Beruflich Dokumente

Kultur Dokumente

How Many Extinguishers Are Required

Hochgeladen von

Be ReevCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How Many Extinguishers Are Required

Hochgeladen von

Be ReevCopyright:

Verfügbare Formate

Search

Criteria

Light (Low) Hazard

Occupancy

Ordinary (Moderate)

Hazard Occupancy

Extra (High) Hazard

Occupancy

Minimum Rated single

extinguisher

2-A 2-A 4-A

Maximum floor area per

unit of A

3,000 ft2 1,500 ft2 1,000 ft2

Maximum floor area for

extinguisher

11,250 ft2 11,250 ft2 11,250 ft2

Maximum travel distance to

extinguisher

75 ft 75 ft 75 ft

Type of Hazard

Basic Minimum Extinguisher

Rating

Maximum Travel Distance to

Extinguisher

5-B 30 ft

Light (Low) 10-B 50 ft

10-B 30 ft

Ordinary

(Moderate)

20-B 50 ft

40-B 30 ft

Extra (High) 80-B 50 ft

There are four topics to review when installing portable fire extinguishers. You must first identify the

hazards that are present, and recognize even trace amounts of each fire classification to determine

the proper number of extinguishers required. Next, you must determine the size of the fire

extinguisher, and establish the quantity of extinguishers needed by the coverage allowed per Local

and National fire codes. Last, you must distribute the portable fire extinguishers per the allowable

travel distance to each fire extinguisher.

Class A Locations

Source: NFPA 10, 2007 edition Table 6.2.1.1 Fire Extinguisher Size and Placement for Class A

Hazards

Class B Locations

Source: NFPA 10, 2007 edition Table 6.3.1.1 Fire Extinguisher Size and Placement for Class B

Hazards

How Many Extinguishers are Required?

What are Fire

Classicfications

What are the Extinguisher

Sizes

What is the Area Hazard

Classification

How Many Extinguishers are

Required

Portable Fire

Extinguishers

Connect With Us

Home About Us Services Who We Serve FAQs Contact Us Request a Survey

Extinguisher Type

Test Interval

(years)

Stored-pressure water, water mist, loaded stream, and/or anti-freeze 1

Pump tank water and pump tank calcium chloride base 1

Dry chemical, cartridge and cylinder operated, with mild steel shells 1

Dry powder, cartridge and cylinder operated, with mild steel shells 1

Wetting agent 1

Stored pressure water 5

Class C Locations

Class C extinguishers are required where energized electrical equipment is directly involved in or

surrounding electrical equipment.

Class D Locations

Class D extinguisher locations shall not be located more than 75 ft. from the hazard. Size

determination for Class D locations is based on the specific combustible metal, particle size, area to

be covered, and manufacturer recommendations.

Class K Locations

Class K hazards shall have a fire extinguisher located where there is a potential for a fire involving

combustible cooking media (vegetable or animal oils and fats). The extinguisher shall be located no

more than 30 ft. from the hazard.

NFPA 10 requires you to maintain your fire protection equipment in good working order and maintain

inspection,

testing and maintenance records. Inspections will be performed on an Annual basis.

EXAMPLES OF WORK PERFORMED DURING AN INSPECTION INCLUDE:

Check that unit is properly hung with the proper manufacturers hanger.

Check the gauge pressure.

Check the condition of the gauge and its compatibility with the extinguisher.

Check the weight of the extinguisher.

Check that the last hydrostatic test date is within code requirements.

Check the last 6year maintenance inspection date if applicable.

Check the valve and shell for damage or corrosion.

Remove the hose and inspect it for cracks or splits.

Check the hose threads for signs of wear.

Check the condition of the discharge horn.

Check for obstructions that interfere with accessibility of the unit.

Break the extinguisher seal and remove the locking pin.

Replace the locking pin and reseal the extinguisher.

Check the valve opening for powder or any foreign matter.

For dry extinguishers, fluff the powder by turning the unit.

Check the condition of the hose/horn retention band at the side of the extinguisher.

Check that the units classification is properly identified with the appropriate decal/signage.

Check that the operating instructions are clean and legible.

Check that the unit is properly located within the normal path of travel, at the required height.

Check that the unit is visible, unobstructed and in proper location.

Compile a complete location report, explaining any deficiencies.

Recommend corrective action to be taken in accordance with recognized codes for care and

maintenance.

Upon completion of inspection and any necessary repairs, applicable inspection documents

and noted deficiencies shall be left at location and available electronically.

Tag all portable fire extinguishers as required and perform required record keeping.

| Mindscape

Stored-pressure dry chemical, with stainless steel shells

Carbon dioxide 5

Wet chemical 5

Dry chemical stored-pressure, with mild steel shells, brazed brass shells, and

aluminum shells

5

Halogenated agents 6

Dry powder, stored pressure, with mild steel shells 6

Field's Fire Protection, Inc. is a member of the National Fire Protection Association (NFPA)

2011 Fields Fire Protection Inc. All Rights Reserved.

Locations Helpful Links Our Mission

Corporate Office

Detroit Office

Chicago Office

Portable Fire Extinguishers

Backflow Devices

Special Hazard Systems

Exit and Emergency Lighting

Fire Extinguisher Guidlines

Fire Safety Training

Testing & Repair

Our Mission

Field's Fire Protection is

committed to exceeding

expectations. We understand the

value of integrity, honesty and

experience, and our dedicated

staff delivers that and more; first

time, every time.

Learn more about our mission.

1-888-670-FIRE

Request a Survey

Email Us

Join Our Team

Join Our Mailing List

Das könnte Ihnen auch gefallen

- Pavel Tsatsouline - Ironman Magazine Interview June 2005Dokument6 SeitenPavel Tsatsouline - Ironman Magazine Interview June 2005kevin100% (2)

- Portable Fire Extinguisher Program Template Portable Fire Extinguisher Program TemplateDokument12 SeitenPortable Fire Extinguisher Program Template Portable Fire Extinguisher Program TemplateMuhammad NuriqramNoch keine Bewertungen

- Portable Fire Extinguisher 135Dokument3 SeitenPortable Fire Extinguisher 135hyde2520015754Noch keine Bewertungen

- 200802261708480.flammable and Combustible LiquidsDokument38 Seiten200802261708480.flammable and Combustible LiquidsFouad Badri100% (1)

- OneSteel Aluminium Price List Effective June 2006Dokument29 SeitenOneSteel Aluminium Price List Effective June 2006stanNoch keine Bewertungen

- Fire Safety Inspection ChecklistDokument3 SeitenFire Safety Inspection Checkliste cubeNoch keine Bewertungen

- Buckeye Catalogo - 2013Dokument28 SeitenBuckeye Catalogo - 2013Marco Antonio Zelada HurtadoNoch keine Bewertungen

- Nfpa 45Dokument19 SeitenNfpa 45Said A Attia100% (1)

- Fire Safety Log Book TemplateDokument21 SeitenFire Safety Log Book TemplateJawad Ali BaigNoch keine Bewertungen

- tkr305p 20201101Dokument1 Seitetkr305p 20201101Nicolas, Charles Franz ConradNoch keine Bewertungen

- Nfpa 45Dokument19 SeitenNfpa 45moha19841100% (1)

- Champions League: UEFA Champions League Anthem (With SATB. Choir Parts)Dokument3 SeitenChampions League: UEFA Champions League Anthem (With SATB. Choir Parts)charles camilo67% (3)

- C 4 FfaDokument35 SeitenC 4 Ffaanjuman ara100% (1)

- English 6 Quarter 2 Summative Test No. 2Dokument4 SeitenEnglish 6 Quarter 2 Summative Test No. 2Jovelyn L. LucioNoch keine Bewertungen

- Fire PPT IiitdDokument48 SeitenFire PPT IiitdSidhartha Sankar RoutNoch keine Bewertungen

- Fire Safety Training: The Loss Prevention Unit of The Office of Risk ManagementDokument53 SeitenFire Safety Training: The Loss Prevention Unit of The Office of Risk ManagementAhmed IdreesNoch keine Bewertungen

- Fire Protection and PreventionDokument43 SeitenFire Protection and PreventionRey Regaspi TuyayNoch keine Bewertungen

- Intramurals 2023Dokument5 SeitenIntramurals 2023Evangeline BaisacNoch keine Bewertungen

- The American University in Cairo: Nfpa 45 Fire Protection For Laboratories Using ChemicalsDokument19 SeitenThe American University in Cairo: Nfpa 45 Fire Protection For Laboratories Using ChemicalsergmmagcymctNoch keine Bewertungen

- Fire Safety in HospitalDokument44 SeitenFire Safety in HospitalDrmonisha MhaNoch keine Bewertungen

- Fundamentals of Fire Protection for the Safety ProfessionalVon EverandFundamentals of Fire Protection for the Safety ProfessionalNoch keine Bewertungen

- How Many Fire Extinguishers RequiredDokument4 SeitenHow Many Fire Extinguishers Requiredmuhammad kamranNoch keine Bewertungen

- Fire Extinguisher OpsDokument51 SeitenFire Extinguisher Opsdsn_sarmaNoch keine Bewertungen

- Resume NFPA 10Dokument8 SeitenResume NFPA 10Myshiba InuNoch keine Bewertungen

- Fire Extinguisher GuideDokument22 SeitenFire Extinguisher GuideSyed Faisal HassanNoch keine Bewertungen

- Catalogo Amerex ExtintoresDokument20 SeitenCatalogo Amerex ExtintoresMiguel Angel Carcamo OrdazNoch keine Bewertungen

- 11 FIRE FIGHTING-dikonversiDokument26 Seiten11 FIRE FIGHTING-dikonversiBull FloresNoch keine Bewertungen

- Fire Safety (Repaired)Dokument22 SeitenFire Safety (Repaired)Hoda ElebrashyNoch keine Bewertungen

- Fire Safety Procedures in The WorkplaceDokument12 SeitenFire Safety Procedures in The Workplacesayed rahmanNoch keine Bewertungen

- Fire Safety ManualDokument12 SeitenFire Safety ManualJun BasaNoch keine Bewertungen

- 50 LB Stored Pressure Wheeled Extinguishers Fa9e8b3cDokument8 Seiten50 LB Stored Pressure Wheeled Extinguishers Fa9e8b3cJEAN FELLIPE BARROSNoch keine Bewertungen

- P A S S ++extinguisherDokument30 SeitenP A S S ++extinguisherJudy Ann GallegoNoch keine Bewertungen

- Flammable and Combustible Liquids Design and Construction RequirementsDokument4 SeitenFlammable and Combustible Liquids Design and Construction RequirementsUmmy AbbyNoch keine Bewertungen

- Why Fireline For Your Fire Protection NeedsDokument2 SeitenWhy Fireline For Your Fire Protection NeedsJenaro UrquietaNoch keine Bewertungen

- 01 Sprinkler 071408Dokument145 Seiten01 Sprinkler 071408Pham Ba ManhNoch keine Bewertungen

- Portable and Fixed Gaseous SystemsDokument53 SeitenPortable and Fixed Gaseous SystemsMuhammad NuriqramNoch keine Bewertungen

- Basis For Code RequirementsDokument4 SeitenBasis For Code RequirementsAngeline SisonNoch keine Bewertungen

- Mosquito Magnet Defender InstructionsDokument18 SeitenMosquito Magnet Defender InstructionsMrFixit1328Noch keine Bewertungen

- Xgard ManualDokument74 SeitenXgard Manualkazishah100% (1)

- Guide to Solvent Recyclers URS2000 & RI 80 ManualDokument19 SeitenGuide to Solvent Recyclers URS2000 & RI 80 ManualDavid TroisiNoch keine Bewertungen

- Fire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Dokument3 SeitenFire Extinguisher Maintenance and Recharge Service Manual MODELS 204-354-504Nego1975Noch keine Bewertungen

- 21 When and Where Should Fire Extinguishers Be Installed - A Practical Guide For BuildingDokument23 Seiten21 When and Where Should Fire Extinguishers Be Installed - A Practical Guide For Buildingm.sofiqur rahmanNoch keine Bewertungen

- Fire SafetyDokument56 SeitenFire SafetykitNoch keine Bewertungen

- Fire ProtectionDokument14 SeitenFire ProtectionTeguh SetionoNoch keine Bewertungen

- Rasheed Panther TD SbaDokument42 SeitenRasheed Panther TD Sbasheedy pantherNoch keine Bewertungen

- Fire Safety - 2022Dokument22 SeitenFire Safety - 2022sapankr5xNoch keine Bewertungen

- Fire Safety Training Course OutlineDokument53 SeitenFire Safety Training Course OutlineRichard R M ThodéNoch keine Bewertungen

- S Fire SafetyDokument4 SeitenS Fire SafetyHasan NudinNoch keine Bewertungen

- Fire Safety SOP GuideDokument4 SeitenFire Safety SOP GuideYonatn DebebeNoch keine Bewertungen

- 5 - Fire Protection SystemDokument77 Seiten5 - Fire Protection SystemLi ReNoch keine Bewertungen

- 50 100 LB Carbon Dioxide Wheeled Extinguishers E77fc9faDokument6 Seiten50 100 LB Carbon Dioxide Wheeled Extinguishers E77fc9faEra ErmerraNoch keine Bewertungen

- Sec 10Dokument10 SeitenSec 10SuadNoch keine Bewertungen

- FireEx GuideDokument20 SeitenFireEx GuideLloyd LloydNoch keine Bewertungen

- Fire Safety Training: The Loss Prevention Unit of The Office of Risk ManagementDokument53 SeitenFire Safety Training: The Loss Prevention Unit of The Office of Risk ManagementFAISAL RAZANoch keine Bewertungen

- Fire Extinguisher Fundamentals: Classes, Types, Ratings & Proper UseDokument64 SeitenFire Extinguisher Fundamentals: Classes, Types, Ratings & Proper Usehyde2520015754Noch keine Bewertungen

- Model H ESFR Sprinkler BulletinDokument2 SeitenModel H ESFR Sprinkler Bulletineng100% (1)

- What Is A Fire Extinguisher InspectionDokument2 SeitenWhat Is A Fire Extinguisher InspectionTFattahNoch keine Bewertungen

- Owners Service Manual NO. 05618: Installation, Operating & Servicing Instructions ForDokument8 SeitenOwners Service Manual NO. 05618: Installation, Operating & Servicing Instructions ForNego1975Noch keine Bewertungen

- Halotron I Portable Extinguishers 4cd46777Dokument6 SeitenHalotron I Portable Extinguishers 4cd46777SODEXO BANBIFNoch keine Bewertungen

- F01 Guide 1Dokument11 SeitenF01 Guide 1vrNoch keine Bewertungen

- Fire ExtinguisherDokument3 SeitenFire Extinguisherblack_3289Noch keine Bewertungen

- FE Product-Catalog (Amarex) PDFDokument20 SeitenFE Product-Catalog (Amarex) PDFfrandyNoch keine Bewertungen

- GAPS Guidelines: Barrel Storage of Distilled SpiritsDokument5 SeitenGAPS Guidelines: Barrel Storage of Distilled Spiritsigor VladimirovichNoch keine Bewertungen

- Owners Service Manual NO. 05602 Installation, Operating & Servicing InstructionsDokument10 SeitenOwners Service Manual NO. 05602 Installation, Operating & Servicing Instructionsrommel76Noch keine Bewertungen

- New Job DSKDokument804 SeitenNew Job DSKdestaNoch keine Bewertungen

- Botvinnik-Bronstein WCC Match (Moscow 1951)Dokument10 SeitenBotvinnik-Bronstein WCC Match (Moscow 1951)navaro kastigiasNoch keine Bewertungen

- Coxing NotesDokument17 SeitenCoxing NotesStryker JacksonNoch keine Bewertungen

- Crane wheels with slide bearing DIN 15 074 without gear ringDokument2 SeitenCrane wheels with slide bearing DIN 15 074 without gear ringGilmar MenegottoNoch keine Bewertungen

- Home Elevator Without CounterweightDokument10 SeitenHome Elevator Without Counterweightcacing ghoibNoch keine Bewertungen

- Pilot Operated Safety Valves Type 95 Anderson Greenwood (Tyco) PDFDokument16 SeitenPilot Operated Safety Valves Type 95 Anderson Greenwood (Tyco) PDFdhaneshbhorNoch keine Bewertungen

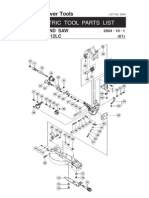

- Hitachi C12LC Compound Saw Parts ListDokument10 SeitenHitachi C12LC Compound Saw Parts Listwindsurferke007Noch keine Bewertungen

- GRP 2p PDFDokument9 SeitenGRP 2p PDFMichael DavenportNoch keine Bewertungen

- Playing Instructions PPGDokument12 SeitenPlaying Instructions PPGFrancisco Javier Martinez LlamasNoch keine Bewertungen

- Manual Handling: Safe Work Practice Safe Work PracticeDokument4 SeitenManual Handling: Safe Work Practice Safe Work PracticegouthamreddysNoch keine Bewertungen

- Case StudyDokument4 SeitenCase StudyBabilash KBNoch keine Bewertungen

- OPSS NPCC Newsletter (1207)Dokument20 SeitenOPSS NPCC Newsletter (1207)OPSS NPCCNoch keine Bewertungen

- 12-Animal Continuous Fist of Xingyiquan in Picture SeriesDokument15 Seiten12-Animal Continuous Fist of Xingyiquan in Picture Seriesfofofofo100% (1)

- Vietnam Football Fan Custom Segments On FBDokument10 SeitenVietnam Football Fan Custom Segments On FBTrịnh Hoàng HuynhNoch keine Bewertungen

- Interchange - 5ed - 1 - Students - Book CONTESTADODokument166 SeitenInterchange - 5ed - 1 - Students - Book CONTESTADORodrigoNoch keine Bewertungen

- Uam-Vertical Science9Dokument23 SeitenUam-Vertical Science9Daryl FCNoch keine Bewertungen

- Gold Medal Heights - SL TYPE 2Dokument23 SeitenGold Medal Heights - SL TYPE 2Guillermo EsquedaNoch keine Bewertungen

- Vanguard 15 Parts Locator DiagramsDokument6 SeitenVanguard 15 Parts Locator Diagramsrlytle875Noch keine Bewertungen

- Courts Tribunals TrackerDokument42 SeitenCourts Tribunals TrackerLegal CheekNoch keine Bewertungen

- DND 5e Loading Screen HintsDokument302 SeitenDND 5e Loading Screen Hintschad irwinNoch keine Bewertungen

- Group A: Bonus/penalty PointsDokument13 SeitenGroup A: Bonus/penalty PointsafaqNoch keine Bewertungen

- Unit 12 - BT MLH Lop 12 - KeyDokument6 SeitenUnit 12 - BT MLH Lop 12 - KeyThao NguyenNoch keine Bewertungen

- Rooms For Fhsaa Region MeetDokument3 SeitenRooms For Fhsaa Region Meetosho99Noch keine Bewertungen

- Unit 3 Basic TestDokument2 SeitenUnit 3 Basic TestksawerystrukNoch keine Bewertungen