Beruflich Dokumente

Kultur Dokumente

Oxidation

Hochgeladen von

alokjadhavCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Oxidation

Hochgeladen von

alokjadhavCopyright:

Verfügbare Formate

Oxidation Oxidation

Oxidation Oxidation

Introduction

Applications Applications

Mechanism

P Process

System

RTO

Introduction Introduction

Siliconreactswithoxygen

Stable oxide compound Stableoxidecompound

WidelyusedinICmanufacturing

Si+O

2

SiO

2

Oxidation

OriginalSiliconSurface

SiliconDioxide

Silicon

O

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

O

2

45% 55%

SomeFactsAboutSilicon

Name Silicon Name Silicon

Symbol Si

Atomic number 14

Atomic weight 28.0855

Discoverer J ns J acob Berzelius Discoverer J ns J acob Berzelius

Discovered at Sweden

Discovery date 1824

Origin of name From the Latin word "silicis" meaning "flint"

Bond length in singlecrystal Si 2 352 Bond length in single crystal Si 2.352

Density of solid 2.33 g/cm

3

Molar volume 12.06 cm

3

Velocity of sound 2200 m/sec

Hardness 6 5 Hardness 6.5

Electrical resistivity

100,000 cm

Reflectivity 28%

Melting point

1414 C

B ili i t

2900 C

Boiling point

2900 C

Thermal conductivity 150 W m

-1

K

-1

Coefficient of linear thermal

expansion

2.610

-6

K

-1

Etchants (wet) HNO

4

and HF, KOH, etc.

Etchants (dry) HBr, Cl

2

, NF

3

, etc.

CVD Precursor SiH

4

, SiH

2

Cl

2

, SiHCl

3

, and SiCl

4

FactAboutOxygen

Name Oxygen

Symbol O

Atomic number 8

Atomic weight 15.9994

Discoverer J oseph Priestley, Carl Scheele

Discovered at England, Sweden

Discoverydate 1774 Discovery date 1774

Origin of name From the Greek words "oxy genes" meaning

"acid" (sharp) and "forming" (acid former)

Molar volume 17.36 cm

3

Velocity of sound 317.5 m/sec

Refractivity 1.000271

Melting point

54.8 K =-218.35 C

Boilingpoint

902K 18295C

Boiling point

90.2 K =-182.95 C

Thermal conductivity 0.02658 W m

-1

K

-1

Applications Thermal oxidation, oxide CVD, reactive

sputtering and photoresist stripping

Main sources O

2

, H

2

O, N

2

O, O

3

Application of Oxidation ApplicationofOxidation

DiffusionMaskingLayer

Surface Passivation SurfacePassivation

Screenoxide,padoxide,barrieroxide

Isolation Isolation

FieldoxideandLOCOS

Gateoxide

Diffusion Barrier DiffusionBarrier

MuchlowerBandPdiffusionratesinSiO

2

than

thatinSi

SiO

2

canbeusedasdiffusionmask

Dopant

SiO

2

SiO

2

Si

SiO

2

SiO

2

Application, Surface Passivation Application,SurfacePassivation

PadOxide ScreenOxide

Sacrificial Oxide Barrier Oxide

SiO

2

SacrificialOxide BarrierOxide

Si

Normallythinoxidelayer(~150)toprotectsilicon

defects from contamination and over stress defectsfromcontaminationandoverstress.

ScreenOxide

Dopant Ions

Photoresist Photoresist

DopantIons

Si Substrate SiSubstrate

ScreenOxide

PadandBarrierOxidesinSTIProcess

PadOxide

Nitride

Silicon

TrenchEtch

USG

l

PadOxide

Nitride

Silicon

USG

BarrierOxide

TrenchFill

Silicon

USGCMP;USGAnneal;NitrideandPadOxideStrip

Application, Pad Oxide Application,PadOxide

Relievestrongtensilestressofthenitride

Preventstressinducedsilicondefects

l d

PadOxide

Siliconnitride

SiliconSubstrate

Application, Device Isolation Application,DeviceIsolation

Electronicisolationofneighboringdevices

Blanketfieldoxide

Local oxidation of silicon (LOCOS) Localoxidationofsilicon(LOCOS)

Thickoxide,usually3,000to10,000

BlanketFieldOxideIsolation

Silicon

WaferClean

Silicon

SiliconDioxide

Fi ld O id

FieldOxidation

ActivationArea

Silicon

FieldOxide

OxideEtch

LOCOSProcess

Siliconnitride

P t b t t

PadOxide

Ptypesubstrate

Padoxidation,nitridedepositionandpatterning

b

Siliconnitride

SiO

2

Ptypesubstrate p

+

p

+

p

+

IsolationDoping

LOCOSoxidation

BirdsBeak

Ptypesubstrate p

+

p

+

p

+

IsolationDoping

SiO

2

Nitrideandpadoxidestrip

LOCOS LOCOS

C ith bl k t fi ld id Comparewithblanketfieldoxide

Betterisolation

Lowerstepheight

Lesssteepsidewall

Disadvantage

roughsurfacetopography

Birdsbeak

Replacingbyshallowtrenchisolation(STI) p g y ( )

Application, Sacrificial Oxide Application,SacrificialOxide

Defectsremovalfromsiliconsurface

STI

USG

SacrificialOxide

NWell

PWell

STI

USG

SacrificialOxidation

NWell

PWell

STI

USG

StripSacrificialOxide

Gate Oxide

NWell

PWell

STI

USG

G t O id ti

GateOxide

GateOxidation

Application, Device Dielectric Application,DeviceDielectric

Gate oxide: thinnest and most critical layer Gateoxide:thinnestandmostcriticallayer

Capacitordielectric

Poly Si

V

D

>0 V

G

n

+

Gate

Thinoxide

Si

n

+

Si Substrate

Source Drain

pSi

Electrons

Oxide and Applications OxideandApplications

NameoftheOxide Thickness Application Timeinapplication

Native 15 20 undesirable

Screen ~200 Implantation Mid70stopresent

Masking ~5000 Diffusion 1960stomid1970s

FieldandLOCOS 3000 5000 Isolation 1960sto1990s

Pad 100 200 Nitridestressbuffer 1960stopresent

Sacrificial <1000 Defectremoval 1970stopresent

Gate 30 120 Gatedielectric 1960stopresent

Barrier 100 200 STI 1980stopresent

Silicon Dioxide Grown on Improperly SiliconDioxideGrownonImproperly

CleanedSiliconSurface

PreoxidationWaferClean

Particulates

Organicresidues

Inorganicresidues g

Nativeoxidelayers

RCA Clean RCAClean

Developed by Kern and Puotinen in 1960 at RCA DevelopedbyKernandPuotinenin1960atRCA

MostcommonlyusedcleanprocessesinICfabs

SC O O O i h 2 i SC1 NH

4

OH:H

2

O

2

:H

2

Owith1:1:5to1:2:7ratio

at70to80Ctoremoveorganiccontaminants.

SC2 HCl:H

2

O

2

:H

2

Owith1:1:6to1:2:8ratioat70

to80Ctoremoveinorganiccontaminates.

DIwaterrinse

HF dip or HF vapor etch to remove native oxide HFdiporHFvaporetchtoremovenativeoxide.

PreoxidationWaferClean

ParticulateRemoval

Highpuritydeionized(DI)wateror

f ll d b i H

2

SO

4

:H

2

O

2

followedbyDIH

2

Orinse.

Highpressurescruborimmersioninheated

dunktankfollowedbyrinse,spindry

and/ordrybake(100to125C).

PreoxidationWaferClean

OrganicRemoval

Strongoxidantsremoveorganicresidues.

H

2

SO

4

:H

2

O

2

orNH

3

OH:H

2

O

2

followedbyDI

H

2

Orinse.

Highpressurescruborimmersioninheated

dunktankfollowedbyrinse,spindry y , p y

and/ordrybake(100to125C).

PreoxidationWaferClean

InorganicRemoval

HCl:H

2

O.

Immersionindunktankfollowedbyrinse,

spindryand/ordrybake(100to125C).

PreoxidationWaferClean

NativeOxideRemoval

HF:H

2

O.

Immersionindunktankorsinglewafer

vaporetcherfollowedbyrinse,spindry

and/ordrybake(100to125C).

Oxidation Mechanism OxidationMechanism

Si+O

2

SiO

2

Oxygen comes from gas Oxygencomesfromgas

Siliconcomesfromsubstrate

O diff i i ili Oxygendiffusecrossexistingsilicon

dioxidelayerandreactwithsilicon

Thethickerofthefilm,thelowerof

thegrowthrate

Oxide Growth Rate Regime OxideGrowthRateRegime

LinearGrowthRegime

B

n

e

s

s

A

X=t

O

x

i

d

e

T

h

i

c

k

n

DiffusionlimitedRegime

X= Bt

O

OxidationTime

<100> Silicon Dry Oxidation <100>SiliconDryOxidation

1 2

1.0

1.2

1200C

<100>SiliconDryOxidation

0.6

0.8

s

s

(

m

i

c

r

o

n

)

1150C

1100C

0 2

0.4

d

e

T

h

i

c

k

n

e

s

1050C

1000C

950C

2 4 6 8 10 12 14 16 18 20

0.2

0

O

x

i

d

900C

OxidationTime(hours)

Wet (Steam) Oxidation Wet(Steam)Oxidation

Si + 2H

2

O SiO

2

+ 2H

2

Si+2H

2

O SiO

2

+2H

2

AthightemperatureH

2

OisdissociatedtoH

and H O andHO

HOdiffusesfasterinSiO

2

thanO

2

Wetoxidationhashighergrowthratethandry

oxidation.

<100>SiliconWetOxidationRate

3.0

1150C

1100 C

<100>SiliconWetOxidation

2 0

2.5

n

)

1100 C

1050C

1000C

1.5

2.0

e

s

s

(

m

i

c

r

o

n

950C

900C

0.5

1.0

x

i

d

e

T

h

i

c

k

n

2 4 6 8 10 12 14 16 18 20 0

Oxidation Time (hours)

O

x

OxidationTime(hours)

Oxidation Rate OxidationRate

Temperature

Chemistry wet or dry oxidation Chemistry,wetordryoxidation

Thickness

P Pressure

Waferorientation(<100>vs.<111>)

Silicondopant

OxidationRate

Oxidation rate is very sensitive (exponentially

Temperature

Oxidationrateisverysensitive(exponentially

related)totemperature

Higher temperature will have much higher Highertemperaturewillhavemuchhigher

oxidationrate.

The higher of temperature is, the higher of the Thehigheroftemperatureis,thehigherofthe

chemicalreactionratebetweenoxygenand

siliconisandthehigherdiffusionrateof

oxygeninsilicondioxideis.

OxidationRate

WaferOrientation

<111>surfacehashigheroxidationrate

h f than<100>surface.

Moresiliconatomsonthesurface.

WetOxidationRate

1.6

1.8

<111>Orientation

1200C

1.2

1.4

m

i

c

r

o

n

)

95CWater

1100C

0.8

0.6

1.0

h

i

c

k

n

e

s

s

(

m

1000C

0.4

0.2

0.6

O

x

i

d

e

T

h

920C

1 2 3 4 0

Oxidation Time (hours) OxidationTime(hours)

OxidationRate

D t C t ti DopantConcentration

Dopantelementsandconcentration

Highlyphosphorusdopedsiliconhashigher

growthrate,lessdensefilmandetchfaster.

Generallyhighlydopedregionhashigher y g y p g g

growratethanlightlydopedregion.

More pronounced in the linear stage (thin Morepronouncedinthelinearstage(thin

oxides)ofoxidation.

Oxidation: Dopants Oxidation:Dopants

PileupandDepletionEffects

Ntypedopants(P,As,Sb)havehigher

solubilityinSithaninSiO

2

,whenSiO

2

growtheymoveintosilicon,itiscall

pileuporsnowploweffect.

BorontendstogotoSiO

2

,itiscalled

depletioneffect.

DepletionandPileupEffects p p

OriginalSiSurface OriginalSiSurface

SiSiO

2

interface SiSiO

2

interface

O i i l Di ib i

t

r

a

t

i

o

n

t

r

a

t

i

o

n

OriginalDistribution

SiO

n

t

C

o

n

c

e

n

t

SiO

n

t

C

o

n

c

e

n

t

SiO

2

D

o

p

a

Si

SiO

2

D

o

p

a

Si

PtypeDopantDepletion NtypedopantPileup

OxidationRate

D d id i (HCl) Dopedoxidation(HCl)

HClisusedtoreducemobileioncontamination.

Widelyusedforgateoxidationprocess.

Growth rate can increase from 1 to 5 percent. Growthratecanincreasefrom1to5percent.

Oxidation Rate OxidationRate

DifferentialOxidation

Thethickeroftheoxidefilmis,theslowerof

theoxidationrateis.

Oxygenneedmoretimetodiffusecrossthe yg

existingoxidelayertoreactwithsubstrate

silicon.

Preoxidation Clean Pre oxidationClean

ThermallygrownSiO

2

isamorphous.

Tends to crosslink to form a crystal Tendstocross linktoformacrystal

Innature,SiO

2

existsasquartzandsand

D f d i l b h l i Defectsandparticlescanbethenucleation

sites

CrystallizedSiO

2

withpoorbarriercapability.

Needcleansiliconsurfacebeforeoxidation.

Oxidation Process OxidationProcess

Dry Oxidation thin oxide DryOxidation,thinoxide

Gateoxide

Pad oxide screen oxide sacrificial oxide etc Padoxide,screenoxide,sacrificialoxide,etc.

WetOxidation,thickoxide

Fieldoxide

Diffusionmaskingoxide

DryOxidationSystem

MFC

To

Process

Tube

MFC

MFC

MFC

ControlValves

Regulator

N

2

N

2

P

r

o

c

e

s

s

P

u

r

g

e

N

O

2

H

C

l

Dry Oxidation DryOxidation

DryO

2

asthemainprocessgas

HCl is used to remove mobile ions for HClisusedtoremovemobileionsfor

gateoxidation

High purity N as process purge gas HighpurityN

2

asprocesspurgegas

LowergradeN

2

asidlepurgegas

Gate Oxidation Steps GateOxidationSteps

IdlewithpurgeN

2

flow

IdlewithprocessN

2

flow

WaferboatspushinwithprocessN

2

flow

TemperaturerampupwithprocessN

2

flow

Temperature stabilization with process N flow TemperaturestabilizationwithprocessN

2

flow

OxidationwithO

2

,HCl,stopN

2

flow

Dangling Bonds and Interface Charge DanglingBondsandInterfaceCharge

Interface State Charge (Positive)

SiO

2

Dangling

Bond

+ + + + +

Si SiO

Si

Si-SiO

2

Interface

Gate Oxidation Steps, Continue GateOxidationSteps,Continue

Oxideannealing,stopO

2

,startprocessflowN

2

Temperature cooldown with process N

2

flow Temperaturecool downwithprocessN

2

flow

WaferboatspulloutwithprocessN

2

flow

Idl i h N fl IdlewithprocessN

2

flow

Nextboatsandrepeatprocess

IdlewithpurgeN

2

flow

Wet Oxidation Process WetOxidationProcess

Faster,higherthroughput

Thick oxide such as LOCOS Thickoxide,suchasLOCOS

Dryoxidehasbetterquality

Process Temperature FilmThickness OxidationTime

Dry oxidation

1000

C

1000 ~ 2 hours Dryoxidation

1000 C

1000 2hours

Wetoxidation

1000

C

1000 ~12minutes

Water Vapor Sources WaterVaporSources

Boiler

Bubbler

Flush Flush

Pyrogenic

Boiler System

Heated Gas line Heated Fore line

BoilerSystem

Process

HeatedGasline HeatedForeline

MFC

Process

Tube

Exhaust

VaporBubbles

Water

Heater Heater

BubblerSystem y

MFC

Process

Tube

N

2

N

2

+H

2

O

Tube

HeatedGasLine

Exhaust

N

2

Bubbles

Water

Heater Heater

FlushSystem

Water

HotPlate

MFC

Process

Tube

N

2

Tube

Heate

r

PyrogenicSteamSystem

HydrogenFlame,2H

2

+O

2

2H

2

O

H

O

2

ToExhaust

H

2

Process Tube

Wafer Boat

ThermalCouple

ProcessTube

WaferBoat

Paddle

Pyrogenic System PyrogenicSystem

Advantage

Allgassystem g y

Preciselycontrolofflowrate

Disadvantage Disadvantage

Introducingofflammable,explosivehydrogen

TypicalH

2

:O

2

ratioisbetween1.8:1to1.9:1.

Pyrogenic Wet Oxidation System PyrogenicWetOxidationSystem

MFC

MFC

Process Tube

MFC

MFC

MFC

Wafers

Burn Box

Control Valves

Regulator

o

c

e

s

s

N

2

u

r

g

e

N

2

O

2

H

2

Scrubbier

P

r

o

P

u

Exhaust

Wet Oxidation Process Steps WetOxidationProcessSteps

IdlewithpurgeN

2

flow

IdlewithprocessN

2

flow

RampO

2

withprocessN

2

flow

WaferboatpushinwithprocessN

2

andO

2

flows

TemperaturerampupwithprocessN

2

andO

2

flows

TemperaturestabilizationwithprocessN

2

andO

2

flows

Ramp O turn off N flow RampO

2

,turnoffN

2

flow

StabilizetheO

2

flow

Wet Oxidation Process Steps WetOxidationProcessSteps

TurnonH

2

flow,ignitionandH

2

flowstabilization

2

, g

2

SteamoxidationwithO

2

andH

2

flow

Hydrogentermination,turnoffH

2

whilekeepingO

2

flow

Oxygentermination,turnoffO

2

startprocessN

2

flow

TemperaturerampdownwithprocessN

2

flow

WaferboatpulloutwithprocessN

2

flow

IdlewithprocessN

2

flow

Next boats and repeat process Nextboatsandrepeatprocess

IdlewithpurgeN

2

flow

RapidThermalOxidation

Forgateoxidationofdeepsubmicrondevice

Verythinoxidefilm,<30

Needverygoodcontroloftemperature

uniformity,WIWandWTW.

RTOwillbeusedtoachievethedevice

requirement.

RTPProcessDiagram

Ramp

up1&2

Cool

down

RTA Load

wafer

Unload

wafer

RTO

O

2

flow

Temperatur

e

HClflow

N

2

flow

Time

HighPressureOxidation

Faster growth rate Fastergrowthrate

Reducingoxidation

temperature: temperature:

1amt.=30C

Higherdielectricstrength

High Pressure Oxidation HighPressureOxidation

StainlessSteelJacket

HighPressure

InertGas

HighPressure

OxidantGas

QuartzProcessChamber

High Pressure Oxidation HighPressureOxidation

Oxidationtimetogrow10,000wetoxide

Temperature Pressure Time

1atmosphere 5hours 1 atmosphere 5 hours

1000 C

5 atmosphere 1 hour

25 t h 12 i t 25 atmosphere 12 minutes

High Pressure Oxidation HighPressureOxidation

Oxidationtemperaturetogrow10,000wetoxidein5hours

Time Pressure Temperature

1atmosphere

1000C

1 atmosphere

1000 C

5 hours

10 atmosphere

700 C

HighPressureOxidation

Complex system Complexsystem

Safetyissues

NotwidelyusedinICproduction

Oxide Measurement OxideMeasurement

Thickness

Uniformity

Gateoxide

Break down Uniformity

C l h

Breakdown

voltage

C V

Colorchart

Ellipsometry

CV

characteristics

Reflectometry

Ellipsometry

EllipticallyPolarized

Reflected Light

Ellipsometry

LinearlyPolarizedIncidentLight

ReflectedLight

s

p

n

1

,k

1

, t

1

n

2

,k

2

Reflectometry

Humaneyeor

Reflectometry

1

Incidentlight

y

photodetector

2

1

g

t

Dielectric film n(

)

Substrate

Dielectricfilm,n(

)

Substrate

CV Test Configuration C VTestConfiguration

Capacitor

Meter

LargeResistor

Aluminum

Oxide

MetalPlatform

Silicon

Heater Heater

Summary of Oxidation SummaryofOxidation

Oxidationofsilicon

Highstabilityandrelativelyeasytoget.

Application Application

Isolation,masking,pad,barrier,gate,andetc.

W t d D WetandDry

MoredryprocessesforadvancedICchips

Rapidthermaloxidationandannealingfor

ultrathingateoxide

Das könnte Ihnen auch gefallen

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- F2cfe613 IndustrialDokument266 SeitenF2cfe613 Industrialjvega_534120100% (2)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (73)

- Liquid Crystals Seminar SMDokument7 SeitenLiquid Crystals Seminar SMSmriti100% (1)

- Cisco: Basic Switch and VLAN Configuration Guide With ExamplesDokument17 SeitenCisco: Basic Switch and VLAN Configuration Guide With Examplessmuscat72Noch keine Bewertungen

- Technical Specification Rmu Frtu Rev 01Dokument55 SeitenTechnical Specification Rmu Frtu Rev 01Ramesh Ananthanarayanan100% (1)

- Arduino DroneDokument16 SeitenArduino DroneBằng Trần DuyNoch keine Bewertungen

- Chapter 5 DC MachinesDokument49 SeitenChapter 5 DC Machinesquocdung NguyenNoch keine Bewertungen

- Camera Shading BasicsDokument5 SeitenCamera Shading BasicsRenzo Satti100% (2)

- Manual SkyconnectDokument62 SeitenManual SkyconnectCarlos GomezNoch keine Bewertungen

- d5 Ueq User Doc 3 0 1 Std (Arris Ipqam d5用户手册)Dokument962 Seitend5 Ueq User Doc 3 0 1 Std (Arris Ipqam d5用户手册)freextr100% (2)

- Exp D - FFDokument5 SeitenExp D - FFalokjadhavNoch keine Bewertungen

- Nmos Configuration ImplementationDokument7 SeitenNmos Configuration ImplementationalokjadhavNoch keine Bewertungen

- PCS - Communication Systems - Linear ModulationDokument111 SeitenPCS - Communication Systems - Linear Modulationaccessgm0% (1)

- Post Layout Delay Calculation Using RCXDokument6 SeitenPost Layout Delay Calculation Using RCXalokjadhavNoch keine Bewertungen

- Pmos Configuration ImplementationDokument7 SeitenPmos Configuration ImplementationalokjadhavNoch keine Bewertungen

- Common Source Amplifier: Experiment Date: 4 October 2011 Name: P.JAGADEESH (11MVD0015)Dokument11 SeitenCommon Source Amplifier: Experiment Date: 4 October 2011 Name: P.JAGADEESH (11MVD0015)alokjadhavNoch keine Bewertungen

- 8.RCX - View of CMOS Inverter and Nand GateDokument6 Seiten8.RCX - View of CMOS Inverter and Nand GatealokjadhavNoch keine Bewertungen

- 1 3Dokument7 Seiten1 3Gaurav MittalNoch keine Bewertungen

- Noise AnalysisDokument9 SeitenNoise AnalysisalokjadhavNoch keine Bewertungen

- FALLSEM2013 14 CP2782 21 Aug 2013 RM01 Power Efficiency of Modulation SchemesDokument7 SeitenFALLSEM2013 14 CP2782 21 Aug 2013 RM01 Power Efficiency of Modulation SchemesalokjadhavNoch keine Bewertungen

- 1 10Dokument63 Seiten1 10Gaurav GoyalNoch keine Bewertungen

- FALLSEM2013 14 CP2782 21 Aug 2013 RM01 Power Efficiency of Modulation SchemesDokument7 SeitenFALLSEM2013 14 CP2782 21 Aug 2013 RM01 Power Efficiency of Modulation SchemesalokjadhavNoch keine Bewertungen

- RFICDokument9 SeitenRFICalokjadhavNoch keine Bewertungen

- Pipelined ProcessorsDokument17 SeitenPipelined Processorsalokjadhav100% (1)

- CMOS Question FN-3Dokument3 SeitenCMOS Question FN-3alokjadhavNoch keine Bewertungen

- EpitaxyDokument23 SeitenEpitaxyalokjadhavNoch keine Bewertungen

- CH 04 POCADokument36 SeitenCH 04 POCAalokjadhavNoch keine Bewertungen

- BSIM4 Gate Leakage Model Including Source-Drain PartitionDokument4 SeitenBSIM4 Gate Leakage Model Including Source-Drain PartitionalokjadhavNoch keine Bewertungen

- 1 3Dokument7 Seiten1 3Gaurav MittalNoch keine Bewertungen

- Pipelined ProcessorsDokument17 SeitenPipelined Processorsalokjadhav100% (1)

- 1 Modeling TutorialDokument13 Seiten1 Modeling TutorialalokjadhavNoch keine Bewertungen

- Analog Lab 6Dokument4 SeitenAnalog Lab 6alokjadhavNoch keine Bewertungen

- Cov LetterDokument4 SeitenCov LetteralokjadhavNoch keine Bewertungen

- 1 10Dokument63 Seiten1 10Gaurav GoyalNoch keine Bewertungen

- Testing Lab Assignment IIDokument25 SeitenTesting Lab Assignment IIalokjadhav100% (1)

- Testing Lab Assignment IIDokument25 SeitenTesting Lab Assignment IIalokjadhav100% (1)

- Testing Lab Assignment IIDokument25 SeitenTesting Lab Assignment IIalokjadhav100% (1)

- DFT IntroDokument14 SeitenDFT IntroalokjadhavNoch keine Bewertungen

- Practice ProblemsDokument48 SeitenPractice ProblemsalokjadhavNoch keine Bewertungen

- Sylvania 6626lctDokument60 SeitenSylvania 6626lctAdkinsTV100% (1)

- Calculo de Filtros Armonicos AccusineDokument2 SeitenCalculo de Filtros Armonicos AccusineYolandaNoch keine Bewertungen

- Digital Lab ManualDokument87 SeitenDigital Lab ManualKALAIMATHINoch keine Bewertungen

- GATE 2022 Syllabus For Electronics and Communication Engineering (ECE) - Check Here!Dokument15 SeitenGATE 2022 Syllabus For Electronics and Communication Engineering (ECE) - Check Here!PurvaNoch keine Bewertungen

- Ovp Orava ctv-2181 16.1 SMDokument22 SeitenOvp Orava ctv-2181 16.1 SMdancalin64Noch keine Bewertungen

- ECEPurdue MOSFET Lundstrom L2.3v3bDokument22 SeitenECEPurdue MOSFET Lundstrom L2.3v3balNoch keine Bewertungen

- Proposed Curriculum Full Draft PDFDokument251 SeitenProposed Curriculum Full Draft PDFAadi BurlagaddaNoch keine Bewertungen

- Co4011B-Fl: Single Chip Canopen Controller For Remote I/ODokument45 SeitenCo4011B-Fl: Single Chip Canopen Controller For Remote I/OKrum KashavarovNoch keine Bewertungen

- Power Amplifier: Service ManualDokument20 SeitenPower Amplifier: Service ManualLeonardo MarraffiniNoch keine Bewertungen

- Panasonic TX-p42u30e TX-p42ux30e TX-p42u30j TX-pr42u30 TX-pr42u31 Chassis Gpf14d-EDokument113 SeitenPanasonic TX-p42u30e TX-p42ux30e TX-p42u30j TX-pr42u30 TX-pr42u31 Chassis Gpf14d-ESorin DanielNoch keine Bewertungen

- Analysis of Iron and Steel With Desktop Optical Emission SpectrometerDokument4 SeitenAnalysis of Iron and Steel With Desktop Optical Emission SpectrometerJunaid JamshedNoch keine Bewertungen

- Chapter 9: Ethernet Pronet Center: Identifies The Source and Destination ApplicationsDokument5 SeitenChapter 9: Ethernet Pronet Center: Identifies The Source and Destination ApplicationsChivinh NguyenNoch keine Bewertungen

- Primary-Side Regulation PWM Power Switch General Description FeaturesDokument10 SeitenPrimary-Side Regulation PWM Power Switch General Description FeaturespopoNoch keine Bewertungen

- SS460 InstructionsDokument4 SeitenSS460 InstructionsDiego Fernando Sanchez FlorezNoch keine Bewertungen

- Mitutoyo - Mikroskopy Pomiarowe TM Seria - E14013 - 2015Dokument4 SeitenMitutoyo - Mikroskopy Pomiarowe TM Seria - E14013 - 2015D.T.Noch keine Bewertungen

- CPE400 Lab8 ARCONADO DEVELLES 2 PDFDokument10 SeitenCPE400 Lab8 ARCONADO DEVELLES 2 PDFKimNoch keine Bewertungen

- Sampling of Continuous-Time SignalsDokument11 SeitenSampling of Continuous-Time SignalsGregory LevantNoch keine Bewertungen

- Voltage Source InverterDokument77 SeitenVoltage Source InverterSaied Aly SalamahNoch keine Bewertungen

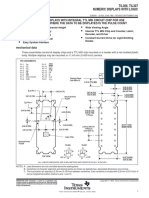

- TIL306, TIL307 Numeric Displays With LogicDokument9 SeitenTIL306, TIL307 Numeric Displays With LogicAndy ScriptorNoch keine Bewertungen

- Manual CRT SS7900 ENG-3Dokument23 SeitenManual CRT SS7900 ENG-3Dante NeroNoch keine Bewertungen

- Charles Proteus SteinmetzDokument7 SeitenCharles Proteus SteinmetzKelvinNoch keine Bewertungen