Beruflich Dokumente

Kultur Dokumente

Closed Loop Control CFBC

Hochgeladen von

Jawahar Bhattacharya0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

64 Ansichten3 Seiten1. The document provides comments on various control schematics for a cement plant project in India. It notes issues with load dependent curves, boiler emergency vent valve logic, missing details in schematics, and proposes changes to combustion, steam temperature, furnace pressure, and other control logics.

2. Key issues raised include lack of clarification around boiler controls below 60% load, unclear trigger for boiler emergency vent valve cycling, missing sensor details, incorrect air-fuel ratio calculations, absence of limestone and bed material feeding controls.

3. The comments suggest modifications like adding time blocks, setting alarm/trip points, correcting damper logics, clarifying purging sequences, and rechecking sensor tags

Originalbeschreibung:

Comments on CFBC closed loops

Copyright

© © All Rights Reserved

Verfügbare Formate

DOC, PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument melden1. The document provides comments on various control schematics for a cement plant project in India. It notes issues with load dependent curves, boiler emergency vent valve logic, missing details in schematics, and proposes changes to combustion, steam temperature, furnace pressure, and other control logics.

2. Key issues raised include lack of clarification around boiler controls below 60% load, unclear trigger for boiler emergency vent valve cycling, missing sensor details, incorrect air-fuel ratio calculations, absence of limestone and bed material feeding controls.

3. The comments suggest modifications like adding time blocks, setting alarm/trip points, correcting damper logics, clarifying purging sequences, and rechecking sensor tags

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

64 Ansichten3 SeitenClosed Loop Control CFBC

Hochgeladen von

Jawahar Bhattacharya1. The document provides comments on various control schematics for a cement plant project in India. It notes issues with load dependent curves, boiler emergency vent valve logic, missing details in schematics, and proposes changes to combustion, steam temperature, furnace pressure, and other control logics.

2. Key issues raised include lack of clarification around boiler controls below 60% load, unclear trigger for boiler emergency vent valve cycling, missing sensor details, incorrect air-fuel ratio calculations, absence of limestone and bed material feeding controls.

3. The comments suggest modifications like adding time blocks, setting alarm/trip points, correcting damper logics, clarifying purging sequences, and rechecking sensor tags

Copyright:

© All Rights Reserved

Verfügbare Formate

Als DOC, PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 3

COMMENTS ON CONTROL SCHEMATICS

PROJECT : INDIA CEMENTS LTD., VISHNUPURAM

Dwg. No. D13-4CF-2031P R!-0 - Co"#$o% S&'()#*&+

COMMON

1. It is noted that various load dependent curves have been given in a tabular form where the min load is considered

60%. This may mean two

things:-

- The boiler controls can be run in auto mode only above 60% load

-r! the outputs of these "#$% bloc&s will remain the same as they

are at or above 60% load.

This needs clarification.

'. (here is the control for bed material )"*+s, - 11-1'-.-/001-2

0. .ain 3team 4mergency )ent )alve logic: It is not clear what is the trigger for the valve to open and close in cyclic

manner. It appears that when the boiler is in steady state! the valve 5)-610 will &eep opening and closing cyclically

without any trigger. Is the condition of temperature from 3team temp high or "64T7 /89

:lease clarify and correct this.

/. :lease refer 3ht-'0 :

- "or all switches healthy condition of the switch contact should be shown without which the logic is not

understandable to the *;3 vendor.

- 1s per <ev-1 of : = I*! the 1tomising air pressure low switch is

:3>-?0' and not :3>-?'0

- There is no fuel oil temperature sensor in the "iring : = I*

- 3canner cooling air pressure switch is :3>-'1? as per <ev-0 of 1ir

:ath : = I*.

- "uel oil pressure low switch is :3>-?01 as per <ev-1

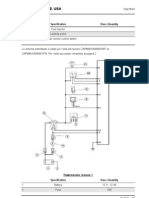

,ED TEMPERATURE CONTROL -S'#-2.

1. :lease include 9 sec T* bloc& to trip <1) from 1>>-@01-@0'

'. :lease note that >1A-@0'->1>-@0' will go to AI;-@91 and >1A-@01-lal-@01

will go to AI;-@9'

0. :lease indicate the set points for alarm and trip flags in the drawing.

/. <efer Bote ': (ill the *:I;-100 3: change by C-- 1'% or to C-- 1'%.

COM,USTION CONTROL

1. The computation of fuel that can be supported is computed after totaliDing :1 and 31 flow whereas the

1ir-"uel ratio is different for 31 and :1. (e feel the :1 ad 31 flow should be divided by respective air-"uel

ratio before summation.

'. The clamping of $ygen controller shall be between 0.8 and 1.'. This should be mentioned.

0. There is no mention of the limestone <1) )"* control. Aow is the limestone to be added in right proportion

while firing different fuel ,

/. There is no mention of the fuel being fed from 2un&er-' by <1)Es which is to be added to the flow of 2un&er

-1 fuel by *;". Aow is the total flow computed ,

9. Is the 2un&er-1 dedicated for different coals and 2un&er-' for petco&e ,

6. Aow is the combination fuel firing addressed in the loop ,

@. "uel oil control is only AI; controlled. :lease correct this.

8. The combustion control scheme does not mention anything about control of

limestone feeding or bed material feeding through the )"* controlled <1)+s.

Is 2un&er-' dedicated for :etco&e and imported coal only, Is Indian ;oal to

be loaded in 2un&er-1 only. The control scheme loo&s li&e that.

SH STEAM TEMP CONTROL

1. :lease add the AI; control loops fro F)-910 and F)-916

FURNACE PRESSURE CONTROL

1. 3ince there are :3>> and :3AA! show only :1A and :1> from the :T. Trippigs will be ta&en from the

pressure switches.

'. 3how the interrupts for force closing the dampers in case of the corresponding I*" trip.

ASH COOLER AIR SLIDE DAMPER/COOLIN0 AIR DAMPER LO0IC -S'#-12.

1. (hy the BT gate is reGuired at the output to force close these dampers

FURNACE PUR0E LO0IC 1S'#-13

1. :lease correct the scaling for :1 and 31 flow as per the proHect reGuirement. It is 0-1'0 T:A.

'. Bormally coal firing is started after establishing fire by oil! which goes through the purging cycle. (hen is

this purging reGuired. Is this I:urge <eGuiredJ- I :urge ;ompletedJ etc indications different from those of the

2.3 logic,

AIR PREHEATER DAMPER LO0IC 1 S'#-12

1. (here is the loop for 1:A cold end temperature control ,

'. The logic for force closing-opening of 1:A dampers is incorrect. In case of both I*" trip #2oiler trip%! only the

:1 inlet to 1:A will force open and the others will force close. :lease correct this logic.

MDC ,3PASS DAMPER LO0IC 1 S'#-12A

1. It is not clear what >1>> is doing in this logic. :lease elaborate in the write up. (e feel it is not reGuired.

,ED LEVEL CONTROL- S'#-14

1. :lease remove AI;Es and show the selector switch for selecting 1sh ;ooler-1 or '.

STEAM PUR0E LO0IC-S'#-21

1. It appears that in case of 2oiler trip! the steam purging starts and continues till the bed temperature goes

below '00 deg ;. Aow long that will ta&e, (ill oil firing be reGuired to restart,

ELECTROMATIC VALVE LO0IC- S'#-22

1. The transmitter tag is :T-61'1-2-; through median value selector.

MISCELANEOUS LO0ICS-S'#-23

1. :lease rechec& and correct the sensor tags with respect to the latest revision of : =I*

'. There is no "uel oil temperature alarm.

0. It is not clear why this sheet is reGuired since these are covered in 2.3 logic drawing *10-/;"-'0/0:

4.4<64B;K )4BT )1>)4 >6I; L 3heet-'/

1. It appears that the valve will &eep recycling L opening for 10 sec in every 10 min. (hat is the trigger for such

activity and what is the purpose when the boiler is running M.

'. Is steam temperature or "46T temp. :lease chec& with respect to the write up.

Das könnte Ihnen auch gefallen

- The Mystic Class 11 Updated Psionics For 5eDokument36 SeitenThe Mystic Class 11 Updated Psionics For 5eShaadJackNoch keine Bewertungen

- A727 - A904 Techtran ManualDokument80 SeitenA727 - A904 Techtran ManualTodd Palmer80% (5)

- U-340 Valve BodyDokument19 SeitenU-340 Valve BodyAle100% (4)

- Aw60 41sn Zip BookDokument8 SeitenAw60 41sn Zip BookRiki Nurzaman100% (3)

- Marciniak Barbara The PleiadiansDokument89 SeitenMarciniak Barbara The Pleiadiansaman100% (3)

- Cooling Fan System (1Az-Fe) : On-Vehicle InspectionDokument53 SeitenCooling Fan System (1Az-Fe) : On-Vehicle InspectionMusat Catalin-Marian100% (6)

- B767 PowerplantDokument15 SeitenB767 PowerplantGustavo Avila Rodriguez100% (2)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceVon EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNoch keine Bewertungen

- ARL-300 Error Codes - enDokument4 SeitenARL-300 Error Codes - enDaceDrop79% (29)

- Road ConstructionDokument5 SeitenRoad ConstructionmetincetinNoch keine Bewertungen

- Air ConditioningDokument108 SeitenAir ConditioninglogammicNoch keine Bewertungen

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGVon EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNoch keine Bewertungen

- MRTT 3Dokument4 SeitenMRTT 3Jeremy TohNoch keine Bewertungen

- Tr7-8fi ManualDokument82 SeitenTr7-8fi ManualClint CooperNoch keine Bewertungen

- Duel Fuel System DescriptionDokument14 SeitenDuel Fuel System DescriptionParmeshwar Nath TripathiNoch keine Bewertungen

- Pipe Rack DesignDokument51 SeitenPipe Rack Designsur50% (2)

- Technical Service Information3Dokument4 SeitenTechnical Service Information3JoseNoch keine Bewertungen

- LPG Lecho Sec Eco InstructionDokument37 SeitenLPG Lecho Sec Eco InstructionZoli Borbely100% (1)

- 210 MW O & M AnualDokument207 Seiten210 MW O & M Anualsenthil031277100% (1)

- Guidelines For Design and Construction of Geosynthetic Reinforced Embankments On Soft FoundationsDokument40 SeitenGuidelines For Design and Construction of Geosynthetic Reinforced Embankments On Soft FoundationsManish Kumar Singh100% (1)

- TP30427-1 Lh-Jet v2 b23fDokument42 SeitenTP30427-1 Lh-Jet v2 b23fAchim Maximilian Naumann d'Alnoncourt100% (1)

- A320 Family Notes 1Dokument103 SeitenA320 Family Notes 1antynccbzersdrodiz100% (1)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementVon EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNoch keine Bewertungen

- Harsha Akka 013759 Unit 13 CRP Report PDFDokument94 SeitenHarsha Akka 013759 Unit 13 CRP Report PDFMinda RajanNoch keine Bewertungen

- Combi Compact and Thermocompact Logical Fault FindingDokument16 SeitenCombi Compact and Thermocompact Logical Fault FindingW4S1MNoch keine Bewertungen

- EHTCDokument22 SeitenEHTCVicky Singh100% (1)

- EPR in Waste ManagementDokument11 SeitenEPR in Waste Managementdorexp17Noch keine Bewertungen

- C130 Fuel Temp Info PDFDokument20 SeitenC130 Fuel Temp Info PDFPolkaboy2Noch keine Bewertungen

- 04 - Turbine Trip (CNK 12 M Ove Oi 204C) +Dokument7 Seiten04 - Turbine Trip (CNK 12 M Ove Oi 204C) +Your FriendNoch keine Bewertungen

- Galaxy R Service Manual PDFDokument58 SeitenGalaxy R Service Manual PDFPedro Bortot56% (9)

- Hyundai Accent 98 MFI Control SystemDokument98 SeitenHyundai Accent 98 MFI Control Systemwessamalex100% (1)

- APHDokument1 SeiteAPHsai987650Noch keine Bewertungen

- Remotivation Therapy (Sammm)Dokument4 SeitenRemotivation Therapy (Sammm)Sam Venezuelȧ100% (3)

- CPT-0013 Commissioning Procedure of Boiler Ignition SystemDokument7 SeitenCPT-0013 Commissioning Procedure of Boiler Ignition SystemJ Bagien100% (1)

- OWN Project Details Wise For Support Regarding FicoDokument13 SeitenOWN Project Details Wise For Support Regarding Ficobikash das100% (1)

- ASC ZR (T) 160-900 VSD Tab04 Commissioning Procedure 2946 0282 02Dokument9 SeitenASC ZR (T) 160-900 VSD Tab04 Commissioning Procedure 2946 0282 02Leonardo SilvaNoch keine Bewertungen

- Oil System TuningDokument2 SeitenOil System TuningHosseinNoch keine Bewertungen

- Air Compressor House: Guide Book For Utility Operation, Section 9: Air Compressor Page 1 of 12Dokument12 SeitenAir Compressor House: Guide Book For Utility Operation, Section 9: Air Compressor Page 1 of 12joymotiNoch keine Bewertungen

- Cold Startup 1Dokument51 SeitenCold Startup 1Vel MuruganNoch keine Bewertungen

- Null PDFDokument70 SeitenNull PDFQuán Cóc Sài GònNoch keine Bewertungen

- Cooling System (2Az-Fe) : On-Vehicle InspectionDokument27 SeitenCooling System (2Az-Fe) : On-Vehicle InspectionTung NguyenNoch keine Bewertungen

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Dokument23 SeitenIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNoch keine Bewertungen

- Manual Trident Klasik 200Dokument12 SeitenManual Trident Klasik 200DanielMachadopovoa100% (1)

- CBIP PublicationDokument6 SeitenCBIP PublicationVamsi ManojNoch keine Bewertungen

- Conair Temperature Control ManualDokument27 SeitenConair Temperature Control ManualArmando RiveraNoch keine Bewertungen

- EKC312Dokument12 SeitenEKC312bmw72Noch keine Bewertungen

- Front View OF Ecp Sim Ulator: Electronic Control Panel (Ec P) SimulatorDokument7 SeitenFront View OF Ecp Sim Ulator: Electronic Control Panel (Ec P) SimulatornaveenNoch keine Bewertungen

- Question#1 (10 Marks) : Start Switch. StopDokument4 SeitenQuestion#1 (10 Marks) : Start Switch. StopOmar YehiaNoch keine Bewertungen

- AC001 Carrier 30HWC035 Chiller Wiring-30HWADokument12 SeitenAC001 Carrier 30HWC035 Chiller Wiring-30HWACelso OtalNoch keine Bewertungen

- Blow Off Valves DescriptionDokument12 SeitenBlow Off Valves DescriptionParmeshwar Nath TripathiNoch keine Bewertungen

- Arl 300 Error Codesen PDFDokument4 SeitenArl 300 Error Codesen PDFAbdul sattar100% (1)

- LC HDP 1100 D2数显喷油器13版说明书Dokument22 SeitenLC HDP 1100 D2数显喷油器13版说明书DariusNoch keine Bewertungen

- Demo Case Siemens Lmv5Dokument8 SeitenDemo Case Siemens Lmv5Arturo Rumba Hernandez CalixtoNoch keine Bewertungen

- 3gts250 Workshop Manual-3Dokument109 Seiten3gts250 Workshop Manual-3Fernando MattinaNoch keine Bewertungen

- B737 200a - JT8D 15aDokument1 SeiteB737 200a - JT8D 15aMohammad AhmedNoch keine Bewertungen

- Ata 70Dokument6 SeitenAta 70phonesavanh.dod1989Noch keine Bewertungen

- Comments On GM ValvesDokument2 SeitenComments On GM ValvesNaveen NagisettiNoch keine Bewertungen

- Warning Chiller PDFDokument64 SeitenWarning Chiller PDFnurcahyo febriNoch keine Bewertungen

- Riello Burners Gas3-2 RMG PDFDokument16 SeitenRiello Burners Gas3-2 RMG PDFchnanduNoch keine Bewertungen

- Ac Heater System AutoDokument18 SeitenAc Heater System AutoToua YajNoch keine Bewertungen

- DTC 24 Intake Air Temp. Sensor Circuit MalfunctionDokument6 SeitenDTC 24 Intake Air Temp. Sensor Circuit Malfunctionrahul_nissanNoch keine Bewertungen

- SSP 296 1.4 & 1.6 FSi EngineDokument24 SeitenSSP 296 1.4 & 1.6 FSi Engineภูเก็ต เป็นเกาะ100% (3)

- P0158 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairDokument17 SeitenP0158 (ALL Diagnostic Trouble Codes (DTC) ) - ALLDATA RepairMuhammad Attohar Ibnu RafiNoch keine Bewertungen

- Starting: Operating Instructions For Thermic Fluid HeatersDokument4 SeitenStarting: Operating Instructions For Thermic Fluid HeatersSachin PatelNoch keine Bewertungen

- Chapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesDokument6 SeitenChapter 4 Part C:: Fuel and Exhaust Systems - K-Jetronic Fuel Injection - 16 Valve EnginesmohhizbarNoch keine Bewertungen

- G Group 6 Troubleshooting: 1. When Starting Switch Is Turned On, Cluster Lamp Does Not Light UpDokument9 SeitenG Group 6 Troubleshooting: 1. When Starting Switch Is Turned On, Cluster Lamp Does Not Light UpPriscila RodriguesNoch keine Bewertungen

- A310 ExamDokument27 SeitenA310 ExamdariushshNoch keine Bewertungen

- Marvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SVon EverandMarvel Carbureter and Heat Control: As Used on Series 691 Nash Sixes Booklet SNoch keine Bewertungen

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitVon EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitNoch keine Bewertungen

- Summer Internship in JaipurDokument12 SeitenSummer Internship in JaipurLinuxWorldIndiaNoch keine Bewertungen

- JOURNAL REVIEW Government Policy of Indonesia To Managing Demographic Bonus and Creating Indonesia Gold in 2045Dokument5 SeitenJOURNAL REVIEW Government Policy of Indonesia To Managing Demographic Bonus and Creating Indonesia Gold in 2045albertus amandaruNoch keine Bewertungen

- Previous HSE Questions and Answers of The Chapter "SOLUTIONS"Dokument97 SeitenPrevious HSE Questions and Answers of The Chapter "SOLUTIONS"ABDUL RAZACKNoch keine Bewertungen

- Lec04 - Types of RegistersDokument17 SeitenLec04 - Types of RegistersBilal ImranNoch keine Bewertungen

- Patient Safety - Examining Every Aspect of Every System To Improve OutcomesDokument3 SeitenPatient Safety - Examining Every Aspect of Every System To Improve OutcomesBeni BolngNoch keine Bewertungen

- TestDokument4 SeitenTestAlina DushachenkoNoch keine Bewertungen

- Atma Rama Anandha Ramana - Scenes PDFDokument2 SeitenAtma Rama Anandha Ramana - Scenes PDFKoushik KattaNoch keine Bewertungen

- Asgkit Coding STDDokument10 SeitenAsgkit Coding STDDavid ZamudioNoch keine Bewertungen

- Xtraction User GuideDokument63 SeitenXtraction User Guidegunalprasadg100% (1)

- Criteria For SQF Certification Bodies: 7th EditionDokument12 SeitenCriteria For SQF Certification Bodies: 7th EditioncristinaNoch keine Bewertungen

- 2014 Rondy GuideDokument60 Seiten2014 Rondy GuideJeffrey RivetNoch keine Bewertungen

- Dictum Giftideas 2012Dokument40 SeitenDictum Giftideas 2012Alexandre LetellierNoch keine Bewertungen

- Descriptive Lab Report GuideDokument3 SeitenDescriptive Lab Report GuideOluwafisayomi LawaniNoch keine Bewertungen

- Role of Women in Urban and Rural AreasDokument3 SeitenRole of Women in Urban and Rural AreasUmair AltafNoch keine Bewertungen

- Transient Torque Rise of A Modern Light Duty Diesel Engine With Variable Valve ActuationDokument12 SeitenTransient Torque Rise of A Modern Light Duty Diesel Engine With Variable Valve ActuationdheepanasNoch keine Bewertungen

- Case Study: Question 1)Dokument2 SeitenCase Study: Question 1)Hoai CoiNoch keine Bewertungen

- 6 Tutorial The Rail Dispute DebriefDokument16 Seiten6 Tutorial The Rail Dispute DebriefjesseNoch keine Bewertungen

- T Shirt Design in Adobe Illustrator For Beginner To AdvancedDokument3 SeitenT Shirt Design in Adobe Illustrator For Beginner To AdvancedAlejandro ZozorangaNoch keine Bewertungen

- Minimum Drag Velocity ExplainedDokument4 SeitenMinimum Drag Velocity ExplainedpersesutiNoch keine Bewertungen

- Kullu Tamam Merged - Cropped - TextDokument345 SeitenKullu Tamam Merged - Cropped - TextEuro-trading GroupNoch keine Bewertungen