Beruflich Dokumente

Kultur Dokumente

Bump Test

Hochgeladen von

varunstuffCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Bump Test

Hochgeladen von

varunstuffCopyright:

Verfügbare Formate

ISO 9001:2008 Registered

EnviroMed

56 Clyde Avenue Tel: (709) 368-9000 Fax: (709) 368-1256

Mt. Pearl, NL A1N 4S1 e-mail: enviromed@enviromed.ca website: www.enviromed.ca

"Bump test" before detector use!

The only way to ensure worker safety is to verify accuracy on a daily basis

By Jason Pike, Technical Specialist- Biosystems

Gas detectors are designed for the detection and measurement of

potentially life threatening atmospheric conditions. Hazards such as

oxygen deficiencies, explosive atmospheres, and toxic gases and vapors

regularly kill more than three-hundred workers per year in North America,

many of them during confined space entry procedures. The only way to

insure conditions are safe is to use an accurate atmospheric monitor. The

only way to know that the readings are accurate is to expose the instrument

to known concentration test gas; in other words, to check the accuracy of

the instrument on a regular basis.

Some manufacturers actually take the approach that it is not necessary to

verify the accuracy of their instruments in the field at all, but to send them back to the factory once or twice a

year where they can be adjusted if necessary. We think this is a morally bankrupt approach to business! The

primary concern must be keeping workers safe.

The regulations say "Verify accuracy daily!"

Gad detectors are usually classified by Underwriters Laboratories (UL) or the Canadian Standards

Association (CSA) as being intrinsically safe for use in hazardous locations Class I, Division I, Groups A, B,

C, and D. Both UL and CSA require that any instrument carrying their approval must be checked with

known concentration test gas before any daily period of use. It is not necessary to make an adjustment if the

instrument is found to be accurate, but it is necessary to verify accuracy by daily testing.

The new OSHA standard governing confined space entry procedures (29 CFR 1910.134) stresses the

importance of calibration. Section (c)(5)(ii) says only "calibrated, direct reading instruments" may be used

when testing the atmosphere prior to entry. In Appendix E the code goes on to explain that atmospheric

monitoring equipment must be calibrated and maintained in accordance with manufacturer guidelines.

Instruments can lose accuracy due to contamination

Sensors may be poisoned or suffer degraded performance if exposed to certain substances in the atmosphere.

Bumps verify that your sensors are accurate. If exposure to test gas indicates a loss of sensitivity, the

instrument needs to be adjusted. The important thing to understand is that if you never test the instrument

with known concentration gas, you will never know if you need to adjust the sensitivity of the sensors.

"Bump" tests verify accuracy

A simple functional "bump" test is all that is necessary to verify accuracy. Simply turn your instrument on,

allow the readings to stabilize, slip on the calibration adapter, flow calibration gas to the sensors, and wait for

the readings to stabilize (about 45 seconds). Note the readings. If the readings are accurate, it is safe to use the

instrument without further adjustment. If the readings are off the mark, then a span calibration adjustment

should be made before further use.

Don't take a chance with your life. Verify accuracy daily!

Gas detectors are designed to help keep you safe in potentially life threatening environments. If you test your

instrument on a daily basis, you know that your readings are accurate. Confined spaces and other areas where

the air is potentially dangerous are environments where you want to be sure your monitor is accurate!

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (399)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Safety Check List For Night WorksDokument2 SeitenSafety Check List For Night Worksvarunstuff100% (1)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Health and Safety Risk AssessmentDokument10 SeitenHealth and Safety Risk AssessmentAnwar MohamedNoch keine Bewertungen

- A-2.2!04!23-02 - Incoming Correspondence Register FormatDokument1 SeiteA-2.2!04!23-02 - Incoming Correspondence Register Formatvarunstuff100% (1)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Hse Plan Asl PDFDokument87 SeitenHse Plan Asl PDFBudi Prasetyo100% (1)

- Pre Pouring Inspection ChecklistDokument2 SeitenPre Pouring Inspection Checklistvarunstuff75% (4)

- Eight Hour Mandatory Modules 1 To 4 - 1Dokument147 SeitenEight Hour Mandatory Modules 1 To 4 - 1ds-nurse100% (1)

- Outgoing Correspondence Register TemplateDokument1 SeiteOutgoing Correspondence Register TemplatevarunstuffNoch keine Bewertungen

- MAN B&W Alpha DieselDokument12 SeitenMAN B&W Alpha Dieselamin_corporation100% (3)

- Hot Work PermitDokument1 SeiteHot Work PermitvarunstuffNoch keine Bewertungen

- H&S Monthly StatsDokument6 SeitenH&S Monthly StatsvarunstuffNoch keine Bewertungen

- PPE Warning Letter TemplateDokument1 SeitePPE Warning Letter Templatevarunstuff100% (3)

- Revision date: 01/06/2015 Revision: Issue 8Dokument7 SeitenRevision date: 01/06/2015 Revision: Issue 8osheIntanNoch keine Bewertungen

- Fire Response PlanDokument4 SeitenFire Response PlanArchana GaonkarNoch keine Bewertungen

- Daily Repair Register: Project Name Project No. LocationDokument1 SeiteDaily Repair Register: Project Name Project No. LocationvarunstuffNoch keine Bewertungen

- Increased Sugarcane Productivity Through Trench MethodDokument4 SeitenIncreased Sugarcane Productivity Through Trench MethodvarunstuffNoch keine Bewertungen

- A-2.2!04!23-01 - Correspondence Receipt Stamp FormatDokument1 SeiteA-2.2!04!23-01 - Correspondence Receipt Stamp FormatvarunstuffNoch keine Bewertungen

- Emami Infrastructure Limited: Safety Inspection ReportDokument1 SeiteEmami Infrastructure Limited: Safety Inspection ReportvarunstuffNoch keine Bewertungen

- Daily Site Observation ReportDokument2 SeitenDaily Site Observation ReportvarunstuffNoch keine Bewertungen

- Schedule of Operator Training: Project: ClientDokument1 SeiteSchedule of Operator Training: Project: ClientvarunstuffNoch keine Bewertungen

- Emami Infrastructure Safety Report Highlights MM/YYYYDokument1 SeiteEmami Infrastructure Safety Report Highlights MM/YYYYvarunstuffNoch keine Bewertungen

- Weekly Status of Pour Card Mm/Yyyy: Emami Infrastructure LimitedDokument1 SeiteWeekly Status of Pour Card Mm/Yyyy: Emami Infrastructure LimitedvarunstuffNoch keine Bewertungen

- Daily Site Observation ReportDokument2 SeitenDaily Site Observation ReportvarunstuffNoch keine Bewertungen

- ENGS-37 Fall 2006 Introduction To Environmental Engineering Quiz #6Dokument1 SeiteENGS-37 Fall 2006 Introduction To Environmental Engineering Quiz #6varunstuffNoch keine Bewertungen

- Monthly Safety Review ReportDokument2 SeitenMonthly Safety Review ReportvarunstuffNoch keine Bewertungen

- Times of India Article May 18 2016Dokument1 SeiteTimes of India Article May 18 2016varunstuffNoch keine Bewertungen

- Daily Site Observation ReportDokument2 SeitenDaily Site Observation ReportvarunstuffNoch keine Bewertungen

- Daily Site Observation ReportDokument2 SeitenDaily Site Observation ReportvarunstuffNoch keine Bewertungen

- Times of India Article May 18 2016Dokument1 SeiteTimes of India Article May 18 2016varunstuffNoch keine Bewertungen

- Environmental Issues Associated With The Atmosphere: Quality of The Air ClimateDokument10 SeitenEnvironmental Issues Associated With The Atmosphere: Quality of The Air ClimateAhmedSalemNoch keine Bewertungen

- Daily Site Observation ReportDokument2 SeitenDaily Site Observation ReportvarunstuffNoch keine Bewertungen

- Times of India Article May 18 2016Dokument1 SeiteTimes of India Article May 18 2016varunstuffNoch keine Bewertungen

- Monthly Scheme SGDokument14 SeitenMonthly Scheme SGvarunstuffNoch keine Bewertungen

- Times of India Article May 18 2016Dokument1 SeiteTimes of India Article May 18 2016varunstuffNoch keine Bewertungen

- ResumeDokument15 SeitenResumevarunstuffNoch keine Bewertungen

- Repairs and RectificationsDokument6 SeitenRepairs and RectificationsvarunstuffNoch keine Bewertungen

- Advertisement PMIDC JobsDokument7 SeitenAdvertisement PMIDC JobsSukhpal SinghNoch keine Bewertungen

- SAMSUNG RSG257AARS Refrigerator User Manual 3Dokument1 SeiteSAMSUNG RSG257AARS Refrigerator User Manual 3gevera1217Noch keine Bewertungen

- 31.03.2023 - UK MSN - 1874 - Amendment - 7Dokument350 Seiten31.03.2023 - UK MSN - 1874 - Amendment - 7sonerNoch keine Bewertungen

- Method Statement - Installation of Domestic PumpsDokument12 SeitenMethod Statement - Installation of Domestic Pumpssarmad spectrumNoch keine Bewertungen

- User Manual: Szgh-Cnc1500Mdc Milling Control System - Operation-V3.0Dokument96 SeitenUser Manual: Szgh-Cnc1500Mdc Milling Control System - Operation-V3.0Everton FernandesNoch keine Bewertungen

- Kidpower Safety SignalsDokument6 SeitenKidpower Safety SignalsÀlexNoch keine Bewertungen

- Risk PerceptionDokument16 SeitenRisk PerceptionleidianeNoch keine Bewertungen

- Rescue: Phoenix Regional Standard Operating ProceduresDokument3 SeitenRescue: Phoenix Regional Standard Operating ProceduresPEDRO CAPARACHIN PALPANoch keine Bewertungen

- 4396-13.0-01-04 - 0 Operation & Maintenance InstructionDokument56 Seiten4396-13.0-01-04 - 0 Operation & Maintenance InstructionJAIME100% (1)

- Asad 2Dokument17 SeitenAsad 2mysticmirza1Noch keine Bewertungen

- Learning Guide-18: Basic Clerical Work Level-IDokument38 SeitenLearning Guide-18: Basic Clerical Work Level-IAbel ZegeyeNoch keine Bewertungen

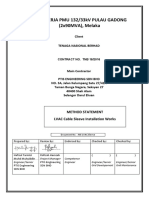

- MS - LVAC Cable Sleve Installation WorksDokument17 SeitenMS - LVAC Cable Sleve Installation WorksHafizul TarmiziNoch keine Bewertungen

- Winch, Casing Stabbing Board (FA2BMR) Manual SupplementDokument13 SeitenWinch, Casing Stabbing Board (FA2BMR) Manual SupplementTony100% (2)

- 27f Line Break PermitDokument2 Seiten27f Line Break PermitMohammed MinhajNoch keine Bewertungen

- SSPC Confined Space Fact SheetDokument5 SeitenSSPC Confined Space Fact Sheetrondulf goNoch keine Bewertungen

- PPE in WeldingDokument19 SeitenPPE in WeldingRonel SuanNoch keine Bewertungen

- Pmls Ch2 TransDokument2 SeitenPmls Ch2 TransBSLMS1D - Depasupil, Laurice Ann A.Noch keine Bewertungen

- TR - Cable TV Installation NC IIDokument66 SeitenTR - Cable TV Installation NC IIKarenNoch keine Bewertungen

- SK Pump: User GuideDokument98 SeitenSK Pump: User GuideThanhTung NguyenNoch keine Bewertungen

- Work Procedure For Touch Up Painting (Restoration)Dokument9 SeitenWork Procedure For Touch Up Painting (Restoration)ResearcherNoch keine Bewertungen

- Compact NSX Wiring Diagrams Under 40 CharactersDokument9 SeitenCompact NSX Wiring Diagrams Under 40 CharactersBojan KitanovskiNoch keine Bewertungen

- 201 18-NM8Dokument156 Seiten201 18-NM8iwanNoch keine Bewertungen

- ASMI-OSHMS-PR-04 - OSH Risk Management ProcedureDokument17 SeitenASMI-OSHMS-PR-04 - OSH Risk Management ProcedureJHUPEL ABARIALNoch keine Bewertungen

- Facade Wall ConstructionDokument12 SeitenFacade Wall ConstructionChoubi ChoubacaNoch keine Bewertungen

- COMAH Site-Prioritisation-MethodologyDokument11 SeitenCOMAH Site-Prioritisation-MethodologyDanny BoysieNoch keine Bewertungen