Beruflich Dokumente

Kultur Dokumente

Protective Concrete Coating Guide

Hochgeladen von

Tori SmallOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Protective Concrete Coating Guide

Hochgeladen von

Tori SmallCopyright:

Verfügbare Formate

constructive solutions

Page 1

Br ushbond

Ac r yl i c pol ymer modi f i ed pr ot ec t i ve and

dec or at i ve c oat i ng f or c onc r et e and

masonr y

Uses

To protect atmospherically exposed reinforced concrete

structures from attack by acid gases, chloride irons,

oxygen and water. The product is also suitable to protect

other cementitious substrates and masonry. It is suitable

for use on all types of structures, including those in costal

environments. It is equally suitable for new and existing

structures. The product is designed to re-face and even

out variations in concrete and masonry surfaces and

bridge shrinkage cracks. It provides a seamless, flexible

waterproof coating suitable for water tanks, reservoirs and

roofs. The product provides a tough durable wear

resistant coating which can withstand light pedestrian

traffic, has excellent weather resistance for exterior

applications and provides a decorative function.

Advant ages

Excellent barrier to carbon dioxide, chloride ions

and water.

Allows water vapour to escape from the structure.

Waterproof suitable for water retaining structures.

High resistance to the effects of long-term

weathering, durable in all climatic conditions

including UV attack.

Minimum surface preparation needed and low

labour costs.

Non-toxic ideal for potable water tanks.

Flexible, with thermal expansion similar to

concrete.

Covers honeycombed and pitted poured concrete

effectively.

St andar ds c ompl i anc e

Tested by Al-Futtain-Wimpey, Dubai to BS 6920 section

4.2.8 immersion test negligible effect on potable water.

Tested to ASTM C-190, ASTM C-348, ASTM C-321.

Desc r i pt i on

Brushbond comprises a two component acrylic polymer

modified cementitious coating supplied in ready to mix

kits. It requires only the site addition of clean water to

produce an easily brushable coating. Brushbond can be

simply applied by stiff brush, roller, spray or trowel to

obtain the desired texture.

Tec hni c al suppor t

Fosroc offers a comprehensive range of high

performance, high quality repair, maintenance and

construction products. In addition, Fosroc offers a

technical support package to specifiers, end-users and

contractors as well as on-site technical assistance in

locations all over the world.

Desi gn c r i t er i a

The coating should be applied in two coats to achieve a

total dry film thickness of not less than 2 mm. Areas

subjected to light foot traffic should receive minimum 2

mm thickness and an additional 2 mm coating should be

applied to areas of moderate to heavy pedestrian

conditions. To achieve the correct protective properties,

Brushbond must be applied on to the substrate at the

coverage rates recommended.

Pr oper t i es

Pot life:

1 hour at 20

o

C

20 minutes at 35

o

C

Mixed density: 1.65 gm/cm

3

(brushable

consistency)

Colour: Grey, white and special

colours on request

Application temperature: Not less than 5

o

C

Toxicity: To BS 6920 Section 4.2.8.

immersion test - negligible

effect on potable water.

Properties (cured): Brushbond Slurry Coat*

Tensile strength: 5.0 N/mm

2

2.0 N/mm

2

Compressi ve strength: 39 N/mm

2

18 N/mm

2

Flexural strength: 11 N/mm

2

4 N/mm

2

Bond strength: 3.5 N/mm

2

0.5 N/mm

2

Chloride ion resistance: Coated Un-coated

1 month (% Cl detected) 0.0004 0.0063

6 month (% Cl detected) 0.0004 0.0344

Moisture vapour

permeability flux

(g/m

2

/day):

204.1

844.3

Carbonation resistance

depth of penetration

(mm):

1

7

8 hours test on 7 days aged sample: 86% reduction in

carbonation. Brushbond acts as a significant barrier to

chloride, stopping a minimum 92% of chloride ions when

compared to an uncoated substrate.

* A 1:3 sand/cement slurry coat adjusted with water for

same workability as mixed Brushbond for brush

application.

Br ushbond

Page 2

constructive solutions

Spec i f i c at i on c l ause

Acrylic polymer modified protective/decorati ve

coating

The protective coating shall comprise specially selected

cements, graded hardwearing aggregates and additives

supplied in powder form together with a liquid component

of blend acrylic co-polymers and wetting agents. The total

dry film thickness of the coating shall be not less than 2

mm and shall be capable of providing resistance to wear

and weather and good chemical resistance to mild

inorganic acid solution, diesel oil, gasoline, chlorides de-

icing salts, effluents and organic solvents. It shall exhibit

positive water pressure resistance up to 7 meter head,

dependent on coating thickness.

Appl i c at i on i nst r uc t i ons

Preparation

All surfaces should be dry and free from contamination

such as oil, grease, loose particles, decayed matter, moss

algal growth, laitance, and all traces of mould release oils

and curing compounds. This is best achieved by lightly

grit-blasting the surface. Where moss, algae or similar

growths have occurred, treatment with a proprietary

biocide should be carried out after the grit-blasting

process. Spalled and deeply disintegrated concrete

should be removed to sound concrete and repaired with a

Fosroc repair system. For further advice, consult the

local Fosroc office.

It is essential that all surfaces to be treated be pre-soaked

with clean water prior to application of Brushbond.

Mixing

Brushbond liquid concentrate should be poured from the

plastic container into the metal drum provided. An equal

volume (4 litres) of clean fresh water is added for brush

application consistency and mixing commenced with a

propeller agitator attached to a slow speed drill (500 rpm).

The powder component should be added gradually to the

liquid to avoid lump formation and mixed for 2 to 4

minutes. Brushbond should be immediately used after

mixing. Do not mix more material than can be used within

the pot life. Keep mixing Brushbond during the

application.

Mixing ratio

Application: Brush Spray Trowel

Components:

Powder: 23 23 23

Liquid: 4 4 4

Water: 4 6-7 2

Application

For best results, surfaces should be damp. In order to

obtain the protective properties of Brushbond, it is

important that the correct rates of application are

observed. Use a short stiff brush preferably 120 200

mm width and apply in one or two coats as required.

Spray or trowel applications should use the correct mixing

ratio to obtain satisfactory consistency. In hot climatic

conditions, it is likely that spray application will be the best

for exterior decorative finishes. Nozzle size should be 3

4 mm and pressure of 6 8 bars should be used.

The application of Brushond should not commence if the

temperature of the substrate is below 5

o

C. Application of

Brushbond on hot substrates, i.e. over 40

o

C surface

temperature will need the application of a primer coat of

mixed Brushbond and water in slurry like consistency and

apply Brushbond over the primer whilst it is still wet. It is

recommended that for general resurfacing each coat

should be 1 mm thick. Areas subjected to light foot traffic

should receive at least 2 mm thickness of Brushbond and

an additional 2 mm should be applied if conditions are

moderate to heavy pedestrian traffic.

If in doubt about the condition of the substrate, the local

Fosroc office should be consulted.

Cleaning

Brushbond should be removed from tools and equipment

with clean water immediately after use. Hardened

material can be removed mechanically.

Li mi t at i ons

Brushbond is formulated for application to clean, sound

concrete or masonry. Where subsequent coatings or

paints are required, trials should be conducted to ensure

compatibility. Brushbond is compatible with most forms of

subsequent coating. Compatibility and soundness should

be assessed on a trial area. For further advice, consult

the local Fosroc office.

Application of Brushbond should not commence if the

temperature of the substrate is below 5

o

C.

Bruishbond should not be applied where there is a

likelihood of exposure to frost within 48 hours of the

application. The product should not be applied in windy

conditions where early-age dust adhesion may occur, or

where rain is likely within 2 hours at 20

o

C or 20 hours at

5

o

C (up to 80% RH). It should not be applied when the

prevailing relative humidity exceeds 90%.

Est i mat i ng

Supply

Industrial kit: (27 kg pack consisting of)

Powder: 23 kg bag

Liquid: 4 litre pail

Telephone: +966 2 637 5345 Fax: +966 2 637 5891 email: fosam@fosroc.com

Regi onal Of f i c es

J eddah Sales Office Tel: (02) 6080999 Fax: (02) 635 3330 Yanbu Tel: (04) 322 4280 Fax: (04) 391 2980

J eddah Showroom Tel: (02) 665 0787 Fax: (02) 667 4884 Makkah Tel: (02) 542 0869 Fax: (02) 542 0869

Riyadh Tel: (01) 482 9303 Fax: (01) 482 7562 Medinah Tel: (04) 845 1767 Fax: (04) 846 3195

Dammam Tel: (03) 814 1282 Fax: (03) 814 1581 J ubail Tel: (03) 362 3904 Fax: (03) 362 3875

Khamis Mushayt Tel: (07) 250 0469 Fax: (07) 250 0469

Registered Office: Industrial Area, Phase 4, Road No. 414, Street No. 407

Fosam Company Li mi t ed

Head Office

Post Box 11081

J eddah 21453

Saudi Arabia

w w w .f osr oc .c om

Page 3

Br ushbond

FO SA/Brushbond/05/A

Important note:

Fosroc products are guaranteed against defective materials and manufacture and are sold subject to its standard Conditions

for the Supply of Goods and Services, copies of which may be obtained on request. Whilst Fosroc endeavours to ensure that

any advice, recommendation, specification of information it may give is accurate and correct, it cannot, because it has no direct

or continuous control over where or how its products are applied, accept any liability either directly or indirectly arising from the

use of its products, whether or not in accordance with any advice, specification, recommendation of information given by it.

Coverage (1 mm thickness)

Brushbond applied: 18 20 m

2

per kit

Spray applied: 22 24 m

2

per kit

Trowel applied: 14 16 m

2

per kit

The coverage figures are theoretical due to wastage

factors and the variety and nature of possible substrates,

practical coverage figures will be reduced.

UN packaging regulations

To comply with current regulations, all products of a

hazardous nature which are subjected to a sea crossing as

part of their delivery requirements, must be packed in UN

approved receptacles.

When a known sea crossing is involved, whether locally or

for export, Fosroc will supply in the correct UN packaging.

Where Fosroc are requested to deliver within a mainland

boundary but the Purchaser intends to onward ship, it is

incumbent upon the Purchaser to specify that UN packaging

is required at the time of placing the order. Otherwise, once

received, responsibility rests with the Purchaser. The use of

UN packaging may affect the selling price of products.

Please consult the local Fosroc Area Manager or office.

St or age

Shelf life

All products have a shelf life of 12 months if kept in a dry

store in the original unopened packs.

Storage conditions

Store in cool, dry conditions, away from sources of heat and

naked flames, in the original, unopened packs. If stored at

high temperatures and/or high humidity conditions the shelf

life may be reduced. Brushbond liquid component should

be protected from frost.

Pr ec aut i ons

Health and safety

Brushbond contains cement powders which, when mixed or

become damp, release alkalis which can be harmful to the

skin. During use, avoid inhalation of dust and contact with

skin and eyes. Wear suitable protective clothing, gloves,

eye protection and respiratory protective equipment. The

use of barrier creams provide additional skin protection. In

case of contact with skin, rinse with plenty of clean water,

then cleanse with soap and water. In case of contact with

eye, rinse immediately with plenty of clean water and seek

medical advice. If swallowed, seek medical attention

immediately do not induce vomiting.

Fire

Brushbond components are non-flammable.

For further information, refer to the Product Material Safety

Data Sheet.

Addi t i onal I nf or mat i on

Fosroc manufactures a wide range of complementary

products which include:

Waterproofing membranes & waterstops

J oint sealants & filler boards

Cementitious & epoxy grouts

Specialized flooring materials

Fosroc additionally offers a comprehensive package of

products specifically designed for the repair and

refurbishment of damaged concrete. Fosrocs Systematic

Approach to concrete repair features the following:

hand-placed repair mortars

spray grade repair mortars

fluid micro-concretes

chemically resistant epoxy mortars

anti-carbonation/anti-chloride protective coatings

chemical and abrasion resistant coatings

For further information on any of the above, please consult

your local Fosroc office - as below.

Das könnte Ihnen auch gefallen

- Brush BondDokument4 SeitenBrush BondVenkata RaoNoch keine Bewertungen

- Brushbond PDFDokument4 SeitenBrushbond PDFpravi3434Noch keine Bewertungen

- Protect and Decorate Concrete & Masonry with Acrylic CoatingDokument4 SeitenProtect and Decorate Concrete & Masonry with Acrylic CoatingVedachalam ManiNoch keine Bewertungen

- Super Cast Fosroc AdmixturesDokument10 SeitenSuper Cast Fosroc AdmixturesVedachalam ManiNoch keine Bewertungen

- Waterproof Concrete CoatingDokument2 SeitenWaterproof Concrete CoatingkalidindivenkatarajuNoch keine Bewertungen

- Fosroc-Brushbond (Waterproofing Coating)Dokument2 SeitenFosroc-Brushbond (Waterproofing Coating)Boy GalihNoch keine Bewertungen

- Nitocote cm210Dokument4 SeitenNitocote cm210Venkata RaoNoch keine Bewertungen

- Renderoc HSDokument2 SeitenRenderoc HSAdnan JadoonNoch keine Bewertungen

- Fosroc Renderoc CS PuneDokument2 SeitenFosroc Renderoc CS Punealdred_chezkaNoch keine Bewertungen

- Hydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneDokument2 SeitenHydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneVenkata Raju KalidindiNoch keine Bewertungen

- 7 Renderoc SP30Dokument4 Seiten7 Renderoc SP30samueltee212Noch keine Bewertungen

- Waterproof Concrete & Masonry CoatingDokument3 SeitenWaterproof Concrete & Masonry Coatingmarzuki0202Noch keine Bewertungen

- Brushbond FLXIII PDFDokument2 SeitenBrushbond FLXIII PDFdejanmicic972Noch keine Bewertungen

- Nitoseal 220Dokument4 SeitenNitoseal 220Venkata RaoNoch keine Bewertungen

- Brushbond FLXIII Provides Tough WaterproofingDokument2 SeitenBrushbond FLXIII Provides Tough WaterproofingTori SmallNoch keine Bewertungen

- Eco-friendly protective coatingDokument2 SeitenEco-friendly protective coatingRaed Naim KhammashNoch keine Bewertungen

- Fosroc Renderoc FCXtra Technical Data SheetDokument35 SeitenFosroc Renderoc FCXtra Technical Data SheetAjit Singh Rathore100% (1)

- Brush BondDokument4 SeitenBrush BondGibbs PerNoch keine Bewertungen

- Zincanode 304 pc142Dokument3 SeitenZincanode 304 pc142kushar_geoNoch keine Bewertungen

- Cemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmDokument4 SeitenCemtop 400SD: Cement Based, Self Levelling, Industrial Floor Surfacing System - 6mm To 12mmBalasubramanian AnanthNoch keine Bewertungen

- Nitocote cm210Dokument4 SeitenNitocote cm210pravi3434Noch keine Bewertungen

- Protect Concrete & Masonry with Fosroc BrushbondDokument4 SeitenProtect Concrete & Masonry with Fosroc BrushbondSabyasachi BangalNoch keine Bewertungen

- Render CureDokument2 SeitenRender CureVenkata RaoNoch keine Bewertungen

- Nitoproof 30 - Water Proofing CompoundDokument2 SeitenNitoproof 30 - Water Proofing CompoundChethan BhatNoch keine Bewertungen

- Fosroc Conbextra GP2Dokument4 SeitenFosroc Conbextra GP2awsdhnjkklmNoch keine Bewertungen

- Renderoc RsxtraDokument4 SeitenRenderoc RsxtraBalasubramanian AnanthNoch keine Bewertungen

- Plasteroc MPRDokument2 SeitenPlasteroc MPRTori SmallNoch keine Bewertungen

- Nitomortar TC2000Dokument3 SeitenNitomortar TC2000MuhammedHafis100% (1)

- Renderoc S2Dokument4 SeitenRenderoc S2chandelsinghNoch keine Bewertungen

- Nitocote HT120Dokument4 SeitenNitocote HT120Venkata Raju KalidindiNoch keine Bewertungen

- Nitoseal 290Dokument4 SeitenNitoseal 290shanon33Noch keine Bewertungen

- Crystalline Waterproofing ConcreteDokument2 SeitenCrystalline Waterproofing ConcreteBalasubramanian AnanthNoch keine Bewertungen

- Abrasion-Resistant Epoxy Lining MortarDokument4 SeitenAbrasion-Resistant Epoxy Lining MortarBalasubramanian AnanthNoch keine Bewertungen

- Interzone 954Dokument0 SeitenInterzone 954hennawijayaNoch keine Bewertungen

- Renderoc S Structural Repair MortarDokument3 SeitenRenderoc S Structural Repair Mortarmyke_0101Noch keine Bewertungen

- Renderoc LA80Dokument4 SeitenRenderoc LA80Balasubramanian AnanthNoch keine Bewertungen

- Proofex SM PDFDokument4 SeitenProofex SM PDFmilanbrasinaNoch keine Bewertungen

- sHOTPATCH 10 v3 PDFDokument2 SeitensHOTPATCH 10 v3 PDFAnkita Baban GavadeNoch keine Bewertungen

- PlastisealDokument4 SeitenPlastisealVenkata RaoNoch keine Bewertungen

- TDS Levelling - PlasterDokument3 SeitenTDS Levelling - PlasterNandhagopal DhandapaniNoch keine Bewertungen

- Interzone 101Dokument0 SeitenInterzone 101hennawijayaNoch keine Bewertungen

- Renderoc BF2: Design CriteriaDokument2 SeitenRenderoc BF2: Design CriteriaShyam SinghNoch keine Bewertungen

- Polycoat RbeDokument2 SeitenPolycoat RbejovindhaNoch keine Bewertungen

- 21-5 PDS AiDokument3 Seiten21-5 PDS Aiuocmogiandi_aNoch keine Bewertungen

- Carboguard 703 GFDokument2 SeitenCarboguard 703 GFlhanx2100% (2)

- TDS Epoxy Zinc Phosphate Primer HB 50 GreyDokument3 SeitenTDS Epoxy Zinc Phosphate Primer HB 50 GreySAlman Khan50% (2)

- Renderoc Plug: Uses SpecificationDokument2 SeitenRenderoc Plug: Uses SpecificationVenkata RaoNoch keine Bewertungen

- 4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1Dokument5 Seiten4 Rockgrip 27 en Prep Plaster Primer WB 2022 Rev1yoxan25808Noch keine Bewertungen

- Fosroc Dekguard PU: Constructive SolutionsDokument4 SeitenFosroc Dekguard PU: Constructive SolutionsganmosesNoch keine Bewertungen

- Nitomortar TC2000 Epoxy ResinDokument3 SeitenNitomortar TC2000 Epoxy ResingrtunaNoch keine Bewertungen

- Concure 90 PDFDokument4 SeitenConcure 90 PDFmilanbrasinaNoch keine Bewertungen

- Fast-setting emergency patching mortar for concreteDokument4 SeitenFast-setting emergency patching mortar for concreteBalasubramanian AnanthNoch keine Bewertungen

- Nitowrap Method StatementDokument10 SeitenNitowrap Method StatementBalasubramanian AnanthNoch keine Bewertungen

- Detailers Dictionary Volume 2: The Industry StandardVon EverandDetailers Dictionary Volume 2: The Industry StandardNoch keine Bewertungen

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsVon EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNoch keine Bewertungen

- Creative Resin: Easy techniques for contemporary resin artVon EverandCreative Resin: Easy techniques for contemporary resin artNoch keine Bewertungen

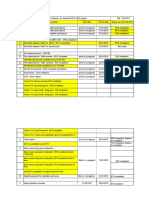

- Item Quantities of Phase-1Dokument4 SeitenItem Quantities of Phase-1Tori SmallNoch keine Bewertungen

- JYM Project - Schedule (Rev-3, 11.09.2015)Dokument15 SeitenJYM Project - Schedule (Rev-3, 11.09.2015)Tori SmallNoch keine Bewertungen

- Course Book 6Dokument19 SeitenCourse Book 6Tori SmallNoch keine Bewertungen

- Assets List for File #23352 Alfanar Construction CoDokument1 SeiteAssets List for File #23352 Alfanar Construction CoTori SmallNoch keine Bewertungen

- 7-2-c Form - Gen Consultant PQ Summary Rev-0Dokument4 Seiten7-2-c Form - Gen Consultant PQ Summary Rev-0Tori SmallNoch keine Bewertungen

- 5-Star Element Hemraj InjuryDokument7 Seiten5-Star Element Hemraj InjuryTori SmallNoch keine Bewertungen

- Project: JUAYMAH380/230KV BSP: SL No ADokument4 SeitenProject: JUAYMAH380/230KV BSP: SL No ATori SmallNoch keine Bewertungen

- SVC Safaniyah (BSP) Punch List (4) XLSX 1Dokument52 SeitenSVC Safaniyah (BSP) Punch List (4) XLSX 1Tori SmallNoch keine Bewertungen

- 380kv BSP project civil works schedule Juaymah substationDokument2 Seiten380kv BSP project civil works schedule Juaymah substationTori SmallNoch keine Bewertungen

- 5-Star Element Hemraj InjuryDokument7 Seiten5-Star Element Hemraj InjuryTori SmallNoch keine Bewertungen

- I Site Progress Civil Works: A 380 KV GIS BuildingDokument3 SeitenI Site Progress Civil Works: A 380 KV GIS BuildingTori SmallNoch keine Bewertungen

- Assets List for File #23352 Alfanar Construction CoDokument1 SeiteAssets List for File #23352 Alfanar Construction CoTori SmallNoch keine Bewertungen

- SI No 02 For Erection of Steel Structure For MarjanDokument3 SeitenSI No 02 For Erection of Steel Structure For MarjanTori SmallNoch keine Bewertungen

- Request# Status: Visitor Management SystemDokument1 SeiteRequest# Status: Visitor Management SystemTori SmallNoch keine Bewertungen

- Assets List Against File # 17920: Alfanar ConstructionDokument1 SeiteAssets List Against File # 17920: Alfanar ConstructionTori SmallNoch keine Bewertungen

- Expense Sheet TitleDokument4 SeitenExpense Sheet TitleTori SmallNoch keine Bewertungen

- 230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Dokument10 Seiten230kv Ohtl Sub - 10 Cut Over Plan Updated 29.2.16Tori SmallNoch keine Bewertungen

- Drawing2 - GIBDokument1 SeiteDrawing2 - GIBTori SmallNoch keine Bewertungen

- BSP AccessDokument14 SeitenBSP AccessTori SmallNoch keine Bewertungen

- DPR - 22!12!2015 Safaniyah BSP, SVC and Sub-10Dokument12 SeitenDPR - 22!12!2015 Safaniyah BSP, SVC and Sub-10Tori SmallNoch keine Bewertungen

- Details of Company Car Expenses (01.12.15)Dokument266 SeitenDetails of Company Car Expenses (01.12.15)Tori SmallNoch keine Bewertungen

- Online job application for Prism Engineering ConsultantsDokument2 SeitenOnline job application for Prism Engineering ConsultantsTori SmallNoch keine Bewertungen

- Current & Previous Reading For Brake Pad Change (June 2015)Dokument2 SeitenCurrent & Previous Reading For Brake Pad Change (June 2015)Tori SmallNoch keine Bewertungen

- Acomplishment Chart 380kVDokument8 SeitenAcomplishment Chart 380kVTori Small100% (1)

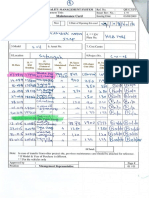

- Concrete ChaklistDokument1 SeiteConcrete ChaklistTori SmallNoch keine Bewertungen

- Imam Hussain Sermon at MinaDokument15 SeitenImam Hussain Sermon at MinaTori SmallNoch keine Bewertungen

- Car Wash Dec 14 (New)Dokument2 SeitenCar Wash Dec 14 (New)Tori SmallNoch keine Bewertungen

- Tuhaf Al UqulDokument840 SeitenTuhaf Al Uqulapi-3738883Noch keine Bewertungen

- Main Lab: FT-A-21226 29Y Female SelfDokument1 SeiteMain Lab: FT-A-21226 29Y Female SelfTori SmallNoch keine Bewertungen

- Shahrour FreedomDokument14 SeitenShahrour FreedomTori SmallNoch keine Bewertungen

- Fosroc Nitofill LV TDSDokument3 SeitenFosroc Nitofill LV TDSmrameshceNoch keine Bewertungen

- Approximate Analysis For Frames Subjected To Lateral Loads: Portal Frame MethodDokument27 SeitenApproximate Analysis For Frames Subjected To Lateral Loads: Portal Frame MethodAlaine SobredoNoch keine Bewertungen

- CH 6 - Earthing Systems 2010-2011 A4Dokument27 SeitenCH 6 - Earthing Systems 2010-2011 A4norhaidarNoch keine Bewertungen

- Memorandum Circular No. 21-22 With List of Products Under Mandatory Certification As of 31 May 2021Dokument32 SeitenMemorandum Circular No. 21-22 With List of Products Under Mandatory Certification As of 31 May 2021MonNoch keine Bewertungen

- 04 40 Masonry - Catalogue - Nelissen Handmoulded Facing BrickDokument35 Seiten04 40 Masonry - Catalogue - Nelissen Handmoulded Facing BrickKH LeeNoch keine Bewertungen

- Evaluating The Effects of Sugarcane-Bagasse Ash and Rice-Husk Ash On The Mechanical and Durability Properties of MortarDokument14 SeitenEvaluating The Effects of Sugarcane-Bagasse Ash and Rice-Husk Ash On The Mechanical and Durability Properties of MortarHidayat UllahNoch keine Bewertungen

- Water Couplings: "King" Combination NipplesDokument5 SeitenWater Couplings: "King" Combination NipplesrweidlingNoch keine Bewertungen

- Truck HubDokument4 SeitenTruck HubDrei SupremoNoch keine Bewertungen

- Electrical Estimator S Manual PDFDokument226 SeitenElectrical Estimator S Manual PDFSahul Hameed100% (6)

- Dlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious GroutDokument4 SeitenDlc-Grout C100: General Purpose, High Strength, Non-Shrink Cementitious Grout4919404Noch keine Bewertungen

- Allegheny Bradford Corporation: Craftsmen in StainlessDokument11 SeitenAllegheny Bradford Corporation: Craftsmen in Stainlessアルビン ベネNoch keine Bewertungen

- Notes Earthing 23 03 20 PDFDokument11 SeitenNotes Earthing 23 03 20 PDFAkhilesh MendonNoch keine Bewertungen

- Design of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992Dokument76 SeitenDesign of RCC Chimney Data: DESIGN CODE: IS 4998 - (PART-1) :1992bhargavramudu 2019Noch keine Bewertungen

- JIS B2220 DimensionDokument5 SeitenJIS B2220 DimensionArunNoch keine Bewertungen

- Company Profile-ILYCHDokument2 SeitenCompany Profile-ILYCHrashid isaarNoch keine Bewertungen

- Method of Test For Preparation of Marshall SpecimensDokument14 SeitenMethod of Test For Preparation of Marshall SpecimensKiplagat ChelelgoNoch keine Bewertungen

- Vs Datasheet - Released 0410Dokument2 SeitenVs Datasheet - Released 0410Masood KhanNoch keine Bewertungen

- 316 316L Technical Information SheetDokument5 Seiten316 316L Technical Information SheetfejlongNoch keine Bewertungen

- Breaker Quicklag GFCIDokument3 SeitenBreaker Quicklag GFCIdanielliram993Noch keine Bewertungen

- 13953995srt Owners ManualDokument76 Seiten13953995srt Owners Manualrace egrNoch keine Bewertungen

- Material ReconciliationDokument10 SeitenMaterial ReconciliationBscpl Repalle to EeppurpalemNoch keine Bewertungen

- Walls That Could Replace Air ConditioningDokument3 SeitenWalls That Could Replace Air Conditioningmohd asif asifNoch keine Bewertungen

- Copper-Brazed Steel Tubing: Standard Specification ForDokument4 SeitenCopper-Brazed Steel Tubing: Standard Specification ForSofiaJabadanEspulgar100% (1)

- Rock Anchor NDokument4 SeitenRock Anchor NNitesh SinghNoch keine Bewertungen

- Safety Fence Installation GuideDokument5 SeitenSafety Fence Installation Guidegowtham reddyNoch keine Bewertungen

- House that Rains Light and ColorDokument16 SeitenHouse that Rains Light and Colorrupali lateNoch keine Bewertungen

- Cement Class 12 ChemistryDokument11 SeitenCement Class 12 ChemistryRohit JaiswalNoch keine Bewertungen

- Astm D2672Dokument4 SeitenAstm D2672Hernando Andrés Ramírez GilNoch keine Bewertungen

- Precast HandbookDokument179 SeitenPrecast HandbookFernando LopezNoch keine Bewertungen