Beruflich Dokumente

Kultur Dokumente

MP I Objective

Hochgeladen von

mitmandsaur0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten25 SeitenOriginaltitel

MP I Objective.doc

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

16 Ansichten25 SeitenMP I Objective

Hochgeladen von

mitmandsaurCopyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 25

Shrof S.R.

Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

Sr.No. Question Answer

1.

Side rake angle of a single point cutting tool is the angle

A. By which the face of the tool is inclined towards back

B. By which the face of the tool is inclined sideways

C. Between the surface of the flank immediately below the point and a

plane at right angles to the centre line of the point of the tool

D. Between the surface of the flank immediately below the point and a line

drawn from the point perpendicular to the base

B

.

!nternal gears can be made by

A. "obbing

B. shaping with pinion cutter

C. shaping with rack cutter

D. milling

B

#.

Segmental chips are formed during machining

A. mild steel

B. cast iron

C. high speed steel

D. high carbon steel

B

$. Drilling is an e%ample of

A. orthogonal cutting

B

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

B. obli&ue cutting

C. simple cutting

D. uniform cutting

'.

(hen the cutting edge of the tool is dull) then during machining

A. continuous chips are formed

B. discontinuous chips are formed

C. continuous chips with built*up edge are formed

D. no chips are formed

C

+.

A single point thread cutting tool should ideally ha,e

A. -ero rake angle

B. positi,e rake angle

C. negati,e rake angle

D. point angle

A

..

/he work or surface speed for cylindrical grinding ,aries from

A. ' to 10 m1min

B. 10 to 0 m1min

C. 0 to #0 m1min

D. $0 to +0 m1min

C

2.

/he cutting tool in a milling machine is mounted on

A. A. spindle B. C. arbor

D. B. column 3. D. knee

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

4.

A push broach as compared to pull broach

A. "as less number of teeth

B. !s short and stocky

C. remo,es less material for each pass of the tool

D. all of the abo,e

D

10.

/wist drills are made of

A. high speed steel

B. carbon steel

C. stainless steel

D. either 5a6 or 5b6

D

11.

A twist drill is a

A. side cutting tool

B. front cutting tool

C. end cutting tool

D. none of these

C

1.

/he lip angle of a single point tool is usually

A. A. 07 to $07

B. B. $07 to +07

C. C. +07 to 207

D. D. none of these

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

1#

A fi%ture is defined as a de,ice which

A.

holds and locates a workpiece and guides and controls one or more cutting

tools

B.

holds and locates a workpiece during an inspection or for a manufacturing

operation

C. is used to check the accuracy of workpiece

D. all of the abo,e

B

1$

A drill considered as a cutting tool ha,ing -ero rake) is known as a

A. flat drill

B. straight fluted drill

C. parallel shank twist drill

D. tapered shank twist drill

B

1'

/he lead screw of a lathe has 8888888888 threads.

A. single start

B. double start

C. multi*start

D. any one of these

A

1+ A left hand tool on a lathe cuts most efficiently when it tra,els

A. from left to right end of the lathe bed

B. from right to left end of the lathe bed

C. with the help of a compound slide

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

D. across the bed

1.

(hich of the following statement is incorrect with reference of lathe cutting

tools9

A.

/he flank of the tool is the surface or surfaces below and ad:acent to the

cutting edges

B.

/he nose is the corner) arc or chamfer :oining the side cutting and the end

cutting edges

C.

/he heel is that part of the tool which is shaped to produce the cutting

edges and face

D.

/he base is that surface of the shank which bears against the support and

takes tangent pressure of the cut

C

12

;apping is an operation of

A. <aking a cone*shaped enlargement of the end of a hole

B. Smoothing and s&uaring the surface around a hole

C. Si-ing and finishing a small diameter hole

D.

=roducing a hole by remo,ing metal along the circumference of a hollow

cutting tool

C

14

/he different spindle speeds on a lathe form

A. Arithmetical progression

B. >eometrical progression

C. "armonical progression

D. any one of these

B

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

0

/he e%ample of snag grinding is

A. /rimming the surface left by sprues and risers on castings

B. >rinding the parting line left on castings

C. ?emo,ing flash on forgings

D. All of these

D

1

/he lathe spindles are usually made hollow and pro,ided with

A. !nternal taper

B. 3%ternal taper

C. !nternal and e%ternal taper

D. No taper

A

/he top and sides of the table of a shaper usually ha,e

A. ;*type slots B. /*type slots

C. !*type slots D. Any one of these B

#

!n machining metals) chips break due to 8888888888 of work material.

A. /oughness

B. Ductility

C. 3lasticity

D. (ork hardening

D

$ (hich of the following statement is correct regarding grinding of high carbon

steel9

A.

>rinding at high speed results in the reduction of chip thickness and

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

B. Aluminum o%ide wheels are employed.

C. /he grinding wheel has to be of open structure.

D. all of the abo,e

'

/he rear teeth of a broach

A. perform burnishing operation

B. remo,e minimum metal

C. remo,e ma%imum metal

D. remo,e no metal

C

+

(hen the end of a tap is tapered for about three or four threads) it is known as a

A. /aper tap B. Bottoming tap

C. Second tap D. None of these

C

.

Crater wear is predominant in

A. Carbon tool steels B. /ungsten carbide tools

C. high speed steel tools D. ceramic tools

B

2

!n a shaper) the length of stroke is increased by

A. increasing the centre distance of bull gear and crank pin

B. decreasing the centre distance of bull gear and crank pin

C. increasing the length of the arm

D. decreasing the length of the slot in the slotted le,er

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

4

/he abrasi,e recommended for grinding materials of high tensile strength is

A. silicon carbide

B. Aluminum o%ide

C. sand stone

D. diamond

B

#0

/he factor responsible for the formation of continuous chips with built up edge is

A. low cutting speed and large rake angle

B. low cutting speed and small rake angle

C. high cutting speed and large rake angle

D. high cutting speed and small rake angle

B

#1

An important geometrical &uantity in the cutting of metals which can be used as a

criterion for machinability of metals is

A. cutting speed

B. feed rate

C. shear angle

D. tool geometry

C

#

!n metal cutting) use of low feeds and high cutting speeds is desired when the

ob:ecti,e is

A. high metal remo,al rate

B. dry machining

C. use of soft cutting tool

D. surface finish

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

##

/he angle on which the strength of the tool depends is

A. rake angle

B. cutting angle

C. clearance angle

D. lip angle

A

#$

(hich of the following statement is correct for orthogonal cutting system9

A. /he cutting edge of the tool is perpendicular to the direction of tool tra,el.

B. /he cutting edge clears the width of the workpiece on either ends.

C.

/he chip flows o,er the tool face and the direction of the chip flow

,elocity is normal to the cutting edge.

D. all of the abo,e

D

#'

/hread grinding re&uires work speed from

A. 1 to # m1min

B. ' to 10 m1min

C. 10 to 1$ m1min

D. 1$ to 0 m1min

A

#+

/hreading is an operation of

A. smoothing and s&uaring the surface around a hole

B. si-ing and finishing a small diameter hole

C.

producing a hole by remo,ing metal along the circumference of a hollow

cutting tool

D. cutting helical groo,es on the e%ternal cylindrical surface

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

#.

/he cutting speed is minimum while machining 8888888888 with a high speed

steel tool.

A. cast iron

B. mild steel

C. brass

D. aluminum

A

#2

A process of remo,ing metal by pushing or pulling a cutting tool is called

A. up milling

B. down milling

C. forming

D. broaching

D

#4

(hich of the following operations can be performed with milling cutters9

A. cutting key ways on shafts

B. cutting e%ternal screw threads

C. cutting teeth of spur gears

D. all of these

D

$0

(hile cutting helical gears on a non*differential gear hobber) the feed change gear

ratio is

A. independent of inde% change gear ratio

B. dependent on speed change gear ratio

C. inter*related to inde% change gear ratio

D. independent of speed and inde% change gear ratio

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

$1

/he swing diameter o,er the bed is 8888888888 the height of the centre measured

from the bed of the lathe.

A. e&ual to B. /wice

C. thrice D. one*half

B

$

Down milling is also called

A. con,entional milling

B. climb milling

C. end milling

D. face milling

B

$#

Any number of e&ual di,isions can be obtained on milling machine by

A. direct inde%ing

B. simple inde%ing

C. compound inde%ing

D. differential inde%ing

B

$$

/he depth of cut in drilling is 8888888888 the drill diameter.

A. e&ual to

B. one*fourth

C. one*half

D. double

C

$' /he type of tool used on lathe) shaper and planer is

A. single point cutting tool

B. two point cutting tool

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

C. three point cutting tool

D. multi*point cutting tool

$+

/he relation between tool life 5T6 and cutting speed 5V6 is VT

n

@ Constant. !n this

relation) the ,alue of n depends upon

A. work material B. /ool material

C. working conditions D. type of chip produced

B

$.

!n order to grind soft material

A. coarse grained grinding wheel is used

B. fine grained grinding wheel is used

C. medium grained grinding wheel is used

D. any one of these

A

$2

/he type of reamer used for reaming operation in a blind hole) is

A. straight fluted reamer

B. left hand spiral fluted reamer

C. right hand spiral fluted reamer

D. any one of these

C

$4 !n a single point tool) the angle between the surface of the flank immediately

below the point and a line drawn from the point perpendicular to the base) is

known as

A. side relief angle

B. end relief angle

C. back rake angle

B

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

D. side rake angle

'0

/he grinding operaion is a

A. shaping operation

B. forming operation

C. surface finishing operation

D. dressing operation

C

'1

/he guideways are of

A. flat type B. A*type

C. Do,etail type D. any one of these

D

'

/he ,elocity of tool along the tool face is known as

A. shear ,elocity

B. chip ,elocity

C. cutting ,elocity

D. mean ,elocity

B

'#

/he purpose of :igs and fi%tures is to

A. increase machining accuracy

B. facilitate interchangeability

C. decrease e%penditure on &uality control

D. all of these

D

'$

!n which of the following milling machine) the table can be tilted in a ,ertical

plane by pro,iding a swi,el arrangement at the knee9

A. Bni,ersal milling machine

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

B. =lain milling machine

C. Cmni,ersal milling machine

D. "and milling machine

''

"igh speed steel cutting tools operate at cutting speeds 8888888888 than carbon

steel tools.

A. to # times lower

B. to # times higher

C. ' to 2 times higher

D. 2 to 0 times higher

B

+1

"igh speed steel tools retain their hardness upto a temperature of

A. '07C B. #'07C

C. '007C D. 4007C

D

'.

/he cutting force in up milling 8888888888 per tooth mo,ement of the cutter.

A. is -ero

B. is ma%imum

C. decreases from ma%imum to -ero

D. increases from -ero to ma%imum

D

'2

/he height of each tooth of a broach is

A. same throughout

B. in progressi,ely decreasing order

C. in progressi,ely increasing order

D. none of these

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

'4

/he surface finish is impro,ed by the increase in

A. cutting speed

B. nose radius

C. true rake angle

D. all of these

D

+0

/he cutting speed for drilling copper with high speed steel drills ,aries from

A. 10 to 0 m1min

B. 12 to #0 m1min

C. $ to $' m1min

D. +0 to 40 m1min

B

+

Dor machining a mild steel workpiece using carbide tool) the ma%imum material

will be remo,ed at a temperature of

A. '07C B. 1007C

C. 1.'7C D.

.'7C

B

+#

(hich of the following statement is wrong9

A.

/he diamond is the hardest tool material and can run at cutting speeds

about '0 times that of high speed steel tool.

B.

/he ceramic tools can be used at cutting speeds $0 times that of high speed

steel tools.

C.

/he cemented carbide tools can be used at cutting speeds 10 times that of

high speed steel tools.

D. /he ceramic tools can withstand temperature upto +007C only.

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

+$

Climb milling is chosen while machining because

A. the chip thickness increase gradually

B. it enables the cutter to dig in and start the cut

C. the specific power consumption is reduced

D. better surface finish can be obtained

B

+'

/he material which on machining produces chips with built up edge is

A. brittle material

B. tough material

C. hard material

D. ductile material

D

++

/he chuck used for setting up of hea,y and irregular shaped work should be

A. four :aw independent chuck

B. three :aw uni,ersal chuck

C. magnetic chuck

D. drill chuck

A

+.

(hich of the following operations is carried out at a minimum cutting ,elocity if

the machines are e&ually rigid and the tool work materials are the same9

A. /urning B. >rinding

C. Boring D. <illing

D

+2 /he si-e of a shaper is gi,en by

A. stroke length

B. motor power

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

C. mass of machine

D. rate si-e

+4

/he main purpose of a boring operation) as compared to drilling) is to

A. drill a hole

B. finish the drilled hole

C. correct the hole

D. enlarge the e%isting hole

D

.0

Carbide tipped tools usually ha,e

A. negati,e rake angle

B. positi,e rake angle

C. any rake angle

D. no rake angle

A

.1

/he saw milling is an operation of

A.

producing groo,es around the periphery of a cylindrical or conical

workpiece

B. producing narrow slots or groo,es on a workpiece

C. reproduction of an outline of a template on a workpiece

D. machining se,eral surfaces of a workpiece simultaneously

B

. /he high cutting speed and large rake angle of the tool will result in the formation

of

A. continuous chips

B. discontinuous chip

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

C. continuous chips with built up edge

D. none of these

.#

!n obli&ue cutting system) the ma%imum chip thickness

A. occurs at the middle

B. may not occur at the middle

C. depends upon the material of the tool

D. depends upon the geometry of the tool

B

.$

/he tool material) for faster machining) should ha,e

A. wear resistance

B. red hardness

C. toughness

D. all of these

D

.'

!n a single point turning operation with a cemented carbide and steel combination

ha,ing a /aylor e%ponent of 0.') if the cutting speed is hal,ed) then tool life will

become

A. half

B. two times

C. eight times

D. si%teen times

D

.+ An open structure of a grinding wheel is used for

A. soft materials

B. tough materials

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

C. ductile materials

D. all of these

..

A twist drill is specified by its

A. shank) material and diameter

B. shank) lip angle and si-e of flute

C. material) length of body and heli% angle

D. any one of these

A

.2

>la-ing in grinding wheels takes place when the

A. wheel is too hard or wheel re,ol,es at a ,ery high speed

B. wheel is too soft or wheel re,ol,es at a ,ery slow speed

C. wheel is too hard and wheel re,ol,es at ,ery slow speed

D. wheel is too soft and wheel re,ol,es at a ,ery high speed

A

.4

!n which of the following machine) the work remains stationary and the tool is

rotated9

A. Aertical boring machine

B. "ori-ontal boring machine

C. =recision boring machine

D. Eig boring machine

B

20 /he cutting speed of a drill depends upon the

A. material of drill

B. type of material to be drilled

C. &uality of surface finish desired

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

D. all of these

21

/he chamfering is an essential operation after

A. knurling

B. rough turning

C. boring

D. thread cutting

D

2

/he broaching operation in which either the work or the tool mo,es across the

other) is known as

A. pull broaching

B. push broaching

C. surface broaching

D. continuous broaching

C

2#

A :ig is defined as a de,ice which

A.

holds and locates a workpiece and guides and controls one or more cutting

tools

B.

holds and locates a workpiece during an inspection or for a manufacturing

operation

C. is used to check the accuracy of workpiece

D. all of the abo,e

A

2$ A mandrel is used to hold

A. an eccentric work

B. a hea,y work

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

C. a thin work

D. none of these

2'

A dense structure of a grinding wheel is used for

A. hard materials

B. brittle materials

C. fnishing cuts

D. all of these

D

2+

>ears can be best produced on mass production by

A. shaping B. casting

C. forming D. hobbing

D

2.

!n a plain milling machine) the table can be mo,ed

A. longitudinally

B. crosswise

C. ,ertically

D. all of these

D

22

!n drilling operation) the metal is remo,ed by

A. shearing

B. e%trusion

C. shearing and e%trusion

D. shearing and compression

C

24

Chip breakers are used to

A. increase tool life

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

B. remo,e chips from bed

C. break the chips into short segments

D. to minimise heat generation

40

/he factor responsible for the formation of discontinuous chips is

A. low cutting speed and large rake angle

B. low cutting speed and small rake angle

C. high cutting speed and large rake angle

D. high cutting speed and small rake angle

B

41

/he actual feed in centreless grinders is gi,en by 5where d @ Dia. of regulating

wheel)n @ ?e,olutions per minute) and F @ Angle of inclination of wheel6

A. Gd

B. Gd n

C. Gd n sin F

D. Gd n cos F

C

4

An operation of embossing a diamond shaped pattern on the surface of a

workpiece) is known as

A. counter*boring B. groo,ing

C. knurling D. facing

C

4# /he lathe centres are pro,ided with standard taper known as

A. <orse taper

B. SellerHs taper

C. Chapman taper

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

D. Brown and Sharpe taper

4$

!n a plain milling cutter) the portion of the gash ad:acent to the cutting edge on

which the chip impinges is called

A. face B. fillet

C. land D. lead

A

4'

Cutting fluids are used to

A. cool the tool

B. impro,e surface finish

C. cool the workpiece

D. all of these

D

4+

!n which of the following machine) the work rotates and the tool is stationary9

A. Aertical boring machine

B. "ori-ontal boring machine

C. =recision boring machine

D. Eig boring machine

A

4.

/he cutting fluid mostly used for machining alloy steels is

A. water

B. soluble oil

C. dry

D. sulphurised mineral oil

D

42

!n reaming process

A. metal remo,al rate is high

C

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

B. high surface finish is obtained

C. high form accuracy is obtained

D. high dimensional accuracy is obtained

44

Dlank wear occurs mainly on the

A. nose part) front relief face and side relief face of the cutting tool

B. face of the cutting tool at a short distance from the cutting edge

C. cutting edge only

D. front face only

A

100

/he process of changing the shape of grinding wheel as it becomes worn due to

breaking away of the abrasi,e and bond) is called

A. truing B. dressing

C. facing D. clearing

A

Discontinuous chips are formed during machining of

A. brittle metals

B. ductile metals

C. hard metals

D. soft metals

A

!n a planer

A. tool is stationary and work reciprocates

B. work is stationary and tool reciprocates

C. tool mo,es o,er stationary work

D. tool mo,es o,er reciprocating work

A

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Shrof S.R. Rotary Institute of Chemical Technology

Principal Supporter & Sponsor-United Phosphorus Ltd (UPL)/ Shrof family

Managed By n!lesh"ar #otary $ducation Society

ppro%ed &y '()$* +e" ,elhi* -o%t. of -u/arat & -)U 0liated

__________________________________________________________________________________

(hich of the following operation is first performed9

A. Spot facing

B. Boring

C. /apping

D. Drilling

B

/he si-e of a lathe is specified by the

A. length between centres

B. swing diameter o,er the bed

C. swing diameter o,er the carriage

D. all of these

D

______________________________________________________________________________

Block No:40! "t: #ataria! "nklesh$ar%#alia Roa&! Ta: #alia! 'ist:

Bharuch

(hone No:0)4*%+0,-! +...4-,.-/,.) 0%

mail:hr.srict1gmail.com! $$$.srict.in

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- I6 - 4.0 Engine PerformanceDokument121 SeitenI6 - 4.0 Engine Performancekristi5683Noch keine Bewertungen

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- QuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service ManualDokument21 SeitenQuickServe Online - (3666087) B3.9, B4.5, B4.5 RGT, and B5.9 Service Manualshashiraj50% (2)

- Boring MachineDokument38 SeitenBoring Machinemitmandsaur67% (3)

- Boring MachineDokument38 SeitenBoring Machinemitmandsaur67% (3)

- MercedesBenz CLK55 AMG W208 M113-EngineSpecificationsDokument159 SeitenMercedesBenz CLK55 AMG W208 M113-EngineSpecificationsrodolfodiaz100% (1)

- Knife Deburring Book PDFDokument24 SeitenKnife Deburring Book PDFDavid M.V.67% (3)

- Instruction Bgm-100 enDokument37 SeitenInstruction Bgm-100 enLalo LeloNoch keine Bewertungen

- AMS 2452 Superfinishing of HVOF Applied Tungsten Carbide Coatings PDFDokument13 SeitenAMS 2452 Superfinishing of HVOF Applied Tungsten Carbide Coatings PDFJose GasparNoch keine Bewertungen

- GT1109Dokument100 SeitenGT1109Metin YilmazNoch keine Bewertungen

- 2.superfinishing ProcessDokument9 Seiten2.superfinishing ProcessVikrant Sharma100% (1)

- Busch R 5 0160 0250 0400 0502 0630 B MRDokument32 SeitenBusch R 5 0160 0250 0400 0502 0630 B MRgoran100% (1)

- Quotation For A Granite Line PolisherDokument7 SeitenQuotation For A Granite Line PolisherKrishna Kant JethliyaNoch keine Bewertungen

- Energy Forms and ChangesDokument44 SeitenEnergy Forms and Changesdoudouthekiller100% (1)

- Eme Lesson PlanningDokument4 SeitenEme Lesson PlanningmitmandsaurNoch keine Bewertungen

- Eme Lesson PlanningDokument4 SeitenEme Lesson PlanningmitmandsaurNoch keine Bewertungen

- ME364 Machining BoringDokument2 SeitenME364 Machining BoringRaghuNoch keine Bewertungen

- Shroff S. R. Rotary Institute of Chemical Technology: Timetable - Chemical Engineering - Semester-I (Jul-Dec 2014)Dokument16 SeitenShroff S. R. Rotary Institute of Chemical Technology: Timetable - Chemical Engineering - Semester-I (Jul-Dec 2014)mitmandsaurNoch keine Bewertungen

- Sub:-Manufacturing Process - 1: Prepared by Chintan Charola Mayurrajsinh ChauhanDokument11 SeitenSub:-Manufacturing Process - 1: Prepared by Chintan Charola Mayurrajsinh ChauhanmitmandsaurNoch keine Bewertungen

- Shroff S. R. Rotary Institute of Chemical TechnologyDokument2 SeitenShroff S. R. Rotary Institute of Chemical TechnologymitmandsaurNoch keine Bewertungen

- Check ListDokument1 SeiteCheck ListmitmandsaurNoch keine Bewertungen

- FuelsDokument43 SeitenFuelsmitmandsaurNoch keine Bewertungen

- Shroff S. R. Rotary Institute of Chemical TechnologyDokument2 SeitenShroff S. R. Rotary Institute of Chemical TechnologymitmandsaurNoch keine Bewertungen

- Manufacturing Processes - IDokument2 SeitenManufacturing Processes - IshekhadaaNoch keine Bewertungen

- List of PracticalsDokument1 SeiteList of PracticalsmitmandsaurNoch keine Bewertungen

- Syllabus of Engineering Graphics As Per GtuDokument1 SeiteSyllabus of Engineering Graphics As Per GtumitmandsaurNoch keine Bewertungen

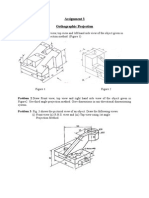

- Orthographic Projection AssisgnmentDokument1 SeiteOrthographic Projection AssisgnmentmitmandsaurNoch keine Bewertungen

- Criteria For An SAE Collegiate ClubDokument1 SeiteCriteria For An SAE Collegiate ClubmitmandsaurNoch keine Bewertungen

- Eme Lesson PlanningDokument3 SeitenEme Lesson PlanningmitmandsaurNoch keine Bewertungen

- Capstan & Turret LathesDokument22 SeitenCapstan & Turret LathesAhmed Kamal100% (1)

- SVKM MD&CG SyllabusDokument2 SeitenSVKM MD&CG SyllabusmitmandsaurNoch keine Bewertungen

- CNC Programme For BILLET X30 Z60Dokument1 SeiteCNC Programme For BILLET X30 Z60mitmandsaurNoch keine Bewertungen

- Always Leave Office On TimeDokument1 SeiteAlways Leave Office On TimemitmandsaurNoch keine Bewertungen

- Core DesignDokument1 SeiteCore DesignmitmandsaurNoch keine Bewertungen

- THE Cylinder CompanyDokument6 SeitenTHE Cylinder CompanyNguyễn Đức CườngNoch keine Bewertungen

- Adding and Altering: Surface FinishingDokument11 SeitenAdding and Altering: Surface FinishingVijay Raj PuniaNoch keine Bewertungen

- DownloadDokument28 SeitenDownloadmoonstarNoch keine Bewertungen

- PW Consumables en 2013Dokument8 SeitenPW Consumables en 2013Vicente Elías Venegas LunaNoch keine Bewertungen

- PGDDokument168 SeitenPGDkarvadNoch keine Bewertungen

- Stone Marble FinishesDokument14 SeitenStone Marble FinishesjembuildersupplyNoch keine Bewertungen

- 8.2 Fundamentals of Manufacturing For EngineersDokument13 Seiten8.2 Fundamentals of Manufacturing For EngineersKhánh ĐàoNoch keine Bewertungen

- Cylinder Condition Monitoring and Reconditioning 2 Stroke EnginesDokument5 SeitenCylinder Condition Monitoring and Reconditioning 2 Stroke Enginesastalavista143Noch keine Bewertungen

- Service Experience 2009Dokument19 SeitenService Experience 2009Alexandru AlexNoch keine Bewertungen

- Objective: To Study About Construction of Lathe and Various Operations On Lathe MachineDokument27 SeitenObjective: To Study About Construction of Lathe and Various Operations On Lathe MachineMuhit ChowdhuryNoch keine Bewertungen

- Sample FmeaDokument21 SeitenSample FmeaDhananjay PatilNoch keine Bewertungen

- c006b QDokument54 Seitenc006b QpchakkrapaniNoch keine Bewertungen

- SR - NO. Chapter Name Page NoDokument61 SeitenSR - NO. Chapter Name Page Nodeep bahirshetNoch keine Bewertungen

- Depl. ING KIT410 MP Kit Levigatura Portatile X 60 100 125 + Ricambi 3.0 20111Dokument2 SeitenDepl. ING KIT410 MP Kit Levigatura Portatile X 60 100 125 + Ricambi 3.0 20111azer tyNoch keine Bewertungen

- The Necessity of A Plateaued Cylinder Wall FinishDokument28 SeitenThe Necessity of A Plateaued Cylinder Wall FinishguguimirandaNoch keine Bewertungen

- Gear HoningDokument2 SeitenGear HoningMargam Kiran KumarNoch keine Bewertungen

- Factsheet Faessler HMX 400 V01 enDokument2 SeitenFactsheet Faessler HMX 400 V01 enAjay Sharma100% (2)

- Mobilgrind Series Mobilgrind Series Mobilgrind Series Mobilgrind SeriesDokument2 SeitenMobilgrind Series Mobilgrind Series Mobilgrind Series Mobilgrind SeriesDennis Alexander Oseguera OsegueraNoch keine Bewertungen

- Mitsu 14 Technical DataDokument52 SeitenMitsu 14 Technical DataRajesh Mishra100% (1)

- Piston Skirt ClearanceDokument5 SeitenPiston Skirt ClearanceJose CencičNoch keine Bewertungen