Beruflich Dokumente

Kultur Dokumente

Mangalore Tiles

Hochgeladen von

manisanusuyaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Mangalore Tiles

Hochgeladen von

manisanusuyaCopyright:

Verfügbare Formate

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 654 (1992): Clay Roofing Tiles, Mangalore

Pattern-Specification [CED 30: Clay and Stabilized Soil

Products for Construction]

lndian Standard

CLAY ROOFING TILES, MANGALORE

PATTERN -- SPECIFICATION

( Third Revision )

UDC 66674

0 BIS 1992

BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

March 1992

Price Group 4

( Reaffirmed 2002 )

Clay Products for Buildings Sectional Committee, CED 30

FOREWORD

This Indian Standard ( Third Revision ) was adopted by the Bureau of Indian Standards, after the

draft finalized by the Clay Products for Buildings Sectional Committee had been approved by the

Civil Engineering Division Council.

Clay roofing tiles of interlocking type, a particular pattern of which is known as Mangalore pattern

in the trade, are being manufactured in large scale in southern part of this country. The provision

in regard to the minimum quality requirements of these tiles was provided in this standard which

was first published in 1957 and revised in 1962. This second revision in 1972 contained provision

in regard to the uniformitv in colour and also the actual sizes of tiles. In this third revision, an

alternat!: method to determine breaking load of the tile has been included apart from incorporating

amendments to the standard so far.

The Sectional Committee responsible for the preparation of this standard has taken into

consideration the views of producers, consumers and technologists and has related the standard to

the manufacturing and trade practices followed in the country in this field.

For the purpose of deciding whether a particular requirement of this standard is complied with, the

final value, observed or calculated, expressing the result of a test, shall be rounded off in accordance

with1S 2 : 1960 Rules for rounding off numerical values (revised). The number of significant

places retained in the rounded otI value should be the same as that of the specified value in this

standard.

IS 654:1992

Indian Standard

CLAY ROOFING TILES,MANGALORE

PATTERN---SPECIFICATION

( Third Revision )

1 SCOPE 5.3 Shape

This standard covers the specification of

machine-pressed clay interlocking roofing tiles of

the Mangalore Pattern.

2 REFERENCES

When the roofing tile is placed on either face on

a plane surface, the gap at the corners shall be

not more than 6 mm.

5.4 Lugs

The Indian Standard is a necessary adjunct to

this standard.

5.4.1 Batten Lugs

IS No. Title

I S 2248 : 1991 Glossary of terms relating to

structural clay products ( second

revision ).

3 TERMINOLOGY

The tile shall have at least 2 batten lugs with base

thickness (thickness at bottom ) not less than 15

mm and thickness at top not less than 10 mm.

The projection from surface of the tile shall be

between 7 and 12 mm ( see Fig. 1 ).

For the purpose of this standard, the

definition of terms given in IS 2248 : 1991 shall

apply-

5.4.2 Eave Lugs

4 CLASSIFICATION

Roofing tiles, Mangalore Pattern, shall be of

two classes, namely Class AA and Class A and

shall be classified as per the characteristics as

specified in Table 1.

5 GENERAL QUALITY

The tile shall be at least 2 eave lugs with base

thickness not less than 15 mm and thickness at

top not less than 10 mm. The projection from

surface of lug shall be not less than 10 mm and

shall be shaped to fit into the corrugations

( see Fig. 1 ).

5.5 Corrugations and Cross Ribs

5.1 The roofing tiles shall be made from suitable

clay of even texture and shall be well burnt. They

shall be free from irregularities, such as twists,

bends, cracks and laminations.

The cross section of the roofing tile shall be such

as to give the tile structural rigidity. This

may be achieved by providing longitudinal

corrugations with intermediate cross ribs or

stiffeners ( see Fig. 1 ).

5.2 The roofing tile shall be free from impurities

like particles of stone, lime or other foreign

materials visible to the naked eye either on

the surface or on the fractured face of the

tile obtained by breaking the tile. However,

occasional particles up to 2 mm in size may be

permissible. When struck, the tile shall give a

characteristic ringing sound and when broken the

fracture shall be clean and sharp at the edges.

The Class AA tile shall be of uniform colour.

5.6 Tie Down Hole

At least one hole shall be provided in one of the

cross ribs near the eave end of the tile for securing

the tile to the reeper or batten with wire. The

hole shall be clear and true and shall be

not more than 2 mm in diameter, but shall be

large enough to pass a 16 mm wire easily

( see Fig. 1 ).

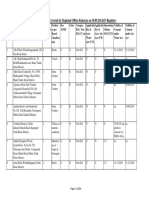

SI No.

i)

ii )

Table 1 Classification of Roofing Tiles

(Clauses4.1, 7.5.3, 7.5.4, 8.1 and8.3 )

Characteristic Requirement

r--___-- -------- h_____________~

Class AA Class A

Water absorption percent, A4trx 18 20

Breaking load, kN, Mix

a) Average 10 ( for 410x 235 mm ) 080 ( for 410X 235 mm )

110 ( for 420 x 250 mm 090 ( for 420 x 250 mm

and 425 x 260 mm ) and 425 x2601mm )

b) Individual 090 ( for 410 X 235 mm ) 068 ( for 410 x 23.5 mm )

100 ( for 420 x 250 mm 078 ( for 420x 250 mm

and 425 x 260 mm ) and 425 X 260 mm )

1

IS 654 : 1992

6 DIMENSIONS AND TOLERANCES

6.1 Dimensions

There shall be three sizes of tiles, with principal

dimensions as given in Table 2. The tolerances

in length and width are given in 6.2.

Table 2 Dimensions of Tiles

Sl No. Overall Length Overall Width

(1) (2) (3)

mm mm

i)

410 235

ii) 420 250

iii) 425 260

NOTE - If the maximum overlaps are kept, the tilt

at SI No. (i) is used for batten spacing up to 320 mm,

SI No. (ii) up to 350 mm and SI No. (iii) up to

360 mm. However by reducing suitably overlaps in

the tiles at SI No. (i) and (ii) these can also be used

for batten spacing up to 350 and 360 mm.

6.1.1. The minimum overlap ( see Fig. 1 ) shall

be 60 mm lengthwise and 25 mm widthwise for

each type of tiles.

SECTION YY PLAN FACE OF TILE

6.2 Tolerances

For measurement of variations in length/width of

tiles the difference between:

a) the overall length/width of three tiles

( measured in accordance with 6.2.1 ), and

b) the length/width of a tile;

is calculated and this value shall be within

the limits mentioned below:

FOF Tile Value for Value .for

Sizes Length Width

mm mm mm

410 x 235 630 to 650 410 to 430

420 x 250 670 to 690 420 to 440

425 x 260 690 to 710 430 to 450

6.2.1 Three tiles shall be selected at random from

the sample selected under 7.3. All blisters, loose

particles of clay and small projections shall be

removed. These shall be arranged upon a level

surface interlocked along length/widthwise on

straight line in tight position, and overall dimen-

sions are measured ( see Fig. 2 ).

OVERLAP

25 mm MIN

PLAN BACK OF TILE

---CORRUGATIONS

,- CROSS-RIB

-EAVES LUGS

FIG. 1 T,YPICAL DETAILS

2

OF MANGALORE TILE

IS 654:1992

2A ARRANGEMENT OF THREE flLES

LENGTHWISE IN TIGHT POSITION

28 ARRANGEMENT OF THREE TILES

BREADTHWISE IN TIGHT POSITION

FIG. 2 MEASUREMENT OF TOLERANCES

6.3 Weight

The average weight of the six tiles, when dried

at 105 to 110C to constant weight and weighed,

shall be not less than

2 kg and not more than

3 kg.

6.3.1 The weight of tile shall be noted correct to

the nearest 001 kg.

7 SAMPLING

7.1 The sample for testing shall be taken by the

purchaser or his representative or by any person

appointed to superintend the works for the

purpose of which the tiles are required or by the

latters representative.

7.2 Lot

In any consignment all the tiles of the same class

and size and from the same batch of manufacture

shall be grouped into a minimum number of lots

of 50 000 tiles or part thereof.

7.3 The number of tiles to be selected at random

from the lot shall depend upon its size and shall

be in accordance with co1 1 and 2 of Table 3.

7.4 Number of Tests

7.4.1 All the tiles selected as in 7.3 shall be

examined for shape ( see 5.3), dimensions ( see 6 )

and weight ( see 6.3 ).

Table 3 Sample Size and Criterion for

Conformity

( Clause 7.3 )

Lot Size

(1)

up to 3 000

3 001 to 10000

10001 to 35000

35 001 and above

Sample Size Permissible

Number of

Defective Tiles

(2) (3)

32 3

50 5

80 7

125 10

7.4.2 Eighteen tiles shall be selected out of those

already examined as in 7.4.1, six each for water

absorption test, breaking load test and

permeability test ( see 8 ).

7.5 Criteria for Conformity

7.5.1 The lot shall be considered as conforming

to the requirements of the specification if the

conditions mentioned under 7.5.2 to 7.5.5 are all

satisfied.

7.5.2 The number of tiles failing to satisfy

the requirements of any of the characteristics

mentioned in 7.4.1 shall not exceed the

corresponding number given in co1 3 of Table 3.

7.5.3 From the test results for water absorption,

the average ( x) and range ( R ) shall be

calculated. The value of the expressing

( X + 05 R ) shall be less than or equal to the

corresponding limit given in Table 1.

7.5.4 All the individual values of breaking load

shall be above the corresponding minimum value

specified for individual in Table 1. The average

of the six test results shall be above the correspond-

ing minimum limit specified for the average in

Table 1.

7.5.5 In the case of permeability test all the tiles

tested for permeability shall satisfy the require-

ments of the test.

8 STRENGTH REQUIREMENTS

8.1 Water Absorption Test

The water absorption of tiles shall conform to the

requirements laid down in Table 1, when deter-

mined in accordance with the procedure laid

down in Annex A.

8.2 Permeability Test

The tiles shall also be tested for permeability, if

so specified by the purchaser, in accordance with

the procedure laid down in Annex B.

8.2.1 The tiles shall be considered as satisfying

the test, if no water dripping is found at the

bottom of the tile after the test.

3

IS 654 : 1992

8.3 Breaking Load Test

The breaking load of tiles shall conform to the

requirements laid down in Table 1, when deter-

mined in accordance with the procedure laid

down in Annex C.

9 NON-COMPLIANCE WITH TESTS

If any of the roofing tiles in the samples fails

to comply with the requirements of any of the

tests specified in 8 another sample shall be

similarly drawn and tested. If any of the tiles in

the second sample also fails to comply with the

requirements of tests specified in 8 then the whole

lot from which the samples were taken be rejected

as not complying with this standard.

10 MARKING

10.1 Each roofing tile shall be legibly and

indelibly marked with the name of the manu-

facturer or his trade-mark, if any; the marking

shall not cover more than five percent of the area

of the specimen.

10.1.1 Each roofing tile may also be marked with

the Standard Mark.

ANNEX A

( Clause 8.1 )

WATER ABSORPTION TEST

A-l TEST SPECIMEN A-3 EVALUATION AND REPORT OF TEST

A-l.1 Six tiles shall be used for this lest from the

RESULTS

sample selected in the manner given under 7.

A-3.1 The percentage water absorption shall be

A-2 PROCEDURE

calculated using the following formula:

A-2.1 Dry the six tiles selected in an oven at a

Percentage absorption = A B-A x 100

temperature of 105 to 110C till they attaiu

where

constant weight and then cool and weigh. When

cool, immerse the dry specimens completely in

B = weight of the specimen after 24 h

clean water 24 to 30C for 24 h. Remove each

immersion in cold water, and

specimen, wipe off the surface water carefully with

A = weight of the dry specimen.

a damp cloth and weigh the specimen. Weigh the A-3.2 The average percentage water absorption

specimen nearest to a grain within three minutes of the six tiles shall be calculated and reported as

after removing the specimen from the tank. the percentage water absorption.

ANNEX B

( Clause 8.2 )

PERMEABILITY TEST

B-l TEST SPECIMEN

B-l.1 Six tiles shall be used for this test from the

sample selected in the manner given under 7.

B-2 APPARATUS

B-2.1 The test shall be conducted in a rectangular

trough ( see Fig. 3 ) which is open at bottom, the

dimensions at bottom being equal to the size of

the Mangalore Pattern tile. When the tile is kept

against its bottom, it shall be held in position

and the fitment shall facilitate easy plugging of

the space between the edges of the tiles against

leakage of water.

B-3 TEST PROCEDURE

B-3.1 The test shall be conducted at temperature

of 27 i- 2C and relative humidity of 65 + 5

percent.

B-3.2 The tile shall be fitted at the bottom of the

trough and the space between the tile and the

sides of the trough plugged water-tight with a

suitable material like wax, bitumen, etc.

FIG. 3 ARRANGEMENTS FOR PERMEABILITY TEST

B-3.2.1 Water shall be poured into the mould so

that it stands over the lowest tile surface to a

height of 5 cm.

B-3.3 The water in the trough shall be allowed to

stand for a period of six hours. The bottom of

the tile shall then be carefully examined to see

whether the water has seeped through the tile.

4

IS 654 : 1992

ANNEX C

( Cluuse 8.3 )

DETERMINATION OF BREAKING LOAD

C-l TEST SPECIMEN

C-l.1 Six tiles shall be used for this test from the

sample selected in the manner as given under 7.

C-2 APPARATUS

C-2.1 The apparatus ( see Fig. 4 ) shall consist of

two parallel self-aligning cylindrical steel bearers,

with the bearing surface rounded to 40 mm

diameter, so placed that the distance between the

centres could be altered. The load is applied

through a third ,steel bearer of similar shape

placed midway between and parallel to the

supports. The length of all the bearers shall

exceed the maximum width of the tile under test.

C-2.1.1 The loading device may consist of a bucket

connected either directly or through levers to the

loading arms. The loading shall be at a uniform

rate of 450 to 550 N/min by allowing lead s!rots

to flow into the bucket. Provision shall be made

to arrest the flow of lead shorts immediately the

tile breaks.

C-2.2 Alternatively, a suitably modified hand

operated compression testing machine with a

minimum load frame capacity of 10 tons may be

used ( see Fig. 5 ). In this system the bearer

assembly is mounted on a rigid mild steel plate

and the third central loading bearing is fixed

through a suitable dial micrometer ( least count

025 mm ) or an equally Sensitive devise to bear

on the loading member or on the specimen at mid

span. The specimen is supported on the bottom

parallel bearers separated by a distance of

minimum three-fourths ( 3/4 ) of the length of

the tile.

C-2.2.1 The error in the load reading shall not

exceed 22 N for loads upto 220 N and

for greater load, the error shall not exceed

I percent of the maximum load. The rate of

loading should be uniform and varv in the range

of 450-550 N/min ( 45 to 55 kg/min ).

C-3 PROCEDURE

C-3.1 Test, six tiles after soaking them in water

at 27 & 2C for 24 11, in the wet condition.

Support the tile evenly Ratwise on the bearers set

with a span of 25 cm and resting on the bottom

surface. Apply the load with the direction of

the load perpendicular to the span, at a uniform

rate of 450 to 550 N/min.

C-4 EVALUATION AND REPORT OF TEST

RESULTS

C-4.1 The individual breaking load of each of

the six tiles separately in wet condition shall be

recorded and the average calculated.

IS 654 : 1992

I i

EEVATION

.

P-

AU dimensions in millimetres.

FIG. 4 TILE TESTING MACHINE

6

IS 654:1992

X =SPAN AS PER TILE SIZE

i-

GOmm

-f

SECTION XY

J-----F

250mm P

1LOmm ---j

X

r I

cl-_-_

-

V

DETAIL OF BEARER A

X

I

I

-4 /-D

I /

I

cPlOmm

f

SECTION U v

DETAIL 0F &ARER

B

FIG. 5 ESSENTIALS OF APPARATUS FOR TRANSVERSE TEST

7

Standard Mark

The use of the Standard Mark 1s governed by the provisions of the Bureau oj- Indian

Standards Act, 1956 and the Rules and Regulations made thereunder. The Standard Mark on

products covered by an Indian Standard conveys the assurance that they have been produced

to comply with the requirements of that standard under a well defined system of inspection,

testing and quality control which is devised and supervised by BIS and operated by the

producer. Standard marked products are also continuously checked by BIS for conformity

to that standard as a further, safeguard. Details of conditions under which a licence for the

use of the Standard Mark may be granted to manufacturers or producers may be obtained

from the Bureau of Indian Standards.

Bureau of Indian Standards

BIS is a statutory institution established under the Bureau of Indian Standurds Act, 1986 to promote

harmonious development of the activities of standardization, marking and quality certification of goods

and attending to connected matters in the country.

Copyright

BIS has the copyright of all its publications. No part of these publications may be reproduced in

any form without the prior permission in writing of HIS. This does not preclude the free use, in the

course of implementing the standard, of necessary details, such as symbols and sizes, type or grade

designations. Enquiries relating to copyright be addressed to the Director ( Publications ), BIS.

Revision of Indian Standards

Indian Standards are reviewed periodically and revised, when necessary and amendments, if any, are

issued from time to time. Users of lndian Standards should ascertain that they are in possession of

the latest amendments or edition. Comments on this Indian Standard may be sent to BlS giving the

following reference :

Dot : No. CED 30 ( 4910 1

Amendments Issued Since Publication

Amend No.

Date of Issue

Text Affected

BUREAU OF INDIAN STANDARDS

Headquarters:

Manak Bhavan, 9 Bahadur Shah Zafar Marg, New Delhi 110002

Telephones : 331 01 31, 331 13 75

Regional Offices:

Central : Manak Bhavan, 9 Bahadur Shah Zafar Marg

NEW DELHI 110002

Eastern : l/14 C. I. T. Scheme VII M, V. I. P. Road, Maniktola

CALCUTTA 700054

Northern : SC0 445-446, Sector 35-C, CHANDIGARH 160036

Southern : C. I. T. Campus, IV Cross Road, MADRAS 600113

Western : Manakalaya, E9 MIDC, Marol, Andheri ( East )

BOMBAY 400093

Telegrams : Manaksanstha

( Common to all Offices )

Telephone

I 331 331 01 13 75 31

37 86 62

53 38 43

235 02 16

6 32 92 95

Branches : AHMADABAD. BANGALORE. BHOPAL. BHUBANESHWAR. COIMBATOKE.

FARIDABAD. GHAZIABAD. GUWAHATI. HYDERABAD. JAIPUR. KANPUR.

LUCKNOW. PATNA. SRINAGAR. THIRUVANANTHAPURAM.

Printed at Printrade, New Delhi, India

Das könnte Ihnen auch gefallen

- Advances in Ceramic Armor XIVon EverandAdvances in Ceramic Armor XIJerry C. LaSalviaNoch keine Bewertungen

- Is 1077 1992Dokument10 SeitenIs 1077 1992Prakash SharmaNoch keine Bewertungen

- Geotechnical Engineering: Testing ManualsVon EverandGeotechnical Engineering: Testing ManualsBewertung: 5 von 5 Sternen5/5 (1)

- Is 15622 2006 PDFDokument20 SeitenIs 15622 2006 PDFPatel SumitNoch keine Bewertungen

- Increasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionVon EverandIncreasing the Durability of Paint and Varnish Coatings in Building Products and ConstructionNoch keine Bewertungen

- Is 4253 2 2008Dokument14 SeitenIs 4253 2 2008Ashutosh SinghNoch keine Bewertungen

- Reinforced Concrete Buildings: Behavior and DesignVon EverandReinforced Concrete Buildings: Behavior and DesignBewertung: 5 von 5 Sternen5/5 (1)

- Disclosure To Promote The Right To InformationDokument11 SeitenDisclosure To Promote The Right To InformationAkshay SamadhiyaNoch keine Bewertungen

- Is 653 96 LinoleumDokument10 SeitenIs 653 96 LinoleumvpmohammedNoch keine Bewertungen

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsVon EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNoch keine Bewertungen

- Is.13630.1-5.2006 CERAMIC TILESDokument50 SeitenIs.13630.1-5.2006 CERAMIC TILESBattula SridharNoch keine Bewertungen

- Mechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingVon EverandMechanical Behavior of Organic Matrix Composites: Effect of Thermo-oxidative AgeingNoch keine Bewertungen

- Is 2180 1988Dokument6 SeitenIs 2180 1988Venugopalan ManaladikalamNoch keine Bewertungen

- The Fabrication of Materials: Materials TechnologyVon EverandThe Fabrication of Materials: Materials TechnologyBewertung: 5 von 5 Sternen5/5 (1)

- Is 1077 Common Burnt Clay Building BricksDokument7 SeitenIs 1077 Common Burnt Clay Building BricksKathiravan ManimegalaiNoch keine Bewertungen

- Durability Design of Concrete Structures: Phenomena, Modeling, and PracticeVon EverandDurability Design of Concrete Structures: Phenomena, Modeling, and PracticeNoch keine Bewertungen

- Is 10701 2012Dokument18 SeitenIs 10701 2012JGD123Noch keine Bewertungen

- Sewage Disposal Works: Their Design and ConstructionVon EverandSewage Disposal Works: Their Design and ConstructionNoch keine Bewertungen

- Clayroofingcounrrytiles, Half Roundandflattiles-SpecificationDokument8 SeitenClayroofingcounrrytiles, Half Roundandflattiles-SpecificationAnonymous i6zgzUvNoch keine Bewertungen

- Civil Engineering Structures According to the Eurocodes: Inspection and MaintenanceVon EverandCivil Engineering Structures According to the Eurocodes: Inspection and MaintenanceNoch keine Bewertungen

- Is 13712 2006Dokument10 SeitenIs 13712 2006kavi_prakash6992Noch keine Bewertungen

- Mechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesVon EverandMechanical Properties and Performance of Engineering Ceramics and Composites X: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesDileep SinghNoch keine Bewertungen

- Spiral Wound GasketsDokument7 SeitenSpiral Wound GasketsPrem NautiyalNoch keine Bewertungen

- Mangalore TilesDokument14 SeitenMangalore Tilesravi03121Noch keine Bewertungen

- Is 459Dokument10 SeitenIs 459AmbrishNoch keine Bewertungen

- IS:2201 (Part1)Dokument25 SeitenIS:2201 (Part1)greatpic100% (1)

- Disclosure To Promote The Right To InformationDokument17 SeitenDisclosure To Promote The Right To InformationIndira MukherjeeNoch keine Bewertungen

- Is 16162Dokument11 SeitenIs 16162Parthasarathi Paul100% (1)

- Is 1838 3 2011 PDFDokument12 SeitenIs 1838 3 2011 PDFjaianit89Noch keine Bewertungen

- IS 14246-1995 Galvalume SheetDokument10 SeitenIS 14246-1995 Galvalume SheetkumarchemNoch keine Bewertungen

- Is.1875 1992Dokument14 SeitenIs.1875 1992Sadashiva sahooNoch keine Bewertungen

- Is 15622-2006 PDFDokument17 SeitenIs 15622-2006 PDFravi03121100% (2)

- Disclosure To Promote The Right To InformationDokument8 SeitenDisclosure To Promote The Right To InformationdombipinNoch keine Bewertungen

- C 4 - 02 - QzqtmdiDokument6 SeitenC 4 - 02 - Qzqtmdimhamed1Noch keine Bewertungen

- C 56 - 96 (Reapproved 2001)Dokument3 SeitenC 56 - 96 (Reapproved 2001)Muhammad Ismail HafizhNoch keine Bewertungen

- Is 1659 2004Dokument26 SeitenIs 1659 2004bharathirajan964Noch keine Bewertungen

- Is 4990 2011 PDFDokument20 SeitenIs 4990 2011 PDFPratik DiyoraNoch keine Bewertungen

- 1659 Block BoardsDokument21 Seiten1659 Block BoardsmadhuwadiNoch keine Bewertungen

- Is 3115 - 1992 (Lime Based Blocks)Dokument8 SeitenIs 3115 - 1992 (Lime Based Blocks)satnam1979Noch keine Bewertungen

- BS 812-Part 113-90Dokument10 SeitenBS 812-Part 113-90anish_am2005Noch keine Bewertungen

- Is 6523Dokument21 SeitenIs 6523shilpsvsNoch keine Bewertungen

- IS13630-ceramic Tiles PDFDokument50 SeitenIS13630-ceramic Tiles PDFAlfia BanoNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument20 SeitenDisclosure To Promote The Right To InformationJGD123Noch keine Bewertungen

- 10646Dokument6 Seiten10646Richa JainNoch keine Bewertungen

- D351Dokument6 SeitenD351Mohamed Farag100% (1)

- Is 5454 Method For Sampling of Clay Building Brick R1.182104719Dokument9 SeitenIs 5454 Method For Sampling of Clay Building Brick R1.182104719hareenchNoch keine Bewertungen

- Is 4923 1997Dokument19 SeitenIs 4923 1997Akhil GargNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument23 SeitenDisclosure To Promote The Right To InformationSantosh KumarNoch keine Bewertungen

- 5766 PDFDokument9 Seiten5766 PDFDileep KumarNoch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument13 SeitenDisclosure To Promote The Right To Informationravisingh26591Noch keine Bewertungen

- Disclosure To Promote The Right To InformationDokument18 SeitenDisclosure To Promote The Right To InformationSantosh KumarNoch keine Bewertungen

- IS 2185 (Part 3) 1984Dokument18 SeitenIS 2185 (Part 3) 1984Nagaraju ChintaNoch keine Bewertungen

- Is - 4253-2004Dokument6 SeitenIs - 4253-2004Sahil AggarwalNoch keine Bewertungen

- Is 4031 6 1988Dokument11 SeitenIs 4031 6 1988HiteshAgarwalNoch keine Bewertungen

- 5369Dokument4 Seiten5369Parmod GodaraNoch keine Bewertungen

- Dimension of Sheets and Plate - Is.1730.1989 PDFDokument14 SeitenDimension of Sheets and Plate - Is.1730.1989 PDFArindamNoch keine Bewertungen

- Is 210Dokument16 SeitenIs 210Debopriyo GhoshNoch keine Bewertungen

- JLL Inland Port Marketing BrochureDokument4 SeitenJLL Inland Port Marketing Brochuremutton moonswamiNoch keine Bewertungen

- Szenario Study Logistics 2050 2Dokument184 SeitenSzenario Study Logistics 2050 2Ahmet BabayevNoch keine Bewertungen

- Planning Design and Estimation of A Ware HouseDokument72 SeitenPlanning Design and Estimation of A Ware Housemutton moonswami100% (1)

- Roland Berger Studie Global Logistics Markets Fin 20140820 PDFDokument49 SeitenRoland Berger Studie Global Logistics Markets Fin 20140820 PDFmutton moonswamiNoch keine Bewertungen

- Log ParkDokument92 SeitenLog Parkmutton moonswamiNoch keine Bewertungen

- EY The Indian Warehousing Industry An OverviewDokument17 SeitenEY The Indian Warehousing Industry An OverviewdjijNoch keine Bewertungen

- Trucking Perspectives Top100 0915Dokument17 SeitenTrucking Perspectives Top100 0915mutton moonswamiNoch keine Bewertungen

- Office, Retail, Industrial Complex: HighlightsDokument2 SeitenOffice, Retail, Industrial Complex: Highlightsmutton moonswamiNoch keine Bewertungen

- Industrial Warehouse Building: Project FeaturesDokument3 SeitenIndustrial Warehouse Building: Project Featuresmutton moonswamiNoch keine Bewertungen

- Warehouse Distribution Building: AvailableDokument2 SeitenWarehouse Distribution Building: Availablemutton moonswamiNoch keine Bewertungen

- Japanese FDI in IndiaDokument7 SeitenJapanese FDI in Indiamutton moonswamiNoch keine Bewertungen

- Light Industrial/Manufacturing Space: Building HighlightsDokument4 SeitenLight Industrial/Manufacturing Space: Building Highlightsmutton moonswamiNoch keine Bewertungen

- 009 103 209 Logistics-center-DevelopmentDokument24 Seiten009 103 209 Logistics-center-Developmentmutton moonswamiNoch keine Bewertungen

- Embassy Industrial Parks Web BrochureDokument11 SeitenEmbassy Industrial Parks Web Brochuremutton moonswamiNoch keine Bewertungen

- Burton Centrum 415Dokument6 SeitenBurton Centrum 415mutton moonswamiNoch keine Bewertungen

- List of Organisations Covered by Regional Office-Kolar (As On 30.09.2014) (F-Register)Dokument284 SeitenList of Organisations Covered by Regional Office-Kolar (As On 30.09.2014) (F-Register)mutton moonswamiNoch keine Bewertungen

- NTC2014 SU R 06 - ListDokument57 SeitenNTC2014 SU R 06 - Listmutton moonswamiNoch keine Bewertungen

- A Review of The Indian Logistics Industry and Policy: Rhitam DasDokument55 SeitenA Review of The Indian Logistics Industry and Policy: Rhitam Dasmutton moonswamiNoch keine Bewertungen

- Reasearh Doc 1Dokument4 SeitenReasearh Doc 1mutton moonswamiNoch keine Bewertungen

- Designing Eco-Industrial Parks: The North American Experience Ed Cohen-RosenthalDokument16 SeitenDesigning Eco-Industrial Parks: The North American Experience Ed Cohen-Rosenthalmutton moonswamiNoch keine Bewertungen

- Imp Doc On LogisticsDokument13 SeitenImp Doc On Logisticsmutton moonswamiNoch keine Bewertungen

- Pressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedVon EverandPressure Vessels: Design, Formulas, Codes, and Interview Questions & Answers ExplainedBewertung: 5 von 5 Sternen5/5 (1)

- Principles of Welding: Processes, Physics, Chemistry, and MetallurgyVon EverandPrinciples of Welding: Processes, Physics, Chemistry, and MetallurgyBewertung: 4 von 5 Sternen4/5 (1)

- Real Life: Construction Management Guide from A-ZVon EverandReal Life: Construction Management Guide from A-ZBewertung: 4.5 von 5 Sternen4.5/5 (4)

- A Place of My Own: The Architecture of DaydreamsVon EverandA Place of My Own: The Architecture of DaydreamsBewertung: 4 von 5 Sternen4/5 (242)

- The Aqua Group Guide to Procurement, Tendering and Contract AdministrationVon EverandThe Aqua Group Guide to Procurement, Tendering and Contract AdministrationMark HackettBewertung: 4 von 5 Sternen4/5 (1)

- Building Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesVon EverandBuilding Physics -- Heat, Air and Moisture: Fundamentals and Engineering Methods with Examples and ExercisesNoch keine Bewertungen

- 1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideVon Everand1,001 Questions & Answers for the CWI Exam: Welding Metallurgy and Visual Inspection Study GuideBewertung: 3.5 von 5 Sternen3.5/5 (7)

- The Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyVon EverandThe Complete Guide to Building With Rocks & Stone: Stonework Projects and Techniques Explained SimplyBewertung: 4 von 5 Sternen4/5 (1)

- How to Estimate with RSMeans Data: Basic Skills for Building ConstructionVon EverandHow to Estimate with RSMeans Data: Basic Skills for Building ConstructionBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AVon EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANoch keine Bewertungen

- Civil Engineer's Handbook of Professional PracticeVon EverandCivil Engineer's Handbook of Professional PracticeBewertung: 4.5 von 5 Sternen4.5/5 (2)

- Sustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsVon EverandSustainable Design and Build: Building, Energy, Roads, Bridges, Water and Sewer SystemsNoch keine Bewertungen

- The Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialVon EverandThe Complete HVAC BIBLE for Beginners: The Most Practical & Updated Guide to Heating, Ventilation, and Air Conditioning Systems | Installation, Troubleshooting and Repair | Residential & CommercialNoch keine Bewertungen

- Starting Your Career as a Contractor: How to Build and Run a Construction BusinessVon EverandStarting Your Career as a Contractor: How to Build and Run a Construction BusinessBewertung: 5 von 5 Sternen5/5 (3)

- The Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsVon EverandThe Complete Guide to Alternative Home Building Materials & Methods: Including Sod, Compressed Earth, Plaster, Straw, Beer Cans, Bottles, Cordwood, and Many Other Low Cost MaterialsBewertung: 4.5 von 5 Sternen4.5/5 (6)

- Building Construction Technology: A Useful Guide - Part 1Von EverandBuilding Construction Technology: A Useful Guide - Part 1Bewertung: 4 von 5 Sternen4/5 (3)

- Piping Engineering Leadership for Process Plant ProjectsVon EverandPiping Engineering Leadership for Process Plant ProjectsBewertung: 5 von 5 Sternen5/5 (1)

- Estimating Construction Profitably: Developing a System for Residential EstimatingVon EverandEstimating Construction Profitably: Developing a System for Residential EstimatingNoch keine Bewertungen

- Practical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsVon EverandPractical Guides to Testing and Commissioning of Mechanical, Electrical and Plumbing (Mep) InstallationsBewertung: 3.5 von 5 Sternen3.5/5 (3)

- The Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseVon EverandThe Complete Guide to Building Your Own Home and Saving Thousands on Your New HouseBewertung: 5 von 5 Sternen5/5 (3)

- Fire Protection Engineering in Building DesignVon EverandFire Protection Engineering in Building DesignBewertung: 4.5 von 5 Sternen4.5/5 (5)

- Woodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsVon EverandWoodworking: 25 Unique Woodworking Projects For Making Your Own Wood Furniture and Modern Kitchen CabinetsBewertung: 1 von 5 Sternen1/5 (4)