Beruflich Dokumente

Kultur Dokumente

Modeling &torque Ripple Minimization of Switched Reluctance Motor For High Speed Applications

Hochgeladen von

Moon3pellOriginaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Modeling &torque Ripple Minimization of Switched Reluctance Motor For High Speed Applications

Hochgeladen von

Moon3pellCopyright:

Verfügbare Formate

International Journal of Science and Modern Engineering (IJISME)

ISSN: 2319-6386, Volume-1, Issue-10, September 2013

15

AbstractThis paper deals with the analysis, study and

modeling of the torque ripple minimization setup for the closed

loop control of Switched Reluctance Motor.SRM is becoming

more and more popular for high speed industrial application

environments due to its rugged and robust construction. For low

cost, variable speed drives SRM are most widely used. But the

torque pulsations in SRM are relatively higher compared to

sinusoidal machines due to the doubly salient structure of the

motor. Nonlinear inductance profile and pulse magnetizing

make the torque ripple unavoidable. Both machine design and

electronic control approaches have been used to minimize the

torque ripples in SRM. This paper gives an extensive review of the

origin of the torque ripple and approaches adopted to minimize

the torque ripple.The mathematical modeling of three phase SRM

is developed and integrated with different converter topologies in

Matlab / Simulink environment along with control methods. The

power spectrum density wave forms of torque are studied to verify

the simulation results obtained.

Index Terms. Switched Reluctance Motor, mathematical

modeling & simulation, converter topologies, torque ripple

minimization, Power spectrum density

I. INTRODUCTION

With the advent of modern control technology and power

electronics, switched reluctance motor drive are becoming

increasingly popular. Because of high efficiency over wide

operating range, the absence of rotor windings, and the

maintenance free type of motor, SRMs have some advantages

over other types of electrical machines

The primary disadvantages of SRMs are the torque ripple and

acoustic noise. Torque production mechanism of SRM is

basically successive excitation of each stator phases. Torque

dip between two subsequent phases excitation dictates the

existence of torque ripple. It has been agreed that the main

source of the noise produced by SRM are the radial forces.

The torque ripple and acoustic noise are not necessarily

detrimental for the system in all cases, but it depends on the

application. The torque ripple is particularly intolerable in

servo or servo type systems, where its presence is painfully

felt by the user or harmfully reflected on the load. While the

drives designed in the early stages of SRM development were

notoriously noisy with high torque ripples, significant

progress have been made over the past decade to overcome

the issues with decent success.

Manuscript received on September, 2013.

Joseph Peter, M Tech Power Electronics & Drives, SELECT, VIT

University, Vellore Tamil Nadu, India.

There are primarily two approaches for reducing the torque

ripple. One method is to improve the magnetic design of the

motor, while the other is to use sophisticated electronic

control techniques.

It is possible to separate the attraction force exerted on the

rotor poles by the excited stator poles into two components as

normal and tangential in an SRM. Tangential component of

the force produces torque but radial component cause an

attraction between stator and rotor poles and vibrations and

acoustic noise occur in stator. The machine designers are able

to reduce the torque pulsations by changing the stator and

rotor pole structures, but only at the expense of some specific

motor outputs. The electronic approach is based on

optimizing the control parameters, which include the supply

voltage, turn-on and turn-off angles, and current level. The

minimization of torque ripple through electronic control may

lead to a reduction in the average torque, since the motor

capabilities are not being fully utilized at all power levels.

II. TORQUE RIPPLES

A. Origin of torque ripples

Torque pulsations are inherent in SRMs due to the doubly

salient structure of the machine. The reluctance principle for

torque production is utilized in these machines, where the

phases operate independently and in succession. The machine

torque is essentially defined by the nonlinear phase

torqueanglecurrent characteristics and the magnetization of

the phases. The magnetization pattern of the individual phases

together with the characteristics of the motor dictate the

amount of torque ripple during operation .[1]

B. Principle of operation

The switched reluctance motor is a rotating electric

machine where both, stator and rotor have salient poles. The

stator consists of simple concentric windings. There are

neither windings or bar wires on the rotor. Stator windings

on diametrically opposite poles are connected in series form

to a single phase. When the stator pole pair is energized by

the phase winding, the nearest rotor pole pair is attracted

toward the position, where the magnetic path has the

minimum reluctance. Thus, by energizing the consecutive

stator phases in sequence, it is possible to develop a torque in

either direction of rotation

III. INDUCTANCE PROFILE

The inductance of switched reluctance motor with various

rotor positions has a non linear relationship as follows

Modeling &Torque Ripple Minimization of

Switched Reluctance Motor for High Speed

Applications

Joseph Peter

Modeling & Torque Ripple Minimization of Switched Reluctance Motor for High Speed Applications

16

Figure 1.Inductance and Torque profile

Figure 2.Variation of inductance with rotor positions

A. Modeling of SRM

This paper describes a Matlab / Simulink environment to

simulate a 6/4-switched reluctance motor. From its linear

model to the non-linear model, its dynamics is described and

discussed in detail. All simulations are completely

documented through the paper by their block diagrams and

corresponding special Matlab functions and parameters to the

reader quickly develop its model.[2] Based on the developed

model, simulation studies are performed and compared.

Motor phase currents for hysteresis control strategies, are

measured and studied the steady-state motor operation to

validate the model.

B. Equations

Applying KVL to SRM phase electromagnetic circuit,

Figure 3 equivalent circuit

(1)

(2)

(3)

(4)

(5)

Where V is the DC link voltage, Rs is the electrical phase

resistance, is the flux linkage related to inductance (L) and

current (i) in the electromagnetic circuit, Eb is the back

electromotive force developed.

The electromagnetic torque developed is

(6)

(7)

Where Tl is the load torque, J is the inertia of the rotating part,

B is the frictional coefficient, is the angular speed.

(8)

(9)

C. Matlab simulink model

The plant model of SRM with position sensor is given below

Figure 4.Open loop SRM Matlab model

The mathematical model of 6/4 SRM is developed in Matlab

Simulink environment based on the mathematical equations

given above.

The modeling of the switched reluctance motor is based on

certain assumptions.

1. SRM is having 6 stator poles and 4 rotor poles

2. SRM is initially aligned with phase C

3. Stroke angle ,the angle at which rotor moves when we

give stator excitation in SRM is 2/ q Nr, where q is the

number of phases and Nr is the number of rotor poles.

So we have stroke angle =30

4. Stator and rotor is having same pole arc, s = r

5. Magnetic saturation is neglected

6. Mutual inductance is neglected

The model subsystem for SRM is given below

dt

d

i Rs V

+ = *

d

i dL

i

dt

di

i L i Rs V

) , (

) , ( * + + =

dt

i i dL

i Rs V

) , (

*

+ =

{ } Eb iR V

L dt

di

=

1

d

dl

i Te

2

2

1

=

B

dt

d

J Tl Te + =

( )

B Tl Te

J

dt

d

=

1

=

( ) i i L * , =

International Journal of Science and Modern Engineering (IJISME)

ISSN: 2319-6386, Volume-1, Issue-10, September 2013

17

Figure 5 .Subsystem of SRM

SRM consists of three phases. Each phase in SRM is excited

according to the rotor positions control signals and rotor

moves to the minimum reluctance position. Inside the position

sensor we produce signals for each stroke angle . In 90, each

phase will be excited once. In 360 , ie one revolution cycle

,each phase will be excited four times.

The main challenges faced in the mathematical modeling

of SRM are

1. The variation of inductance of SRM with rotor

positions are non linear

2. The current and torque profiles of SRM are non

linear .

So for getting the inductance profile we can go for look up

table method or linear algebraic equations for each stroke

angle. [3]

From the basic electrical equations we will calculate the

current and from current ,torque of each phases are calculated.

Torque in a SRM is depending upon rate of change of

inductance with rotor positions and is independent on the

direction of phase currents.

The machine parameters are as follows:

Table 1. Ratings of SRM

Machine parameters Values Units

Rated power 1.8 K w

Dc link voltage 150 Volts

L max 60 mH

L min 10 mH

Frictional coefficient .0183 Nm/rad/sec

Moment of inertia .0013 Kgm

2

IV. SIMULATION RESULTS

The simulated results of open loop three phase SRM are

given. A load torque of 3 Nm are applied after 2 seconds of

simulation

Figure 6.Simulation results of open loop SRM

V. CONVERTER TOPOLOGIES IN SRM

Asymmetric bridge converter

The asymmetric bridge converter considering only one phase

of the SRM is shown.. The rest of the phases are similarly

connected. Turning on transistors T1 and T2 will circulate a

current in phase A of the SRM. If the current rises above the

commanded value, T1 andT2are turned off. The energy stored

in the motor winding of phase A will keep the current in the

same direction until it is depleted. Hence, diodes D1and

diodes D 2will become forward biased leading to recharging

of the source. The classic converter is one in which two switch

per phase are employed. The upper transistor is used to

control the amount of current in the ending, while the lower

transistor synchronizes the proper operation of that phase with

the rotor position sensor

Figure 7Asymmetric bridge converter

Miller converter

In an Miller converter circuit for N phase motor one transistor

is common to all the phases for the control of the current

,while the other transistor are used for the proper operation of

the phases. This type of converter circuit directs the excess

energy back to the source through a diode.[4]

Modeling & Torque Ripple Minimization of Switched Reluctance Motor for High Speed Applications

18

Figure 8.Miller converter

When transistor T1 and T2 are ON, current flows through

phase 1. When transistor T2 is off and T1, T3 are switched

ON, then current flows through phase 2 and phase 1 current

do not reduces to zero as it freewheels through T1 and D1.

Similarly when T2, T3 are OFF , AND T1,T4 are ON , current

flows through phase 3.and phase 1 and phase 2 currents do not

reduce to zero as it freewheels through T1,D1 and T1,D2 .

Again when phase 1 is switched on then current in phase 2 and

phase 3 has not reduced to zero. Hence at higher speeds the

current start rising in each phase before reaching the zero

value causing negative torque and excessive heat in the

windings

Figure 9.current and torque

The pulses of switching signals are as follows

Figure 10.Switching pulses

Modified miller converter

Figure 11 . Modified miller

Figure 12 .Pulses of switching signals

T

1

, T

21

on-current flows through phase1 &T

1

, T

21

off, T

22

, T

3

on current flows through phase2 & phase1 current reduced to

zero through D

21

, D

1

. T

22

off and T

3

, T

4

on current flows

through phase3. Phase1 current reduced to zero & Phase2

current freewheels through T

3

, D

22

.Again when phase1 is on

,Current in phase3&2 reduced to zero &I

ph2

take some time to

reduced to zero & all phase currents reduced to zero

VI. CONTROL STRATEGIES OF SRM.

Current and speed control

In the control method the magnitude of the current flowing

into windings is controlled using a control loop with a current

feedback. The current in a motor phase winding is directly

measured with a current/voltage converter or a current sense

resistor connected in series with the phase. [5]The current is

compared with a desired value of current, forming an error

signal. The current error is compensated via a control law,

such as a PID, and an appropriate control action is taken. The

block diagram below shows that both current and position

feedback are needed for controlling the SR motor. Position

feedback is needed to synchronize the current flow, with

respect to the rotor position, in order to generate the desired

motoring torque.[6] Position feedback is also needed to

compute the rotor mechanical speed, which is compared with

the desired value of speed

.

Block Diagram of SRM

Figure13. Block diagram

SRM with asymmetric bridge converter

The Matlab Simulink diagram for the current control using

asymmetric bridge converter is given as follows

International Journal of Science and Modern Engineering (IJISME)

ISSN: 2319-6386, Volume-1, Issue-10, September 2013

19

Figure 14 Closed loop SRM model

Figure 15. Simulation result with asymmetric converter

SRM with Miller converter

Miller converter is having (n+1) switches for n phases.

Although it reduces the number of switches, the problem of

overlapping of phase currents at higher speeds creates a

problem of negative torque.The Matlab Simulink diagram for

the current control using miller converter topology is done

The simulation results are as follows

Figure 16. Simulation result with miller converter

SRM with modified Miller

Modified miller topology have (2n-1) switches for n phase

SRM. The converter topology help to improve the problem of

overlapping of phase currents.

The simulation results of modified miller using Matlab

Simulink are as follows

Figure 17. Simulation results with modified miller

converter

VII. POWER SPECRUM DENSITY (PSD)

Power spectral density function (PSD) shows the strength of

the variations(energy) as a function of frequency. In other

words, it shows at which frequencies variations are strong and

at which frequencies variations are weak.Computation of

PSD of torque wave form in each cases is done directly by the

method called FFT or computing autocorrelation function and

then transforming it. In open loop SRM, PSD gives different

frequencies corresponding to variable power levels. This

means there are higher ripple content in the open loop SRM

Figure 18. Power spectrum of torque in open loop SRM

The closed loop operation of SRM gives ripple less torque

waveforms. when we do the PSD of the corresponding torque

waveforms using asymmetric, miller ,modified miller

converter topologies less number of variable frequencies with

different energy levels compared to open loop SRM are

obtained which proves the control of SRM with converters

helps to minimize the torque ripples in switched reluctance

motor.

Figure 19 .Power spectrum of torque with asymmetric

converter

Modeling & Torque Ripple Minimization of Switched Reluctance Motor for High Speed Applications

20

Figure 20.Power spectrum of torque with Miller converter

Figure 21. Power spectrum of torque with modified miller

IX. CONCLUSION

In this paper, mathematical modelling of SRM and advanced

PI and hysteresis controllers for SRM position control have

been presented. The parameters of the speed PI controller are

adjusted according to the load torque and rotor speed. The

control scheme is based on the various converter topologies

and it is capable for maintaining the torque ripple at an

acceptable level over a wide speed range. Thus, it provides

quick response and high-precision position control of the

SRM drive. The proposed control scheme has been applied on

a three-phase 6/4 SRM, with asymmetric, miller and modified

miller converter topologies and several simulation results

have been presented. Power spectrum density of the torque

waveforms has been studied. Asymmetric converter is having

six switches topology for three phases. Miller topology is

having four switches but there is a problem of overlapping of

phase currents and less utilisation of the devices at higher

speeds. Modified miller converter topologies have number of

switches greater than miller converter and lesser than

asymmetric bridge converter. Also the problem of

overlapping of phase currents has been reduced resulting in

lesser torque ripples and can be used for closed loop operation

of switched reluctance motor

REFERENCES

[1] Torque ripple minimization in SRM drives by PWM current control.

Iqbal hussain , M.ehsani IEEE Jan 1996

[2] Simulation of a 6/4 SRM Based on Matlab/Simulink Environment . F

. Soares , P.J. Costa Branco IEEE July 2001

[3] Naresh Vattikuti, Vandana Rallabandi and B. G. Fernandes, A

Novel High Torque, Low Weight Segmented SRM", IEEE June

2008.

[4] Miller, T. J. E. (1993) Switched Reluctance Motors and their

Control.

[5] Modeling simulation analysis design and applications of SRM R.

Krishnan

[6] A new power converter for SRM drive S.Gairola,Priti and L .N.

Paliwal IEEE 2010

Joseph Peter received the B.Tech. degree in EE from

MACE ,M.G.University, India, in 2009, and the

M.Tech. degree in Power Electronics and Drives from

VIT University Vellore,India, in 2012..He is currently

working towards the Ph.D. degree in electrical

engineering in the Department of Electrical

Engineering, National Institute of Technology

Calicut, India. His major research interests are PWM

techniques and control of motor drives,

.

Das könnte Ihnen auch gefallen

- Iecon 2019 8926922Dokument6 SeitenIecon 2019 8926922godspower brunoNoch keine Bewertungen

- Switched Reluctance MotorDokument52 SeitenSwitched Reluctance MotorChandru PrasathNoch keine Bewertungen

- Numerical and Analytical Modeling of Switched Reluctance MachinesDokument8 SeitenNumerical and Analytical Modeling of Switched Reluctance Machinesvinay3450% (1)

- A Comprehensive Study of Multilevel Inverter Fed Switched Reluctance Motor For Torque Ripple Minimization With Multicarrier PWM StrategiesDokument7 SeitenA Comprehensive Study of Multilevel Inverter Fed Switched Reluctance Motor For Torque Ripple Minimization With Multicarrier PWM Strategiesicees2018 EEENoch keine Bewertungen

- Le Huay0Dokument6 SeitenLe Huay0Noor KareemNoch keine Bewertungen

- Simulation Modelling and Fault Analysis of Switched Reluctance MotorDokument5 SeitenSimulation Modelling and Fault Analysis of Switched Reluctance MotorNokhwrang BrahmaNoch keine Bewertungen

- Rotary and Linear Switched Reluctance MotorsDokument12 SeitenRotary and Linear Switched Reluctance Motorskarthikeyan249100% (2)

- On Modeling of A Four-Quadrant Switched PDFDokument11 SeitenOn Modeling of A Four-Quadrant Switched PDFSergeyNoch keine Bewertungen

- Unit3 (Ac Drives)Dokument20 SeitenUnit3 (Ac Drives)vedala chaitanyaNoch keine Bewertungen

- 037 Takau Full PaperDokument5 Seiten037 Takau Full PaperJose FrancisNoch keine Bewertungen

- Ann TechDokument76 SeitenAnn TechPidikiti Surendra BabuNoch keine Bewertungen

- Dynamic Analysis of Synchronous Reluctance Motor Drives Based On Simulink and Finite Element ModelDokument5 SeitenDynamic Analysis of Synchronous Reluctance Motor Drives Based On Simulink and Finite Element ModelenmnabilNoch keine Bewertungen

- Chapter-3 Switch Reluctance Motor Characteristics 3.1 Switched Reluctance MotorDokument9 SeitenChapter-3 Switch Reluctance Motor Characteristics 3.1 Switched Reluctance MotorSree GaneshNoch keine Bewertungen

- Modified (N+L) Switch Converter For Switched Reluctance Motor DrivesDokument7 SeitenModified (N+L) Switch Converter For Switched Reluctance Motor DrivesDeepak RonankiNoch keine Bewertungen

- Thesis On Switched Reluctance MotorDokument4 SeitenThesis On Switched Reluctance Motorbsqxd5g1100% (2)

- Mixer Grinder MotorDokument6 SeitenMixer Grinder MotorKkbhuvan KkNoch keine Bewertungen

- Sensitivity Analysis of Geometrical Parameters of A Switched Reluctance Motor With Modified Pole ShapesDokument7 SeitenSensitivity Analysis of Geometrical Parameters of A Switched Reluctance Motor With Modified Pole ShapesBalaji M.Noch keine Bewertungen

- Slamet Riyadi Regular Paper A Control Strategy For SRM Drive To Produce Higher Torque and Reduce Switching LossesDokument12 SeitenSlamet Riyadi Regular Paper A Control Strategy For SRM Drive To Produce Higher Torque and Reduce Switching LossesLukas BudiNoch keine Bewertungen

- Speed Control of Switched Reluctance Motor-LibreDokument9 SeitenSpeed Control of Switched Reluctance Motor-LibreIndrajithSrNoch keine Bewertungen

- Modelare Si ControlDokument4 SeitenModelare Si ControlDobai SzilardNoch keine Bewertungen

- Thesis Switched Reluctance MotorDokument6 SeitenThesis Switched Reluctance Motormelissalusternorman100% (2)

- Analysis of Switched Reluctance Motor Behavior Under Electrical Fault ConditionsDokument8 SeitenAnalysis of Switched Reluctance Motor Behavior Under Electrical Fault ConditionsAndSolNoch keine Bewertungen

- 2013 - Sensorless Control in SRM Drives For Four Quadrant OperationDokument5 Seiten2013 - Sensorless Control in SRM Drives For Four Quadrant OperationMarcelo Vinicius de PaulaNoch keine Bewertungen

- Labview Simulation of Induction Motors: Zhaoxian Zhou and James Matthew JohnsonDokument8 SeitenLabview Simulation of Induction Motors: Zhaoxian Zhou and James Matthew JohnsonR Sathish Kumar KumarNoch keine Bewertungen

- DSP Control of Stepper MotorDokument5 SeitenDSP Control of Stepper MotorAhmedHyderMohdNoch keine Bewertungen

- 6/4 Switched Reluctance Motor Modeling Using MATLAB: T.Srihari R. Saravana Kumar, R. Vignesh PrabhuDokument8 Seiten6/4 Switched Reluctance Motor Modeling Using MATLAB: T.Srihari R. Saravana Kumar, R. Vignesh PrabhuHaripriya PalemNoch keine Bewertungen

- Unit Iii Switched Reluctance MotorDokument18 SeitenUnit Iii Switched Reluctance MotorMürlî MünnâNoch keine Bewertungen

- Parameter Identification and Comparision of An Induction Motor ModelsDokument11 SeitenParameter Identification and Comparision of An Induction Motor ModelsJUAN4201Noch keine Bewertungen

- srm123 PDFDokument6 Seitensrm123 PDFPathella SudhakarNoch keine Bewertungen

- 1 Direct InstantaneousDokument6 Seiten1 Direct InstantaneouskarnatisharathNoch keine Bewertungen

- Design and Analysis of Switched Reluctance Motors: Ibrahim SENGOR, Abdullah POLAT and Lale T. ERGENEDokument5 SeitenDesign and Analysis of Switched Reluctance Motors: Ibrahim SENGOR, Abdullah POLAT and Lale T. ERGENESandesh BhakthaNoch keine Bewertungen

- FuzzyDokument68 SeitenFuzzyPidikiti Surendra BabuNoch keine Bewertungen

- Simulation of 8/6 and 8/14 Switched Reluctance Motor Based On Matlab/Simulink EnvironmentDokument5 SeitenSimulation of 8/6 and 8/14 Switched Reluctance Motor Based On Matlab/Simulink EnvironmentshonmlrNoch keine Bewertungen

- Modeling, Simulation, and Analysis of Permanent-Magnet Motor Drives, The Brushless DC Motor DriveDokument6 SeitenModeling, Simulation, and Analysis of Permanent-Magnet Motor Drives, The Brushless DC Motor Drivekishan kharelNoch keine Bewertungen

- 1 - Switched Reluctance MotorDokument5 Seiten1 - Switched Reluctance MotorHARSHIT TOMARNoch keine Bewertungen

- Sliding Controller of Switched Reluctance Motor: Ahmed Tahour and Abdel Ghani AissaouiDokument15 SeitenSliding Controller of Switched Reluctance Motor: Ahmed Tahour and Abdel Ghani AissaouihasanmasoudiNoch keine Bewertungen

- DQ InductanceDokument11 SeitenDQ Inductancegthulasi789193Noch keine Bewertungen

- A Review of Torque Ripple Control Strategies of Switched Reluctance MotorDokument5 SeitenA Review of Torque Ripple Control Strategies of Switched Reluctance Motorsuntchou julesNoch keine Bewertungen

- Evaluation of The Transient Response of A DC MotorDokument6 SeitenEvaluation of The Transient Response of A DC MotorNesuh MalangNoch keine Bewertungen

- Module 2 - Switched Reluctance MotorDokument20 SeitenModule 2 - Switched Reluctance MotorkesavantNoch keine Bewertungen

- Matlab Simulink Implementation of Switched Reluctance Motor With Direct Torque Control TechniqueDokument7 SeitenMatlab Simulink Implementation of Switched Reluctance Motor With Direct Torque Control Techniquemarris09Noch keine Bewertungen

- Reluctance MotorDokument24 SeitenReluctance Motorpraveenpv7100% (1)

- Mathematical Modeling and Analysis of Different VeDokument13 SeitenMathematical Modeling and Analysis of Different Veramadhanifarahum19Noch keine Bewertungen

- Modeling and Simulation of BLDC Motor Using Soft Computing TechniquesDokument5 SeitenModeling and Simulation of BLDC Motor Using Soft Computing TechniquesJulián Peláez RestrepoNoch keine Bewertungen

- Direct Torque Control For The 4-Phase Switched Reluctance Motor DrivesDokument5 SeitenDirect Torque Control For The 4-Phase Switched Reluctance Motor Drivesapi-26587237100% (1)

- New Sensor LessDokument10 SeitenNew Sensor LessAbhishek AgarwalNoch keine Bewertungen

- Arindam Seminar 11Dokument6 SeitenArindam Seminar 11Arindam BhattacharjeeNoch keine Bewertungen

- An Off Line Technique For Prediction of Performance Characteristics of Three Phase Induction Motor IJERTV2IS1417Dokument6 SeitenAn Off Line Technique For Prediction of Performance Characteristics of Three Phase Induction Motor IJERTV2IS1417Rayhana KararNoch keine Bewertungen

- Bahçeşehir University: 111equation Chapter 1 Section 1212equation Chapter 2 Section 1Dokument10 SeitenBahçeşehir University: 111equation Chapter 1 Section 1212equation Chapter 2 Section 1Wael M. AbulafiNoch keine Bewertungen

- BobanDokument13 SeitenBobanSung Ryoung LimNoch keine Bewertungen

- Simulation of Six Phase Permanent Magnet Synchronous Generator in MATLABDokument5 SeitenSimulation of Six Phase Permanent Magnet Synchronous Generator in MATLABجمال ضيفيNoch keine Bewertungen

- DW TechTip Brushless Servo SystemsDokument14 SeitenDW TechTip Brushless Servo SystemsgubiliNoch keine Bewertungen

- Practical Induction 01Dokument5 SeitenPractical Induction 01sathishNoch keine Bewertungen

- Ijeet: International Journal of Electrical Engineering & Technology (Ijeet)Dokument18 SeitenIjeet: International Journal of Electrical Engineering & Technology (Ijeet)IAEME PublicationNoch keine Bewertungen

- Switched Reluctance Motor (SRM)Dokument8 SeitenSwitched Reluctance Motor (SRM)Ömer Faruk AbdullahNoch keine Bewertungen

- Field Oriented Control For Space Vector Modulation Based Brushless DC Motor DriveDokument8 SeitenField Oriented Control For Space Vector Modulation Based Brushless DC Motor DriveSushant MandalNoch keine Bewertungen

- Electrical Machines: Lecture Notes for Electrical Machines CourseVon EverandElectrical Machines: Lecture Notes for Electrical Machines CourseNoch keine Bewertungen

- DC Battery Bank Sizing PDFDokument37 SeitenDC Battery Bank Sizing PDFflyzalNoch keine Bewertungen

- Short Circuit Calculations: Circuit Breaker Asymmetric Switching DutyDokument11 SeitenShort Circuit Calculations: Circuit Breaker Asymmetric Switching DutyMoon3pellNoch keine Bewertungen

- ADokument2 SeitenAMoon3pellNoch keine Bewertungen

- Siemens Three Windings Transforemr ImpedancesDokument19 SeitenSiemens Three Windings Transforemr ImpedancesMoon3pellNoch keine Bewertungen

- Section 6 Battery SizingDokument54 SeitenSection 6 Battery SizingAca ChchNoch keine Bewertungen

- How To Solve The Inertia Issues in The GridDokument4 SeitenHow To Solve The Inertia Issues in The GridMoon3pellNoch keine Bewertungen

- General IELTS Writing Task 1, Letter SamplesDokument20 SeitenGeneral IELTS Writing Task 1, Letter SamplesMoon3pellNoch keine Bewertungen

- Creating EPLAN PartsDokument56 SeitenCreating EPLAN PartsMoon3pellNoch keine Bewertungen

- Ups BatteriesDokument8 SeitenUps Batteriesegal1100% (1)

- IELTS HIGHER GeneralTraining Practice Test 02 PDFDokument50 SeitenIELTS HIGHER GeneralTraining Practice Test 02 PDFMoon3pellNoch keine Bewertungen

- IELTS Practice Materials General TrainingTestDokument57 SeitenIELTS Practice Materials General TrainingTestMoon3pell100% (1)

- Ringmaster: Distribution Transformer Protection Benefits of Circuit BreakersDokument4 SeitenRingmaster: Distribution Transformer Protection Benefits of Circuit BreakersMoon3pellNoch keine Bewertungen

- Ups BatteriesDokument8 SeitenUps Batteriesegal1100% (1)

- General IELTS Writing Task 1, Letter SamplesDokument20 SeitenGeneral IELTS Writing Task 1, Letter SamplesMoon3pellNoch keine Bewertungen

- B Electrical NetworksDokument21 SeitenB Electrical NetworksMoon3pellNoch keine Bewertungen

- Management PDFDokument7 SeitenManagement PDFIshmo KueedNoch keine Bewertungen

- Expression of Wish Form: Beneficiary 1 Beneficiary 2Dokument1 SeiteExpression of Wish Form: Beneficiary 1 Beneficiary 2Moon3pellNoch keine Bewertungen

- Course Objectives and TopicsDokument3 SeitenCourse Objectives and TopicsMoon3pellNoch keine Bewertungen

- Merlin Gerin Technical Guide Medium VoltageDokument80 SeitenMerlin Gerin Technical Guide Medium Voltagepavlovicg100% (1)

- Project Nr. 663 External Id. 7249896) Electrical EngineerDokument3 SeitenProject Nr. 663 External Id. 7249896) Electrical EngineerMoon3pellNoch keine Bewertungen

- Gas Tech Electric Motor PaperDokument16 SeitenGas Tech Electric Motor PaperAshish PatelNoch keine Bewertungen

- PDFDokument15 SeitenPDFJohansen HasugianNoch keine Bewertungen

- MV Switchgear Insulating MediumsDokument25 SeitenMV Switchgear Insulating MediumsMoon3pellNoch keine Bewertungen

- Management PDFDokument7 SeitenManagement PDFIshmo KueedNoch keine Bewertungen

- STK - StockholmDokument6 SeitenSTK - StockholmMoon3pellNoch keine Bewertungen

- Speed Control of D C MOTOR Using Chopper-1308Dokument7 SeitenSpeed Control of D C MOTOR Using Chopper-1308Moon3pellNoch keine Bewertungen

- TheoryDokument16 SeitenTheoryMoon3pellNoch keine Bewertungen

- Setting of Distance RelaysDokument4 SeitenSetting of Distance RelaysMohamed WahidNoch keine Bewertungen

- Arc Flash A Practical Approach To Arc Flash Hazard Analysis and ReductionDokument16 SeitenArc Flash A Practical Approach To Arc Flash Hazard Analysis and ReductionMoon3pellNoch keine Bewertungen

- PDF 012Dokument2 SeitenPDF 012Moon3pellNoch keine Bewertungen

- Electrical Circuit SymbolsDokument38 SeitenElectrical Circuit Symbolsanwar9602020Noch keine Bewertungen

- Rogowski Coil Design and SimulationDokument2 SeitenRogowski Coil Design and SimulationTonyPeace100% (2)

- EC469 Opto Electronic DevicesDokument2 SeitenEC469 Opto Electronic DevicesAnitha JersonNoch keine Bewertungen

- QUAD 405 Amplifier Information and ModificationDokument1 SeiteQUAD 405 Amplifier Information and ModificationVerecondoOrtalliNoch keine Bewertungen

- Remy Hybrid Application Manual Rev 2.0Dokument28 SeitenRemy Hybrid Application Manual Rev 2.0EvTech PhilNoch keine Bewertungen

- PhysicsDokument15 SeitenPhysicsmamo alzozNoch keine Bewertungen

- Electrical Load EstimationDokument8 SeitenElectrical Load EstimationWidhi ImranovichNoch keine Bewertungen

- Connector Connector: GH Connector GH ConnectorDokument4 SeitenConnector Connector: GH Connector GH ConnectorNitin KeshavNoch keine Bewertungen

- W 5105 H - InstalareDokument40 SeitenW 5105 H - InstalareMarius Costan0% (1)

- Control Real World Devices With Your PCDokument15 SeitenControl Real World Devices With Your PCWeb devNoch keine Bewertungen

- Jeac PDFDokument13 SeitenJeac PDFIshfaq AhmadNoch keine Bewertungen

- Belden InfinityDokument1 SeiteBelden InfinityHenry Avilés ChongNoch keine Bewertungen

- Week 5Dokument31 SeitenWeek 5HadeedAhmedSherNoch keine Bewertungen

- Chapter 5 - TransformerDokument84 SeitenChapter 5 - TransformerZulfikri Zulkifli50% (2)

- Wiring 2 Wire TransmittersDokument3 SeitenWiring 2 Wire TransmittersPravin GaikwadNoch keine Bewertungen

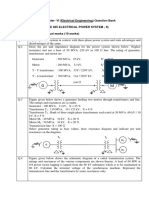

- BE Semester-VI (Electrical Engineering) Question Bank (E 605 Electrical Power System - Ii) All Questions Carry Equal Marks (10 Marks)Dokument5 SeitenBE Semester-VI (Electrical Engineering) Question Bank (E 605 Electrical Power System - Ii) All Questions Carry Equal Marks (10 Marks)Adesh Bhortakke100% (1)

- MPPT Techniques For PV Systems Under Different Scenarios: ReviewDokument6 SeitenMPPT Techniques For PV Systems Under Different Scenarios: ReviewAnurag KumarNoch keine Bewertungen

- Lec 11Dokument4 SeitenLec 11Abdullah AloglaNoch keine Bewertungen

- What Is A Tuned AmplifierDokument4 SeitenWhat Is A Tuned AmplifierSaiyma Fatima RazaNoch keine Bewertungen

- KD600S-Newest-Manual-Book MANUAL EN ESPAÑOL (001-091)Dokument91 SeitenKD600S-Newest-Manual-Book MANUAL EN ESPAÑOL (001-091)armando valle durantesNoch keine Bewertungen

- Measure DC Voltage SubtitlesDokument2 SeitenMeasure DC Voltage Subtitlesguasko9035Noch keine Bewertungen

- Power Monitor Chip: Features Pin AssignmentDokument9 SeitenPower Monitor Chip: Features Pin Assignmentchafic WEISSNoch keine Bewertungen

- MAGNETIC LEVITATION TRAINS (SeminarDokument19 SeitenMAGNETIC LEVITATION TRAINS (SeminarTejas KadamNoch keine Bewertungen

- Semi Detailed Lesson Plan in Electricity g71Dokument6 SeitenSemi Detailed Lesson Plan in Electricity g71Edessa MasinasNoch keine Bewertungen

- Low Frequency QsDokument6 SeitenLow Frequency QsRon FranklinNoch keine Bewertungen

- CNV 03 BDokument4 SeitenCNV 03 BMaitry ShahNoch keine Bewertungen

- Power System GroundingDokument2 SeitenPower System GroundingMujtaba HusseinNoch keine Bewertungen

- Design of Ridged Waveguides by Hofer PDFDokument10 SeitenDesign of Ridged Waveguides by Hofer PDFవేలుసామి లింగాసామిNoch keine Bewertungen

- User Guide: Tracer™ TD7 With UC 800Dokument24 SeitenUser Guide: Tracer™ TD7 With UC 80001666754614Noch keine Bewertungen

- Detailed Lesson Plan Physics 9Dokument16 SeitenDetailed Lesson Plan Physics 9Tetchie GonzalesNoch keine Bewertungen