Beruflich Dokumente

Kultur Dokumente

AUD Q10!04!017 - TMBV Certificate C001

Hochgeladen von

nonesuchhOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

AUD Q10!04!017 - TMBV Certificate C001

Hochgeladen von

nonesuchhCopyright:

Verfügbare Formate

The manufacturer

may use the mark:

Reports:

AUD 10/04-017 R004 V1 R1

Assessment Report

AUD 10/04-017 R001 V1 R1

FMEDA Report

Validity:

This assessment is valid for

the Ball Valves.

This assessment is valid until

March 1, 2015.

Revision 1.0 Feb 21, 2012

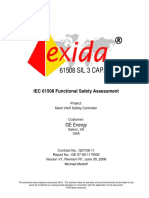

Certificate / Certificat

Zertifikat /

Evaluating Assessor

Certifying Assessor

Page 1 of 2

AUD 1004017 C001

exida hereby confirms that the:

Place embossed

seal here for

originals, lining it

up at the bottom

Ball Valves

Has been assessed per the relevant requirements of:

IEC 61508 : 2010 Parts 1-7

and meets requirements providing a level of integrity to:

Systematic Integrity: SIL 3 Capable

Random Integrity: Type A Element

PFD

AVG

and Architecture Constraints

must be verified for each application

Safety Function:

The Ball Valve will move to the designed safe position per the

actuator design within the specified safety time.

Application Restrictions:

The unit must be properly designed into a Safety Instrumented

Function per the Safety Manual requirements.

L&T / Audco India Limited

Tamil Nadu

India

Certification Services

Certification Services

D

r

a

f

t

SIL Verification:

The Safety Integrity Level (SIL) of an entire Safety Instrumented Function (SIF)

must be verified via a calculation of PFD

AVG

considering redundant

architectures, proof test interval, proof test effectiveness, any automatic

diagnostics, average repair time and the specific failure rates of all products

included in the SIF. Each subsystem must be checked to assure compliance

with minimum hardware fault tolerance (HFT) requirements.

* FIT = 1 failure / 10

9

hours

Form Version Date

C61508 2.7-3 Mar 2011

AUD 1004017 C001

Certificate / Certificat / Zertifikat /

Ball Valves

L&T / Audco India

Limited

Tamil Nadu- India

Systematic Integrity: SIL 3 Capable

Random Integrity: Type A Element

PFD

AVG

and Architecture Constraints

must be verified for each application

SIL 3 Capability:

The product has met manufacturer design process requirements of Safety

Integrity Level (SIL) 3. These are intended to achieve sufficient integrity

against systematic errors of design by the manufacturer.

A Safety Instrumented Function (SIF) designed with this product must not

be used at a SIL level higher than stated without prior use justification by

end user or diverse technology redundancy in the design.

IEC 61508 Failure Rates in FIT*

Page 2 of 2

Certification Services

Certification Services

64 N Main St

Sellersville, PA 18960

Application

SD

SU

DD

DU

Full Stroke, Clean Service 0 0 0 676

Tight Shut-Off, Clean Service 0 0 0 1328

Open on Trip, Clean Service 0 154 0 523

Full Stroke with PVST, Clean Service 0 0 299 378

Tight Shut-Off with PVST, Clean Service 0 0 281 1048

Open on Trip with PVST, Clean Service 152 2 299 224

D

r

a

f

t

Das könnte Ihnen auch gefallen

- FLO 11-01-002 C001 Valdisk 61508 Certificate Oct 2014Dokument2 SeitenFLO 11-01-002 C001 Valdisk 61508 Certificate Oct 2014anon_391099105Noch keine Bewertungen

- Component CertificationDokument2 SeitenComponent CertificationMarcus HartfelderNoch keine Bewertungen

- Eja-E Eja-J Sil CertificateDokument2 SeitenEja-E Eja-J Sil CertificateAthirah Amer HamzahNoch keine Bewertungen

- DeltaV SIS With Electronic Marshalling Certificate Rev 1.2 Oct 2 2014Dokument2 SeitenDeltaV SIS With Electronic Marshalling Certificate Rev 1.2 Oct 2 2014Danny PuchaNoch keine Bewertungen

- D D Ida e Ida E: Certificate / Certificat ZertifikatDokument2 SeitenD D Ida e Ida E: Certificate / Certificat ZertifikatBassemNoch keine Bewertungen

- Asco Series 314 Exida Sil Certificate 2016Dokument2 SeitenAsco Series 314 Exida Sil Certificate 2016AkoKhalediNoch keine Bewertungen

- United Electric Controls CertificateDokument2 SeitenUnited Electric Controls CertificateAmet koko TaroNoch keine Bewertungen

- Certificado Sil II Mezaclas ExplosivasDokument2 SeitenCertificado Sil II Mezaclas ExplosivasCARLOS JAVIER LUNA MARTÍNEZNoch keine Bewertungen

- ASCO SIL CertificateDokument2 SeitenASCO SIL CertificateAnonymous knICaxNoch keine Bewertungen

- Certificate / Certificat Zertifikat /: EJA DP and Pressure Transmitter, E Series and J SeriesDokument2 SeitenCertificate / Certificat Zertifikat /: EJA DP and Pressure Transmitter, E Series and J SeriesRefi SetyawanNoch keine Bewertungen

- Habonim SIL CertificationDokument7 SeitenHabonim SIL Certificationjamil vora0% (1)

- Sil Certificate (Iec61508) PekosDokument4 SeitenSil Certificate (Iec61508) Pekosjamil voraNoch keine Bewertungen

- DVC6200 SIS Positioner CertificateDokument2 SeitenDVC6200 SIS Positioner CertificateBalajiNoch keine Bewertungen

- EJX-A Series Exida SIL CertificateDokument2 SeitenEJX-A Series Exida SIL CertificateAbdeldjalil AchourNoch keine Bewertungen

- Certification - SIL C-Series.Dokument2 SeitenCertification - SIL C-Series.Özlem ÖzkiliçNoch keine Bewertungen

- SIL CertificateDokument2 SeitenSIL CertificateHOOMAN afaghiNoch keine Bewertungen

- Certificate / Certificat ZertifikatDokument2 SeitenCertificate / Certificat ZertifikatMarioAlbertoAlcantarNoch keine Bewertungen

- BPCL ReportDokument3 SeitenBPCL ReportKuppan SrinivasanNoch keine Bewertungen

- Sil-Pov Butterfly ValveDokument2 SeitenSil-Pov Butterfly ValveLata Marine ServicesNoch keine Bewertungen

- GEO 17-04-048 R002 V1R1 P2oo2 TMA AssessmentDokument15 SeitenGEO 17-04-048 R002 V1R1 P2oo2 TMA AssessmentHashem AliNoch keine Bewertungen

- Understanding SIL CertificatesDokument2 SeitenUnderstanding SIL Certificatesuserscribd2011Noch keine Bewertungen

- Cert ABB Reuse 090410 P0005 C002 V1R1Dokument2 SeitenCert ABB Reuse 090410 P0005 C002 V1R1AkoKhalediNoch keine Bewertungen

- Elm 1950060 CV K24 0001Dokument8 SeitenElm 1950060 CV K24 0001Amin GNoch keine Bewertungen

- Sil - Functional Safety CertDokument4 SeitenSil - Functional Safety CertAnonymous knICaxNoch keine Bewertungen

- Hydraulic Accumulators SIL Certificate ExidaDokument17 SeitenHydraulic Accumulators SIL Certificate ExidaAmet koko TaroNoch keine Bewertungen

- All CertificatesDokument8 SeitenAll CertificatesLuis BassoNoch keine Bewertungen

- Iso Work InstructionsDokument115 SeitenIso Work InstructionsEkondroNoch keine Bewertungen

- Cathodic Protection - Quality Control ProcedureDokument7 SeitenCathodic Protection - Quality Control ProcedureAhmed Gomaa100% (5)

- SLG700-Exida-HON 1310109 C001 R1 - 1Dokument2 SeitenSLG700-Exida-HON 1310109 C001 R1 - 1Ferhat KahveciNoch keine Bewertungen

- Inspection & Test PlanDokument19 SeitenInspection & Test Planaszliza100% (1)

- Hitachi 3.3-12K - EMC VERDokument2 SeitenHitachi 3.3-12K - EMC VERvenkatraman JNoch keine Bewertungen

- SIL Working Method ReportDokument35 SeitenSIL Working Method ReportEmzy Hussein90% (10)

- Load Test ProcedureDokument70 SeitenLoad Test ProcedureMohammed Rizwan Ahmed75% (4)

- GEO 17-07-003 R002 V1R1 33000 Series Butterfly Valve IEC 61508 Assessment ReportDokument16 SeitenGEO 17-07-003 R002 V1R1 33000 Series Butterfly Valve IEC 61508 Assessment Reportarmin heidariNoch keine Bewertungen

- Welding Inspection Ass 1Dokument7 SeitenWelding Inspection Ass 1mohd as shahiddin jafriNoch keine Bewertungen

- AC7102.5 Rev. EDokument15 SeitenAC7102.5 Rev. Eamit gajbhiyeNoch keine Bewertungen

- SilDokument15 SeitenSilMohamed Elsayed Hasan0% (1)

- Procurement Engineering Standard Purchase Clause: Code: EqccibDokument6 SeitenProcurement Engineering Standard Purchase Clause: Code: EqccibhendryhispanoNoch keine Bewertungen

- Upvc Project ReportDokument39 SeitenUpvc Project ReportRohit KumarNoch keine Bewertungen

- Assembling Flanged Joints Procedure1Dokument34 SeitenAssembling Flanged Joints Procedure1Ndomadu100% (3)

- Applying The Process Safety StandardsDokument125 SeitenApplying The Process Safety Standardsdangvh78100% (3)

- MTL FSM PosterDokument1 SeiteMTL FSM PosterAnonymous Uqrw8OwFWuNoch keine Bewertungen

- Certificado CP DDokument1 SeiteCertificado CP DVinicius ZanollaNoch keine Bewertungen

- MultiMill IQOQPQDokument32 SeitenMultiMill IQOQPQAtul Sharma75% (8)

- 411-254-0EI Hydraulic EdgeofDock InstallationOwnersManualDokument24 Seiten411-254-0EI Hydraulic EdgeofDock InstallationOwnersManualUttam Kumar GhoshNoch keine Bewertungen

- GE 07-06-11 R002 V1R1 IEC 61508 AssessmentDokument25 SeitenGE 07-06-11 R002 V1R1 IEC 61508 AssessmentHeryanto SyamNoch keine Bewertungen

- PCS250 PCS250G IPR512 IPRS7 EN 50136-1-1 CertificateDokument3 SeitenPCS250 PCS250G IPR512 IPRS7 EN 50136-1-1 Certificate123vb123Noch keine Bewertungen

- Maxseal Solenoid De-Energize To TripDokument5 SeitenMaxseal Solenoid De-Energize To TripAmet koko Taro100% (1)

- R15 Ind780 TM enDokument538 SeitenR15 Ind780 TM envm8119Noch keine Bewertungen

- Method Statement For Gravel Surfacing Around New Lift Station IW-10ADokument6 SeitenMethod Statement For Gravel Surfacing Around New Lift Station IW-10ANazirNoch keine Bewertungen

- ITRANSDokument94 SeitenITRANSGuadalupe HernandezNoch keine Bewertungen

- 77023554-1 Itrans Manual en Rev12 WE (2) GASDokument94 Seiten77023554-1 Itrans Manual en Rev12 WE (2) GASgfedericogNoch keine Bewertungen

- Signal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For RailwaysDokument14 SeitenSignal Directorate: Schedule of Technical Requirement (STR) For Signalling Cable For Railwaysanon_485351313Noch keine Bewertungen

- Solis-Mini-32E6kW-4G-DC c2FWi-Fi Stick - CertificadoDokument2 SeitenSolis-Mini-32E6kW-4G-DC c2FWi-Fi Stick - CertificadoJosé Luis González MartínezNoch keine Bewertungen

- Cathodic ProtectionDokument7 SeitenCathodic ProtectionWaheeb SaidNoch keine Bewertungen

- Certificate - Ems - Marine Abs - Pda - 2025Dokument5 SeitenCertificate - Ems - Marine Abs - Pda - 2025Marbin Claure JaillitaNoch keine Bewertungen

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDokument3 SeitenSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkNoch keine Bewertungen

- Machinery Component Maintenance and RepairVon EverandMachinery Component Maintenance and RepairBewertung: 5 von 5 Sternen5/5 (1)

- The Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceVon EverandThe Safety Critical Systems Handbook: A Straightforward Guide to Functional Safety: IEC 61508 (2010 Edition), IEC 61511 (2015 Edition) and Related GuidanceBewertung: 5 von 5 Sternen5/5 (1)

- China Care Foundation - Fall 2010 NewsletterDokument8 SeitenChina Care Foundation - Fall 2010 NewsletterChinaCareNoch keine Bewertungen

- Volume 2 Part 1 - Civil & Arch SpecificationsDokument173 SeitenVolume 2 Part 1 - Civil & Arch Specificationsanish100% (1)

- Solid State Controller of Drives - ExperimentDokument37 SeitenSolid State Controller of Drives - ExperimentRakesh Singh LodhiNoch keine Bewertungen

- Alzheimer's Disease Inhalational Alzheimer's Disease An UnrecognizedDokument10 SeitenAlzheimer's Disease Inhalational Alzheimer's Disease An UnrecognizednikoknezNoch keine Bewertungen

- Planetary Characteristics: © Sarajit Poddar, SJC AsiaDokument11 SeitenPlanetary Characteristics: © Sarajit Poddar, SJC AsiaVaraha Mihira100% (11)

- 31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngDokument15 Seiten31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngNguyễn Quế Anh100% (1)

- Tyre Industry in IndiaDokument14 SeitenTyre Industry in IndiaH Janardan PrabhuNoch keine Bewertungen

- Moving Money Box: Pig (Assembly Instructions) : The Movements Work Better With Heavier CoinsDokument6 SeitenMoving Money Box: Pig (Assembly Instructions) : The Movements Work Better With Heavier CoinsjuanNoch keine Bewertungen

- Modeling The Dynamic and Static Behavior of Chemical ProcessesDokument4 SeitenModeling The Dynamic and Static Behavior of Chemical ProcessesFatma CahyaniNoch keine Bewertungen

- (Rect-15) Experimental Study On Partial Replacement of Cement With Coconut Shell Ash in ConcreteDokument3 Seiten(Rect-15) Experimental Study On Partial Replacement of Cement With Coconut Shell Ash in Concretefrancis dimakilingNoch keine Bewertungen

- Gilmour Price List Till 20 DecDokument18 SeitenGilmour Price List Till 20 DecnhzaidiNoch keine Bewertungen

- Tsang Mui Millennium School 2019-2020 English Worksheet: Fill in The Blanks With The Correct Form of The VerbsDokument46 SeitenTsang Mui Millennium School 2019-2020 English Worksheet: Fill in The Blanks With The Correct Form of The VerbscocoyipNoch keine Bewertungen

- Math Diagnostic ExamDokument4 SeitenMath Diagnostic ExamMananquil JeromeNoch keine Bewertungen

- HorticultureDokument168 SeitenHorticultureagni sahanaNoch keine Bewertungen

- Driver DST-4812 For 7.2 KG CMDokument5 SeitenDriver DST-4812 For 7.2 KG CMWWW.150775.BUGME.PWNoch keine Bewertungen

- Surface & Subsurface Geotechnical InvestigationDokument5 SeitenSurface & Subsurface Geotechnical InvestigationAshok Kumar SahaNoch keine Bewertungen

- Massimo Cacciari, 1994. The Necessary AngelDokument133 SeitenMassimo Cacciari, 1994. The Necessary AngelAbner J ColmenaresNoch keine Bewertungen

- Ryan's DilemmaDokument11 SeitenRyan's DilemmaAkhi RajNoch keine Bewertungen

- Course For Loco Inspector Initial (Diesel)Dokument239 SeitenCourse For Loco Inspector Initial (Diesel)Hanuma Reddy93% (14)

- Service Manual: RP-6000 MK6 LTD RP-6000 MK6 BDokument44 SeitenService Manual: RP-6000 MK6 LTD RP-6000 MK6 BFivor EdwardsNoch keine Bewertungen

- EPP V6 - V7 - ETS - Removal Switch - Sensor Reactivation V12Dokument15 SeitenEPP V6 - V7 - ETS - Removal Switch - Sensor Reactivation V12Rabin TinkariNoch keine Bewertungen

- SSMTT-27 E1 PDFDokument8 SeitenSSMTT-27 E1 PDFblackNoch keine Bewertungen

- 8v92ta DetroitDokument554 Seiten8v92ta Detroit10000389% (9)

- Bài 1: Fill in The Blank With Present Simple, Present Continuous or Past SimpleDokument6 SeitenBài 1: Fill in The Blank With Present Simple, Present Continuous or Past SimplePhương Anh Đỗ NgọcNoch keine Bewertungen

- A Duality Principle For The Entanglement Entropy of Free Fermion SystemsDokument12 SeitenA Duality Principle For The Entanglement Entropy of Free Fermion SystemsCroco AliNoch keine Bewertungen

- MD 2 MidtermDokument31 SeitenMD 2 MidtermRea Rebenque100% (1)

- 32lh250h Commercial Mode PDFDokument46 Seiten32lh250h Commercial Mode PDFcordero medusaNoch keine Bewertungen

- It Park Design Submission PDFDokument20 SeitenIt Park Design Submission PDFSAKET TYAGI100% (1)

- Oc818 Manual v03-1Dokument5 SeitenOc818 Manual v03-1Luca PayetNoch keine Bewertungen

- Integration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)Dokument19 SeitenIntegration of Phodi Process With Mutation in Bhoomi (Simultaneous Approval of Phodi and The Mutation)seshadrimn seshadrimnNoch keine Bewertungen