Beruflich Dokumente

Kultur Dokumente

1preface Straight

Hochgeladen von

Marian DunareanuCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

1preface Straight

Hochgeladen von

Marian DunareanuCopyright:

Verfügbare Formate

3 DE-STA-CO Subject to technical modifications without notice

Table of content

Pneumatic tools

Series Power [W] Speed [min-

1

] Page

10R90 44 100 000

12R04 / 12R91 70 60 000 / 65 000

6 7

12S10 220 380 34 000

12S20 440 20 000 25 000

12S25 660 430 23 000

12S11 220 28 000

8 9

12S26 660 4700 22 000

12R03 70 80 000

10 11

12S12 220 12 000 20 000

12S27 660 3300 11 000

14CF 300 600 20 000

14CS 440 500 20 000

14CN 660 500 20 000

15SF0 300 1000 5300 12 13

15SF2 300 600 5 300

Accessories for pneumatic tools

Hoses, overhoses, quick connectors, adapters, collets 14

Maintenance units, Chucks, Gear lube, Oil 15

Router assemblies 16

Chamfering and trimmer assemblies 17

Adapter with collet, disc holders, sanding discs 18

Belt sander 19

Carbide burs with MASTER cut

Series 010

20 24

Series 015

u. 041-052

Carbide burs with aluminum cut

Series 101-108

25

Carbide routers with diamond cut

Series 190/191

26

Fiber-glass reinforced Carbide bur sets, Pneumatic grinder sets

cutting wheels series 620 series 010 & 015

27

and

20,21,23

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

4 Subject to technical modifications without notice DE-STA-CO

General, motor designs

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

Tools driven by compressed-air are well known for compact de-

sign, excellent power to weight ratio and low initial and mainte-

nance costs. Compressed-air driven tools are usable in humid and

explosive environments.

Important for the efficient use of a tool is its optimal adaptation to

the special application. Please consider some factors in this deci-

sion e. g. quality, lifetime and serviceability of the tool.

More important are the technical data of the tool: Enough power,

low air consumption and an adequate speed for the chosen rota-

ting tool.

Of interest is also the handling which is determined by the design

and the weight of the tool.

Additional you have to look for the right throttle for the application.

Normally it is important to use a security throttle but sometimes

there is a need of a valve or throttle for a fixed or continuous

operation.

The sound level of the tool should be also included in the decision.

Rear exhaust with overhose will highly silence the tools. A front

exhaust will cool the workpiece but will also blow away the chips.

All these questions should be checked before the tool is bought

and the best way is to talk to a technical consultant of DE-STA-CO.

Our product range includes compressed air driven tools with a po-

wer of 44 W to 660 W and a speed up to 100,000 UPM.

Special accessories for the pneumatic tools and carbide burs al-

low an optimal adaptation of the tools to the application.

A precise manufacturing and a broad quality assurance causes

high liability of DE-STA-CO pneumatic tools and burs.

Motor-designs

Vane motor

Most of our pneumatic tools are driven

by vane motors, which generate their

power by the principle of expanding

compressed air.

Turbine motor

A turbine motor generates its power by

using the velocity and the kinetic energy

of the compressed air. The air flows

through the rotor 1, is redirected by the

stator and flows through rotor 2.

Vane motor

Turbine motor

1.

Air intake

Compressed air flows

into the motor and is

blocked by rotor blade A.

The rotor starts turning.

3.

First exhaust

Most of the

expanded air emits

the motor at the first

exhaust.

2.

Expansion

The compressed air bet-

ween the blades A and B

has now the possibility to

expand. This expansion

causes a torque at the rotor;

the turning of the rotor is

strengthened.

4.

Second Exhaust

The remaining air will

exhaust now.

The right tool for your job!

Design, maintenance

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

5 DE-STA-CO Subject to technical modifications without notice

Types

Due to precision manufactured parts the noise

development of the grinders is rather low.

Mostly you will hear the sound of the expanding

air. This noise could be further reduced by

using overhoses. The function of an overhose is

easily shown at the illustration on the right side.

Using a rear exhaust with an overhose the

exhausting air will be piped away from the

workplace. The noise reduction will be as grea-

ter as farther away the exhaust from the work-

place is. But keep in mind: If the air should cool

attached accessories a front air exhaust should

be chosen.

Valves

Security lever S

On safety reasons this lever only allows to start

the air tool after actuating the ratchet lever (1).

Then the tool can be activated by pressing the

hand lever.

Roll valve R

Turning the valve will start the air tool. This roll

valve could only be found at grinder of the

series 10-90, 12-03 and 12-04.

Maintenance

The durability of a grinder could be highly in-

creased by maintaining the tool. A maintenance

unit is needed (filter regulator lubricator)

and this unit should be installed as near to the

tool as possible. Please oil the tools with 2 or 3

drops per minute.

Exception: series 12R03 and 12R04 should be

oiled with 1 to 2 drops per minute.

Only the turbine grinder 10R9000-03 and

12R9180-43SG should not be oiled.

Recommended oil

We recommend for the air tools a light oil with

a viscosity of app. 18-30 mm/sec at 40C;

like our model-no. 45-0918 (1 litre can, see

page 15).

Compressed air tools marked with a

are ready for use at a reduced oil respectively

oil free operation.

Greasing the gears

To grease the mitre gears of the compressed air

tools the special grease, model-no. 45-0980,

should be used. To grease planetary gears

we recommend the special grease model-no.

45-0983. Please find the recommended lubrica-

ting intervals in the corresponding manual.

Air tool with rear

exhaust

Overhose

Air hose

Nipple Coupler

Compressed air inlet

Quick coupling Maintenance unit

Regulator

with gauge

Lubricator Filter with water separator

Air Exhaust

Overhose with integrated

clamping piece

Air hose flexible and already

fitted

Air Exhaust

Air hose flexible and already

fitted

Rear Exhaust

Front Exhaust

Security lever S Roll valve R

Speed and Power

All in this catalogue specified (free) speeds and

powers are measured at the max. pressure of

6,3 bar.

Speed governor

A patented centrifugal controlled governor is

used for some grinders with 660 watt power.

This governor controls the air flow inside the

tool. At free speed the air flow is regulated on a

minimal base and if the maximal power is nee-

ded the flow has its maximum.

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

6 Subject to technical modifications without notice DE-STA-CO

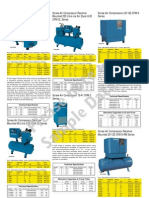

Straight grinder 44/70/220/440/660W

Models 12S1000-36

12S1001-36

Models 12S2000-01

12S2001-01

Models 12S2500-01

12S2565-01

Pictures shows grinder with front exhaust and long collet guard.

Short and long collet guards are standard for series 12S10, 12S20 and 12S25.

Model

12R0400-43

Models 12S1080-36

12S1081-36

Models 12S2080-01

12S2081-01

Models 12S2580-01

12S2582-01

Pictures shows grinder with rear exhaust and short collet guard.

Short and long collet guards are standard for series 12S10, 12S20 and 12S25.

Model

12R9180-43SG

Model

10R9000-03

= ready for oilless use

Series Model-no. Free speed Power Air Noise Air Recommended Standard accessories

consump- level exhaust air hose - please

tion F = front order separately

[min

-1

] [W] [dm

3

/min] [dB (A)] R = rear (Page 14) Model-no.

10R90 10R9000-03 100 000 44 170 75 F

12R04 12R0400-43 60 000 70 170 75 R

12R91 12R9180-43SG 65 000 70 170 75 R

12S1000-36 30 000

1)

83 F

12S1001-36 34 000

1)

83 F

12S10 200 280 45-1408-S

12S1080-36 30 000

1)

78 R

12S1081-36 34 000

1)

78 R

12S2000-01 25 000 84 F

12S2001-01 20 000 84 F

12S20

12S2080-01 25 000

440 570

78 R

45-1508-S

12S2081-01 20 000 78 R

12S2500-01 23 000 84 F

12S2565-01* 15 000 84 F

12S25

12S2580-01 23 000

660 800

78 R

45-1508-S

12S2582-01 18 000 78 R

*=with governor

Grinders with other speeds on request

Collet, 3 mm

Wrench, AE 4,8 mm

Wrench, AE 6,4 mm

Air hose, 2,1 m (Anschl. G 1/4)

Air hose filter

Collet, 3 mm

Air hose, 1,5 m (Anschl. G 1/4)

Overhose, 1,2 m

Wrench, AE 4,8 mm

Wrench, AE 8,7 mm

Collet guard, short

Collet, 3 mm

Air hose, 1,5 m (Anschl. G 1/4)

Overhose, 1,2 m

Wrench, AE 4,8 mm

Wrench, AE 8,7 mm

Collet guard, short

Collet, 6 mm

Wrench, AE 11,1 mm

Wrench, AE 17,5 mm

Collet guard, short

Collet guard, long

Overhose, 1,2 m

(for rear exhaust only(R))

Collet, 6 mm

Wrench, AE 14,3 mm

Wrench, AE 19 mm

Collet guard, short

Collet guard, long

Overhose, 1,2 m

(for rear exhaust only(R))

148-3 mm

14-0803

14-0804

45-1307-S

45-0211

148-3 mm

45-0948-S

45-0956-A

14-0803

14-0822

DO-917

148-3 mm

45-0948-SLA

DO-0974

14-0803

14-0822

DO-917

300-6 mm

14-0807

14-0811

DO-011050

DO-011047

45-2687-A

200-6 mm

14-0809

14-0812

DO-012050

DO-012047

45-2687-A

oil free

Applications

Oilfree turbine grinder 12R9180-43SG for burring,

sanding and milling.

Fiberglass router

assembly

(Page 16)

Router assembly for working on plastics,

wood and nonferrous metals

(Page 17)

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

7 DE-STA-CO Subject to technical modifications without notice

Straight grinder 44/70/220/440/660 W

Dimensions

Deburring high-strength steel workpieces

with 12R0400-43

Finishing a casted workpiece with the

12S1000-36

Routing fiberglass with a 12S2580-01 and a

router assembly along a template (Page 16)

Recommended accessories Applications Dimensions Weight

Page/

Model-No. L L

1

D D

1

D

2

[g]

Maintenance unit G1/4

Collets

Collet guard

Carbide burs

Pneumatic accessories

Maintenance unit G1/4

Collets

Collet guard, long

Carbide burs

Pneumatic accessories

Maintenance unit G1/4

Collets

Collet guard, long

Carbide burs

Pneumatic accessories

Maintenance unit G1/4 or G1/8

Collets

Chamfering assemblies

Router assemblies

Carbide burs & Cutting wheels

Pneumatic accessories

Maintenance unit G1/8

Collets

Chamfering assemblies

Router assemblies

Carbide burs & Cutting wheels

Pneumatic accessories

Page 15

Page 14

14-1280

Page 20

Pages 14, 15

Page 15

Page 14

DO-916

Pages 20, 21

Pages 14, 15

Page 15

Page 14

DO-916

Pages 20, 21

Pages 14, 15

Page 15

Page 14

Pages 16, 17

Pages 16, 17

Pages 22 to 27

Pages 14, 15

Page 15

Page 14

Pages 16, 17

Pages 16, 17

Pages 22 to 27

Pages 14, 15

Deburring, grinding, milling and polishing with carbide

burs (shaft and head- 3mm) and mounted points and

polishing points. Used in tool making, mold making, preci-

sion mechanic and aeronautical engineering.

Deburring, grinding, milling and polishing with carbide

burs (shaft- 3mm and head- max 6,5mm) and mounted

points and polishing points. Used in tool making, mold

making, precision mechanic and aeronautical engineering.

Deburring, grinding, milling and polishing with carbide

burs (shaft- 3mm and head- max 6,5mm) and mounted

points and polishing points. Grinders with other speeds on

request.

Deburring, grinding, milling and polishing with carbide

burs (shaft- 6mm and head- max 12mm) and mounted

points and polishing points. Grinders with other speeds on

request.

Deburring, grinding, milling and polishing with carbide

burs (shaft- 6 or 8mm and head- max 19mm) and

mounted and polishing points. Chamfering, routing and

deburring with accordingly assemblies.

141 25 29 7,5 250

120 11 19 7,5 120

144 11 19 7,5 37 200

151

151

30 38 13 18,5 380

161

161

175

175

185

34 44 20,5 610

185

175

175

185

34 44 20,5 670

185

Model 10R9000-03 Series 12S10*

Model 12R0400-43

with short collet guard (standard)

Model 12R9180-43SG Series 12S20*

12S25*

Collet guard model-no.

14-1280. Please order

separately.

Long collet guard

model-no. DO-916.

Please order separately.

Long collet guard

model-no. DO-916.

Please order separately.

*= shown with short colle guard

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

8 Subject to technical modifications without notice DE-STA-CO

Extended straight grinder 220/440/660W

= ready for oilless use

Model 12S1100-36

Model 12S1101-36

Model 12S1180-36

Model 12S1181-36

Series Model-no. Free Power Air Noise Air Recommended Standard accessories

speed consump- level exhaust air hose - please

tion F = front order separately

[min

-1

] [W] [dm

3

/min] [dB (A)] R = rear (Page 14) Model-no.

S = side

12S11

12S26

12S1100-36

12S1101-36

12S1180-36

12S1181-36

12S2662-01*

12S2680-01

12S2693-01

2)

28 000

12 000

22 000

4 700

220

660

280

800

83

83

78

78

77

76

76

F

F

R

R

S

R

R

45-1408-S

45-1508-S

Collet, 6 mm

Wrench, AE 11,1 mm

Wrench, AE 17,5 mm

Overhose, 1,2 m (for rear

exhaust only(R))

Collet, 6 mm

Wrench, AE 14,3 mm

Wrench, AE 19 mm

Overhose, 1,2 m (for rear

exhaust only(R))

300-6 mm

14-0807

14-0811

45-2687-A

200-6 mm

14-0809

14-0812

45-2687-A

*= with governor

Grinders with other speeds on request

Working at a difficult to access part of a workpiece with 12S1101-36. Grinders wit extensions up to 1000mm on request.

Extended straight grinder 220/440/660W

G

r

i

n

d

e

r

s

a

n

d

B

u

r

s

9 DE-STA-CO Subject to technical modifications without notice

Model 12S2693-01 Model 12S2680-01

Model 12S2662-01

(Side exhaust)

Recommended accessories Applications Dimensions Weight

Page/

Model-No. L L

1

L

2

D D

1

D

2

D

3

[g]

Maintenance unit G1/4 or G1/8

Collets

Carbide burs and cutting wheels

Pneumatic accessories

Maintenance unit G3/8

Collets

Carbide burs and cutting wheels

Pneumatic accessories

Page 15

Page 14

Page 22 - 27

Page 14 u.15

Page 15

Page 14

Pages 22 to 27

Page 14, 15

Deburring, grinding, milling and polishing

with carbide burs (shaft- 6 mm and head-

max. 12 mm) and mounted points and polishing

points.

228

278

238

288

36

86

136

86

136

38 13 18,5 19

500

600

500

600

346

338

385

38 165 44 20,5 32

1.500

1.400

1.700

Deburring, grinding, milling and polishing

with carbide burs (shaft- 6 or 8 mm and

head- max. 19 mm) and mounted points and

polishing points.

Because its low speed model 12S2693-01 is

particularly suitable for working with wire,

nylon brushes and grinding wheels.

Dimensions

Series 12S11 Series 12S26

Das könnte Ihnen auch gefallen

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideVon EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideBewertung: 4 von 5 Sternen4/5 (8)

- Hägglunds Compact Hydraulic Motor Product ManualDokument25 SeitenHägglunds Compact Hydraulic Motor Product ManualP Venkata Suresh100% (2)

- Ta40 TerexDokument462 SeitenTa40 Terexpecirepi100% (6)

- Polaris Hydraulic Gear Pump CatalogDokument88 SeitenPolaris Hydraulic Gear Pump Catalogbtone911100% (1)

- Rexworth Hydraulic MotorDokument28 SeitenRexworth Hydraulic MotorSorin-Adrian Learschi100% (1)

- BogeDokument7 SeitenBogeWage KarsanaNoch keine Bewertungen

- Re 15224Dokument12 SeitenRe 15224Ahmed Abd ElhakeemNoch keine Bewertungen

- 'C' Series Control ValvesDokument12 Seiten'C' Series Control Valvesابزار دقیق100% (1)

- Gas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesVon EverandGas-Engines and Producer-Gas Plants A Practice Treatise Setting Forth the Principles of Gas-Engines and Producer Design, the Selection and Installation of an Engine, Conditions of Perfect Operation, Producer-Gas Engines and Their Possibilities, the Care of Gas-Engines and Producer-Gas Plants, with a Chapter on Volatile Hydrocarbon and Oil EnginesNoch keine Bewertungen

- Scule HidrauliceDokument34 SeitenScule HidraulicelucianbordeutNoch keine Bewertungen

- Okb Top SeriesDokument4 SeitenOkb Top SeriesIrma Pokvić-Ramulj100% (1)

- Fixed Displacement Pump Technical SpecsDokument20 SeitenFixed Displacement Pump Technical SpecsTaz Juan GNoch keine Bewertungen

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1Von EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Bewertung: 3.5 von 5 Sternen3.5/5 (3)

- About Axial Displacement Pump A4VSoDokument68 SeitenAbout Axial Displacement Pump A4VSomrkadu_61Noch keine Bewertungen

- Desalination pump design bookletDokument14 SeitenDesalination pump design bookletBenicio Joaquín Ferrero BrebesNoch keine Bewertungen

- Vibratory Feeders and Conveyors PDFDokument14 SeitenVibratory Feeders and Conveyors PDFArnaldo BenitezNoch keine Bewertungen

- MSV 40 MAX compressor technical data and maintenance instructionsDokument2 SeitenMSV 40 MAX compressor technical data and maintenance instructionsctorres_505746Noch keine Bewertungen

- Gardner Denver Industrial Blowers TF 140L K202Dokument8 SeitenGardner Denver Industrial Blowers TF 140L K202Aleksandar JočićNoch keine Bewertungen

- Air System ComponentsDokument6 SeitenAir System ComponentsEliasNoch keine Bewertungen

- Catalogo Regulador Watts Mod 152-ADokument2 SeitenCatalogo Regulador Watts Mod 152-AGuatemalan1979Noch keine Bewertungen

- Pump Info ReferenceDokument42 SeitenPump Info ReferenceingenieroNoch keine Bewertungen

- Optimex Prei RangeDokument12 SeitenOptimex Prei RangeThomas DamonNoch keine Bewertungen

- Pump STDRDokument7 SeitenPump STDRsopian320Noch keine Bewertungen

- Min1244a12 - Tag 130-Pu-029Dokument7 SeitenMin1244a12 - Tag 130-Pu-029Monty MathewsNoch keine Bewertungen

- Plastic Industrial Fans for Optimizing ProcessesDokument6 SeitenPlastic Industrial Fans for Optimizing ProcessesNicole FelicianoNoch keine Bewertungen

- Grundfos MTS Screw Spindle PumpDokument68 SeitenGrundfos MTS Screw Spindle PumpAnonymous lswzqlo100% (1)

- Sullair Screw Air Compressor As 04-110Dokument4 SeitenSullair Screw Air Compressor As 04-110MuhammadChabibiNoch keine Bewertungen

- Valvula SolenoideDokument6 SeitenValvula SolenoideArnezNoch keine Bewertungen

- MPVN BrochureDokument32 SeitenMPVN Brochurefernando_naciamentNoch keine Bewertungen

- Data Sheet Tag 180-Pu-011eDokument8 SeitenData Sheet Tag 180-Pu-011eSarah PerezNoch keine Bewertungen

- Fix Displacement MotorDokument28 SeitenFix Displacement MotorIan MuhammadNoch keine Bewertungen

- HYD. PumpDokument40 SeitenHYD. Pumprohitbhat2345Noch keine Bewertungen

- KWP Non-Clogging Centrifugal Pump: Automation Products AvailableDokument16 SeitenKWP Non-Clogging Centrifugal Pump: Automation Products Availablefedeparamos5030100% (1)

- 51371180104Dokument21 Seiten51371180104GuillermoadairNoch keine Bewertungen

- Book LayoutDokument8 SeitenBook LayoutaamenaNoch keine Bewertungen

- TDA-F Series: Smokespill Axial FanDokument4 SeitenTDA-F Series: Smokespill Axial Fanjames_chan2178Noch keine Bewertungen

- EASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013 PDFDokument10 SeitenEASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013 PDFmakumba1972Noch keine Bewertungen

- Asco Series 210 General Service CatalogDokument6 SeitenAsco Series 210 General Service CatalogEric ToroNoch keine Bewertungen

- 12AT/50AT Series: Spin-On FiltersDokument8 Seiten12AT/50AT Series: Spin-On FiltersPartsGopher.comNoch keine Bewertungen

- Air Compressor Service CompanyDokument8 SeitenAir Compressor Service CompanyNabil Ibrahim100% (1)

- SMC 100 SB 2827 2008.10Dokument2 SeitenSMC 100 SB 2827 2008.10rbctdiNoch keine Bewertungen

- Leader PPV Positive Pressure Ventilation FanDokument6 SeitenLeader PPV Positive Pressure Ventilation Fandonald_wilson4741Noch keine Bewertungen

- EASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013Dokument10 SeitenEASA-TCDS-E.012 Rolls - Royce Plc. RB211 Trent 900 Series Engines-06-11122013Smit PatelNoch keine Bewertungen

- Ventilator - Mixvent-Td (En)Dokument23 SeitenVentilator - Mixvent-Td (En)Muhidin KozicaNoch keine Bewertungen

- 10 SEER air conditioner specsDokument4 Seiten10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- BSB Series BRCDokument6 SeitenBSB Series BRCsamiNoch keine Bewertungen

- MSB 97e55 001 PDFDokument12 SeitenMSB 97e55 001 PDFAutof FerreiraNoch keine Bewertungen

- Rotrex Technical Datasheet C30 Range V4.0Dokument7 SeitenRotrex Technical Datasheet C30 Range V4.0Blake Newman0% (1)

- Donaldson AccessoriesDokument74 SeitenDonaldson AccessoriesCentral HydraulicsNoch keine Bewertungen

- Marine FanDokument41 SeitenMarine FanMinh ĐứcNoch keine Bewertungen

- 000 Sanyo Scroll CSBN303H8ADokument8 Seiten000 Sanyo Scroll CSBN303H8AYutt WattNoch keine Bewertungen

- Pumps Product OverviewDokument20 SeitenPumps Product OverviewDenis Jimenez0% (1)

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- J. N. Darby - DisciplinaDokument37 SeitenJ. N. Darby - Disciplinadunareanu_marian8668Noch keine Bewertungen

- RPL RPLCDokument16 SeitenRPL RPLCdunareanu_marian8668Noch keine Bewertungen

- Type of Mounting: Type of Mounting: Type of Mounting:: G Series FO Series FL SeriesDokument7 SeitenType of Mounting: Type of Mounting: Type of Mounting:: G Series FO Series FL Seriesdunareanu_marian8668Noch keine Bewertungen

- SheetDokument69 SeitenSheetdunareanu_marian8668Noch keine Bewertungen

- Round ToolingDokument18 SeitenRound Toolingdunareanu_marian8668Noch keine Bewertungen

- Squeeze Action Plier Clamps: Max. Holding Capacity N (LBF.) Maximum Clamping Thickness MM (Inch)Dokument9 SeitenSqueeze Action Plier Clamps: Max. Holding Capacity N (LBF.) Maximum Clamping Thickness MM (Inch)dunareanu_marian8668Noch keine Bewertungen

- RfeDokument8 SeitenRfedunareanu_marian8668Noch keine Bewertungen

- RpeDokument6 SeitenRpedunareanu_marian8668Noch keine Bewertungen

- RPDokument16 SeitenRPdunareanu_marian8668Noch keine Bewertungen

- 'I 2ii 3 + A : 1C-# @+/ (/@#:/ - G C:+@#! C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"Dokument12 Seiten'I 2ii 3 + A : 1C-# @+/ (/@#:/ - G C:+@#! C/ ' Eg B 31 +@+1/ 'I +:1/ 1: #@@#: 1@ ## :G 1e 1+ @C:# 1/@#/@ 4!:G5 Bi"2$i" Ai"$i"dunareanu_marian8668Noch keine Bewertungen

- RuaDokument12 SeitenRuadunareanu_marian8668Noch keine Bewertungen

- RTH DTHDokument22 SeitenRTH DTHdunareanu_marian8668Noch keine Bewertungen

- Straight Line Action Clamps: DestacoDokument28 SeitenStraight Line Action Clamps: Destacodunareanu_marian8668Noch keine Bewertungen

- Spider GripDokument7 SeitenSpider Gripdunareanu_marian8668Noch keine Bewertungen

- Swingclamps AccessDokument9 SeitenSwingclamps Accessdunareanu_marian8668Noch keine Bewertungen

- Pneumatic Swing Clamps: DestacoDokument16 SeitenPneumatic Swing Clamps: Destacodunareanu_marian8668Noch keine Bewertungen

- Tpi152 de enDokument26 SeitenTpi152 de endunareanu_marian8668Noch keine Bewertungen

- Swingclamps AccessDokument9 SeitenSwingclamps Accessdunareanu_marian8668Noch keine Bewertungen

- Rfb7 - de - en Triple Mas 6000Dokument2 SeitenRfb7 - de - en Triple Mas 6000Miguel GonzalezNoch keine Bewertungen

- Relevant Suffixes: For Spherical Roller Bearings in The Paper IndustryDokument4 SeitenRelevant Suffixes: For Spherical Roller Bearings in The Paper IndustryHemanthSKFNoch keine Bewertungen

- Pew de UsDokument8 SeitenPew de Usdunareanu_marian8668Noch keine Bewertungen

- rfb6 de enDokument2 Seitenrfb6 de endunareanu_marian8668Noch keine Bewertungen

- FAG Self Aligning Cylindrical Roller BearingsDokument22 SeitenFAG Self Aligning Cylindrical Roller BearingsJose MorenoNoch keine Bewertungen

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDokument8 SeitenELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668Noch keine Bewertungen

- SSD 14 de enDokument10 SeitenSSD 14 de endunareanu_marian8668Noch keine Bewertungen

- ELGES Alloy Steel Rod Ends: Corrosion-ResistantDokument8 SeitenELGES Alloy Steel Rod Ends: Corrosion-Resistantdunareanu_marian8668Noch keine Bewertungen

- Pew de UsDokument8 SeitenPew de Usdunareanu_marian8668Noch keine Bewertungen

- The Magic of Magnets: Current NewsDokument8 SeitenThe Magic of Magnets: Current Newsdunareanu_marian8668Noch keine Bewertungen

- rfb6 de enDokument2 Seitenrfb6 de endunareanu_marian8668Noch keine Bewertungen

- rfb6 de enDokument2 Seitenrfb6 de endunareanu_marian8668Noch keine Bewertungen