PINION GEAR Z9 M 1,25

17 2222114 BOLT M8 X 90 Z

18 3208762 PULLEY

19 3208752 SPACER

20 2223570 NUT M8 Z

21 2224140 WASHER D=8 Z

22 3213899 BEARING 6209 SKF

23 2227220 CIRCLIP E 40

24 3208756 GEAR Z68

25 3213898 BEARING 6207 SKF

26 2228820 LOCATING PIN D=6X14

27 3208748 DRIVE SHAFT

28 1227330 CIRCLIP E 15

29 2224060 WASHER D=8 Z

TABLE 3 - DRUM REDUCTION UNIT

RIF. COD. DESCRIPTION NOTE

1 3209428 GEAR BOX CASE

2 3209430 COVER

3 3213893 DUMP GEAR M10X110 Z

4 2222465 BOLT M5X15 Z

5 3213811 OIL SEAL RING 47X17X7

6 3209728 SCREW M6X15

7 3213264 PINION GEAR Z 20

8 2229259 KEY WAY 6X6X14

9 3208771 SHAFT

10 2229300 KEY WAY 6X6X20

11 2227320 CIRCLIP E 20

12 3208952 BEARING 6206 2Z

13 2204391 BEARING 6205 2Z

14 2204484 BEARING 6203 2Z

16 2204560 BEARING 6204 2RS

17 3209431 COVER

IMER U.S.A. Inc.

- 14 -

WORKMAN 250 II Multimixer

207 Lawrence avenue

So. San francisco, CA 94080

Tel.(650) 872-2200

Fax(650) 873-6482

U.S.A. INC.

IMER

EQUIPMENT WARRANTY

U.S.A. INC.

We warrant to the original purchaser that the IMER equipment described herein (the "equipment") shall be

free from defects in material and workmanship under normal use and service for which it was intended for

period of one (1) year from the date of purchase by the original purchaser.

Our obligation under this warranty is expressly limited to replacing or repairing, free of charge, F. O.B. our

designated service facility, such part of the equipment as our inspection shall disclose to be defective.

Parts such as engines, motors, pumps, valves, electric motors, etc. furnished by us, but not manufactured

by us, will carry only the warranty of the manufacturer. Transportation charges or duties shall be borne by

purchaser. This shall be the limit of our liability with respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged by reason of

accident, negligence, unreasonable use, faulty repairs, or which has not been maintained and operated in

accordance with our printed instructions for the equipment. Further, this warranty is void if the equipment,

or any of its components, is altered or modified in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to make one on our

behalf. We shall not be liable for consequential damage of any kind, including loss or damage resulting,

directly or indirectly, from the use or loss of use of the machine. Without limiting the generality of the

foregoing, this exclusion from liability embraces the purchaser's expenses for downtime, damages for

which the purchaser may be liable to other person, damages to property, and injury or death of any

persons.

This warranty shall not be deemed to cover maintenance parts, including but not limited to blades, belts,

hoses, hydraulic oil, or filters, for which we shall have no responsability or liability whatsoever.

R

Das könnte Ihnen auch gefallen

- Mercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Von EverandMercedes - Benz Vito & V-Class Petrol & Diesel Models: Workshop Manual - 2000 - 2003Bewertung: 5 von 5 Sternen5/5 (1)

- Operator's Manual: Massey Ferg NDokument78 SeitenOperator's Manual: Massey Ferg Nmendipe40Noch keine Bewertungen

- FMS InstructionsDokument2 SeitenFMS InstructionsBjørn Vest HansenNoch keine Bewertungen

- Tractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorVon EverandTractor Principles: The Action, Mechanism, Handling, Care, Maintenance and Repair of the Gas Engine TractorNoch keine Bewertungen

- Bobcat 753 Service ManualDokument502 SeitenBobcat 753 Service ManualOsama Farah71% (7)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideVon EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideBewertung: 4.5 von 5 Sternen4.5/5 (8)

- BQ270 Operator ManualDokument123 SeitenBQ270 Operator Manualsudalfa0% (1)

- Mercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualVon EverandMercedes Benz & Dodge Sprinter CDI 2000-2006 Owners Workshop ManualNoch keine Bewertungen

- Torin 2-Ton Hydraulic Trolley Jack ManualDokument6 SeitenTorin 2-Ton Hydraulic Trolley Jack ManualWIRAKOCHANoch keine Bewertungen

- Craftsman TillerDokument31 SeitenCraftsman TillerkingwpNoch keine Bewertungen

- Wa65 80-5 Vebm250100Dokument306 SeitenWa65 80-5 Vebm250100Augusto Oliveira100% (5)

- 31737601Dokument32 Seiten31737601sunthron somchaiNoch keine Bewertungen

- AY70-2 Service Manual 3.4.20 PDFDokument105 SeitenAY70-2 Service Manual 3.4.20 PDFramiroNoch keine Bewertungen

- Sears Mower 917.378521 User ManualDokument48 SeitenSears Mower 917.378521 User ManualEv SullivanNoch keine Bewertungen

- Green Panther Earth Auger 2 Men Op GP 2m With Power Head 14 GP 2m 2Dokument24 SeitenGreen Panther Earth Auger 2 Men Op GP 2m With Power Head 14 GP 2m 2muneebNoch keine Bewertungen

- IG1000 Operation ManualDokument40 SeitenIG1000 Operation ManualDan KillkennyNoch keine Bewertungen

- 31723610Dokument43 Seiten31723610sunthron somchaiNoch keine Bewertungen

- SG21-3 Operation and Maintenance ManualDokument154 SeitenSG21-3 Operation and Maintenance ManualPurnama Abhie100% (2)

- Craftsman TillerDokument33 SeitenCraftsman TillerJeff KelleyNoch keine Bewertungen

- Motoniveladora SG18-3Dokument155 SeitenMotoniveladora SG18-3Franco SartoriNoch keine Bewertungen

- Service Manual AU110 ATV 01831Dokument80 SeitenService Manual AU110 ATV 01831StevenNoch keine Bewertungen

- Lawn Mower ManualDokument40 SeitenLawn Mower ManualforedoorhoreNoch keine Bewertungen

- Baudouin 6M16 Operation, Maintenance ManualDokument40 SeitenBaudouin 6M16 Operation, Maintenance Manualmohammed mostafa100% (2)

- Sears Craftsmen Mower Model 917.258661Dokument60 SeitenSears Craftsmen Mower Model 917.258661ToddNoch keine Bewertungen

- Bobcat Skidsteer Service Repair ManualDokument432 SeitenBobcat Skidsteer Service Repair Manualhuskerchamps97% (32)

- MotoculteurDokument25 SeitenMotoculteurNicolas DejaiffeNoch keine Bewertungen

- Operating & Parts Manual 2.0 H.P.: AttentionDokument12 SeitenOperating & Parts Manual 2.0 H.P.: AttentionBrian BlakeNoch keine Bewertungen

- Jcraftsmawj: Rotary Lawn - J3WerDokument31 SeitenJcraftsmawj: Rotary Lawn - J3WerbwkeenanNoch keine Bewertungen

- Capstan - Shin Myung Tech - SMCAPDokument19 SeitenCapstan - Shin Myung Tech - SMCAPjohn smith0% (1)

- Operation & Maintenance Manual: P158LE / - 1 / - 2 / - S / - III P180LE / - 1 / - S / - II P222LE / - 1 / - S / - IIDokument165 SeitenOperation & Maintenance Manual: P158LE / - 1 / - 2 / - S / - III P180LE / - 1 / - S / - II P222LE / - 1 / - S / - IIMuhammad EmamNoch keine Bewertungen

- Component & Control Locations Safety Information: GCV135 GCV160Dokument4 SeitenComponent & Control Locations Safety Information: GCV135 GCV160Chute-NineNoch keine Bewertungen

- Komatsu Wheel Loaders Wa65 5 Shop ManualDokument20 SeitenKomatsu Wheel Loaders Wa65 5 Shop Manualwilliam100% (42)

- L 0207061 CRAFTSMAN ManualDokument65 SeitenL 0207061 CRAFTSMAN Manualapplecakes2100% (1)

- V9 Roamer - V9 BobberDokument193 SeitenV9 Roamer - V9 BobberJose LuisNoch keine Bewertungen

- Diesel Engine: Operation ManualDokument26 SeitenDiesel Engine: Operation ManualBeto VallejoNoch keine Bewertungen

- E20 7255008 enUS SM PDFDokument671 SeitenE20 7255008 enUS SM PDFLacatusu Mircea100% (3)

- Index: Click Here To Go OnDokument40 SeitenIndex: Click Here To Go OnSaad Ben AhmedNoch keine Bewertungen

- Rotavator 310 / 320: User's ManualDokument20 SeitenRotavator 310 / 320: User's Manualsyedthahir6609Noch keine Bewertungen

- 2984 - maverick - hr - plus - rev - n еттерDokument56 Seiten2984 - maverick - hr - plus - rev - n еттерpeterbirtatNoch keine Bewertungen

- D1146 D1146T P086TI Manuals PDFDokument179 SeitenD1146 D1146T P086TI Manuals PDFnpachecorecabarren73% (11)

- C Force 400 Service ManualDokument292 SeitenC Force 400 Service ManualKoncz Csanád NimródNoch keine Bewertungen

- Wokshop Manual X1,7 & X2,5 A030D087 - I1 - 200912Dokument69 SeitenWokshop Manual X1,7 & X2,5 A030D087 - I1 - 200912Wahyu82% (11)

- WR250 (1HC5) 2012 M.SDokument316 SeitenWR250 (1HC5) 2012 M.SJuan MesaNoch keine Bewertungen

- SR20M操作保养说明书 (英文版)Operation and Maintenance ManualDokument173 SeitenSR20M操作保养说明书 (英文版)Operation and Maintenance Manualmessaoudi100% (1)

- 1978.5-1984 FL-FX Service ManualDokument372 Seiten1978.5-1984 FL-FX Service ManualChris Srsc88% (8)

- Sullair 900 PDFDokument67 SeitenSullair 900 PDFjulio lopez100% (1)

- Komatsu Wheel Loaders Wa115 3 Shop ManualDokument10 SeitenKomatsu Wheel Loaders Wa115 3 Shop Manualjoe100% (40)

- Linhai 400 CUV 2Dokument208 SeitenLinhai 400 CUV 2robertstambachNoch keine Bewertungen

- Operator's Manual: Massey Ferg NDokument78 SeitenOperator's Manual: Massey Ferg Nmilan959100% (6)

- 3125 2 Ton Mini Hydraulic Floor JackDokument6 Seiten3125 2 Ton Mini Hydraulic Floor JackAmir Jemal100% (1)

- Manual OperacionDokument267 SeitenManual OperacionMarcos Moncunill Felipe100% (1)

- Bronco SuperBronce ProLineCRT 2012 769-07548Dokument48 SeitenBronco SuperBronce ProLineCRT 2012 769-07548Joe HowardNoch keine Bewertungen

- Manitou 2003 Axel Service ManualDokument6 SeitenManitou 2003 Axel Service Manualsloth185Noch keine Bewertungen

- Yamaha YBR 125 Owners Manual 2003Dokument83 SeitenYamaha YBR 125 Owners Manual 2003Ahmet GungorenNoch keine Bewertungen

- Manual ch.33139Dokument61 SeitenManual ch.33139Gonçalo EncarnaçãoNoch keine Bewertungen

- 1706409Dokument46 Seiten1706409Robert HarrisNoch keine Bewertungen

- C Force 520 Service Manual V1Dokument294 SeitenC Force 520 Service Manual V1ApKNoch keine Bewertungen

- E19 7255013 enUS SM PDFDokument727 SeitenE19 7255013 enUS SM PDFLacatusu Mircea100% (4)

- Honda HR214Dokument49 SeitenHonda HR214chpdxNoch keine Bewertungen

- ReproducersDokument123 SeitenReproducersDouglas Allen Hughes Sr100% (1)

- 031 00 PDFDokument451 Seiten031 00 PDFwholesoulazNoch keine Bewertungen

- Living WaterDokument418 SeitenLiving WaterShawn NelsonNoch keine Bewertungen

- The Attributes of God - David Hocking PDFDokument262 SeitenThe Attributes of God - David Hocking PDFbonzayoyo0% (2)

- HarvestDokument99 SeitenHarvestDouglas Allen Hughes SrNoch keine Bewertungen

- The Final CurtainDokument48 SeitenThe Final CurtainDouglas Allen Hughes SrNoch keine Bewertungen

- The Claims of Christ by Chuck SmithDokument8 SeitenThe Claims of Christ by Chuck SmithDouglas Allen Hughes SrNoch keine Bewertungen

- The Claims of Christ by Chuck SmithDokument8 SeitenThe Claims of Christ by Chuck SmithDouglas Allen Hughes SrNoch keine Bewertungen

- Winning The Spiritual War - Don StewartDokument213 SeitenWinning The Spiritual War - Don StewartDouglas Allen Hughes SrNoch keine Bewertungen

- The Scarlet Thread Through The BibleDokument49 SeitenThe Scarlet Thread Through The BiblefullquiverfarmNoch keine Bewertungen

- Let's Talk - HarvestDokument35 SeitenLet's Talk - HarvestDouglas Allen Hughes SrNoch keine Bewertungen

- World HAWDokument132 SeitenWorld HAWbdisNoch keine Bewertungen

- Evidence Bible NT - Comfort, RayDokument2.733 SeitenEvidence Bible NT - Comfort, RayDouglas Allen Hughes Sr96% (24)

- Harmony of The Gospels Robertson PDFDokument360 SeitenHarmony of The Gospels Robertson PDFDouglas Allen Hughes SrNoch keine Bewertungen

- TelPro 1101 Tele-Tower Operation ManualDokument20 SeitenTelPro 1101 Tele-Tower Operation ManualDouglas Allen Hughes SrNoch keine Bewertungen

- Direct Business 18001027723: Intermediary Code / Name Intermediary Contact Number Intermediary Email IdDokument2 SeitenDirect Business 18001027723: Intermediary Code / Name Intermediary Contact Number Intermediary Email IdHarish GhorpadeNoch keine Bewertungen

- Bolens Models 1969 1972Dokument3 SeitenBolens Models 1969 1972Paul MartinNoch keine Bewertungen

- Wheel Alignment JosamDokument4 SeitenWheel Alignment JosamDeepak Kumar RautNoch keine Bewertungen

- A Flying Cars PresentationDokument13 SeitenA Flying Cars PresentationUrmi Das100% (1)

- Chery A5 Chapter Nine Body DimensionDokument28 SeitenChery A5 Chapter Nine Body DimensionAbbode HoraniNoch keine Bewertungen

- Lecture 11 Vector Control of Induction MotorDokument43 SeitenLecture 11 Vector Control of Induction MotorNaveen Reddy100% (1)

- Ford Everest 20jan2016 Ebrochure PDFDokument19 SeitenFord Everest 20jan2016 Ebrochure PDFelisioNoch keine Bewertungen

- T3-4 Lateral Longitudinal DynamicsDokument74 SeitenT3-4 Lateral Longitudinal DynamicsGashNoch keine Bewertungen

- DDECIV Multi-ECM Troubleshooting Manual PDFDokument943 SeitenDDECIV Multi-ECM Troubleshooting Manual PDFKike RiveroNoch keine Bewertungen

- DJANGO Manual 125-150cc PDFDokument83 SeitenDJANGO Manual 125-150cc PDFsimrs.rsudkojaNoch keine Bewertungen

- Yale MPB 040 EDokument13 SeitenYale MPB 040 EJMautoelevadores El servicio que estabas esperandoNoch keine Bewertungen

- FAA P-8740-66 Flying Twins (Hi-Res) Branded PDFDokument12 SeitenFAA P-8740-66 Flying Twins (Hi-Res) Branded PDFEmonAzzameenNoch keine Bewertungen

- Check Sheet Truck Trailer REV 1Dokument5 SeitenCheck Sheet Truck Trailer REV 1ArifinNoch keine Bewertungen

- PDFDokument230 SeitenPDFanupthattaNoch keine Bewertungen

- IBS Center For Management Research: Secret of Honda's SuccessDokument5 SeitenIBS Center For Management Research: Secret of Honda's SuccessBhagwat BalotNoch keine Bewertungen

- John Deere Service, Parts Catalog, Technical, Operator, Test, DIAGNOSTIC and TEST, DIAGNOSTIC, PDF ManualDokument4 SeitenJohn Deere Service, Parts Catalog, Technical, Operator, Test, DIAGNOSTIC and TEST, DIAGNOSTIC, PDF ManualJohn WeldonNoch keine Bewertungen

- RIDE66 Manual Control Panel S866Dokument5 SeitenRIDE66 Manual Control Panel S866jrcengeNoch keine Bewertungen

- PM 565 BDokument21 SeitenPM 565 BFlorin Gabor100% (1)

- Products Bus Superaerotown SpecDokument8 SeitenProducts Bus Superaerotown SpecBKONoch keine Bewertungen

- Sparepart Price ListDokument7 SeitenSparepart Price ListChristian SitumeangNoch keine Bewertungen

- Everything Merged Airdes PrelimsDokument62 SeitenEverything Merged Airdes Prelimssean buenaventuraNoch keine Bewertungen

- Concrete Mixer Truck, HDJ5380GJBHI (HINO 10m3)Dokument1 SeiteConcrete Mixer Truck, HDJ5380GJBHI (HINO 10m3)tachmidNoch keine Bewertungen

- Heavy Equipment ChecklistDokument1 SeiteHeavy Equipment ChecklistRejan LawrenceNoch keine Bewertungen

- 25 Equipment - FurnishingsDokument114 Seiten25 Equipment - FurnishingsWilson BenincoreNoch keine Bewertungen

- BRAKES Integrated Trailer Brake Module (ITBM) - Electrical Diagnostics - Ram Pickup PDFDokument47 SeitenBRAKES Integrated Trailer Brake Module (ITBM) - Electrical Diagnostics - Ram Pickup PDFcharles100% (3)

- TM 55-2420-224-14Dokument51 SeitenTM 55-2420-224-14AdvocateNoch keine Bewertungen

- Transmission Hydraulic Control Operation 966Dokument12 SeitenTransmission Hydraulic Control Operation 966Walid HouranNoch keine Bewertungen

- Clark CL32000 Transmission ManualDokument152 SeitenClark CL32000 Transmission ManualAnonymous iu95trpxN80% (10)

- Navy Traffic Safety Program 5100 12gDokument21 SeitenNavy Traffic Safety Program 5100 12gTravis BroussardNoch keine Bewertungen

- Dacy 33 35 Parts BookDokument11 SeitenDacy 33 35 Parts BookBoumediene CHIKHAOUINoch keine Bewertungen

- Arizona, Utah & New Mexico: A Guide to the State & National ParksVon EverandArizona, Utah & New Mexico: A Guide to the State & National ParksBewertung: 4 von 5 Sternen4/5 (1)

- New York & New Jersey: A Guide to the State & National ParksVon EverandNew York & New Jersey: A Guide to the State & National ParksNoch keine Bewertungen

- South Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptVon EverandSouth Central Alaska a Guide to the Hiking & Canoeing Trails ExcerptBewertung: 5 von 5 Sternen5/5 (1)

- Japanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensVon EverandJapanese Gardens Revealed and Explained: Things To Know About The Worlds Most Beautiful GardensNoch keine Bewertungen

- Naples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoVon EverandNaples, Sorrento & the Amalfi Coast Adventure Guide: Capri, Ischia, Pompeii & PositanoBewertung: 5 von 5 Sternen5/5 (1)

- The Bahamas a Taste of the Islands ExcerptVon EverandThe Bahamas a Taste of the Islands ExcerptBewertung: 4 von 5 Sternen4/5 (1)