Beruflich Dokumente

Kultur Dokumente

How To Stack Concrete Paving Moulds For The Best Curing

Hochgeladen von

7vortex9Originalbeschreibung:

Originaltitel

Copyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

How To Stack Concrete Paving Moulds For The Best Curing

Hochgeladen von

7vortex9Copyright:

Verfügbare Formate

How to stack

concrete

paving

moulds

for the best curing

How to stack paving moulds for the best

curing.

Top Tips

Curing Concrete

Curing concrete is a term used for stopping freshly poured concrete from

drying out too quickly. This is done because concrete if left to dry out on its

on accord, and will not develop the bond between all of its ingredients.

Curing is one of the most important steps in concrete construction, because

proper curing greatly increases concrete strength and durability.

Aids to curing

Hydration

Concrete hardens as a result of hydration: the chemical reaction between

cement and water.

Add heat during the hydration process

Hydration occurs only if water is available and if the concrete's temperature

stays within a suitable range.

Keep moist

During the curing period (from five to seven days after placement for

conventional concrete) the concrete surface needs to be kept moist to permit

the hydration process. New concrete can be wet with soaking hoses,

sprinklers or covered with wet burlap, or can be coated with commercially

available curing compounds, which seal in moisture.

Using polythene to prevent moisture loss

The plastic should be laid in direct contact with the concrete surface

as soon as possible without marring the surface. The edges of the

sheets should overlap and be fastened with waterproof tape and

then weighted down to prevent the wind from getting under the

plastic. Plastic will make dark streaks wherever a wrinkle touches

the concrete so plastic should not be used on concretes where

appearance is important.

Chemical Membranes

Apply to the concrete surface about one hour after

finishing. Do not apply to concrete that is still bleeding, or

has a visible water sheen on the surface. While a clear

liquid may be used, a white pigment will give reflective

properties, and allow for inspection of coverage. A single

coat may be adequate but where possible a second coat,

applied at right angles to the first, is desirable for even

coverage. If the concrete will be painted, or covered with

vinyl or ceramic tile, then a liquid compound that is non-

reactive with the paint or adhesives must be used, or a

compound that is easily brushed or washed off. On floors,

the surface should be protected from the other trades with

scuff-proof paper after the application of the curing

compound.

Retain the heat of hydration with insulated covers

Temperature extremes make it difficult to properly cure concrete. On hot days,

too much water is lost by evaporation

from newly placed concrete. If the

temperature drops too close to freezing,

hydration slows to nearly a standstill.

Under these conditions, concrete ceases

to gain strength and other desirable

properties. In general, the temperature of

new concrete should not be allowed to fall

below 50 Fahrenheit (10 Celsius) during

the curing period.

A good curing blanket will ensure that

your concrete will cure faster in the summer and enable you to pour concrete

in colder weather. Meaning your team and precast works can keep working

throughout the winter.

A good blanket should have at least 90% heat retention, and be made from a

heavy duty terylene reinforced PVC, whilst being filled with a good insulator

like polyester fibre.

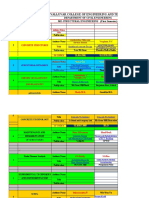

Stacking curing moulds

During the curing process these paving mould can be stacked on top of one

another by using timber separators between the steel casing.

Das könnte Ihnen auch gefallen

- Curing Concrete: by David CarnsDokument3 SeitenCuring Concrete: by David CarnsRobert Candra TarunaNoch keine Bewertungen

- Hollow Block Making - NHADokument14 SeitenHollow Block Making - NHAjowie james octat100% (1)

- Cement Concrete Hollow BlocksDokument10 SeitenCement Concrete Hollow Blocksjohn koraNoch keine Bewertungen

- Concrete Hollow BlocksDokument6 SeitenConcrete Hollow Blocksaljilen hernandezNoch keine Bewertungen

- Curing Concrete - Concrete Technology - Portland Cement Association (PCA)Dokument6 SeitenCuring Concrete - Concrete Technology - Portland Cement Association (PCA)Jay PatelNoch keine Bewertungen

- Concrete Curing Time - The Right Time To Cure ConcreteDokument4 SeitenConcrete Curing Time - The Right Time To Cure ConcreteMohammed SalemNoch keine Bewertungen

- Concrete Proportion and Concrete MixtureDokument12 SeitenConcrete Proportion and Concrete MixtureEnrico luis EscobarNoch keine Bewertungen

- Cement NotesDokument41 SeitenCement NotesPremnath YadavNoch keine Bewertungen

- Mould Materials: - An OverviewDokument5 SeitenMould Materials: - An Overview7vortex9Noch keine Bewertungen

- Specifications For Interlocking Concrete Blockpavement PDFDokument21 SeitenSpecifications For Interlocking Concrete Blockpavement PDFVijaya KumarNoch keine Bewertungen

- Concrete Sealer: - What Does It Do and How Does It Do It?Dokument2 SeitenConcrete Sealer: - What Does It Do and How Does It Do It?7vortex9Noch keine Bewertungen

- Hollow Block Machine DesignDokument116 SeitenHollow Block Machine DesignbernabasNoch keine Bewertungen

- Cement Concrete Block Masonry SpecificationsDokument8 SeitenCement Concrete Block Masonry SpecificationsYannick PrattNoch keine Bewertungen

- Concrete Curing Time and Duration - Right Time of Curing ConcreteDokument4 SeitenConcrete Curing Time and Duration - Right Time of Curing ConcreteJustin MusopoleNoch keine Bewertungen

- CONCRETE: PROPERTIES AND USESDokument5 SeitenCONCRETE: PROPERTIES AND USESDARK KnightNoch keine Bewertungen

- Cement Concrete BlocksDokument21 SeitenCement Concrete BlocksIndika Yapa0% (2)

- Civil Engineering Cracks Types and CausesDokument8 SeitenCivil Engineering Cracks Types and Causeskatia diaNoch keine Bewertungen

- Floors: ARC 2380 Construction and Materials-IiiDokument60 SeitenFloors: ARC 2380 Construction and Materials-IiiAlisha KhanNoch keine Bewertungen

- Special types of concrete explained in detailDokument20 SeitenSpecial types of concrete explained in detailAshok Kumar RajanavarNoch keine Bewertungen

- BPD Master Catalogue-2Dokument18 SeitenBPD Master Catalogue-2Dr. Manamohan R KalgalNoch keine Bewertungen

- New QTJ 4-26 Production Line PDFDokument3 SeitenNew QTJ 4-26 Production Line PDFTwokir A. TomalNoch keine Bewertungen

- Selection of FoundationDokument16 SeitenSelection of FoundationroshanNoch keine Bewertungen

- Flooring PresentationDokument30 SeitenFlooring PresentationNevin PudukadNoch keine Bewertungen

- Concrete Surface Treatments - 2Dokument4 SeitenConcrete Surface Treatments - 2derma_irmawanNoch keine Bewertungen

- DR Fixit Powder WaterproofDokument2 SeitenDR Fixit Powder Waterprooflokeshras12Noch keine Bewertungen

- Building Management System (BMS) OR Building Automation System (BAS)Dokument23 SeitenBuilding Management System (BMS) OR Building Automation System (BAS)NIRU CHAUDHARYNoch keine Bewertungen

- Cemfil Sprayguide WW 12 2008 Rev1Dokument32 SeitenCemfil Sprayguide WW 12 2008 Rev1freidorNoch keine Bewertungen

- Grades of Concrete and Their UsesDokument4 SeitenGrades of Concrete and Their UsesRandyNoch keine Bewertungen

- Concrete Technology Module 1 NotesDokument26 SeitenConcrete Technology Module 1 NotesDEDAN KIMATHINoch keine Bewertungen

- Foamed ConcreteDokument24 SeitenFoamed ConcretewlidhaaaNoch keine Bewertungen

- Tamseal 20Dokument2 SeitenTamseal 20pravi3434Noch keine Bewertungen

- Grouts Standards and TestingDokument12 SeitenGrouts Standards and TestingmithileshNoch keine Bewertungen

- Cracks and Shrinkage On ConcreteDokument3 SeitenCracks and Shrinkage On ConcreteCaryl Louise ObcianaNoch keine Bewertungen

- Dr. C. D. Modhera - Day 3 - Session 1Dokument93 SeitenDr. C. D. Modhera - Day 3 - Session 1mbgfknjhgfNoch keine Bewertungen

- 8 Plastering PDFDokument26 Seiten8 Plastering PDFZayedur RahmanNoch keine Bewertungen

- Waterproofing Membranes Under 40 CharactersDokument4 SeitenWaterproofing Membranes Under 40 CharactersshashiNoch keine Bewertungen

- Cement Mortar: Properties and UsesDokument9 SeitenCement Mortar: Properties and UsesCHRISTIAN COLLIN LOPEZNoch keine Bewertungen

- Concrete Masonry ReportDokument21 SeitenConcrete Masonry ReportPrincess Earl Dianne LaderaNoch keine Bewertungen

- Technical Data BookletDokument53 SeitenTechnical Data Booklettracy8763Noch keine Bewertungen

- Special ConcretesDokument4 SeitenSpecial ConcretesVikash KumarNoch keine Bewertungen

- Construction Materials and TestingDokument61 SeitenConstruction Materials and TestingAliñabo RoqueNoch keine Bewertungen

- Sab 2112 - L7 ConcreteDokument54 SeitenSab 2112 - L7 Concreteapi-19705508Noch keine Bewertungen

- Plugin Paints Coatings New Developments 2k Waterborne Epoxy CoatingsDokument14 SeitenPlugin Paints Coatings New Developments 2k Waterborne Epoxy CoatingsjasminneeNoch keine Bewertungen

- Bond and Compressive Strength of Masonry For Locally Available BricksDokument8 SeitenBond and Compressive Strength of Masonry For Locally Available BricksKamran JavedNoch keine Bewertungen

- Field Tests for Construction MaterialsDokument25 SeitenField Tests for Construction MaterialsAntarjyami PradhanNoch keine Bewertungen

- Properties of Concrete As Construction MaterialDokument22 SeitenProperties of Concrete As Construction MaterialEdisonNoch keine Bewertungen

- Introduction to the Manufacturing Process of Cement Concrete Hollow BlocksDokument17 SeitenIntroduction to the Manufacturing Process of Cement Concrete Hollow BlocksDebasishSwainNoch keine Bewertungen

- Solid Block Manufacturing ProcessDokument4 SeitenSolid Block Manufacturing Processa paul jayakumarNoch keine Bewertungen

- Concrete Construction Article PDF - Heavy Duty Pavements PDFDokument4 SeitenConcrete Construction Article PDF - Heavy Duty Pavements PDFRehanNoch keine Bewertungen

- AdmixtureDokument6 SeitenAdmixtureDunvillNoch keine Bewertungen

- Experimental Investigations On Fiber Reinforced Concrete With Lathe Fibers For Sustainable ConstructionDokument14 SeitenExperimental Investigations On Fiber Reinforced Concrete With Lathe Fibers For Sustainable ConstructionAditya SutarNoch keine Bewertungen

- A Guide To Concretre PracticeDokument56 SeitenA Guide To Concretre Practiceመንግስቱ ፀጋዬNoch keine Bewertungen

- URBAN DESIGN unit-IVDokument16 SeitenURBAN DESIGN unit-IVmrunalini KolaNoch keine Bewertungen

- 2007 Penetron BrochureDokument14 Seiten2007 Penetron Brochurekdee075Noch keine Bewertungen

- S# Item C Waterproofing On SurfacesDokument8 SeitenS# Item C Waterproofing On SurfacesDeepa Junnarkar Degwekar100% (1)

- Common Defects in PlasterDokument2 SeitenCommon Defects in PlasterHatta RizqNoch keine Bewertungen

- Making Building Blocks With The CINVA Ram Block PressDokument24 SeitenMaking Building Blocks With The CINVA Ram Block PressreaderwriteNoch keine Bewertungen

- An Introduction To Concrete TechnologyDokument54 SeitenAn Introduction To Concrete TechnologyBharat ReddyNoch keine Bewertungen

- Curing Concrete: by David CarnsDokument3 SeitenCuring Concrete: by David CarnsNgissah NketiahNoch keine Bewertungen

- A Discussion On Curing and Sealing: By: Hank HaugeDokument11 SeitenA Discussion On Curing and Sealing: By: Hank HaugeErMelvinDiasNoch keine Bewertungen

- Sand Filters Technical Guidelines For The Construction and Management 2009Dokument69 SeitenSand Filters Technical Guidelines For The Construction and Management 20097vortex9Noch keine Bewertungen

- Low Cost Construction TechniquesDokument20 SeitenLow Cost Construction TechniquesJai Belpathak Shejwalkar100% (3)

- Recycled Glass Portland - Cement - Concrete 2001Dokument2 SeitenRecycled Glass Portland - Cement - Concrete 20017vortex9Noch keine Bewertungen

- Release Agent Which Should I UseDokument2 SeitenRelease Agent Which Should I Use7vortex9Noch keine Bewertungen

- Cement 92+ Grade High PerformanceDokument5 SeitenCement 92+ Grade High Performance7vortex9Noch keine Bewertungen

- Reinforcement Corrosion Concrete 2008Dokument9 SeitenReinforcement Corrosion Concrete 20087vortex9Noch keine Bewertungen

- Fly Ash High Volume Concrete (HVFAC) Field Perform. IndiaDokument15 SeitenFly Ash High Volume Concrete (HVFAC) Field Perform. India7vortex9Noch keine Bewertungen

- Precasting Outdoors: - PrecastDokument3 SeitenPrecasting Outdoors: - Precast7vortex9Noch keine Bewertungen

- How To Place Concrete Posts Accurately and EfficientlyDokument2 SeitenHow To Place Concrete Posts Accurately and Efficiently7vortex9Noch keine Bewertungen

- Is My Old Concrete Mixer Costing Me MoneyDokument3 SeitenIs My Old Concrete Mixer Costing Me Money7vortex9Noch keine Bewertungen

- Release Agent Which Should I UseDokument2 SeitenRelease Agent Which Should I Use7vortex9Noch keine Bewertungen

- How To Place Concrete Posts Accurately and EfficientlyDokument2 SeitenHow To Place Concrete Posts Accurately and Efficiently7vortex9Noch keine Bewertungen

- How To Use Less CementDokument3 SeitenHow To Use Less Cement7vortex9Noch keine Bewertungen

- Mould Materials: - An OverviewDokument5 SeitenMould Materials: - An Overview7vortex9Noch keine Bewertungen

- How To Stack Concrete PanelsDokument3 SeitenHow To Stack Concrete Panels7vortex9Noch keine Bewertungen

- Air Entrained ConcreteDokument3 SeitenAir Entrained Concrete7vortex9Noch keine Bewertungen

- How To Reduce Lime BloomDokument3 SeitenHow To Reduce Lime Bloom7vortex9Noch keine Bewertungen

- How To Make Your Own Moulds Using ArmpolDokument11 SeitenHow To Make Your Own Moulds Using Armpol7vortex9Noch keine Bewertungen

- The Past Wasn't So Long Ago: How A WWI-era Concrete Building Surprised Us With Its Connection To The PastDokument7 SeitenThe Past Wasn't So Long Ago: How A WWI-era Concrete Building Surprised Us With Its Connection To The Past7vortex9Noch keine Bewertungen

- Foam ConcreteDokument3 SeitenFoam Concrete7vortex9Noch keine Bewertungen

- Concrete Sealer: - What Does It Do and How Does It Do It?Dokument2 SeitenConcrete Sealer: - What Does It Do and How Does It Do It?7vortex9Noch keine Bewertungen

- Engineering Design GuidelinesDokument26 SeitenEngineering Design Guidelines7vortex9Noch keine Bewertungen

- Concrete Door & Window FramesDokument2 SeitenConcrete Door & Window Frames7vortex9Noch keine Bewertungen

- Benefits of Waterproofer in PrecastDokument3 SeitenBenefits of Waterproofer in Precast7vortex9Noch keine Bewertungen

- Concrete Guide Flatwork Finishes. Aust. 2008Dokument132 SeitenConcrete Guide Flatwork Finishes. Aust. 20087vortex9Noch keine Bewertungen

- Concrete Floating Barges + HomesDokument8 SeitenConcrete Floating Barges + Homes7vortex9Noch keine Bewertungen

- Methods of Repairing Concrete StructuresDokument44 SeitenMethods of Repairing Concrete Structures7vortex9Noch keine Bewertungen

- Branching Structures SmallDokument22 SeitenBranching Structures Small7vortex9Noch keine Bewertungen

- ACC Panel Manufacturing Specs Pan PacificDokument17 SeitenACC Panel Manufacturing Specs Pan PacificSandesh RaneNoch keine Bewertungen

- Boq6 PDFDokument7 SeitenBoq6 PDFmd. shaju ahamedNoch keine Bewertungen

- Sr. No. Description of Sub-Estimate Amount (RS.) Abstract of CostDokument34 SeitenSr. No. Description of Sub-Estimate Amount (RS.) Abstract of CostVIJAYNoch keine Bewertungen

- Baxi Climatizacion Slu - Sila RCV 300 - 1841vs03 - enDokument4 SeitenBaxi Climatizacion Slu - Sila RCV 300 - 1841vs03 - encolomboiplNoch keine Bewertungen

- Flex CellDokument2 SeitenFlex CellNorlizawati Yusof100% (1)

- Admixtures Improve Concrete PropertiesDokument3 SeitenAdmixtures Improve Concrete PropertiesAbhiNoch keine Bewertungen

- Seismic Retrofitting of Unreinforced Masonry Walls by FRP StripsDokument8 SeitenSeismic Retrofitting of Unreinforced Masonry Walls by FRP StripsIbrahim DanishNoch keine Bewertungen

- ABCM - Highrise - Part 1 - JDDokument42 SeitenABCM - Highrise - Part 1 - JDAmey DeshmukhNoch keine Bewertungen

- BD2 Lec Midterm Exam.Dokument18 SeitenBD2 Lec Midterm Exam.Gian MalabananNoch keine Bewertungen

- Room-Integ-TestDokument4 SeitenRoom-Integ-TestBinu Sulochanan100% (1)

- Concrete DesignDokument106 SeitenConcrete DesignBoy AlfredoNoch keine Bewertungen

- Dormer Construuction DrawingDokument1 SeiteDormer Construuction DrawingosviNoch keine Bewertungen

- Approval Material Beton VUB LengkapDokument44 SeitenApproval Material Beton VUB LengkapFatkhur RozakNoch keine Bewertungen

- Residential Specs GuideDokument3 SeitenResidential Specs GuideBernie RomeroNoch keine Bewertungen

- Bar Bending Schedule for 5m x 3.05m x 4.57m Box CulvertDokument1 SeiteBar Bending Schedule for 5m x 3.05m x 4.57m Box CulvertJelal EdrisNoch keine Bewertungen

- ME-Structural BooksDokument11 SeitenME-Structural BooksARUL SANKARANNoch keine Bewertungen

- Reinforced concrete beam and floor slab detailsDokument1 SeiteReinforced concrete beam and floor slab detailsRbcabajes ButalonNoch keine Bewertungen

- Effect of Rice Husk Ash and Sugarcane Bagasse Ash On Mechanical Properties and Sorptivity of ConcreteDokument38 SeitenEffect of Rice Husk Ash and Sugarcane Bagasse Ash On Mechanical Properties and Sorptivity of ConcreteHidayat UllahNoch keine Bewertungen

- Housing Project BOQ Billing FormatDokument125 SeitenHousing Project BOQ Billing Formatarchie_728100% (5)

- Eim DLLDokument4 SeitenEim DLLivy mark villamorNoch keine Bewertungen

- UCL Fire Safety Technical Guide: Key Terms & DefinitionsDokument5 SeitenUCL Fire Safety Technical Guide: Key Terms & DefinitionsByamba BimbaNoch keine Bewertungen

- Cable TrenchDokument5 SeitenCable TrenchFarah SyazanaNoch keine Bewertungen

- Can Be Considered The Thin-Walled Steel Structures Suitable To Be Used in Seismic Regions?Dokument18 SeitenCan Be Considered The Thin-Walled Steel Structures Suitable To Be Used in Seismic Regions?uhu_plus6482Noch keine Bewertungen

- Cooling TowerDokument20 SeitenCooling Towerashish2783100% (1)

- Sewerage and Drainage SectionDokument40 SeitenSewerage and Drainage Sectionmasahin100% (1)

- Trimoterm Technical SpecificationDokument5 SeitenTrimoterm Technical Specificationnajdo1Noch keine Bewertungen

- FosrocDokument83 SeitenFosrocIzwan Buj100% (1)

- HVAC Understanding Basics TOCDokument12 SeitenHVAC Understanding Basics TOCexperthvachomeNoch keine Bewertungen

- Flat Slabs: Design of Flat Slabs With and Without Drops by Direct Design Method of IS Code-Design and DrawingDokument23 SeitenFlat Slabs: Design of Flat Slabs With and Without Drops by Direct Design Method of IS Code-Design and DrawingSenthil KumarNoch keine Bewertungen

- AITECH Manual As of November 2022Dokument36 SeitenAITECH Manual As of November 2022Eric LansangNoch keine Bewertungen

- Principles of Geotechnical Engi - Braja M. Das Khaled SobhanDokument11 SeitenPrinciples of Geotechnical Engi - Braja M. Das Khaled SobhanshivaNoch keine Bewertungen