Beruflich Dokumente

Kultur Dokumente

Procedure For MPT

Hochgeladen von

Saut Maruli Tua SamosirOriginalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Procedure For MPT

Hochgeladen von

Saut Maruli Tua SamosirCopyright:

Verfügbare Formate

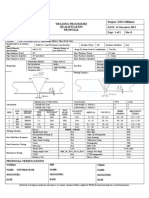

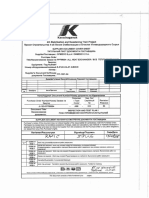

LARSEN & TOUBRO LIMITED

PAGE NO.- 1 OF 4

DATE:-01.11.2007

MSQ (EPCC-1) UPGADATION

PROJECT

REV.NO.- 00

MAGNETIC PARTICLE TEST

PROCEDURE NO.-

LT/MSQ/P/MPT/008

CONTENTS

SCOPE

REFERENCE DOCUMENT

GENERAL

QUALIFICATION OF PERSONNEL

EQUIPMENT

PROCEDURE

INTERPRETATION

POST CLEANING

DOCUMNTATION

SAFETY

APPROVED BY L & T REVIEED ! APPROVED BY JACOBS

LARSEN & TOUBRO LIMITED

PAGE NO.- 2 OF 4

DATE:-01.11.2007

MSQ (EPCC-1) UPGADATION

PROJECT

REV.NO.- 00

MAGNETIC PARTICLE TEST

PROCEDURE NO.-

LT/MSQ/P/MPT/008

1.0 SCOPE

This procedure describes the method for Magnetic Particle Testing of ferromagnetic materials and

welds, for piping construction work of MS !p gradation Pro"ect, #O$% Panipat&

2.0 RE"ERENCE DOCUMENT

'&1 (SM) *oiler + Pressure ,essels code Section -. /ondestructi,e testing

'&2 (SM) *'1&' $hemical plant and petroleum refiner0 piping&

'&' (S/T 1ecommended practice . S/T2T$2(1

#.0 GENERAL

'&1 Magnetic Particle Testing shall be applied to detect surface + sub2surface discontinuities of

ferrous material&

'&2 *efore Magnetic Particle testing, surface to be tested shall be cleaned, to allow the magnetic

particles mo,ement according to flow and direction of magnetic flu3&

4.0 QUALI"ICATION O" PERSONNEL

4&1 #ndi,iduals performing Magnetic Particle Testing shall be trained and 5ualified (S/T le,el2## in

accordance with S/T2T$21( or e5ui,alent&

4&2 %e,el # Person ma0 perform the testing under %e,el ## 5ualified persons6 instruction and

super,ision&

$.0 EQUIPMENTS

4&1 !nless otherwise specified, 0oke t0pe magnet shall be used& This method shall be applied to detect

discontinuities that are opened to the surface of the part to be e3amined&

4&2 The ($ electro magnetic 0oke should ha,e the capacit0 to lift 17 lbs at the ma3imum pole spacing that

will be used& For 8$ or permanent magnetic 0oke shall ha,e a lifting power of 47 lbs at the

ma3imum pole spacing to be used&

4&' The Ferro magnetic particles used in the e3amination medium can be either wet or dr0&

APPROVED BY L & T REVIEED ! APPROVED BY JACOBS

LARSEN & TOUBRO LIMITED

PAGE NO.- ' OF 4

DATE:-01.11.2007

MSQ (EPCC-1) UPGADATION

PROJECT

REV.NO.- 00

MAGNETIC PARTICLE TEST

PROCEDURE NO.-

LT/MSQ/P/MPT/008

4&4 9hen wet particle is used, application of white back ground paint is preferred to obtain contrast

between the magnetic particle and surface being e3amined& The colour of the magnetic particle

shall be sufficientl0 different than the e3amination surface& The magneti:ing current shall be turned

on after the particles ha,e been applied& Flow of particles shall stop with the application of current&

9et particles applied from aerosol spra0 cans ma0 be applied before and;or after magneti:ing

current is applied&

4&4 #f prod t0pe e5uipment is specified, test shall be performed with the prod spacing of <42 277 mm& For

prod techni5ue, magneti:ation is accomplished b0 portable prod t0pe electrical contacts pressed

against the surface in the area to be e3amined&

4&= For prod t0pe e5uipment, dr0 powder magnetic particle should be used instead of wet t0pe&

%.0 PROCEDURE

=&1 The surface being e3amined and ad"acent area within 1> shall be clean + dr0, and free from oil,

grease, loose rust, loose scale ,welding flu3, spatter etc& that could mask the indications due to

discontinuit0&

=&2 MET&OD

=&2&1 $ontinuous method shall be applied for all testing& The 0oke or prod tip shall remain acti,ated

during the application and remo,al of e3cess materials&

=&2&2 The test shall be done twice in each testing area& The second testing shall be conducted with the

lines of magnetic flu3 appro3imatel0 at right angle to the first application&

=&2&' The o,erlap of each testing area shall be sufficient to ensure the entire testing area is co,ered&

=&2&4 The magnetic particle shall be applied b0 either spra0ing or flowing o,er the area to be tested& This

application of magnetic particle should be done while electric power is applied and 0oke is

acti,ated&

=&2&4 (pplication of power shall be maintained for around 17 seconds to allow magnetic particles

gathering on discontinuit0, if an0&

=&2&= #f there is no significant indication, same practice shall be repeated at the ne3t testing area&

APPROVED BY L & T REVIEED ! APPROVED BY JACOBS

LARSEN & TOUBRO LIMITED

PAGE NO.- 4 OF 4

DATE:-01.11.2007

MSQ (EPCC-1) UPGADATION

PROJECT

REV.NO.- 00

MAGNETIC PARTICLE TEST

PROCEDURE NO.-

LT/MSQ/P/MPT/008

7.0 INTERPRETATION

<&1 Surface discontinuities are indicated b0 accumulation of magnetic particles which should contrast

with the e3amination surface& The interpretation shall identif0 if an indication as false, on rele,ant

or rele,ant&

<&2 (ll indications shall be e,aluated in terms of the acceptance standards in accordance with the

applicable standard and specification&

'.0 POST CLEANING

9hen post e3amination cleaning is specified it should be carried out b0 using a process that does

not ad,ersel0 affect the part&

?&7 DOCUMENTATION

The test results shall be recorded in "()*+, N(. LT!MSQ!MPT!017

10.0 SA"ETY

(ll safet0 precautions shall be taken as per @S) re5uirements of the pro"ect&

APPROVED BY L & T REVIEED ! APPROVED BY JACOBS

Das könnte Ihnen auch gefallen

- PROJECT STANDARDS and SPECIFICATIONS Welding Qualification Test Procedure Rev01webDokument5 SeitenPROJECT STANDARDS and SPECIFICATIONS Welding Qualification Test Procedure Rev01webhiyeonNoch keine Bewertungen

- Casting DefectsDokument60 SeitenCasting DefectsVaibhav AwacharNoch keine Bewertungen

- 10) Itp - Tank Fabrication PDFDokument6 Seiten10) Itp - Tank Fabrication PDFAndy Chong100% (5)

- Chemical CompositionDokument219 SeitenChemical CompositionPhan Huy100% (5)

- 2015-21 Exterior PaintingDokument16 Seiten2015-21 Exterior PaintingmaxNoch keine Bewertungen

- Stainless Steel GuideDokument22 SeitenStainless Steel Guideasfarjee67% (6)

- WPSDokument25 SeitenWPSWaqas WaqasNoch keine Bewertungen

- ISO 9001 2008-List of Sample Audit QuestionsDokument5 SeitenISO 9001 2008-List of Sample Audit QuestionsSaut Maruli Tua SamosirNoch keine Bewertungen

- WPQP 6g Smaw API 5lx52 Od10inch 15.9mmDokument1 SeiteWPQP 6g Smaw API 5lx52 Od10inch 15.9mmufomskiNoch keine Bewertungen

- A05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFDokument14 SeitenA05 004 Inspection Test Plan Shell Tube Heat Exchangers 5 210D HA 01 A B C D PDFfdfazfzNoch keine Bewertungen

- Radiographic Interpretation: For The Radiographic Examination of Metallic Materials Using X-And Gamma-Rays"Dokument8 SeitenRadiographic Interpretation: For The Radiographic Examination of Metallic Materials Using X-And Gamma-Rays"Saut Maruli Tua SamosirNoch keine Bewertungen

- Ferrite ContentDokument5 SeitenFerrite ContentMohammad Rizwan100% (1)

- G. Std. ITP For Pipeline Job PDFDokument4 SeitenG. Std. ITP For Pipeline Job PDFAnonymous 4e7GNjzGWNoch keine Bewertungen

- RI CW 2Dokument6 SeitenRI CW 2Saut Maruli Tua Samosir100% (1)

- RI CW 1Dokument6 SeitenRI CW 1Saut Maruli Tua SamosirNoch keine Bewertungen

- Canon Parts ListDokument14 SeitenCanon Parts ListbishoppyrcNoch keine Bewertungen

- RI CW 6Dokument7 SeitenRI CW 6Saut Maruli Tua SamosirNoch keine Bewertungen

- RI CW 7Dokument8 SeitenRI CW 7Saut Maruli Tua SamosirNoch keine Bewertungen

- Ut 04 TwiDokument15 SeitenUt 04 TwiSaut Maruli Tua SamosirNoch keine Bewertungen

- RT Procedure 200-004 Rev. 07Dokument33 SeitenRT Procedure 200-004 Rev. 07abdul aziz67% (6)

- Weld Defect Wall ChartDokument6 SeitenWeld Defect Wall ChartMuhammad Attaulla KhanNoch keine Bewertungen

- MESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167Dokument7 SeitenMESC SPE 74-018 - 2010 - Nickel Alloy Pipe To Astm b167sathi11189Noch keine Bewertungen

- Magnetic Particle Test Inspection Free NDT Sample ProcedureDokument8 SeitenMagnetic Particle Test Inspection Free NDT Sample ProcedureBhavani Prasad0% (1)

- Weld Identification: Welding Procedures ManualDokument2 SeitenWeld Identification: Welding Procedures ManualcarlosNoch keine Bewertungen

- SECTION 09960 High-Performance Coatings Rev 0Dokument48 SeitenSECTION 09960 High-Performance Coatings Rev 0rachedNoch keine Bewertungen

- Enbridge Pipeline Repair Workplan Welding PDFDokument23 SeitenEnbridge Pipeline Repair Workplan Welding PDFquiron2014Noch keine Bewertungen

- RI CW 4Dokument6 SeitenRI CW 4Saut Maruli Tua SamosirNoch keine Bewertungen

- Procedure For Magnetic Particle ExaminationDokument2 SeitenProcedure For Magnetic Particle ExaminationsrinivasansmNoch keine Bewertungen

- Package 2s E0001 - Jupiter DCR 30-10-2021Dokument96 SeitenPackage 2s E0001 - Jupiter DCR 30-10-2021senthilNoch keine Bewertungen

- STS QAC SOP 006 Repair Procedure For Stainless SteelDokument5 SeitenSTS QAC SOP 006 Repair Procedure For Stainless Steelmohd as shahiddin jafriNoch keine Bewertungen

- 0.hydro Test Package Index - 2Dokument13 Seiten0.hydro Test Package Index - 2VISHNUPRASAD ARAKKAL MOHANDASNoch keine Bewertungen

- Procedure For DPT PDFDokument4 SeitenProcedure For DPT PDFSaut Maruli Tua Samosir50% (2)

- Radiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0Dokument13 SeitenRadiography Testing Procedure: Procedure No. BCE/RT/003-2018/Rev-1.0BCE DeNoch keine Bewertungen

- Proposed WPS For API 5LDokument1 SeiteProposed WPS For API 5LMecon HyderabadNoch keine Bewertungen

- Magnetic Particle Examination of WeldsDokument4 SeitenMagnetic Particle Examination of WeldsshruthiNoch keine Bewertungen

- Following Taiichi Ohno's FootstepsDokument30 SeitenFollowing Taiichi Ohno's FootstepsGabriel Gomez0% (1)

- RI CW 3Dokument6 SeitenRI CW 3Saut Maruli Tua Samosir100% (2)

- Hardness Pro Form1Dokument2 SeitenHardness Pro Form1gst ajah100% (1)

- Radiographic Interpretation Assessment: Multi - Choice Question Paper (MSR-ARI-1) NameDokument5 SeitenRadiographic Interpretation Assessment: Multi - Choice Question Paper (MSR-ARI-1) NameSaut Maruli Tua Samosir50% (2)

- RI CW 9Dokument8 SeitenRI CW 9Saut Maruli Tua SamosirNoch keine Bewertungen

- Qualification Procedure No. 7: SSPC: The Society For Protective CoatingsDokument6 SeitenQualification Procedure No. 7: SSPC: The Society For Protective CoatingsRinush SinagaNoch keine Bewertungen

- Magnetic Particle Examination Procedure PorDokument7 SeitenMagnetic Particle Examination Procedure PorFasil ParuvanathNoch keine Bewertungen

- (Painting Works) : Inspection and Test PlanDokument2 Seiten(Painting Works) : Inspection and Test Planrize1159Noch keine Bewertungen

- WPS Steps of MakingDokument51 SeitenWPS Steps of MakingSaut Maruli Tua Samosir100% (1)

- Titanium Cladded Sheet Welding ProcedureDokument4 SeitenTitanium Cladded Sheet Welding ProcedureNaveenNoch keine Bewertungen

- Soil Nail Thesis PresentationDokument36 SeitenSoil Nail Thesis Presentationjoshua humirangNoch keine Bewertungen

- 1sbc100122c0202 ch04Dokument47 Seiten1sbc100122c0202 ch04mathankumar1980Noch keine Bewertungen

- Doc. No Revision No Revision DateDokument6 SeitenDoc. No Revision No Revision DateShyam SinghNoch keine Bewertungen

- RI CW 8Dokument8 SeitenRI CW 8Saut Maruli Tua SamosirNoch keine Bewertungen

- A-Qac-Pro-730-38930 Rev ADokument10 SeitenA-Qac-Pro-730-38930 Rev ARamzi ZoghlamiNoch keine Bewertungen

- Hydrotest Check List PDFDokument1 SeiteHydrotest Check List PDFSaut Maruli Tua Samosir100% (1)

- D. Specs For Field & Shop PaintingDokument10 SeitenD. Specs For Field & Shop PaintingrajeshNoch keine Bewertungen

- Ferrite Content MeasurementDokument5 SeitenFerrite Content MeasurementFasil Paruvanath100% (1)

- Quality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDDokument6 SeitenQuality Assurance Plan: NEW AGE FAB Technologies Pvt. LTDRajnikant PatelNoch keine Bewertungen

- Bgas Test 1 PDFDokument14 SeitenBgas Test 1 PDFMathew CherianNoch keine Bewertungen

- Working ITPDokument4 SeitenWorking ITPStephen BoodooNoch keine Bewertungen

- Cold Tap Coating Report 2Dokument1 SeiteCold Tap Coating Report 2Jamal BakhtNoch keine Bewertungen

- Receiving Material Procedure (Done) (Sudah Direvisi)Dokument8 SeitenReceiving Material Procedure (Done) (Sudah Direvisi)Hardika SambilangNoch keine Bewertungen

- Obite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureDokument22 SeitenObite TC & Ogbogu Cluster - Ultrasonic Examination Procedure For Steel StructureeetuaNoch keine Bewertungen

- Materials and Their Behaviour: Course & CSWIP Examination Package Course Ref: VenueDokument1 SeiteMaterials and Their Behaviour: Course & CSWIP Examination Package Course Ref: VenueAwais TariqNoch keine Bewertungen

- Interseal 670HDokument2 SeitenInterseal 670Hmadmax_mfpNoch keine Bewertungen

- ITP - PP Insulation Using Wire MeshDokument2 SeitenITP - PP Insulation Using Wire MeshBurning TrainNoch keine Bewertungen

- Sl-Elt-Pr-Wps1-4107-C2-S1-Welder QualificationDokument15 SeitenSl-Elt-Pr-Wps1-4107-C2-S1-Welder Qualificationsaeed ghafooriNoch keine Bewertungen

- MSDS MtbeDokument5 SeitenMSDS MtbeViệt HàNoch keine Bewertungen

- 000 A Ee 0230028 513 R0Dokument13 Seiten000 A Ee 0230028 513 R0onur gunesNoch keine Bewertungen

- Prosedur Penetran TestingDokument11 SeitenProsedur Penetran TestingIkhsan DalimuntheNoch keine Bewertungen

- 0610.1 - Shell and Tube Heat ExchangersDokument30 Seiten0610.1 - Shell and Tube Heat Exchangersvenkatrangan2003Noch keine Bewertungen

- 01 Saip 06Dokument7 Seiten01 Saip 06malika_00Noch keine Bewertungen

- PTS-1012 - RA Hardness Test ReportDokument1 SeitePTS-1012 - RA Hardness Test ReportPetrotrim ServicesNoch keine Bewertungen

- 8474l-000-Jsd-2310-001-2-Protective CoatingDokument31 Seiten8474l-000-Jsd-2310-001-2-Protective Coatinglebienthuy100% (1)

- SAIC-W-2077 Weld Joint Identification SystemDokument1 SeiteSAIC-W-2077 Weld Joint Identification Systemkarioke mohaNoch keine Bewertungen

- INS T 004, Tol - OvalityDokument4 SeitenINS T 004, Tol - OvalityDeepakNoch keine Bewertungen

- Pig Launcher Fabrication Activity PlanDokument1 SeitePig Launcher Fabrication Activity PlanbeqsNoch keine Bewertungen

- Receiving Material Procedure CoverDokument1 SeiteReceiving Material Procedure Covergst ajahNoch keine Bewertungen

- Welding Material Control ProcedureDokument12 SeitenWelding Material Control ProcedureWalter RuedaNoch keine Bewertungen

- 2015 Pinnacle 580 Training FlyerDokument2 Seiten2015 Pinnacle 580 Training FlyerAlbertoNoch keine Bewertungen

- Coded Marking Procedure - CM-01Dokument7 SeitenCoded Marking Procedure - CM-01carlosNoch keine Bewertungen

- Floating Head Heat Exchanger Hydrotest ProcedureDokument15 SeitenFloating Head Heat Exchanger Hydrotest ProcedureDoğuhan DenizgezNoch keine Bewertungen

- Welding Processes and Equipment: Course & CSWIP Examination Package Course Ref: VenueDokument1 SeiteWelding Processes and Equipment: Course & CSWIP Examination Package Course Ref: VenueAwais TariqNoch keine Bewertungen

- Interactive Form U-1ADokument1 SeiteInteractive Form U-1ADimas AnugrahNoch keine Bewertungen

- RTDokument14 SeitenRTaravindanNoch keine Bewertungen

- Resume - 01.03.2016Dokument5 SeitenResume - 01.03.2016muthuswamy77Noch keine Bewertungen

- Ultrasonic Testing of Tube To Tube SheetDokument6 SeitenUltrasonic Testing of Tube To Tube SheetDARSHIL RAJPURANoch keine Bewertungen

- MPTDokument4 SeitenMPTbhavin_jsmNoch keine Bewertungen

- QC Inspector (Painting)Dokument4 SeitenQC Inspector (Painting)Saut Maruli Tua SamosirNoch keine Bewertungen

- ISO 9001 2008-AmmendmentsDokument4 SeitenISO 9001 2008-AmmendmentsAshish Gupta100% (5)

- TLC Quicktip ExcelDokument12 SeitenTLC Quicktip ExcelRajas GuruNoch keine Bewertungen

- A Recipe For RustDokument1 SeiteA Recipe For RusttbmariNoch keine Bewertungen

- Wet Film CombsDokument1 SeiteWet Film CombsSaut Maruli Tua SamosirNoch keine Bewertungen

- A Recipe For RustDokument1 SeiteA Recipe For RusttbmariNoch keine Bewertungen

- Certification Mauel For Welding Inspection Chapter 1Dokument10 SeitenCertification Mauel For Welding Inspection Chapter 1moen123456Noch keine Bewertungen

- Variable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aDokument7 SeitenVariable E SE NE Description of Variable As in Code 2011a QW SMAW Welding Variables For WPS - ASME Sec IX 2011aSaut Maruli Tua SamosirNoch keine Bewertungen

- Viscosity Cup PDFDokument16 SeitenViscosity Cup PDFSaut Maruli Tua SamosirNoch keine Bewertungen

- New Microsoft Office Word DocumentDokument9 SeitenNew Microsoft Office Word DocumenthreerNoch keine Bewertungen

- Welding DefectsDokument78 SeitenWelding DefectsSaut Maruli Tua SamosirNoch keine Bewertungen

- UAS Genap Bahasa Inggris Kelas 7Dokument5 SeitenUAS Genap Bahasa Inggris Kelas 7Saut Maruli Tua SamosirNoch keine Bewertungen

- Stainless Steel Chloride Corrosion PDFDokument8 SeitenStainless Steel Chloride Corrosion PDFSaut Maruli Tua SamosirNoch keine Bewertungen

- GaN & SiC Power Semiconductors - Why These Devices Are Gaining Popularity - NewsDokument15 SeitenGaN & SiC Power Semiconductors - Why These Devices Are Gaining Popularity - NewsAmanuel Amare GebrekidanNoch keine Bewertungen

- About Welding Process 43Dokument1 SeiteAbout Welding Process 43XerexNoch keine Bewertungen

- FA - CDS - PLB DuctDokument26 SeitenFA - CDS - PLB Ductmba213Noch keine Bewertungen

- Air Conditioning SystemsDokument14 SeitenAir Conditioning Systemsarslan KhanNoch keine Bewertungen

- High Velocity Oil FlushDokument2 SeitenHigh Velocity Oil FlushNatanael CarpelotiNoch keine Bewertungen

- Catalogo Fire 2009Dokument7 SeitenCatalogo Fire 2009Benicio Joaquín Ferrero BrebesNoch keine Bewertungen

- Catalogue Forpus 2013-2014Dokument116 SeitenCatalogue Forpus 2013-2014Macksym GalatonoffNoch keine Bewertungen

- Sub Sec 1 To 9Dokument7 SeitenSub Sec 1 To 9khan4luvNoch keine Bewertungen

- Steels For Construction Special Steels Structural Steel Construction Steel dd11 PickledDokument2 SeitenSteels For Construction Special Steels Structural Steel Construction Steel dd11 PickledhelderfsnNoch keine Bewertungen

- Ag-Zno Solar Cell Mini ProjectDokument15 SeitenAg-Zno Solar Cell Mini ProjectDeepak BaghelNoch keine Bewertungen

- Eew Longitudinally Welded Double Seam Lwds Pipes PDFDokument4 SeitenEew Longitudinally Welded Double Seam Lwds Pipes PDFktsnlNoch keine Bewertungen

- Karl Fisher TitrimeterDokument5 SeitenKarl Fisher TitrimeterKhalid ZghearNoch keine Bewertungen

- Metals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleDokument18 SeitenMetals: 3D Printed Acetabular Cups For Total Hip Arthroplasty: A Review ArticleUtkarsh AnandNoch keine Bewertungen

- Environmental Laws and RegulationsDokument50 SeitenEnvironmental Laws and RegulationsPaul Santos NonatNoch keine Bewertungen

- Building RepairsDokument8 SeitenBuilding RepairsRenuka ChalikwarNoch keine Bewertungen

- 6410 Stepper Drive Manual En-Us RevADokument82 Seiten6410 Stepper Drive Manual En-Us RevAYazeed MomaniNoch keine Bewertungen

- WWWT 1111 Pt2 Water Distribution 3.3 - (Water Distribution Foundations - 3Dokument11 SeitenWWWT 1111 Pt2 Water Distribution 3.3 - (Water Distribution Foundations - 3marioNoch keine Bewertungen

- Design Procedure of A Pyramid Shaped HopperDokument4 SeitenDesign Procedure of A Pyramid Shaped HopperOkayNoch keine Bewertungen

- Essa® Fire Assay Multiload and Multipour SystemsDokument4 SeitenEssa® Fire Assay Multiload and Multipour SystemsLuz ContrerasNoch keine Bewertungen

- AMIE Sample Paper 2Dokument3 SeitenAMIE Sample Paper 2skannan1980Noch keine Bewertungen

- Standard Price List: Office of The Provincial EngineerDokument27 SeitenStandard Price List: Office of The Provincial EngineerJohn Harvy JoseNoch keine Bewertungen

- Construction of A Low Cost Drip Irrigation System For ProductionDokument4 SeitenConstruction of A Low Cost Drip Irrigation System For ProductionBaba shehu Abba kyariNoch keine Bewertungen

- IQP Final Report 2Dokument81 SeitenIQP Final Report 2Mohamed NasrNoch keine Bewertungen