Beruflich Dokumente

Kultur Dokumente

Design Calculation of Industrial Radiographic Exposure Room: Mohamad Pauzi Ismail, PHD

Hochgeladen von

musaismail8863Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Design Calculation of Industrial Radiographic Exposure Room: Mohamad Pauzi Ismail, PHD

Hochgeladen von

musaismail8863Copyright:

Verfügbare Formate

1

DESIGN CALCULATION OF

INDUSTRIAL RADIOGRAPHIC EXPOSURE ROOM

Mohamad Pauzi Ismail, PhD

The use of X-ray generators and radioactive sources is no doubt danger to

the operator, therefore precautions must be taken to prevent exposure to

direct and scattered radiation and to high voltages. The operator is

normally protected from electrical shocks by the design of the X-ray

equipment, but protection against the insidious affects of radiation has to be

provided partly by the construction of shielded accommodation for the

source of the radiation and partly by the operator's appreciation of the

dangers involved. Whenever practicable a permanent exposure room should

be provided for industrial radiography. Such facility must necessarily be

designed. The following points should be considered in the design or

selection of a radiographic exposure room.

(i) It should have electrical and water connections within especially for X-

ray room.

(ii) There should be a separate place outside the exposure room to house

the control unit so that the operator is not exposed.

(iii) The thickness and the material of the walls or doors should be

sufficient to reduce the dose below the maximum permissible level.

Dense concrete or lead of calculated thickness is usually used.

(iv) Audible and/or visual warning signs shall be provided within the

exposure room. These signs shall be actuated before irradiation begins

and remain actuated until completion of the irradiation.

(v) Reliable locks or interlocks shall be provided to prevent any person

from entering a radiation room during irradiation. In the event of an

exposure being terminated by interlock, it shall only be possible to

initiate the irradiation from the control panel.

2

(vi) Suitable means of exit shall be provided, so that any person who is

accidentally shut in the irradiation room can leave the enclosure

without delay.

(vii) There should be a shielded apartment within the room preferably

underground where gamma containers can be stored while not in use.

The key for this enclosure should be kept with care and responsibility,

(viii) A survey meter should be available in the laboratory. This is required

for checking the dose level before entering the room.

(ix) The flooring and the ceiling of the room should be such as to give

minimum backscatter. Lead lining of the walls, floor and the ceiling

would be an ideal situation.

The design of X-ray or gamma ray radiographic exposure room requires

some calculations on shielding to provide safe operation of the facility and

minimum exposure to radiation workers.

Careful design can lead to economical installations with minimal barriers.

The design depends on the following factors:

(i) Maximum tube voltage or gamma energy,

(ii) The maximum tube current or source strength,

(iii) The permitted full-body dosage at the point of interest. For radiation

workers this would be 100 millirads per-week (10 Gy per-week), and

for other persons, 10 milli-rads per week (10 Gy per week).

(iv) The workload (W). For X-ray equipment this is given in mA-min. per-

week and in rad in air per-week at lm for gamma source.

(v) The use factor (U). This represents the fraction of the work time that

the beam is turned towards the point under consideration. In the

absence-of information obtained by monitoring. Table I gives the

values of U recommended by ICRP.

3

(vi) The-occupancy factor (T). This is the fraction of the work time spent

in the area in question. The recommended values laid down by the

ICRP are given in Table II.

(vii) Maximum dose output from the tube or RHM factor of radioactive

source.

(viii) Shielding materials. Choice of material for a barrier depends on

convenience and cost. The radiographic exposure room is usually

made of concrete with lead lining.

Primary Protective Barriers

Primary protective barriers are those "sufficient to attenuate the useful beam

to the required degree" (1). The thickness required may be obtained after

calculating B, the maximum allowable transmission given by [2],

WUT

d P

B

2

= (1)

where P = maximum permissible exposure for design purpose (0.1 rem/week

or 0.01 rem/week)

d = distance in metres from source to position occupied.

W = weekly workload in mA-min/week or R/week at l m.

U = use factor (Table I)

T = occupancy factor (Table II).

For X-ray up to 3MV, equation (1) yields B in units of R/mA-min at 1 m: for

gamma rays B is transmission. The shield thickness corresponding to the

calculated value of B is read from the appropriate transmission curve.

Figures 5 to 8 show transmission curves for a range of X-ray energies and

gamma rays with lead and concrete.

Lead linings for walls and floors are useful particularly when converting

existing buildings or providing enclosures for X-ray work.

4

Secondary Protective Barriers

Barriers for scatter radiation

For scatter radiation, the maximum allowable transmission B by [2],

WTS

d P

B

s

s

2

100

= (2)

P and T are the same as in equation (1). W is also the same, but if the

source to scatterer distance is not 1 m, equation (2) must be modified

according to the inverse square law; thus if the source to scatterer distance

is 50 cm the denominator is multiplied by 4. S is the percent of the incident

absorbed dose rate or exposure rate scattered to 1 m for the irradiated area

of interest; values of S may be derived from Figs. 9 and 10. It is useful to

note that a change in the source to scatterer distance is balanced by the

resulting change in irradiated area. For high energy X-rays, S must be

multiplied by the ratio of the output at the potential of interest to that of 0.5

MV namely 20 at 1 MV, 300 at 2 MV and 850 at 3 MV. ds is the distance in

metres from the scatterer to the location of interest. The shield thickness

corresponding to the calculated values of B is read from the transmission

chart that is used for calculating primary-barriers.

Barriers for Leakage Radiation

Leakage radiation is defined as "all radiation except the useful beam, coming

from the tube or source housing [1]). It must be below certain limits of

exposure rate. Shielding required for leakage radiation may be calculated

from the number of tenth value thickness NTVT corresponding to the

maximum allowable transmission [2],

P d

T W

N

L

TVT

2

10

log =

5

T, d and P are the same as in equation (1). WL is the weekly leakage

exposure rate, or absorbed dose rate at 1 m from the source. The number of

half-value thickness NHVT is 3.3 NTVT.

The shield thickness is obtained by multiplying NTVT or NHVT by the values

given in Tables IV and V.

If the shield thickness for scatter and leakage radiation differ by 1 TVT or

more, the thicker shield should be adopted for the secondary barrier

thickness. However, if they differ by less than 1 TVT, the thicker shield

should be adopted and 1 HVT added.

Example 1

Examples of X-ray shielding requirements are given in Table VII for primary

barrier and Table VIII for secondary barrier [2]. Table VIII is based on

typical irradiation characteristics:

50 cm source to scatterer distance;

90

0

angle of scatter;

400 cm

2

irradiated area implying 0.1% of the incident exposure rate

scattered to 1m;

200 mA.min/h maximum continuous tube rating at 100 and 150kV and

1000 mA.min/h at 200-400kV;

leakage radiation 0.1R/h at 1m from the target for 100 and 150kV and

1R/h at 1m for 200-400 kV, at the maximum continuous tube ratings.

Example 2

Let us consider a design of exposure room for a 50Ci Ir-192 uncollimated

source. Labyrinth door design is preferred. Consider the design is as in Fig.

4.

For primary barrier (wall)

P = 0.01 rem/week (for non-radiation worker)

6

d = 1 m

W = 0.48 X 50 X 40 R/week (40 working hours/week) = 960

U = 1

T = = 0.25

WUT

d P

B

2

=

25 . 0 * 1 * 960

1 * 01 . 0

2

= B = 4.17*10

-5

Concrete wall thickness = 650 mm.

Primary barrier for control area

P = 0.1 rem/week (for radiation worker)

d = 1 m

W = 0.48 X 50 X 40 R/week (40 working hours/week) = 960

U = 1

T = 1

WUT

d P

B

2

=

1 * 1 * 960

1 * 1 . 0

2

= B = 1.04*10

-4

Concrete wall thickness = 600 mm.

Secondary barrier for lead door

P = 0.01 rem/week (for non-radiation worker)

ds = 3 m

W = 0.48 X 50 X 40 R/week (40 working hours/week) = 960

T =

S = 0.1% incident absorbed dose rate scattered to 1m per 400cm

2

irradiated

area. Scattering angle = 90

0

(Fig. 9).

WTS

d P

B

s

s

2

100

=

7

1 . 0 * 25 . 0 * 960

3 * 01 . 0 * 100

2

=

s

B = 0.375

Lead door thickness = 6 mm (Fig. 11).

Shielding Construction

To provide protection against radiation, the construction should be leak

proof to radiation and this can be achieved by over-lapping the lead sheets

or concrete blocks. Further, nails or screws, which are used to unite plies of

entry door, must be covered with extra lead. In addition, the conduits, pipes

and air ducts, passing through the walls of the shielded area must be

completely shielded. The entry door must overlap with the boundary of

concrete wall to avoid leakage of radiation. Figs. 1 to 4 show typical

protective constructions practice.

If the exposure room is on the lowest floor of a building, the floor of the room

need not be completely protected. However, if the wall is lined with lead, the

lead lining should not stop at the floor level. It should be extended inward

from all four walls. This is to prevent radiation from escaping from the room

by penetrating the floor and then scattering upward outside the protective

barriers. An alternative is to extend the lead protection in the walls

downward from some distance below floor level. The same considerations

apply to the ceiling if the room is located on the top floor of a building. Of

course, if there is occupied space above or below the exposure room, the

ceiling or floor of the exposure room must have a full radiation protection

over its whole area.

Although lead is the most common material for x-ray protection, other

materials may be used. In particular, structural walls of concrete or brick

may afford considerable protection and may reduce the thickness, and

therefore the cost of the lead required. Above 500 kV, concrete is most used

8

as protective material. The thickness of lead required at these higher

energies are so great, where fastening the lead to the walls becomes a

serious problem. Therefore, concrete is often used because of the ease of

construction. In new construction, the use of concrete may have economic

advantages even for protection against radiation generated at low energies

(well below 500 kV). Applicable codes should be examined and any

installations checked for compliance with their requirements.

References

1- ICRP Publication 3, Report of Committee III on Protection against X-rays,

Oxford, Pergamon, 1960.

2- ICRP Publication 15 and 21, 1976 edition.

3- AELB Safety Code of Practise for Industrial Radiography

9

Table I: Use Factors [1]

Full Use

(U=1)

Floors of radiation rooms except dental installations,

doors, wall and ceiling areas of radiation rooms routinely

exposed to useful beam.

Partial Use

(U=1/4)

Doors and wall areas of radiation rooms not routinely

exposed to the useful beam, floors of dental installations.

Occasional Use

(U=1/16)

Ceiling areas of radiation rooms not routinely exposed to

thc useful beam

Table II: Occupancy Factors [1]

Full Occupancy

(T = 1)

Control space, offices, corridors and waiting space large

enough to hold desks, darkrooms, workrooms and shops,

nurse stations, rest and lounge rooms routinely used by

occupationally exposed personnel, living quarters,

children's play areas, occupied space in adjoining

buildings.

Partial

Occupancy

(T = )

Corridors too narrow for desks, utility rooms, rest and

lounge rooms not used routinely by occupationally

exposed personnel, wards and patients rooms, elevators

using operators, unattended parking lots

Occasional

Occupancy

(T = 1/16)

Closets too small for future occupancy, toilets not used

routinely by occupationally exposed personnel, stairways,

automatic: elevators, sidewalks, and streets.

10

Table III: Outputs of Gamma-ray Sources [2]

Nuclides

Half-life

Principal -ray energies

(MeV), and % photon per

disintegration

Exposure rate, R/h

at 1m from 1Ci

60

Co

5.24y

1.17 (100%);

1.33 (100%)

1.30

137

Cs

30y 0.66 (85%) 0.32

192

Ir

74d 0.3 ~ 0.6 0.48

226

Ra

and daughter

1620y 0.074 to 2.4 0.825

Table IV: Approximate Half-Value-Thickness and Tenth-Value-Thickness for

Heavily Attenuated Broad Beams of X-Rays

X-ray Half-value-thickness, cm Tenth-value-thickness, cm

source Lead Concrete Lead Concrete

50 kV 0.005 0.4 0.018 1.3

70 - 1.0 - 3.6

75 0.015 - 0.050 -

100 0.025 1.6 0.084 5.5

125 - 1.9 - 6.4

150 0.029 2.2 0.096 7.0

200 0.042 2.6 0.14 8.6

250 0.086 2.8 0.29 9.0

300 0.17 3.0 0.57 10.0

00 0.25 3.0 0.82 10.0

500 0.31 3.6 1.03 11.9

Table IV: Approximate Half-Value-Thickness and Tenth-Value-Thickness for

Heavily Attenuated Broad Beams of Gamma Rays

Material

Nuclide

Uranium, cm

Lead,cm

Steel, cm

Concrete, cm

HVT TVT HVT TVT HVT TVT HVT TVT

60

Co 0.7 2.2 1.2 4.0 2.0 6.7 6.1 20.3

137

Cs 0.3 1.1 0.7 2.2 1.5 5.0 4.9 16.3

192

Ir 0.4 1.2 0.6 1.9 1.3 4.3 4.1 13.5

11

Table VI: Lead Equivalent of Various Materials for Low Energy X-rays

Material Material

cm lead equivalent at applied kV of

Material Density

gm/cm

3

Thickness

, cm

50 75 100 150 200 250 300 400

Clay

brick

1.6 10

20

30

40

50

0.06

0.14

0.22

-

-

0.08

0.17

0.27

0.38

-

0.09

0.19

0.31

0.45

-

0.08

0.17

0.26

0.37

0.48

0.08

0.17

0.26

0.37

0.48

0.10

0.23

0.40

0.60

0.81

0.11

0.30

0.55

0.83

1.13

0.13

0.45

0.85

1.27

1.71

Barytes

Plaster

or

concrete

3.2 1.0

2.0

2.5

5.0

7.5

10.0

12.5

0.09

0.18

0.23

-

-

-

-

0.15

0.27

0.33

-

-

-

-

0.18

0.33

0.40

-

-

-

-

0.09

0.18

0.22

0.43

0.59

-

-

0.07

0.14

0.17

0.34

0.50

0.68

-

0.06

0.13

0.17

0.36

0.56

0.77

-

0.06

0.14

0.18

0.39

0.61

0.84

1.08

0.08

0.16

0.20

0.43

0.68

0.95

1.21

Steel 7.8 0.1

0.2

0.3

0.4

0.5

1.0

2.0

3.0

4.0

5.0

-

-

-

-

-

-

-

-

-

-

0.01

0.03

0.05

0.07

0.09

-

-

-

-

-

0.02

0.03

0.05

0.07

0.09

-

-

-

-

-

0.01

0.02

0.03

0.04

0.05

0.09

0.17

0.25

0.33

0.40

0.01

0.02

0.03

0.04

0.04

0.08

0.16

0.23

0.30

0.37

-

-

-

-

0.03

0.08

0.17

0.28

0.38

0.49

-

-

-

-

0.03

0.08

0.19

0.33

0.47

0.63

-

-

-

-

0.04

0.09

0.24

0.43

0.65

0.88

12

Table VII: Primary X-Ray Shielding Requirements for 0.1 Rem per Week

Effective cm lead required at cm concrete required at

Potential Workload source distance of source distance of

kV mA.min/week 1m 2m 4m 1m 2m 4m

100 1000 0.24 0.19 0.14 17 13.6 10.4

250 0.19 0.14 0.09 13.6 10.4 7.1

60 0.14 0.09 0.05 10.4 7.1 4.1

150 1000 0.3 0.25 0.19 25.5 21.1 16.8

250 0.25 0.19 0.14 21.1 16.8 12.3

60 0.19 0.14 0.09 16.8 12.3 8

200 40000 0.66 0.58 0.51 46.3 41 35.9

10000 0.58 0.51 0.43 41 35.9 30.6

2500 0.51 0.43 0.35 35.9 30.6 25.4

625 0.43 0.35 0.28 30.6 25.4 20.1

250 40000 51.8 46.5 41

10000 46.5 41 35.4

2500 41 35.4 29.8

625 35.4 29.8 24.1

300 40000 58.4 52.5 46.3

10000 52.5 46.3 40.2

2500 46.3 40.2 34

625 40.2 34 27.8

400 40000 65 59 53

10000 59 53 46.8

2500 53 46.8 40.6

625 46.8 40.6 34.4

13

Table VIII: Scatter and Leakage X-Ray Shielding Requirements for 0.1 Rem

per Week

Effective cm lead required at cm concrete required at

Potential Workload source distance of source distance of

kV mA.min/week 1m 2m 4m 1m 2m 4m

100 1000 0.08 0.04 0.02 5.5 2.7 0.3

250 0.04 0.02 0 2.7 0.3 0

60 0.02 0 0 0.3 0 0

150 1000 0.11 0.06 0.03 8.9 4.9 1.3

250 0.06 0.03 0 4.9 1.3 0

60 0.03 0 0 1.3 0 0

200 40000 0.4 0.32 0.24 26.9 21.6 16.4

10000 0.32 0.24 0.16 21.6 16.4 11.3

2500 0.24 0.16 0.09 16.4 11.3 6.4

625 0.16 0.09 0.04 11.3 6.4 2

250 40000 0.78 0.61 0.45 30.6 25.1 19.4

10000 0.61 0.45 0.28 25.1 19.4 13.9

2500 0.45 0.28 0.14 19.4 13.9 8.5

625 0.28 0.14 0.05 13.9 8.5 3.4

300 40000 34.8 28.7 22.6

10000 28.7 22.6 16.3

2500 22.6 16.3 10.2

625 16.3 10.2 4.6

400 40000 40.8 34.7 28.7

10000 34.7 28.7 22.5

2500 28.7 22.5 16.2

625 22.5 16.2 9.6

14

Fig. 1: Plan views of door entries to exposure rooms, showing incorrect (a)

and correct (b), (c) methods of fitting. (a) Leakage of primary radiation due

to incorrectly fitted sliding door; (b) hinged door; (c) sliding door.

Fig. 2: Methods of shielding when pipes ducts, conduits or cables must

pass through walls of exposure room.

(a)

(b) Hinged door (c) Sliding door

15

Fig. 3: Scatter of radiation through a roof.

3 m

1 m

1 m

Control

Partial

Occupancy

Partial

Occupancy

Partial

Occupancy

Partial

Occupancy

16

Fig. 4: Labyrinth Design of Exposure Room. This is effectively reduced

the lead door thickness. Radiation is reduced to approximately

0.1% on each scatter.

Fig. 5: Broad-beam transmission of X-rays through concrete (= 2.35 g/cm

3

)

17

Fig. 6: Broad-beam transmission of X-rays through lead ( = 11.35 g/cm

3

)

18

Fig. 7: Broad-beam transmission of -rays through concrete (= 2.35 g/cm

3

)

19

Fig. 8: Broad-beam transmission of -rays through concrete (= 2.35 g/cm

3

)

20

Fig. 9: Variation with potential of the absorbed dose rate measured in air

due to X-rays scattered at 90 from various materials. Percent scatter

is related to primary beam measurements in air at the point of

incidence [2].

21

Fig. 10: Scattering patterns of diverging X-ray and gamma ray beams

normally incident on concrete shield. Percent is related to primary

beam measurements in free air at the point of incidence [2].

22

Das könnte Ihnen auch gefallen

- Shielding of Electromagnetic Waves: Theory and PracticeVon EverandShielding of Electromagnetic Waves: Theory and PracticeNoch keine Bewertungen

- Shielding Design GeneralDokument22 SeitenShielding Design GeneralAbu OmarNoch keine Bewertungen

- Insulation Co-ordination in High-voltage Electric Power SystemsVon EverandInsulation Co-ordination in High-voltage Electric Power SystemsBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Chapter 16 Shielding Calculation Helvecio-BwDokument16 SeitenChapter 16 Shielding Calculation Helvecio-BwEurekha MohanNoch keine Bewertungen

- MOS Integrated Circuit DesignVon EverandMOS Integrated Circuit DesignE. WolfendaleNoch keine Bewertungen

- Pub7 EnglishDokument12 SeitenPub7 EnglishjopacameNoch keine Bewertungen

- Tes P 119 07 R0Dokument17 SeitenTes P 119 07 R0Subhash Chekka SEC 115KV Project100% (1)

- Mediciones en AntenasDokument28 SeitenMediciones en AntenasJose FerreiraNoch keine Bewertungen

- Electronic Devices and Circuits: In Three VolumesVon EverandElectronic Devices and Circuits: In Three VolumesBewertung: 3.5 von 5 Sternen3.5/5 (2)

- Application Guide Medium Voltage Networks 01Dokument28 SeitenApplication Guide Medium Voltage Networks 01twinvbooksNoch keine Bewertungen

- Sensors 15 23205 PDFDokument13 SeitenSensors 15 23205 PDFVinoth ProtoSemNoch keine Bewertungen

- Sensors 15 23205 PDFDokument13 SeitenSensors 15 23205 PDFVinoth ProtoSemNoch keine Bewertungen

- A Study of Signal Penetration Into Building MaterialsDokument4 SeitenA Study of Signal Penetration Into Building MaterialsbrentbizzleNoch keine Bewertungen

- Flyer Pulsar GB OldDokument2 SeitenFlyer Pulsar GB OldgaburrNoch keine Bewertungen

- Radiation Hazard Analysis Earth Station AntennaDokument4 SeitenRadiation Hazard Analysis Earth Station AntennaAbhinav SharmaNoch keine Bewertungen

- RT GUide TrainingDokument13 SeitenRT GUide Trainingnaoufel1706Noch keine Bewertungen

- Pulsar GBDokument4 SeitenPulsar GBEkarat NareepangsriNoch keine Bewertungen

- Radiation Protection and Laboratory TechniquesDokument30 SeitenRadiation Protection and Laboratory TechniquesAshfaq KhanNoch keine Bewertungen

- 8.4.4 - Radiographic Training ProgramDokument31 Seiten8.4.4 - Radiographic Training ProgramMaduabuchi Serge Enemuo100% (1)

- Scatter Xray Radiation in ConcreteDokument11 SeitenScatter Xray Radiation in ConcretedhmageNoch keine Bewertungen

- Multi-Color Cavity MetrologyDokument14 SeitenMulti-Color Cavity MetrologyflavioferiNoch keine Bewertungen

- Plans - 2004Dokument5 SeitenPlans - 2004jopacameNoch keine Bewertungen

- الدليل الاسترشادي لتحديد مجالات العمل للمشاريع الخاضعة لنظام التصنيفDokument10 Seitenالدليل الاسترشادي لتحديد مجالات العمل للمشاريع الخاضعة لنظام التصنيفmohmdNoch keine Bewertungen

- ABB LightningProtectionDokument4 SeitenABB LightningProtectionarcjcpNoch keine Bewertungen

- Bias Dependent Attenuation of Coplanar Transmission Lines On SiliconDokument4 SeitenBias Dependent Attenuation of Coplanar Transmission Lines On SiliconEssam KhaterNoch keine Bewertungen

- Design of A Dual-Band Microstrip Patch Antenna For GSM/UMTS/ISM/WLAN OperationsDokument5 SeitenDesign of A Dual-Band Microstrip Patch Antenna For GSM/UMTS/ISM/WLAN OperationsAtiqur RahmanNoch keine Bewertungen

- High Frequency Wide Beam PVDF Ultrasonic Projector For Underwater CommunicationsDokument5 SeitenHigh Frequency Wide Beam PVDF Ultrasonic Projector For Underwater CommunicationsDi ZhangNoch keine Bewertungen

- Cell Tower Radiation EffectsDokument4 SeitenCell Tower Radiation EffectsNeha Kumar100% (1)

- Directivity, Radiation Efficiency, Input Impedance and Polarization.)Dokument40 SeitenDirectivity, Radiation Efficiency, Input Impedance and Polarization.)Mujeeb AbdullahNoch keine Bewertungen

- Characteristics of A Spark Discharge As An Adjustable Acoustic Source For Scale Model MeasurementsDokument5 SeitenCharacteristics of A Spark Discharge As An Adjustable Acoustic Source For Scale Model MeasurementsPanayiotis SeoolasNoch keine Bewertungen

- BBP E Chapter 09 15Dokument6 SeitenBBP E Chapter 09 15kuochuanchuNoch keine Bewertungen

- Review of Some Investigations On Rectangular Microstrip Antennas With Embedded SlotsDokument8 SeitenReview of Some Investigations On Rectangular Microstrip Antennas With Embedded SlotsInternational Journal of Application or Innovation in Engineering & ManagementNoch keine Bewertungen

- Methodology For Shielding Design and Evaluation in Radiotherapy FacilitiesDokument5 SeitenMethodology For Shielding Design and Evaluation in Radiotherapy FacilitiesMaram ShbairNoch keine Bewertungen

- Nuevo Transmisor MetrixDokument18 SeitenNuevo Transmisor Metrixoptech_sacNoch keine Bewertungen

- Biological Effects of Cell Tower Radiation On HumaDokument5 SeitenBiological Effects of Cell Tower Radiation On HumaAmnaNoch keine Bewertungen

- Exposuer Room DesignDokument6 SeitenExposuer Room DesignKhalid KishaNoch keine Bewertungen

- Shielding Tips and TricksDokument23 SeitenShielding Tips and TricksJon HimesNoch keine Bewertungen

- A Plane Wave Transducer - Technology and ApplicationsDokument10 SeitenA Plane Wave Transducer - Technology and ApplicationsAbelardo AlvarezNoch keine Bewertungen

- Em WaveDokument4 SeitenEm WavethinkiitNoch keine Bewertungen

- Microwave Letter Siw May2009 64231Dokument3 SeitenMicrowave Letter Siw May2009 64231Shunmugam ChandrasekaranNoch keine Bewertungen

- Design and Simulation of Printed Antenna and Arrays at X-Band - Abhishek BhatiaDokument8 SeitenDesign and Simulation of Printed Antenna and Arrays at X-Band - Abhishek Bhatiaabhishek_bhatia_18Noch keine Bewertungen

- EE 5171 Fall, 2005 Final Exam: Time (Sec)Dokument6 SeitenEE 5171 Fall, 2005 Final Exam: Time (Sec)Sudipta Romen BiswasNoch keine Bewertungen

- Turyahebwa Victor Bu Ug 2016 98Dokument11 SeitenTuryahebwa Victor Bu Ug 2016 98Prossy NatuhweraNoch keine Bewertungen

- Technical Paper-French Standard NFC 17-102 (2011)Dokument10 SeitenTechnical Paper-French Standard NFC 17-102 (2011)Mohamad HishamNoch keine Bewertungen

- Ans AssignDokument7 SeitenAns AssignrohitpnNoch keine Bewertungen

- Fiber ObticsDokument57 SeitenFiber ObticsMs RawatNoch keine Bewertungen

- Assignment 2 PDFDokument2 SeitenAssignment 2 PDFroop sagar67% (3)

- MonochromatorsDokument105 SeitenMonochromatorsyogeshsingh15Noch keine Bewertungen

- Design and Fabrication of A Microstrip Patch AntennaDokument5 SeitenDesign and Fabrication of A Microstrip Patch AntennaAjinkya Dnyaneshwar DhumaleNoch keine Bewertungen

- DESIGNCALCULATION (Enregistré Automatiquement)Dokument6 SeitenDESIGNCALCULATION (Enregistré Automatiquement)Touil HoussemNoch keine Bewertungen

- 1645388Dokument4 Seiten1645388morteza2885Noch keine Bewertungen

- Chapter19pp171 180 PDFDokument10 SeitenChapter19pp171 180 PDFInderMahesh0% (1)

- So RR - R: F KT, and The Portions BC, B'C, Etc., Have The FrequencyDokument2 SeitenSo RR - R: F KT, and The Portions BC, B'C, Etc., Have The Frequencyali_raza117Noch keine Bewertungen

- Hydroacoustics and Underwater Acoustics: SessionsDokument53 SeitenHydroacoustics and Underwater Acoustics: Sessionsle_luan_166Noch keine Bewertungen

- MIT Radiation Lab Series, V7, Klystrons and Microwave TriodesDokument534 SeitenMIT Radiation Lab Series, V7, Klystrons and Microwave TriodesKevin HaworthNoch keine Bewertungen

- Ags 10 PDFDokument33 SeitenAgs 10 PDFmusaismail8863Noch keine Bewertungen

- API 570 - Mockup OP - Paper 2 + MDokument13 SeitenAPI 570 - Mockup OP - Paper 2 + MShanawas Abdul Razak80% (5)

- C1 13jgfjdfgDokument25 SeitenC1 13jgfjdfgmusaismail8863Noch keine Bewertungen

- WPQ FormDokument1 SeiteWPQ Formudaysrp100% (1)

- AWS PricelistDokument1 SeiteAWS Pricelistmusaismail8863Noch keine Bewertungen

- API 570 Day 2 Book (1 To 51)Dokument65 SeitenAPI 570 Day 2 Book (1 To 51)AbdulQuddus100% (3)

- Bristle BlasterDokument6 SeitenBristle Blastermusaismail8863Noch keine Bewertungen

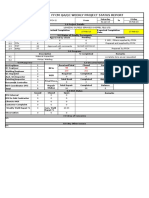

- FFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)Dokument1 SeiteFFCM-MSI QAQC Weekly Project Status Report (07.02. 15-13 02 15)musaismail8863100% (1)

- Material Specification Sheet Saarstahl - C40E (Ck40)Dokument2 SeitenMaterial Specification Sheet Saarstahl - C40E (Ck40)musaismail8863Noch keine Bewertungen

- Guide To ColorsDokument1 SeiteGuide To ColorsMardiSantosoNoch keine Bewertungen

- 120 1224 001 - F03 - 0010Dokument8 Seiten120 1224 001 - F03 - 0010musaismail8863100% (1)

- MDR NDT Drawing Tembikai As of 08.11.2014Dokument1 SeiteMDR NDT Drawing Tembikai As of 08.11.2014musaismail8863100% (1)

- 02 MechanicalDokument44 Seiten02 Mechanicalmusaismail8863Noch keine Bewertungen

- Steel Vessels 2008: Rules For Building and ClassingDokument18 SeitenSteel Vessels 2008: Rules For Building and Classingmusaismail8863Noch keine Bewertungen

- 2009FDokument26 Seiten2009FdaimaheshNoch keine Bewertungen

- Part 1 eDokument70 SeitenPart 1 emusaismail8863Noch keine Bewertungen

- AS 1100 Part 301 Architectural DrawingDokument24 SeitenAS 1100 Part 301 Architectural DrawingHao Much100% (2)

- APPEA Guidelines For Lliting EquipmentDokument41 SeitenAPPEA Guidelines For Lliting EquipmentJason RobertsNoch keine Bewertungen

- ASTM A105 Flange Heat TreatmentDokument16 SeitenASTM A105 Flange Heat TreatmentpuffdNoch keine Bewertungen

- Abs Guide Rules For Fpso ConversionDokument1 SeiteAbs Guide Rules For Fpso Conversionmusaismail8863Noch keine Bewertungen

- D Internet Myiemorgmy Iemms Assets Doc Alldoc Document 5431 Brochure-RevisedDokument2 SeitenD Internet Myiemorgmy Iemms Assets Doc Alldoc Document 5431 Brochure-Revisedmusaismail8863Noch keine Bewertungen

- Anchor Bolt Chair Weld Map Cond N22Dokument1 SeiteAnchor Bolt Chair Weld Map Cond N22sharif339Noch keine Bewertungen

- Risks in Facility Build Quality and Project Handover: What Happened?Dokument3 SeitenRisks in Facility Build Quality and Project Handover: What Happened?musaismail8863Noch keine Bewertungen

- Instruction Manual - Dial Thickness Gauge Kit How Replica Tape WorksDokument6 SeitenInstruction Manual - Dial Thickness Gauge Kit How Replica Tape Worksmusaismail8863Noch keine Bewertungen

- Cidb Green CardDokument1 SeiteCidb Green CardMuhammad Adzim Azizi67% (3)

- 232 50Dokument2 Seiten232 50musaismail8863Noch keine Bewertungen

- Pipe DesignDokument16 SeitenPipe DesignManas KotruNoch keine Bewertungen

- YeldDokument2 SeitenYeldmusaismail8863Noch keine Bewertungen

- To Engineer Is Human: The Role of Failure in Successful DesignVon EverandTo Engineer Is Human: The Role of Failure in Successful DesignBewertung: 4 von 5 Sternen4/5 (138)

- Cable Supported Bridges: Concept and DesignVon EverandCable Supported Bridges: Concept and DesignBewertung: 5 von 5 Sternen5/5 (1)

- The Great Bridge: The Epic Story of the Building of the Brooklyn BridgeVon EverandThe Great Bridge: The Epic Story of the Building of the Brooklyn BridgeBewertung: 4.5 von 5 Sternen4.5/5 (59)

- Crossings: How Road Ecology Is Shaping the Future of Our PlanetVon EverandCrossings: How Road Ecology Is Shaping the Future of Our PlanetBewertung: 4.5 von 5 Sternen4.5/5 (10)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNoch keine Bewertungen

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansVon EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansBewertung: 4.5 von 5 Sternen4.5/5 (21)

- Summary of Neil Postman's Amusing Ourselves to DeathVon EverandSummary of Neil Postman's Amusing Ourselves to DeathBewertung: 4 von 5 Sternen4/5 (2)

- Troubleshooting and Repair of Diesel EnginesVon EverandTroubleshooting and Repair of Diesel EnginesBewertung: 1.5 von 5 Sternen1.5/5 (2)

- Structural Cross Sections: Analysis and DesignVon EverandStructural Cross Sections: Analysis and DesignBewertung: 4.5 von 5 Sternen4.5/5 (19)

- Construction Innovation and Process ImprovementVon EverandConstruction Innovation and Process ImprovementAkintola AkintoyeNoch keine Bewertungen

- The Finite Element Method: Linear Static and Dynamic Finite Element AnalysisVon EverandThe Finite Element Method: Linear Static and Dynamic Finite Element AnalysisBewertung: 5 von 5 Sternen5/5 (3)

- Piping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationVon EverandPiping and Pipeline Calculations Manual: Construction, Design Fabrication and ExaminationBewertung: 4 von 5 Sternen4/5 (18)

- Transportation Decision Making: Principles of Project Evaluation and ProgrammingVon EverandTransportation Decision Making: Principles of Project Evaluation and ProgrammingNoch keine Bewertungen

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Finite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesVon EverandFinite Element Analysis and Design of Steel and Steel–Concrete Composite BridgesNoch keine Bewertungen

- Rocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyVon EverandRocks and Minerals of The World: Geology for Kids - Minerology and SedimentologyBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Pile Design and Construction Rules of ThumbVon EverandPile Design and Construction Rules of ThumbBewertung: 4.5 von 5 Sternen4.5/5 (15)

- Up and Running with AutoCAD 2020: 2D Drafting and DesignVon EverandUp and Running with AutoCAD 2020: 2D Drafting and DesignNoch keine Bewertungen

- The Diesel That Did It: General Motors' FT LocomotiveVon EverandThe Diesel That Did It: General Motors' FT LocomotiveNoch keine Bewertungen

- CAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementVon EverandCAREC Road Safety Engineering Manual 3: Roadside Hazard ManagementNoch keine Bewertungen

- Compendium of Best Practices in Road Asset ManagementVon EverandCompendium of Best Practices in Road Asset ManagementNoch keine Bewertungen

- Engineering Rock Mass Classification: Tunnelling, Foundations and LandslidesVon EverandEngineering Rock Mass Classification: Tunnelling, Foundations and LandslidesBewertung: 4 von 5 Sternen4/5 (5)