Beruflich Dokumente

Kultur Dokumente

Sis Global Forum 2014 Abstracts

Hochgeladen von

ArmandoEsquivel0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

486 Ansichten223 SeitenThis document contains summaries of several presentations on topics related to oil and gas exploration and production. The summaries are:

1) One presentation discusses using high-density, full-azimuth seismic surveys calibrated with well log data to characterize thin, tight sand reservoirs in the Sichuan Basin of China. This improved seismic characterization allowed for delineation of hydrocarbon-bearing sand channels.

2) Another presentation outlines how to transition from an aging subsurface interpretation platform to a modern one with minimal disruption to exploration and development activities. It emphasizes factors like corporate capability, operating processes, and data management.

3) A third presentation discusses challenges in characterizing deep water reservoirs in the Gulf of Mexico for PEMEX, including modeling thin

Originalbeschreibung:

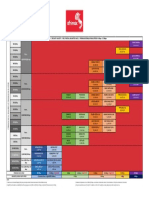

Services that Schlumberger Information Systems has to provide with examples of applications.

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis document contains summaries of several presentations on topics related to oil and gas exploration and production. The summaries are:

1) One presentation discusses using high-density, full-azimuth seismic surveys calibrated with well log data to characterize thin, tight sand reservoirs in the Sichuan Basin of China. This improved seismic characterization allowed for delineation of hydrocarbon-bearing sand channels.

2) Another presentation outlines how to transition from an aging subsurface interpretation platform to a modern one with minimal disruption to exploration and development activities. It emphasizes factors like corporate capability, operating processes, and data management.

3) A third presentation discusses challenges in characterizing deep water reservoirs in the Gulf of Mexico for PEMEX, including modeling thin

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

486 Ansichten223 SeitenSis Global Forum 2014 Abstracts

Hochgeladen von

ArmandoEsquivelThis document contains summaries of several presentations on topics related to oil and gas exploration and production. The summaries are:

1) One presentation discusses using high-density, full-azimuth seismic surveys calibrated with well log data to characterize thin, tight sand reservoirs in the Sichuan Basin of China. This improved seismic characterization allowed for delineation of hydrocarbon-bearing sand channels.

2) Another presentation outlines how to transition from an aging subsurface interpretation platform to a modern one with minimal disruption to exploration and development activities. It emphasizes factors like corporate capability, operating processes, and data management.

3) A third presentation discusses challenges in characterizing deep water reservoirs in the Gulf of Mexico for PEMEX, including modeling thin

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 223

RAISING EXPECTATIONSQUANTITATIVE UNCONVENTIONAL RESERVOIR

CHARACTERIZATION ENABLED BY BREAKTHROUGH SEISMIC TECHNOLOGY

Presented by J. Quigley (Schlumberger)

In recent years thin, tight reservoirsboth sand and carbonatehave represented two

important types of hydrocarbon exploration and development targets in Jurassic strata in

central, northwest, and northeast areas of the Sichuan Basin. Most production from these

onshore areas has been closely associated with numerous small faults, fracture corridors,

and micro-cracks in thin carbonate layers; and in high-porosity zones in tight, thin sand

bodies. With reserve estimates for the Sichuan Basin most likely higher than current

estimates, demand for increased production from the area has made it imperative to perform

reservoir characterization with the highest possible accuracy.

This presentation discusses a case study in which seismic characterization of Sichuan thin,

tight sand reservoirs was dramatically improved through use of a state-of-the-art, high-

density, full- azimuth, point-receiver land seismic survey, calibrated with well log data. The

method used involved a comprehensive data-processing sequence utilizing algorithms

developed for the high- density, full-azimuth applications. Quantitative reservoir

characterization was achieved by well log data correction, rock physics analysis,

simultaneous amplitude-versus-offset (AVO) inversion and lithology identification.

Specifically, we have been able to successfully delineate the geometry of the hydrocarbon

bearing sand channels. Quantitative multiscale fracture characterization was also achieved

by simultaneous azimuthal AVO (AVOaz) inversion and seismic post-stack ant-tracking. The

resultant dataset has provided a radically different view of the subsurface reservoir that was

previously unseen and will enable future drilling decisions.

HOW TO IMPLEMENT A SUBSURFACE INTERPRETATION SYSTEM WHILST MINIMISING

BUSINESS IMPACT

Presented by D. Hodgson (Woodside)

Making the decision to move from an ageing subsurface interpretation platform to a modern

platform with additional benefits is a relatively easy decision to make. Moving from the old to

the new however is not straightforward and is something E&P companies will typically

undertake once every 10-20 years. Changing the software applications is just one element of

change needed to successfully complete the move. Other factors such as corporate

capability, operating processes and supporting technology are key ingredients. Moving the

mountain of corporate data is not a simple cut and paste exercise.

How do you make such a transition without major disruption to Exploration and Development

activities and allow users to deliver on work commitments. This presentation will highlight the

key ingredients needed to make a successful transition to Petrel and Studio applications with

a particular focus on Geoscience and best practices in data management.

RESERVOIR CHARACTERIZATION DEEP WATER WELLS (20112013)

Presented by T. Martinez (Pemex)

New challenges in Deep Water Reservoirs are facing in PEMEX Activo de Exploracin

Aguas Profundas Norte (AEAPN) with the need to incorporate new oil reserves that

contribute to the production that Mexico requires. In order to accomplish this goal an

accurate Reservoir Characterization is need it for reserve certification, a large amount of

information such as logs and cores from new Wells, 3D high-resolution seismic, 3D EM data,

making cutting edge technological solutions necessary.

Inside Perdido fold belt area are the first successful wells for AEAPN and the first oil

producers on Depth Water environment in all Mexico. The Structural and Stratigraphic

complexity encounter on these fields required a Characterization Model able to reproduce

thin layers geological behavior in order to be representative by 3D model in an accurate

way, challenging the number of cells necessary modeling the fast variation of petrophysical

properties on vertical direction.

Create 3D models with enough level of detail considering that areas to be modeled are

around 1000 km bring new challenges to handle the number of cells necessary modeling

the New Reservoirs, making necessary the combination of Technology in software and

software as well as advance geological knowledge.

PEMEX Need to incorporate New Reserves bring an opportunity for Characterization group

to innovate the way that 3D Reservoir Models are build it, using the same Technology

across the life of the well, starting the characterization preparation phase together with

well drilling surveillance and updating this model as new data arrives from well, reducing

the amount of time need it to deliver a reserve certification when well is finished, the

successful way to achieve this it with the precise combination between Technology and

People knowledge, that will be described on this Document.

INTEGRATED PLAY AND PROSPECT ASSESSMENT IN EXPLORATION

Presented by A. Acevedo (Schlumberger)

The most critical decisions in exploration aim to answer three questions: which acreage to

acquire, which prospect to drill first, and where to drill the first well on each prospect.

Traditionally, the answers are based on geological interpretation, risk assessment, and economic

evaluation of exploration projects. However, often these assessments are performed by different

teams and by using disconnected technology. The latter leads to issues with time efficiency and

more critically, may lead to decisions taken out of context. We introduce an integrated play to

prospect risking approach. This empowers you to perform full geological evaluations linked to

maps, interpretations, and the risked economic models, while remaining spatially referenced.

MITIGATING GEOMECHANICAL RISKS IN YOUR ASSETS

Presented by A. R. Herrera (Schlumberger)

Many reservoirs in the world can experience geomechanical issues. These can affect the

reservoir drive mechanism, create damaging stresses on wells, and potentially breach the cap

rock of the reservoir. This demonstration will show how a combination of the Petrel and Techlog

platforms, and the Eclipse and Visage simulators are used to address and mitigate these risks

through the use of mechanical earth models coupled to reservoir simulators. It will be shown that

reservoir performance can be more realistically evaluated, the risks to long-term well

survivability identified, and a drainage strategy created to reduce the strain on the cap rockall

during the field-development phase.

A 4D GEOMECHANICS SOLUTION APPROACH TO NATURAL FRACTURE PREDICTION IN

OPERATION

Presented by Xavier Legrand (PETRONAS)

Since the Seventies, Exploration and Production challenges in Sundaland regularly lead to

improved understanding of its tectonic setting. According to land-based geologists this region

was previously considered as tectonically stable and did not exhibit any evidence of far-field

deformation. Currently, the Malay basin located East offshore of the Malay Peninsula is known to

have undergone a succession of major tectonic events. The basin originated in the Late

Cretaceous and was developed through structural changes consistent with a polyphase

extrusion model and displacements in which India has successively pushed Sundaland

(Tapponnier et al., 1986). Initially, the extrusion imparted sinistral transtensional wrenching on the

axial basement fault along the basin length. In post Mid-Miocene, wrench slip reversal produced

transpression, accompanied by a positive structural inversion. At present day, this complex

tectonics confers to the basin a singular fracture model through time.

A natural fracture prediction (NFP) study is used to depict the fracture model associated with the

tectonic calendar. An innovative geomechanically-based methodology describes the different

steps to reduce uncertainty in the natural fracture zone assessment both in estimating (i) the

paleo-geometry of the structures from a 2D & 3D geomechanics-based reconstruction (Maerten

and Maerten, 2006) and (ii) the paleo-tectonic stresses, recovered by a fracture clustering based

on Andersons theory of faulting (Anderson, 1942), and used in the geomechanical simulations

from the inversion technology (Maerten, 2010). As a consequence, the understanding of the

reservoir characterization was greatly improved.

References

Anderson, E. M. [1942] The dynamics of faulting and dyke formation: with applications to Britain. Nature,

149, 651-652.

Maerten, F. [2010] Geomechanics to solve geological structure issues: forward, inverse and restoration

modeling: Ph.D. thesis, page 450, University of Montpellier II, Montpellier, France.

Maerten, L. and Maerten, F. [2006] Chronologic modelling of faulted and fractured reservoirs

using geomechanically based restoration: Technique and industry applications. AAPG Bulletin, 90, 1201-

1226.

Tapponnier, P., Peltzer, G. and Armijo, R. [1986] On the mechanics of the collision between India and

Asia. From Coward, M. P. & Ries, A. C. (eds), 1986, Collision Tectonics. Geological Society Special

Publication, 19, 115-157.

PRODUCTION AND INJECTION MONITORING AND

SURVEILLANCE MYSIP

Presented by O. Agudelo

(Ecopetrol)

The Casabe Technology Alliance between Ecopetrol and Schlumberger started its

operation in 2004 in Casabe field. The field came originally into production several

decades ago and by 2004 was producing close to 5,000 BOPD.

The alliance went into a re-development of the field with an aggressive strategy to

increase Oil production through selective water injection for secondary recovery. The

re-development considered a significant increase of producing and selective injector

wells, something that poses a challenge in terms of injection and production data

handling, engineering worklfows for better decision making.

Casabe Alliance decided to implement an integrated operation decisional system for

supporting key production and operational business processes bringing to end-users the

right information at the right time for better decision. The scope includes not only

automation of some business processes along with the underlying system but also the

business change management activities for managing the change.

This project consists in adjusting operational processes, in providing different

component to implement as:

1. Component 1: Data Management

Data consolidation and creation of only one and unique data

source of information for CASABEs asset historical production.

2. Component 2: to-be Production business processes and mapping of information

flows.

Analyze and document the current injection / production process,

which allow identify improvements related to data management

3. Component 3: Production information and engineering workflows Management

Expert Automatic System Intelligent workflows based on

pattern recognition.

Data visualization and alarms generation.

Link operational Data Base with the other applications

Ensure data quality for the follow up and

analysis. The key benefits for the Casabe Alliance are:

Decision making process Improvement that should impact OPEX

(reduction) and Production (increase)

Protect the historical data: Accessibility, tracking , integration of in a timely

manner

Surveillances focus in production and Injection wells (manifolds)

Effective water flooding control

Timely decision from current and reliable information

Data transfer to internal and external applications with limited human manipulation

MODELLING AND OPTIMISATION OF GAS STORAGE AND PRODUCTION SYSTEMS

Dr Bishop Falope (PetroFlow)

Gas production, storage and injection facilities are an economical way to sell gas when price

is right and store when prices are unfavourable. Operating a gas production and injection

system combines the challenges normally associated with wet gas production i.e. hydrate and

liquid management, with the need to be able to switch from production to injection modes to

at short notice. In order to simplify the complexity associated with operating such facilities,

operators adopt simply and easy to follow procedures. This however comes at the expense of

optimal operation due to the adoption of very conservative criteria.

This paper presents the use of OLGA for simulating the operation of a production-injection

facility using compositional tracking. The model was constructed to allow production and

injection to be modelled with a single model and was benchmarked against transient

operating data provided by the client. The remarkable representation of the facilitys operation

by the model led to its use for significantly simplifying the operating procedures and allowing

decisions to be made more easily and cost effectively. The model was further used as a virtual

temperature sensor taking the place of a damaged sensor.

The results of this analysis show how the full benefit of simulation can be realised for

operations support, asset performance optimisation and cost saving.

PETROLEUM PROSPECTIVITY OF PAKISTAN WITH SPECIAL REFERENCE TO EXPLOITATION

OF UNCONVENTIONAL HYDROCARBON RESOURCES AND ITS CURRENT STATUS

Presented by Moin R. Khan (Pakistan Petroleum Limited)

The presentation will give an overview of Pakistans existing E&P scenario vis--vis its vast

sedimentary basins and the huge conventional and unconventional hydrocarbon potential these

basins offer.

The global energy scenario has been evolving with declining production in the face of rising

demand for both oil and gas. As a result, reserves replacement ratios are going down and

currently stand at less than 50 percent. This means that the current global trend in energy supply

and demand is patently unsustainable. In addition, the gradually rising gap between demand and

supply of oil is filled mostly by gas and, more recently, unconventional energy resources. At the

projected growth rate, the world will need to find new reserves, ensuring additional production to

the tune of 42 MMboepd by 2035 on account of depleting reserves from large fields, both new and

old, and future growth requirements.

Pakistans Exploration and Production scenario is not very different despite the fact that energy

consumption in the country has grown at an average rate of over 5 percent per year during the

last 15 years, which is one-third of the world average. As such, the country is struggling to meet

growing energy demand in the face of fast-depleting oil and gas reserves, high oil prices and

escalating capital costs.

Since 2006 2007, energy supply has been unable to fulfill demand. And as new reserves have

not been discovered at the desired rate, the gap is continually rising. So far, 56 Tcf of gas and

about a billion barrels of oil have been discovered in 242 oil and gas fields through 780 exploration

wells with a success ratio of 1: 3.3 wells, which is very high compared to world standards.

The trend for Pakistans oil and gas discoveries called the creaming curve indicates that size of

discoveries is progressively decreasing despite an increase in success ratios resulting in a large

number of discoveries. However, this creaming curve represents only that part of the country

where exploration activities have been focused. Drilling of 780 Exploration wells in a sedimentary

area of over 800,000 Sq. Km is too little by any standard.

This makes it imperative to accelerate the exploration efforts for both conventional and

unconventional resources to meet present and future energy supply challenges. This is to say

that exploration for unconventional hydrocarbon reserves, which is an integral part of the energy

mix in North America, a game changer in that region, and on which very little concrete work has

been done in Pakistan, deserves special attention.

As such, increased focus is required on unconventional reserves such as tight and shale gas to

meet present and future energy supply challenges. This is to say that exploration for

unconventional hydrocarbon reserves, which is an integral part of the energy mix in North

America, a game changer in that region, and on which very little concrete work has been done in

Pakistan, deserves special attention. Quite developed in North America, this is an emerging play

type in the rest of the world and holds great promise for Pakistan too. The North American model

can be replicated in Pakistan if an operational synergy and the economies of scale is created.

If 56 Tcf and one billion barrels of conventional gas and oil reserves respectively have been

discovered, there has got to be organic rich shales (known to be of Early Cretaceous and

Paleocene age) that have generated at least 10 times that much gas/oil, 50% of which would have

been retained by these rocks. Based on conservative estimates, unconventional reserves of Tight

and Shale gas in the country stand at about 100 Tcf. Similarly there are known tight gas reserves

of 38 Tcf that needs immediate exploiting, while the potential reserves estimates are close to 100

Tcf. Shale gas is expected to be associated with Shale Oil. This is clearly not the kind of statistics

that we can afford to overlook any longer if we are to ensure the countrys future energy needs.

To this end, it is imperative for geoscientists, petroleum engineers, service providers and policy

makers to strategize together and chalk out the roadmap for a way forward.

ROCK PHYSICS & SEISMIC INVERSION TO CHARACTERIZE A TIGHT GAS SAND

Presented by Jorge I. Adrian (PetroSA)

A reservoir is exposed to a great number of analyses in all stages of its active life (exploration-

appraisal-development-enhanced recovery) in order to optimize the asset value and to reduce

the uncertainly of geological and production factors. Seismic data has come to rule an essential

role in this process. However, seismic has a limitation: It represents an interface property,

instead of a rock property, so in principle the seismic data is inverted into a volume of elastic

properties such as Acoustic Impedance, VP/VS, etc. The remaining challenge is to understand

the elastic response to changes in petrophysical properties (porosity, lithology, hydrocarbon

saturation, etc.). In order to address this dilemma, rock physics modelling has been undertaken.

The broad objective of this presentation is to show a methodology to characterize in PETREL a

tight Gas Sand reservoir based on 2-main steps:

(a) To perform in situ and perturbational log derived rock physics forward modelling to

understand the effect of varying fluid fill, porosity, clay content and thickness; and study

the AVO attribute responses to help determine which, if any, AVO attributes or cross plot

products may be useful to discriminate between pay vs wet targets or lower and higher

porosity, etc.

(b) To invert seismic reflection data into quantitative elastic-properties (Pre-stack inversion)

to sufficiently differentiate geological features with similar P-impedance signatures. This

method uses multiple angle seismic partial stacks and their associated wavelets as input

to generate P-impedance, S-impedance and density as outputs.

The study area is situated off-shore South Africa, in water depths of less than 200 m. The target

reservoir is the Early Valanginian gas bearing sandstones in the Upper Shallow Marine unit.

OVERVIEW OF THE CHALLENGES TO EXPLORATION POSED BY DEEPWATER SHALLOW HAZARDS AND

SALT IN THE ATLANTIC BASIN

Presented by J. Dribus (Schlumberger)

At the end of the Permian Period over 250 million years ago, the supercontinent of Pangea began to be rifted into

the smaller continents we are familiar with today forming the Gulf of Mexico and then the greater Atlantic Ocean

basin. This talk reviews the geologic evolution of the Atlantic basin and the filling of parts of the basin margins by

layered evaporate complexes in Brazil and across the conjugate margin in Angola, and massive halite deposits

within the Gulf of Mexico.

This talk also reviews several of the key exploration challenges posed by shallow hazards in the deepwater

operating environments, and discusses additional drilling hazards created by massive salt and layered

evaporates, including possible problems drilling into, through, and out of salt (such as cap rock, inclusions,

rubble zones, and feeders).

WELL PLANNING AND RELIEF WELL SIMULATION

Presented by S. Forsyth (Schlumberger)

Designing wells in the Petrel E&P software platform has changed, with new trajectory algorithms,

a user-friendly design interface, and driller-friendly spreadsheets. Trajectory uncertainties

associated with surveying equipment have also been implemented, taking well design to the next

level.

Relief well simulation focuses on the new screening facility available in the Petrel platform for

relief wells, using the pumping, trajectory, construction, and mud parameters to perform a

dynamic multiphase simulation to assess the outcome of the well kill operation, before the

original well is even drilled.

IMPACT OF SUBSURFACE AND SURFACE MODELING FORECASTING PRODUCTION

Presented by D. L. Clements (Schlumberger)

The cost of deepwater wells reduces the number of appraisal wells drilled. Therefore, when

developing a deepwater field, the information collected in the reservoir may be limited. This

demonstration will examine how the uncertainty in the reservoir will impact the field.

ADVANCES IN STRUCTURAL INTERPRETATION

Presented by G. Van Der Hoff (Schlumberger)

Structural interpretation of the subsurface is a fundamental process in the E&P lifecycle, as

accurate interpretation of geological structures are the building blocks for velocity modeling,

property modeling, assessment, and risk analysis of hydrocarbon volumetrics. In complex

geological regimes, making a fast and confident structural interpretation is a significant

challenge.

In this presentation we will demonstrate how advanced structural interpretation in the 2014

release of the Petrel E&P software platform redefines conventional structural interpretation

workflows by efficiently combining manual and automatic interpretation approaches,

complimented with comprehensive QC tools to easily correct wrong interpretation in a user

environment that delivers a step change in productivity.

Most importantly, tectonic and depositional relationships can be incorporated through interactive

seismic reconstruction based on geomechanical principles, followed by modeling-while-

interpreting, which provides a powerful tool for fast and accurate interpretation. This reduces

interpretation uncertainty and delivers a confident, validated structural framework of the

subsurface that can be used directly in subsequent workflows such as property and fracture

modeling, as well as volumetric workflows.

DEVELOPING ASSETS: AN INSIGHT INTO HIGH-RESOLUTION MODELING

Presented by J. Quijano (Schlumberger)

The industry is developing many complex fields, which require a large amount of capital

investment and often do not perform as expected or are delivered behind schedule. Today, there

is a greater understanding of the structure, geology, and fluids. This presentation will show how

the INTERSECT high-resolution reservoir simulator uses this greater understanding to provide

more accurate forecasts of recoverable reserves, production forecasts, and fluid breakthrough,

which form the essential cornerstone to developing complex fields.

UNCERTAINTY TO ECONOMICS: INTEGRATING DYNAMIC SIMULATION AND ECONOMIC

MODELLING TO MAKE BETTER DECISIONS

Presented by Russell Julier (BG Group)

A Petrel RE to PEEP plug-in has been developed by BG Group in partnership with

Schlumberger to allow project cost, subsurface and economic uncertainties to be considered

in a single integrated environment.

The presentation will demonstrate an end-to-end Uncertainty to Economics workflow that

integrates Schlumbergers Petrel RE and Eclipse products with the Schlumberger Meraks

PEEP product. Discuss why BG Group developed the workflow and supporting plug-in and the

advantages the workflow brings to the assessment of uncertainty and decision making.

The widespread implementation of multi-realisation geological and reservoir simulation

software has transformed the subsurface workflows used of many operators. The ability to

incorporate uncertainty and multiple alternate subsurface realisations has allowed a better

understanding of the resource risk profiles associated with new opportunities to be

developed. This is particularly important during the appraisal and pre-sanction development

phases where the ability to create value is at its greatest.

However, much information is lost when relatively few discrete cases from the full resource

distribution are taken forward for detailed economic analysis allowing only a partial view of a

project NPV risk profile to be created and preventing the economic impact of many

uncertainties to be fully considered.

The incorporation of an economic model within an automated workflow potentially offers a

significant improvement in both quantity and quality of information available to decision

makers by allowing the many more realisations to be evaluated economically and the full risk

NPV risk profile to be described.

This integration is achieved by the near concurrent running of multiple realisation Petrel RE

static and dynamic models together with the PEEP economic model to calculate economic

KPIs using the Plug-in.

Subsurface, Project (Cost) and Commercial (Price) uncertainties can be considered within a

single environment to provide multiple discrete NPV values for sensitivity, decision tree

analysis and Monte Carlo analysis.

The automated use of existing PEEP economic models via the Petrel RE-PEEP plug-in thus

offers increased efficiency, better understanding and improved decision making.

HOW TO BUILD A DATA MANAGEMENT PROGRAMME

Presented by Fabio Feneri (Eni)

It is well known that the maintenance of quality information leads to a higher probability of

finding hydrocarbon reserves and a reduced cycle time. As part of our on-going cycle of

continuous improvement eni recently commissioned Schlumberger to assess the overall

management of corporate data across the global exploration function. This assessment

detailed processes and workflows in the headquarters, in selected affiliates and in the way

those entities interact.

Following on from the recommendation made by Schlumberger in the assessment eni are now

on course to re-engineering several of our global processes with a view to providing an

overall increase in efficiency and of improving information quality world-wide.

STUDIO CUSTOMIZATION, IMPLEMENTATION AND CHALLENGES

Presented by D. Aziz (Petronas)

In 2010, PETRONAS has defined Petrel as their foundation platform for G&G and RE community.

This is to ensure the flow of information will be on the same platform, from seismic to reservoir.

The amount of information and knowledge that travels through the eco-systems are enormous.

The needs to streamline data management workflows and capturing knowledge - has to be done

via Studio.

PETRONAS started to access Studio back in late 2012 and the deployment started 6-months later.

Studio has to be designed to suit the three main PETRONAS E&P business units Explorations,

Development & Regulator. The deployment involves development of process to streamline data

workflows, managing users and data.

This paper will illustrate the journey that PETRONAS undertake to adopt Studio in its organization,

as well as, highlighting some of the challenges facing the team.

OUR G2 E4 UNCONVENTIONAL FIELD DEVELOPMENT METHOD

Presented by Steve Geetan (EP Energy Corporation)

In todays fast cycle Unconventional field development, the drilling and completion design steps

are mostly done independent of a 3D geological model or a deformable 3D geomechanical model.

Dynamic reservoir simulation is commonly done using models not informed by a well constrained

geologic model and when done are mostly single well simulations due to the computational cost

in simulating a multi-well fracture volume. Moreover when available, the geomodels are normally

built after the drilling and completion of the important pilot phases of an unconventional

development. These disconnect among the key disciplines causes a disruptive learning cycle

which can easily erode value.

The G2 E4 workflow starts with a geologic property model and a discrete fracture network (DFN)

using seismic and or well centric data (image logs, core, and specialized gas logs such as

helium). These results then feed the 3D Mechanical Earth Model (MEM) where the DFN features

are used to perturb the wellbore scale stress field. Using observations from the drilling

experience, the completions hydraulic fracture treatment pressures and the effects of producing

the reservoir over time we can calibrate the model through many feedback loops improving its

reliability even when initially built with measurements that have high uncertainty. This is achieved

by fast numerical simulation allowing many calibrating experiments to be performed when

selecting the geomechanical parameters.

The resulting 3D MEM allows us to build multi-well models providing significant insights into well

interference, order of fracturing wells and stage spacing by numerical simulation of the evolving

stress field. This method provides a strong link between the geoscientists and engineers allowing

all observations to be integrated, bridging the gap among these disciplines and improving chance

of success.

ASSET OPTIMIZATION SOLUTIONS TO ENHANCE RATES, RECOVERY, AND EFFICIENCIES

Presented by Kirk Pitts (Schlumberger)

In field development planning, the best industry practice is an integrated asset approach. The

same best practice applies in the production phase, in which the aim is to maximize value

extraction. This is done through asset optimization, which means simply doing better tomorrow

than is being done today. This involves making decisions to improve field performance in a live

operating environment, in which software is connected to the field to better understand the

surface/subsurface.

However, asset optimization is more than just technology: it is the ability to see online

information, to understand the state of the field, and to use software systems to analyze and make

the right decisions to improve recovery and hit target ratesefficiently. This presentation will

cover the asset optimization offering from Schlumberger. It will expand on how our multifaceted

approach integrates technology, information, people, processes, and organization to maximize

asset production performance with a balanced view across the entire hydrocarbon pathway.

BUILDING GEOLOGICAL MODELS IN EXTENSIONAL AND COMPRESSIONAL SETTINGS

Presented by C. Chahine (Schlumberger)

The simplest structural and stratigraphic traps have mostly all been found. Today, E&P

companies are increasingly exploring for and producing hydrocarbons in more and more complex

geological environments. To reduce risk and maximize return, new techniques are needed to

produce a reliable representation of the subsurface that can be integrated from interpretation to

simulation.

The main challenges in this complex area are often related to the numbers of faults and the

relation between them, as well as handling complex reverse faulting or thrust. Associated to any

of these cases, the variation of thickness of the geological formation and the handling of multi-z

formation are also challenging and often not handled very well with the conventional modeling

methods. In these areas, understanding the relationship between the faults, formation, and the

associated timing is critical. It is clear that to be able to do this efficiently, having separate

workflows for interpretation and geological model construction is not an optimal approach and

leads to inaccuracy and repetition.

Today, the volume based modeling approach within the Petrel E&P software platform helps to

tackle each of these structural and stratigraphic challenges, while simultaneously integrating the

interpretation and model-building process. This presentation details complex examples from

extensional and compressional provinces, showing how they have been handled in the Petrel

platform from the interpretation to the gridding.

SEISMIC DEPTH IMAGING COLLABORATION BETWEEN STATOIL AND WESTERNGECO

Presented by Mike Cogan (Statoil)

Successful seismic imaging is critical to Statoils exploration success in many basins, particularly

the Gulf of Mexico, Angola, and Brazil where there is considerable geologic complexity. While all

exploration work requires seismic data for interpretation and sometimes, lithology and fluids

prediction, in the most complex geology, seismic images are even more important. It is therefore

particularly frustrating that the seismic image tends to break down exactly where it is most

needed. Examples from the Gulf of Mexico abound where a prospects trap geometry is highly

uncertain because overlying salt formations refract, mode convert, and scatter seismic energy,

leaving, noisy, washed-out images.

A decade of advances in seismic acquisition (wide and full azimuth marine data, broadband) and

seismic imaging technologies (true 3D demultiple, reverse time migration depth imaging, full

waveform inversion, anisotropic velocity model building) have made an impact on our

understanding of the subsurface. There are many examples of the compounding effects of these

new technologies, but with better data, exploration has progressed to deeper targets and more

complex geology, where the improvement from the latest technology is often localized, with many

important areas still poorly imaged. In the Gulf of Mexico, the recent increase in activity in deep

water Paleogene targets is a good example.

How will the current set of challenges be solved? Some progress is being made by

understanding the problems and making better assumptions. Rock physics information and basin

models are being used successfully to constrain velocity model building efforts. In some areas,

subsurface understanding comes from incremental improvements in seismic images achieved by

iteratively testing plausible scenarios (geologic models). Seismic imaging workflows that

incorporate geologic constraints and multiple forms of non-seismic data can help drive us

towards the best image. Seismic imaging algorithms and the high performance computers they

run on have to be both accurate and efficient to produce images from models in hours instead of

days.

Statoil and WesternGeco are collaborating to solve complex imaging challenges in Statoils

Houston Seismic Imaging and Processing center. This presentation will provide a look back on

two years of the Omega/Petrel Imaging solution in Houston, what both companies have learned,

and new directions for the future.

INTEGRATED APPROACH TO PETROLEUM SYSTEMS MODELING IN UNCONVENTIONAL

PLAYS

Presented by A. Madhoo (Schlumberger)

In recent years, as North America has led the way to full, large-scale commercial production of

unconventional oil and gas, the exploration industry has benefitted from high well counts and

generally, dense networks of onshore subsurface data. Europe, on the other hand, has a low

existing well count for conventional resources and notable socio-political and infrastructure

challenges, such as high-population densities. Success, therefore, relies on using all existing

data and drilling a reduced number of exploration wells.

An integrated 3D geological and petroleum systems model of the onshore Netherlands is

presented, which includes critical spatial information such as geographical terrains and surface

constraints. Results from this approach clearly demonstrate areas of higher prospectivity, and,

importantly, their associated uncertainty. This allows E&P companies to select areas that have

the best chance of success.

CONCEPTUAL TO DETAIL ENGINEERING OF THE PRODUCTION SYSTEM

Presented by W. Oliveira (Schlumberger)

Subsea capital expenditure is forecast to double over the next five years, in line with the

development of more complex subsea fields in deep water. This presentation will address how

Schlumberger software enables engineers to assure flow from pore to process through the

conceptual and detailed design, using steady-state and dynamic simulationaddressing

challenges such as lift requirements, thermal management, and operability, and thus providing

the best return on the capital investment.

HOW TO LEVERAGE YOUR INVESTMENT IN PEEP TO DO DECISION ANALYSIS AND

PROBABILISTIC ECONOMICS

Presented by Bernardo Gurfinkel (Hess Corporation)

At Hess Corporation, we have been using Merak Peep with FML (Fiscal Model Library) as our

core economic engine since 2007. One year after the implementation, we developed our first

Merak Peep extension called The Budget Tool that optimized the workflow for the capture of

project level production, capital expenditure, reserve migration, and economic data for all our

Production and Developments assets.

Since then, the need for economic services has grown dramatically within Hess: we now self-

certify reserves, the number of wells to be evaluated has increased in tandem with our

unconventional portfolio, and senior management now requires more probabilistic based analysis.

In order to meet this growing demand the company implemented the Hess Economic Suite (HES)

in 2011. HES was built over 4 basic pillars:

1. A "cloud" based platform that reduces calculation and response time by running, when possible,

economic cases in parallel.

2. Merak Peep as our global economic engine.

3. An App framework that lets us implement new workflows faster.

4. A Plug and Play philosophy to leverage 3rd party software.

This presentation explains how Hess has leveraged HES and its Peep investment to do decision

analysis and probabilistic economics. It describes the different workflows being used and what

challenges still remains.

3D ELECTRICAL RESISTIVITY DATA PROCESSING IN PETREL BY IERP

Presented by O. Tokareva (CJSC Irkutsk Electroprospecting Company)

Methods other than seismic are becoming ever more actual in petroleum exploration, among them

advanced electromagnetic survey. Being complementary to seismics, the advanced electromagnetic

survey can identify subsurface structure and its parameters in depth range from a few meters to

kilometers and reduce well placement risks by constraining reservoir locations and fluid type.

CJSC Irkutsk Electroprospecting Company (IERP) is the only Russian service company to offer joint

processing of resistivity and seismic data in Petrel, which opens new capabilities in reservoir

characterization. Converting geoelectrical parameters to the universal SGY format with a specially

designed technique allows integrating resistivity data into geological modeling in Petrel. Geoelectric

patterns have implications for lithology, reservoir zones and their saturations, and presence of

igneous rocks and faults. Either 2D or 3D resistivity data can be used at different exploration phases.

With 3D data, cubes of geoelectrical and seismic attributes can be created.

The partners and clients of IERP are the leading operators and service companies around the world,

such as PETRONAS, PrizePetroleum, Gazprom, Gazpromneft, Novatek, Surgutneftegaz, Irkutsk Oil

Company, Institute of Petroleum Geology & Geophysics and SNIIGGiMS Institute (Novosibirsk), and

others.

The efficiency of IERP technologies have been proven in extreme weather and climate conditions in

Northern Russia, India, Saudi Arabia and Southeast Asia. The experience of using Petrel for 3D

resistivity data processing is illustrated with examples from East Siberia (Russia), Borneo (Malaysia),

and Sumatra (Indonesia).Resistivity survey was successful in resolving structural and oil-gas

exploration tasks in various geological conditions. Comprehensive analysis of Vendian clastic

reservoirs based on resistivity and structural patterns has improved prediction quality for East

Siberian prospects. Resistivity data can be the only source of structure information in the cases

when seismic data quality is low.

CHEMICAL EOR SIMULATION USING ECLIPSE

Presented by Mehdi Izadi (Tiorco)

Short overview of Chemical Enhanced Oil Recovery (CEOR) technologies including; Surfactant,

Polymer, Thermally active polymer (Bright Water) will be presented. Main key laboratory data

required for modeling each technology and how Eclipse was used in utilizing laboratory data, and

model these technologies will be addressed. The presentation would also include core-flood

history matching using eclipse and a how the laboratory model can be scaled up to full field scale

simulation. This paper describes the workflow to evaluate technical simulation methodologies of

thermally active polymer technology for proper pilot project designs. The main challenges for

predictability of such models, besides the modeling approaches depend on how the

heterogeneity is incorporated to the model, dose model capture ILT/PLT data and how the

channel and thief zone is incorporated into the model.

CORPORATE DATAFLOW: A CASE STUDY OF WOODSIDES SYSTEM DESIGN FOR

TECHLOG

Presented by J. Crosby (Woodside Energy Ltd, Australia)

Over the last two years, Woodside (an Australian Oil and Gas Exploration and Production

company) has completed its evaluation, design, migration, roll out and optimisation of the

Techlog Interactive Suite as a replacement for a competitors product. This case study

examines some of the challenges faced along the way, and examines the chosen system

design, particularly focussing on the implementation of Techlog Projects as a primary

reference store for petrophysical interpretation in lieu of a more conventional, yet 3

rd

party

database.

In migrating to Techlog, Woodside moved from having a reference and working database

pairing for each project area, or basin, to having a single reference and multiple user projects

for each basin we do not currently connect Techlog projects with a database solution such

as Recall or OpenSpirit. We also moved from having multiple users in the one working

database (along with all associated pros and cons) into having one project per user.

Subsequently there has been significant effort required to optimise dataflows (the system by

which data moves between projects and users) to facilitate ease and speed of access whilst

maintaining data integrity. As Schlumberger harmonises its trinity of solutions under the

Studio umbrella, dataflows are about to receive a lot of attention. Woodside hopes that the

vision for Techlog Studio is one that will also benefit Techlog deployment in a corporate

environment defined by users who simultaneously consider a wealth of wellbore data for

ongoing field appraisal rather than catering primarily for production line operations where

data is imported, processed and subsequently exported.

This presentation will look in finer detail at: the implementation and development of

Woodsides Techlog solution; the challenges weve overcome deploying Techlog and

managing data over our network; the introduction, implementation and limitations of the

Techlog Synchronization tool and Reference Repository for our dataflows; and the preparation

and planning being done for the future introduction of Studio for Techlog, and its perceived

impact on the Woodside Techlog solution design.

THE DEPLOYMENT OF STUDIO IN AN ASSET TEAM; DATA MANAGEMENT IS THE

KEY TO SUCCESS

Presented by Dr Claire Andrews (Apache)

Studio is presented by Schlumberger as the solution to working in Petrel with in a high

well count area and to increase collaboration within an asset team as well as being a

core component to future links between other software such as OFM & Avocet.

The Case Study presented here is the deployment of Studio within an asset team actively

drilling in North America to facilitate collaboration and efficient handling of data. During

the course of the deployment many key lessons were learned regarding the necessity of

data manipulation to preserve & create a matching GUID environment to enable the

migration in to Studio. The changes in workflow & understanding of the data has become

key to a successful deployment & has generated much discussion with Schlumberger on

functionality required in the Studio DB environment. The project was successfully

completed with minimum disruption to daily activities of the team with the second step

commencing for end user training and the changes required in the workflow to use

Studio. The further enhancement to the speed of Interpretation & Engineering workflows

that connections with production systems and corporate data stores will allow is

considered a key advantage of Studio & much anticipated.

NEW GENERATION ISOTHERMS DATASET FOR UNCONVENTIONAL RESERVE ESTIMATION

Presented by M. D. Campos (Schlumberger)

Organic-rich shales and coals contain hydrocarbon fluids that are under strong influence of their

pore walls due to the nanometric level pore-size distribution. At this scale, pore walls affect fluid

phase transitions and its physicochemical properties, which in turn have an impact on current

volumetric methods for calculating oil and gas reserve estimation in a typical unconventional

field.

Isotherm tables currently used in the oil industry refer to the equation derived by Langmuir. Such

isotherm represents fluid properties in which wall effects are not considered and single

adsorption layers are assumed for any porous media. Hence, it fails to accurately represent the

fluid properties and volumetrics for calculating the reserves of organic-rich shales and coal

reservoirs.

New generation isotherm tables are therefore needed to take into account the added complexity

in volumetric calculation for shale gas and shale oil estimation.

This presentation describes the methodology for which the new generation isotherm dataset has

been created by utilizing molecular dynamics simulation results.

Use of the new isotherm will give an accurate result for volumes of gas in any shale type

reservoir. The process of history matching will be reduced greatly as the results are more

representative to field rates. A faster decision to report the volume of gas to partners,

governmental bodies can be achieved thus creating confidence in the result.

MODELLING COMPLEX STRUCTURESVOLUME BASED MODELLING OPENS NEW

PERSPECTIVES

Presented by Thierry Modiano (Total E&P Nigeria)

Dealing with complex structures, industry has been for a long time waiting for robust techniques

allowing obtaining precise structural models and reservoir grids while respecting the complexity

of fault and horizon patterns. Building a geologically consistent representation of horizons when

the fault network presents complex truncation has been a challenge for a long time, especially

when horizons are represented by sparse data.

The new Volume Based Modeling (VBM) approach introduced in Petrel version 2013.2 is a global

approach. Fault and horizon data are used to build an implicit function representing the

geological time. This function is defined everywhere in the volume of interest. Horizons are

simply iso-values of the implicit function.

VBM was used on a complex deep water field offshore Nigeria. In previous models, the structural

complexity of the field obliged to split the model in three stratigraphic reservoir units and to

proceed to many fault simplifications to remove internal truncations. Even with the

simplifications, the process of grid building using the classical pillar gridding method was very

long and many compromises were done to get an acceptable grid without distorting too much the

fault geometry.

With VBM, the whole model without very few simplifications was successfully built in a very

limited time, using the tops and bottom horizons of the three reservoir levels. A structural grid (full

stairstep) was derived from this structural model.

A second structural model was built by adding internal horizons picked as tops and bases of

sedimentary bodies. A second structural grid was built using this model. The objective of this

detailed model was to get a structurally consistent representation of all sedimentary units. The

zone property was then resampled in the first grid to obtain a discrete region property.

QUANTITATIVE INTERPRETATION IN THE PETREL PLATFORM

Presented by M. Volcan (Schlumberger)

In many cases, inversion or AVO studies to predict reservoir parameters are carried out on data

that has lost its context from the processing center. The analysis usually requires the use of

multiple software packages to complete a full analysis. In this presentation, we will see how

advantageous it is to perform data conditioning, inversion, and AVO workflows in one platform

the Petrel platform to achieve an accurate subsurface characterization.

Technology to perform the inversion simultaneously allows the direct generation of the three rock

propertiesAI, Vp/Vs and Densitywhich can help interpret the presence of fluids. This

workflow highlights the practical aspects of quantitative interpretation in order to assist with

prospect validation and reservoir characterization.

The Petrel platform is used to condition the data, and prestack is then used to evaluate and

create deterministic and stochastic inversion results.

The ability to combine rock physics models with seismic is achieved by modeling the AVO

response in our well to predict pore fluids in the seismic. The methodology to estimate lithology

by using the acoustic impedance contrast is also showcased.

STRATEGIC TO OPERATIONAL INTEGRATED PLANNING

Presented by Rick Lobrecht (Schlumberger)

Portfolio management is an important aspect of oil and gas business planning to support the

efficient allocation of capital and other scarce resources. As oil and gas becomes more difficult

and expensive to find and extract, petroleum companies are looking to portfolio management for

competitive advantage. However, traditional portfolio management has sometimes missed the

opportunity to consider the operational reality at the asset team or regional level. Each

investment must be consistently evaluated for its ability to contribute to the corporate strategy,

while maximizing the usage of available resources.

This talk will show how integrating strategic and operational planning provides benefits when

used at every stage in the asset development life cycle (from exploration through to production

and abandonment) as well as at different levels in the corporation (asset teams through business

units to corporate planning) to drive efficient business planning. It will focus on what the critical

business issues are, how to model the corporate long-term direction through measurable goals

and key performance indicators, and what key objectives companies pursue when allocating and

budgeting capital.

The presentation will highlight specific examples of ways in which portfolio management can

resolve operational issues, such as rig-scheduling optimization, facility constraints, and asset

performance monitoring, while maintaining the golden thread connection to the long-term

strategy.

This integrated approach to portfolio management will allow corporate and asset planners to

balance long term strategic goals with operational constraints from the business unit down to the

asset team. It results in a more balanced and diversified portfolioan achievable planand

drives better decisions in the capital allocation process.

MODERNIZING OIL & GAS SOFTWARE: HOW INTEL AND SCHLUMBERGER INCREASED

PIPESIM PERFORMANCE 10X

Presented by Joseph Curley (Intel)

By working together to parallelize Schlumbergers PIPESIM Steady-State Multiphase Flow

Simulator, Intel and Schlumberger enable oil and gas companies to explore many more pipeline

production operation scenarios by capitalizing on the latest multi-core processing architectures

to run simulations faster, with greater accuracy, and explore more design alternatives.

ASSESSING THE IMPACT OF EOR IN YOUR RESERVOIR

Presented by Omer Gurpinar (Schlumberger)

This is the most exciting time for EOR in recent memory. At last, almost everyone is talking about

increasing recovery factors, and IOR/EOR is being considered a natural component of reservoir

management. Furthermore, many traditional philosophies are being openly challenged. EOR planning is

happening as part of field development plans. Proven technologies are being adapted in new, smart ways

and new technologies are constantly evolving from research to commercial applications, making

successful EOR projects more likely.

These new directions are the result of a variety of factors. Most fields, including the giant ones, are

maturing, and producing liquid hydrocarbons is getting tougher in all kind of reservoir types (conventional

and unconventional alike). Leaving about 65% of the in-place reserves left unrecovered has been

challenged.

There have been developments on many fronts (i.e., advanced reservoir characterization, multiphase flow

physics, smart well and intelligent completions, advancements in recovery research, monitoring and

control technologies, new EOR chemicals, new EOR pilot concepts, and new observation-well concepts).

The collective impact of these is going to make new EOR projects more successful than before.

Increasing recovery factors has been considered as a fully integrated multidomain activity (from pore

space to separator, and everything in between). Severe production decline in tight-light (unconventional

oil reservoirs) reservoirs is also making the industry think about recovery challenges.

EOR has been brought into field development planning in most recent offshore oil developments, and the

integrator media, reservoir modeling, is now ready to tackle the recovery challenge.

Broadening the scope of recovery challenge to all domains will make realizations of new reserves more

likely, but this change will bring additional challenges. Modeling for EOR is no longer limited to

investigation of mobilizing the trapped oil, but incorporation of all scales, from pore-scale (sometimes

molecule scale) to reservoir scale, including the performance of exotic EOR pilots with monitoring sensors

and controls.

Geomechanics, which came to our industry first for the drilling domain, will have to be part of EOR

modeling in reservoir scale. Additionally, new EOR schemessuch as loSAL, hybrid applications (VAPEX),

and new conformance ideas including foams and nanoparticleswill push us to better understand the

recovery thermodynamics, physics, and multiphase flow in porous media.

Evolution in recovery phenomena will guide us to set the right granularity in reservoir and fluid

characterization, which will in turn enhance the capabilities of reservoir models. If we continually push the

science, an opportunity to double recovery factors exists.

A ROADMAP TO ASSET OPTIMIZATION: THE PRODUCTION DATA MANAGEMENT

PLATFORM

Presented by T. Tran (Bien Dong Petroleum Operating Company)

Bien Dong POC operates the Hai Thach and Moc Tinh gas/condensate fields located offshore

Vietnam and exports the produced gas to the Nam Con Son Pipeline. Bien Dong POC has decided

upon the Schlumberger Information Solutions (SIS) Avocet Platform technology that

encompasses functionality designed to collect, manage and compute production data in high and

low frequency, produce meaningful reports supporting the analysis and enhancement of the

operational activity. With this data converted into information Bien Dong POC can safely operate

the current and future oil and gas assets, accurately report to authorities and stakeholders,

perform asset surveillance, diagnosis and ultimately optimize production amid operational

constraints.

In order to obtain the most of this solution, the Avocet Platform project was implemented before

the first commercial gas, allowing them to be readily prepared for first gas, enjoy the benefits of

tracking all the production and operation parameters since day one for operational purposes and

also enabling the ability to understand better the reservoir dynamics at very early stage of the

production.

As Avocet provides foundation layer for managing the production for the two fields, and is helping

today to improve the timely decision making process through the use of accurate, and validated

data; this effect is impacting positively by allowing Bien Dong POC to adjust production rates to

deliver contractual terms of demanded production in a matter of few hours.

The goal of this paper is to highlight the advantages and benefits that can be drawn from the

utilization of the Avocet Platform Solution as key foundation block today and how it fits in the

Roadmap to Asset Optimization in the future for Bien Dong POC.

THE USE OF A VOLUME BASED MODEL WORKFLOW TO RESOLVE THE COMPLEX

ARCHITECTURE OF A FIELD ON THE NORTH WEST SHELF, AUSTRALIA

Presented by A. Kaiko (Woodside)

Until recently the complex fault architecture of the North Rankin Field was not able to be

modelled, using standard pillar gridding techniques, without significantly over simplifying the

faulting pattern of the field. In order to better understand the dynamic performance of the

field it is important that the complex fault architectures be captured. The use of the Structural

Framework workflow with the release of the Volume Based Modelling (VBM) algorithm and

Stair Step Gridding, has enabled the complex architecture of the North Rankin Field to be

modelled and a more representative grid generated. This grid is now able to be used in the

dynamic realm to help provide a better understanding of the potential aquifer influx, pressure

baffling and production history of the field.

The fault styles within the North Rankin Field include top truncation, multiple stacked

antithetic and crossing faults. From a range of varying data inputs, the use of VBM is able to

generate horizons honouring the complex fault architecture and stratigraphic trends even in

areas of little well control. The seismic inputs for the model consist of the complex fault set

and three key highly detailed input horizons to give the overall framework. A secondary set of

four more sparsely interpreted horizons were also used to provided further infill to the model.

Well tops and occasional seismic infill picks in complex areas provide the final input to

complete the complex framework build. A stair step grid is then generated which was

populated with the various properties to be used for dynamic assessment of the field

performance.

The use of the VBM workflow and a tiered seismic interpretation approach allows a new level

of structural complexity to be modelled, while minimizing the seismic interpretation required.

TECHNIQUES FOR EXPLORATION AND EVALUATION OF TURBIDITES

Presented by A. Acevedo (Schlumberger)

Over the last decade, there have been several discoveries of very significant oil accumulations in

deepwater reservoirs. With advances in research and the availability of high-resolution seismic

data, their variability and complexity have been well documented. For hydrocarbon exploitation

purposes, however, the industry has been lacking an integrated approach to interpret these

reservoirs using multiple domains and data efficiently. This presentation describes a series of

innovative and interrelated techniques to improve the understanding of these types of reservoir at

three scales: basin, sequence, and reservoir. The combination of multiple disciplines (such as

geophysics, stratigraphic forward modeling, and geostatistics) at these three levels leads to a

more realistic representation of these plays.

CREATING ADVANTAGE THROUGH EXTENSIBILITY WITH THE OCEAN FRAMEWORK

Presented by Ahmed Aqrawi (Schlumberger)

The Ocean software development framework gives you the freedom to create advantage. By

building or integrating specialized applications and workflows inside the Schlumberger software

platforms, you can leverage your own proprietary technology and ideas, and immediately put

innovation into the hands of geoscientists. These capabilities can be developed internally or by

working with Ocean partners to rapidly incorporate new science into your workflows.

In this presentation, discover how you can make use of best-in-class technology without the

disadvantages and inconvenience of multiple fragmented software solutions. Extend your

Schlumberger technologies with the unique Ocean framework and choose tools that meet your

needs from Schlumberger and third parties via the Ocean store.

FLAIR, ISOTOPE, ACC: THE ROLE OF THE SURFACE CONTINUOUS FORMATION EVALUATION

Presented by Isaac Easow (Schlumberger)

In the last few years, advanced surface technology has gained fast popularity among several oil

companies as trusted and valuable tools for formation evaluation. The quasi real-time availability

makes these technologies suitable for quantitative and repeatable rock and fluid evaluation prior

to subsurface logging or downhole fluid sampling runs.

FLAIR fluid logging and analysis in real time, Real-Time Isotope logging and ACC (Advanced

Cutting Characterization) services represent a unique and complete formation evaluation portfolio

in the mudlogging market. The FLAIR service continuously analyzes hydrocarbons extracted from

drilling mud returns at surface, providing C1C5 composition analogous to the downhole reservoir

fluid. The increased number of data available for analysis and the need to integrate all of them in

a unique platform has led GSS to choose the Techlog wellbore software platform. The powerful

functionalities of this software meet perfectly the requirements for an advanced formation

evaluation analysis.

This presentation focuses on a US shale gas play, where elemental composition of the cuttings

showed great potential for chemo-steering and production allocation.

COST-EFFICIENT SOLUTIONS FOR SIMULATING INTEGRATED RESERVOIR MODELS AND

PRODUCTION NETWORKS USING INTERSECT AND A FAST NETWORK SOLVER

Presented by C. Casciano (Eni)

It is a well-known fact that, in many cases, predicting and optimizing field production involves the

simulation of different reservoirs sharing a common production network. Various solution have

been proposed, ranging from a combination of simple Network and Reservoir Coupling options in

black-oil simulators like ECLIPSE 100 to more elaborate solutions where a controller application

drives reservoir models and a fully-fledged network simulator/optimizer. If the latter option is

more accurate, the former solution is often much more efficient and gives similar results.

In this presentation we describe, within the INTERSECT simulation framework, a pre-commercial

but effective work-flow aimed at integrating independent reservoir models and a common

production Network.

In this solution, INTERSECT Field Manager integrates in an iteratively lagged manner a fast

network solver, where pressure drops along flow lines are computed using VFP tables, with

INTERSECT models simulating fluid flow from reservoir to well-head.

The methodology is first described and then highlighted by means of some key real field

applications. Advantages with respect to more elaborate solutions are also discussed.

ASSET OPTIMIZATION AND RESERVOIR/PETROLEUM ENGINEERING DATA MANAGEMENT

Presented by E. Kabadayi (ConocoPhillips)

The ultimate goal for this project was to set up a foundational data access for

reservoir/production engineers to run variety of engineering, analytical and visualization

applications. Building a gas lift management system to monitor and optimize the Greater Ekofisk

assets as well as building alarm systems and other engineering applications and workflow

optimizations were planned as later phases of the initial project. Ekofisk is one of the biggest and

oldest assets in Norwegian continental shelf having some 200 wells, waterflooded, and majority

of wells are gaslifted. To add to the complexity of the asset, some of the wells are 40 year old and

not much of instrumentation while some others are fairly advanced and highly instrumented. As a

known challenge for this type of brown fields there are many data sources, sometimes several

places to look for the same data. The aim was to generate a single system intelligence based on

the Avocet platform including all the engineering data types built across multiple data sources,

automatically pulling in data with the right frequency, QCing it, and connecting to BI or

engineering analysis tools. The commercial data sources are PI (daily/hourly operational data

such as pressure, temperature, and flowrate readings), EC (daily/monthly allocated volumes),

WellView (static well data such as completion details), and OpenWorks (static well ID and

location data). The custom-built data sources are a couple of Oracle/MS Access based

databases containing reservoir parameters, well tests, ion tracers, etc.

This system is now connected to engineering analysis tools such as OFM, business intelligence

tools such as Spotfire and the Petrel to perform reservoir engineering workflows. The next step is

to build optimization workflows on the top of the system and at the moment CoP Norway is

evaluating options in this regard.

DYNAMIC FLOW MODELINGCRITICAL TOOLS IN RISK MANAGEMENT FOR WELL

CONTROL

Presented by Fred Ng (Wild Well Control, Inc.)

Recent events have heightened awareness from industry and governmental authorities regarding

well control issues and consequences. Management of these risks involves development of

mitigation and contingency options for identified risks. This paper discusses the critical role of

dynamic flow modeling in developing such options, as well as the important differences resulting

from application of advanced technologies in recent years. These include multiphase modeling

to address well plan and kick tolerance evaluation for mitigation options, as well as relief well

planning and simulation of blowouts and dynamic kill for contingency planning. Advanced

applications, such as those involved in SIS well control software, allow complete and accurate

modeling of the physical effects, which are typically not feasible with the oversimplified models

used by others. Case histories will be presented to illustrate these effects, which include mud

compressibility, gas solubility in oil based fluids, PVT effects of multiphase influx, migration of gas

in the wellbore, temperature effects, unloading of the well in developing a blowout, and mud / gas

swapping in the wellbore. Discussions will also include changes needed to meet new

developments in drilling operations.

THE HYDROCARBON PATHWAYINTEGRATED DRILLING SOLUTIONS

Presented by Stuart Jardine (Schlumberger)

Drilling is an integral part and a key component of the hydrocarbon pathway. Meeting the

objective of your well is a critical activity in each of the lifecycle stages and with increasing well

complexity, getting it right the first time has never been more important.

This presentation covers key workflows throughout the drilling lifecycle, from planning through

engineering, execution, and evaluation of the completed drilling program. The drilling workflows

highlight well planning in a geological context, workflow integration, and unique technologies for

todays high-value complex wells.

Well trajectory design is implemented using efficient iterations between the geologist and drilling

engineer. The initial design is optimized for the drilling pressure window and includes a review of

the potential wellbore stability issues that may lead to drilling problems. With the well trajectory

finalized and the safe operating window calculated, we use dynamic hydraulic models

including dynamic temperature calculationsto ensure that the bottomhole pressures in the well

can be maintained within this window. The focus on well control highlights a new solution to

simplify relief well and blowout contingency planning utilizing advanced multiphase hydraulics

simulation capabilities.

Real-time data services, combined with drilling performance analysis capabilities, complete the

drilling lifecycle. All relevant well information is immediately available to feed into the plan and

offset analysis for the next well to be drilled.

FRACTURE INTERPRETATION AND MODELING

Presented by J. Klinger (Schlumberger)

Having a confident understanding of the fracture orientation, distribution, and characteristics is

crucial in a general context where 80% of the worlds largest hydrocarbon bearing fields are

fractured reservoirs. The methodology proposed here will combine a deterministic

geomechanical inversion through a boundary element method engine (BEM), with the reservoirs

structural interpretation (cf. fault framework) and estimate the locally perturbed paleostress-field

in order to describe the natural fractures generated by a given tectonic event. Calibration to the

fractures interpreted at the wellbore will ensure we have reached the global minimum of the

inversion step.

Subsequently, information of the present-day stress field within the reservoir (obtained via similar

inversion workflow using break-out information to calibrate against, or other means) will be used

in order to compute a fracture reactivation potential property. Such information can be highly

valuable for well, completion, and stimulation planning protocols.

MAKING KNOWLEDGE WORK IN THE WELLBORESTUDIO FOR TECHLOG

Presented by P. Dineen (Schlumberger)

With the pace of change in our industry todayand the increasing effort on exploring,

developing, and producing challenging reservoirs in both conventional and unconventional

environmentsthere is significant focus on user and team productivity in an E&P organizations

quest for optimization of workflows across the lifecycle of the asset.

The Studio E&P knowledge environment addresses these challenges by delivering a new level of

collaboration across multiple assets and multiple domains to support your teams along the

hydrocarbon pathway. The Studio environment focuses on empowering end users, both

petrotechnical users and data managers, with a powerful platform for collaboration with utilities,

tools, and workflows that enable them to access, review, capture and share critical knowledge

and insight as part of their technical analysis and decisions, all delivered as part of the

Schlumberger platforms, as well as a dedicated Studio Manager to proactively oversee and

administer the Studio environment.

This presentation will share the advances made around the Techlog platform and integration into

the Studio ecosystem for collaboration and knowledge management.

We will review the core workflows delivered with Techlog 2014 and Studio 2014 that deliver a

step change in the collaboration between Techlog users and across the asset with the Petrel

platform, enabling your teams to increase productivity and collaboration to improve insight and

decisions in the dynamic environment they are working in.

A SAFE HARBOR FOR DATA IN THE OCEAN ENVIRONMENT

Presented by J. Whelan (ExxonMobil)

The management of data is a fundamental component of ExxonMobils system of management