Beruflich Dokumente

Kultur Dokumente

Consideration For Approval of ATU For Use in Trinidad and Tobago

Hochgeladen von

Jeffrey James100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

152 Ansichten5 SeitenApplication to WASA for ATU

Originaltitel

Consideration for Approval of ATU for use in Trinidad and Tobago

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenApplication to WASA for ATU

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

100%(1)100% fanden dieses Dokument nützlich (1 Abstimmung)

152 Ansichten5 SeitenConsideration For Approval of ATU For Use in Trinidad and Tobago

Hochgeladen von

Jeffrey JamesApplication to WASA for ATU

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 5

CONCEPTULIZATION . DESIGNS . IMPLEMENTATION .

MANAGEMENT OF PLUMBING SYSTEMS

180 RIVERSIDE AVENUE, MT. HOPE, TRINIDAD

TeleFax: 1.868.638.2548 - Mobile: 1.868.319.0214 - eMail: wssmltd@gmail.com

Member: THE PLUMBERS ASSOCIATION OF TRINIDAD AND TOBAGO

WATER SERVICES & SYSTEMS MANAGEMENT

A FULL SERVICE PLUMBING COMPANY

VAT Reg. No.

126040

Our Ref : PC168- RFA1/ATU

September 4

th

, 2013

The Manager,

New Services Department

WATER AND SEWERAGE AUTHORITY

Valsayn

ST. JOSEPH

Dear Madam,

RE: CONSIDERATION FOR APPROVAL OF PROPOSED WASTEWATER TREATMENT PLANT

Water Services and Systems Management Limited (WSSM) has been invited to submit a proposal for the

Supply, Installation and Maintenance of a suitable Packaged Wastewater Management System to service

a proposed Primary School to be constructed in Central Trinidad. The projects Engineering Design team

has requested your Consideration for Approval for the proposed Wastewater Treatment Plant.

For this project, WSSM intend to utilize an Extended Aeration Aerobic Treatment system by AERO-TECH.

This process diffuses air into the wastewater using a patented aeration pump which requires less power,

has no noise, no odor, requires little maintenance, and significantly surpasses not only all NSF 40

requirements, but also exceeds our Environmental Management Authoritys Water Pollution Rules,

Second Schedule (rule 8) Permissible Levels for the discharge of Effluent into Inland Surface Waters.

We have attached detailed technical data for your review and information for the consideration of this

plant. Should you require and additional information I will avail myself at your convenience.

Thanking you in advance.

Respectfully,

WATER SERVICES AND SYSTEMS MANAGEMENT LTD

MANAGING DIRECTOR

WSSM

PLUMBING SERVICES

YOUR PLUMBING PROFESSIONALS

TECHNICAL DATA AND INFO FOR PROPOSED WWTP

The proposed elementary school will have a total population of 230 persons, but the school will be

developed in 2 phases, Phase 1 will have a population of 115 persons (students and staff). Phase 2 of the

project will be implemented some 3 years later.

We propose:

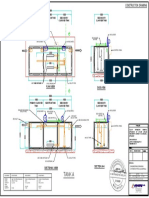

Primary Treatment

A full capacity Double Compartment Septic Tank at project start-up to handle the

wastewater.

Secondary Treatment

2 No. Extended Aeration AERO-TECH Units (AT-750) in series, each with a capacity of

2840 lit/day

Tertiary Treatment

1 No. UV Disinfection system with a capability of 375 lit/hr.

We have attached a Design Basis calculation (see Table 1) for your perusal

Design Basis

Elementary School

CALCULATIONS

Phase 1 population 115 persons

Phase 2 population 115 persons

TOTAL POPULATION 230 persons

Wastewater Flow 48 lit/person/day Guidelines - Table 3.1 - No. 3.4

TOTAL WASTEWATER FLOW (TWF) 11040 lit/day

P

R

I

M

A

R

Y

T

R

E

A

T

M

E

N

T

Required Septic Tank Capacity (TWF x 1.5)

16560 lit

16.56 m

3

Double Compartment Septic Tank

Length 5 m

Width 2.5 m

Liquid Depth 1.5 m

Proposed Septic Tank Capacity 18.75 m

3

Proposed ST > Required ST 13%

S

E

C

O

N

D

A

R

Y

T

R

E

A

T

M

E

N

T

Phase 1 population 115 persons

Wastewater Flow 48 lit/person/day

PHASE 1 WASTEWATER FLOW 5520 lit/day

Extended Aeration Unit (AT-750) 2840 lit/day

Amt of units in series 2 no.

TOTAL DAILY TREATMENT CAPACITY 5680 lit/day

Treatment capacity > Wastewater Flow 3%

T

E

R

T

I

A

R

Y

T

R

E

A

T

M

E

N

T

Hours of School operation 16 hrs.

PHASE 1 WASTEWATER FLOW

5520 lit/day

345 lit/hr.

UV Disinfection system capability 375 lit/hr.

Disinfecting capability>Wastewater Flow 9%

Table 1

WSSM

PLUMBING SERVICES

YOUR PLUMBING PROFESSIONALS

The AERO-TECH design & technology creates an efficient economical wastewater system that achieves

the highest degree of treatment for any application, residential, commercial or institutional. No other

system can diffuse air as efficiently or is capable of achieving the water purity levels as AERO-TECH

Wastewater Management System.

BENEFITS

Treatment--NSF Standard 40 results:

o Biochemical Oxygen Demand (BOD

5

) - 5 mg/L (98% reduction)

o Total Suspended Soils (TSS) - 6 mg/L (97% reduction)

o Dissolved Oxygen at least (DO) - 4 mg/L

o De-nitrification: - 49%

No Noise

No Odor

No filters, diffuser stones, or compressors

Highly effective on Fats, Oils, & Grease (FOG)

Expanded for future growth

SUMMARY OF TREATMENT PLANT EQUIPMENT

Scope & Operation

AERO-TECH has been involved in hundreds of commercial and residential wastewater systems, providing

education, design assistance, equipment, installation oversight, and operational support throughout the

Caribbean. This has allowed AERO-TECH to recognize the importance of a long-term relationship between

the technology provider and the entity responsible for the successful management and operation of the

wastewater infrastructure. To address this need, AERO-TECHs systems department includes a division

with individuals dedicated to asset management and support, this divisions responsibility is to work with

collection and treatment system operators and owners to keep the systems working efficiently and cost-

effectively.

AERO-TECHs Treatment System and its components are designed in a manner that allows for low cost &

effective operation for the life of the system. Unlike other treatment systems available, AERO-TECH uses

little electricity, comparatively, thanks to the use of patented aeration pumps, not compressors.

In addition to low-power consumption, the maintenance requirements for AERO-TECH are minimal,

which further enhances the systems cost-effective operation, especially when compared to other

treatment systems. AERO-TECH Extended Aeration Systems work better and last longer because a

stringent O & M program is designed and implemented from start-up.

Speed of startup & process

The startup capability of Extended Aeration pump is unsurpassable. Since the aeration process begins

immediately, so does treatment. The basic purpose of the activated sludge system is to establish and

maintain a viable population of microorganisms by supplying food (BOD

5

) and the proper environment. In

the proper environment the microorganisms convert the soluble and colloidal material present in the

wastewater into new cells (activated sludge) and end products (CO

2

and water). In actual operation the

activated sludge process is run as a continuous process. Within the system, incoming wastewater is

intimately mixed with the active biological mass and provided with the necessary dissolved oxygen by the

action of the air bubbles released from the aeration pump. This pump is located at the bottom center

and causes a spiraling flow pattern to develop which rolls the chamber contents from the influent to

effluent end. In the chamber, the suspended solids (MLSS) and liquid are separated by gravity. The

separated solids are returned to the aeration compartment as return sludge while the clear water in the

WSSM

PLUMBING SERVICES

YOUR PLUMBING PROFESSIONALS

upper clarifying chamber is then discharged through the surge resistant disposal system to the UV

sterilizing system then finally discharged into the storm drainage system.

Low routine maintenance requirements

Annual routine maintenance includes inspection of effluent for clarity (e.g., turbidity, grease and oily

films, foam, color, etc.) and odor, as well as skimming the clarifier and flushing distribution piping if

necessary. Because the AERO-TECH is highly efficient, minimal sludge removal is required from the

aeration tank. Solids do slowly accumulate in the tank and should partially be removed every 3 years.

The septic tank (primary) tank solids should also be cleaned every 3 years.

Ease of maintenance

Maintenance of AERO-TECH is service friendly and especially suited for management programs, due to:

a. Detailed installation and operation manuals that identify specific service, testing and

troubleshooting techniques

b. Specially engineered pumps that can be visually inspected and easily replaced

c. Controls that monitor and alert service providers directly upon electro-mechanical malfunctions,

as well as water usage and system functioning abnormalities.

Treatment

Typical Influent (Septic Tank Effluent)

Constituent Average

BOD5 230 mg/L

TSS 210 mg/L

The expected effluent quality of the system will be 5 mg/L cBOD and 6mg/L TSS. AERO-TECH is NSF

Standard 40 Certified with these results. Typical ATUs rarely achieve 30 mg/L for either.

The average AERO-TECH Extended Aeration pump only consumes approximately 0.5 CFM of air, the small

CFM of AERO-TECH is one of the many reasons our systems have no odors. Another significant item is the

high Dissolved Oxygen (DO) of AERO-TECH. We average 4.0 mg/L (DO). AERO-TECH output will not

pollute so it is ideal for public waterway discharge.

WATER POLLUTION RULES - SECOND SCHEDULE

(Rule 8) PERMISSIBLE LEVELS

No.

Water Pollutants Receiving Environment

Parameters or Substances

Inland Surface Water

Required Levels or

Conditions

AERO-TECH output

3 Hydrogenion (pH) 6 to 9 6 to 9

4

Five day Biological Oxygen

Demand (BOD5 at 20C)

30 5 mg/L

6 Total Suspended Solids (TSS) 50 6 mg/L

12 Total Residual Chlorine (Cl

2

) 1 0.75 mg/L

28 Faecal Coliforms 400 300 mg/L

Expected Effluent AERO-TECH

Constituent Average

cBOD5 5 mg/L

TSS 6 mg/L

WSSM

PLUMBING SERVICES

YOUR PLUMBING PROFESSIONALS

Das könnte Ihnen auch gefallen

- WASA Design Guideline Manual Oct 2008Dokument230 SeitenWASA Design Guideline Manual Oct 2008Jeffrey James100% (1)

- C08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFDokument123 SeitenC08-006 - UV Disinfection Options For Wastewater Treatment Plants - US PDFAbdelilah KadriNoch keine Bewertungen

- Wastewater Treatment Plant General Design ChecklistDokument4 SeitenWastewater Treatment Plant General Design ChecklistJeffrey James100% (1)

- WSA 03 AnnexuresDokument8 SeitenWSA 03 AnnexuresShahabShoaeeNoch keine Bewertungen

- SECTION 22 61 19 Compressed-Air Equipment For Laboratory and Healthcare FacilitiesDokument7 SeitenSECTION 22 61 19 Compressed-Air Equipment For Laboratory and Healthcare FacilitiesKaruna KaranNoch keine Bewertungen

- Lab DI Water Systems Guide - Filtration, RO, Resin Filters ExplainedDokument6 SeitenLab DI Water Systems Guide - Filtration, RO, Resin Filters ExplainedHaidee Che RizminNoch keine Bewertungen

- Water and Sewerage AuthorityDokument43 SeitenWater and Sewerage AuthorityCarl Crow100% (1)

- ASPE DataBook Vol.3Dokument278 SeitenASPE DataBook Vol.3dadhouNoch keine Bewertungen

- Process and Instrumentation SymbolsDokument7 SeitenProcess and Instrumentation SymbolsVocem LuxNoch keine Bewertungen

- TTS 16 80 400 Septic Tank DesingsDokument16 SeitenTTS 16 80 400 Septic Tank DesingsJeffrey James100% (2)

- TTS 16 80 400 Septic Tank DesingsDokument16 SeitenTTS 16 80 400 Septic Tank DesingsJeffrey James100% (2)

- Geberit Piping Systems Catalogue 2010/2011Dokument95 SeitenGeberit Piping Systems Catalogue 2010/2011Catalin Frincu0% (1)

- HepworthDokument147 SeitenHepworthldbautista2005Noch keine Bewertungen

- Development of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PDokument20 SeitenDevelopment of Vietnamese Codes and Standards in Construction - Ws2006-Nbnguyen-PSen HuNoch keine Bewertungen

- ROEDIGER 2007 RoeVac Vacuum Sewer System PDF PresentationDokument69 SeitenROEDIGER 2007 RoeVac Vacuum Sewer System PDF PresentationClaudio Della RoccaNoch keine Bewertungen

- Septage Management Guide 1Dokument43 SeitenSeptage Management Guide 1Ria Tiglao FortugalizaNoch keine Bewertungen

- MMG Wastewater ManagementDokument376 SeitenMMG Wastewater ManagementIndrasis DasNoch keine Bewertungen

- Chlorine Feed CalculatorDokument1 SeiteChlorine Feed CalculatorAssef ZraouraNoch keine Bewertungen

- Water Treatment Plant Performance Evaluations and OperationsVon EverandWater Treatment Plant Performance Evaluations and OperationsNoch keine Bewertungen

- Peza CheklistDokument24 SeitenPeza CheklistAce Christian OcampoNoch keine Bewertungen

- What Is Anaerobic DigestionDokument3 SeitenWhat Is Anaerobic DigestionRalf Jade Vince GundranNoch keine Bewertungen

- Waste WaterDokument16 SeitenWaste WaterJeffrey JamesNoch keine Bewertungen

- Calculation Maturation and Pond From Literature PDFDokument7 SeitenCalculation Maturation and Pond From Literature PDFanon_51960941Noch keine Bewertungen

- SMWWTPGLDokument161 SeitenSMWWTPGLPremasiri KarunarathnaNoch keine Bewertungen

- WWTA Sanitary Sewer SpecificationsDokument155 SeitenWWTA Sanitary Sewer SpecificationsCash IfYaNsty100% (1)

- Water Quality Regulations 2021 Edition 5Dokument67 SeitenWater Quality Regulations 2021 Edition 5Samer KhaledNoch keine Bewertungen

- DesalinationDokument6 SeitenDesalinationNavneet SinghNoch keine Bewertungen

- Aco Rainwater Outlets BrochureDokument32 SeitenAco Rainwater Outlets Brochurerajkumar_chinniah100% (1)

- Secondary Clarification - Design CalculationsDokument12 SeitenSecondary Clarification - Design CalculationslitargirioNoch keine Bewertungen

- WWTP Mardan 1st PhaseDokument41 SeitenWWTP Mardan 1st Phasemohammad armaghan100% (1)

- Design Details of Sewage Treatment Plan With SBR PDFDokument8 SeitenDesign Details of Sewage Treatment Plan With SBR PDFali ahmadiNoch keine Bewertungen

- SANS 966 Part 2 PVC-M pipe wall thickness and massDokument1 SeiteSANS 966 Part 2 PVC-M pipe wall thickness and massAnonymous eq5zSUNoch keine Bewertungen

- Licensed Sanitary Constructors (Plumbers) in Trinidad and TobagoDokument8 SeitenLicensed Sanitary Constructors (Plumbers) in Trinidad and TobagoJeffrey James100% (1)

- Licensed Sanitary Constructors (Plumbers) in Trinidad and TobagoDokument8 SeitenLicensed Sanitary Constructors (Plumbers) in Trinidad and TobagoJeffrey James100% (1)

- Grease Trap Calculations TemplateDokument1 SeiteGrease Trap Calculations TemplateJeffrey JamesNoch keine Bewertungen

- BS en 12255-8 2001 Waste Water Treatment PlantsDokument20 SeitenBS en 12255-8 2001 Waste Water Treatment PlantsAbey VettoorNoch keine Bewertungen

- Sludge Treatment: 1-Thickening 2-Stabilization 3-DewateringDokument11 SeitenSludge Treatment: 1-Thickening 2-Stabilization 3-Dewateringomar alasadiNoch keine Bewertungen

- Media MBBR (BIOCIP)Dokument25 SeitenMedia MBBR (BIOCIP)mektan0% (1)

- PVC-U Robineti VEEIV063 PDFDokument299 SeitenPVC-U Robineti VEEIV063 PDFCrisTimNoch keine Bewertungen

- Field Trip Report SampleDokument8 SeitenField Trip Report SampleAddrien DanielNoch keine Bewertungen

- Proper Excreta Disposal Critical for Public HealthDokument32 SeitenProper Excreta Disposal Critical for Public HealthRamniwasMahoreNoch keine Bewertungen

- V3i4 Ijertv3is040786 PDFDokument5 SeitenV3i4 Ijertv3is040786 PDFsarikagNoch keine Bewertungen

- Profile of A Professional Plumber - Jeffrey JamesDokument9 SeitenProfile of A Professional Plumber - Jeffrey JamesJeffrey JamesNoch keine Bewertungen

- COP 101 Version 9.1 Document (Text) Jan 2006Dokument41 SeitenCOP 101 Version 9.1 Document (Text) Jan 2006MarcusNoch keine Bewertungen

- Manganese Greensand PlusDokument4 SeitenManganese Greensand PlusPT Purione MegatamaNoch keine Bewertungen

- Ten States Standards PDFDokument175 SeitenTen States Standards PDFYashika AgarwallaNoch keine Bewertungen

- Mechanical Survey.Dokument13 SeitenMechanical Survey.Ashara AakashNoch keine Bewertungen

- Terrain Rainwater BrochureDokument56 SeitenTerrain Rainwater BrochureterinthomasNoch keine Bewertungen

- 4.3 Basic Design Awwa D100 & Api 650Dokument7 Seiten4.3 Basic Design Awwa D100 & Api 650Miguel Martinez Guerrero100% (1)

- Four laning NH-161 from Kandi to RamsanpalleDokument68 SeitenFour laning NH-161 from Kandi to RamsanpalleNarendraDugarNoch keine Bewertungen

- BUET DEEP TUBE WELL INSTALLATIONDokument27 SeitenBUET DEEP TUBE WELL INSTALLATIONMahfuzur RahmanNoch keine Bewertungen

- 2006 NC Fuel Gas Code AmendmentsDokument20 Seiten2006 NC Fuel Gas Code AmendmentsjameyconnorNoch keine Bewertungen

- PH008 - Grease Interceptor Sizing REVISEDDokument8 SeitenPH008 - Grease Interceptor Sizing REVISEDcoolth2Noch keine Bewertungen

- SCE 443 Lect 15Dokument32 SeitenSCE 443 Lect 15khamaludinNoch keine Bewertungen

- TrueUnion - True Union Ball ValveDokument4 SeitenTrueUnion - True Union Ball ValveKarthick VenkateshNoch keine Bewertungen

- Typical Potable Water DemandDokument4 SeitenTypical Potable Water DemandbtjajadiNoch keine Bewertungen

- GENERALDokument9 SeitenGENERALshaik mahaboobNoch keine Bewertungen

- Phosphoric Acid 75%-85%: Safety Data SheetDokument8 SeitenPhosphoric Acid 75%-85%: Safety Data SheetYeison Durán0% (1)

- Fire Safety Requirements Part 5 - Water Supplies For Fire-Fighting PDFDokument28 SeitenFire Safety Requirements Part 5 - Water Supplies For Fire-Fighting PDFkhurshidoman123Noch keine Bewertungen

- Tuttle and Bailey CircularDokument2 SeitenTuttle and Bailey CircularTalha BaigNoch keine Bewertungen

- LANL Sustainable Design Guide PDFDokument264 SeitenLANL Sustainable Design Guide PDFThanh Nguyen NgocNoch keine Bewertungen

- Essential LV Room, Z8-0880Dokument10 SeitenEssential LV Room, Z8-0880bhima irabattiNoch keine Bewertungen

- 120 Optima HX Manual RevJDokument51 Seiten120 Optima HX Manual RevJEdwin CalmaNoch keine Bewertungen

- Constraint Factors of Domestic Solid Waste Management (Case Study: Agona Swedru)Dokument28 SeitenConstraint Factors of Domestic Solid Waste Management (Case Study: Agona Swedru)Nhyiraba Okodie Adams100% (1)

- Public Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inDokument10 SeitenPublic Works Department: of The Chief 2325856:0471-2325856 Pwd@kerala - Gov.inSanthosh BabuNoch keine Bewertungen

- 1729Dokument52 Seiten1729praj24083302Noch keine Bewertungen

- Water Quality for Medical Device ProcessingDokument6 SeitenWater Quality for Medical Device Processingkaka**Noch keine Bewertungen

- D. Design Load D.1. Loading DataDokument14 SeitenD. Design Load D.1. Loading DataEdNoch keine Bewertungen

- Waste Water Piping and Vent System Sir FhaDokument40 SeitenWaste Water Piping and Vent System Sir Fhabradley100% (1)

- Start Up & Field Check-Out Procedures Manual SWPADokument32 SeitenStart Up & Field Check-Out Procedures Manual SWPARicardo BarrosNoch keine Bewertungen

- Plinth Area RatesDokument10 SeitenPlinth Area Ratessunilrathi86Noch keine Bewertungen

- Rainwater Harvesting Workshop Manual-UK-RHA - 2012Dokument36 SeitenRainwater Harvesting Workshop Manual-UK-RHA - 2012Erin Lim100% (1)

- Step-by-Step Guide To Making An Application For Registration To ECSADokument4 SeitenStep-by-Step Guide To Making An Application For Registration To ECSAclintNoch keine Bewertungen

- Sanitary Engineer II: Passbooks Study GuideVon EverandSanitary Engineer II: Passbooks Study GuideNoch keine Bewertungen

- Corrosion Failures: Theory, Case Studies, and SolutionsVon EverandCorrosion Failures: Theory, Case Studies, and SolutionsNoch keine Bewertungen

- PSA Jeffrey James and WASA JudgementDokument27 SeitenPSA Jeffrey James and WASA JudgementJeffrey JamesNoch keine Bewertungen

- Water and Sewerage ActDokument116 SeitenWater and Sewerage ActJeffrey JamesNoch keine Bewertungen

- TTFS Fire Hydrant InfoDokument6 SeitenTTFS Fire Hydrant InfoJeffrey JamesNoch keine Bewertungen

- WASA Fee ScheduleDokument1 SeiteWASA Fee ScheduleJeffrey JamesNoch keine Bewertungen

- OAS Chile Scholarship Announcement UWI Open Trinidad and Tobago (June 20, 2019)Dokument4 SeitenOAS Chile Scholarship Announcement UWI Open Trinidad and Tobago (June 20, 2019)Jeffrey JamesNoch keine Bewertungen

- TPATT Membership RatesDokument1 SeiteTPATT Membership RatesJeffrey JamesNoch keine Bewertungen

- Nestle Promoters Q1 Sales Roster (Rev.21.03.16)Dokument3 SeitenNestle Promoters Q1 Sales Roster (Rev.21.03.16)Jeffrey JamesNoch keine Bewertungen

- File Copy of Witness Statement of David West Pgs 7-12 PDFDokument6 SeitenFile Copy of Witness Statement of David West Pgs 7-12 PDFJeffrey JamesNoch keine Bewertungen

- Nestle Promoters Q1 Sales Roster (Rev.21.03.16)Dokument3 SeitenNestle Promoters Q1 Sales Roster (Rev.21.03.16)Jeffrey JamesNoch keine Bewertungen

- Draft National Plumbing Policy of Trinidad and Tobago: Discussion PaperDokument11 SeitenDraft National Plumbing Policy of Trinidad and Tobago: Discussion PaperMandy ThomasNoch keine Bewertungen

- WASA Requirements For Approval of Packaged WWTP PDFDokument6 SeitenWASA Requirements For Approval of Packaged WWTP PDFJeffrey JamesNoch keine Bewertungen

- WASA Requirements For Approval of Packaged WWTP PDFDokument6 SeitenWASA Requirements For Approval of Packaged WWTP PDFJeffrey JamesNoch keine Bewertungen

- Witness Statement of David West Pgs 1-6Dokument6 SeitenWitness Statement of David West Pgs 1-6Jeffrey JamesNoch keine Bewertungen

- Jeffrey James Transcript StatementDokument1 SeiteJeffrey James Transcript StatementJeffrey JamesNoch keine Bewertungen

- Biography: Music, or Die Trying'Dokument1 SeiteBiography: Music, or Die Trying'Jeffrey JamesNoch keine Bewertungen

- National Plumbing Code of Trinidad and TobagoDokument49 SeitenNational Plumbing Code of Trinidad and TobagoJeffrey James90% (10)

- Sample of LicenseDokument1 SeiteSample of LicenseJeffrey JamesNoch keine Bewertungen

- Darcel Bradshaw BioDokument1 SeiteDarcel Bradshaw BioJeffrey JamesNoch keine Bewertungen

- Meelah's ProfileDokument1 SeiteMeelah's ProfileJeffrey JamesNoch keine Bewertungen

- I Tonio BioDokument1 SeiteI Tonio BioJeffrey JamesNoch keine Bewertungen

- Meelah's ProfileDokument1 SeiteMeelah's ProfileJeffrey JamesNoch keine Bewertungen

- Experiment No. 5 Date: Title:: Determination of Sludge Volume Index in A Given Wastewater SampleDokument7 SeitenExperiment No. 5 Date: Title:: Determination of Sludge Volume Index in A Given Wastewater SampleMac357GNoch keine Bewertungen

- Decanting System - Decanting - Water Discharge - Sequencing Batch Reactor1Dokument1 SeiteDecanting System - Decanting - Water Discharge - Sequencing Batch Reactor1Anonymous qRe192Noch keine Bewertungen

- Low Cost Sanitation Scheme for Nambul River ConservationDokument5 SeitenLow Cost Sanitation Scheme for Nambul River ConservationHarish Kumar MahavarNoch keine Bewertungen

- Ijert Ijert: Proposed Wastewater Treatment Plant Design of Harihar CityDokument8 SeitenIjert Ijert: Proposed Wastewater Treatment Plant Design of Harihar CityTushar KambleNoch keine Bewertungen

- Grey Water Treatment Plant DesignDokument40 SeitenGrey Water Treatment Plant DesignCallesNoch keine Bewertungen

- Faecal Sludge and Septage TreatmentDokument370 SeitenFaecal Sludge and Septage TreatmentEddie MtongaNoch keine Bewertungen

- Wastewater ProcessingDokument32 SeitenWastewater Processingﭘﺮﻭﻳﺰ ﺟﻬﻴﺪ100% (1)

- Análisis de La Disposición de Los Desechos Sólidos y Generacion de Biogas en El Relleno Sanitario de Ambato, EcuadorDokument19 SeitenAnálisis de La Disposición de Los Desechos Sólidos y Generacion de Biogas en El Relleno Sanitario de Ambato, EcuadorMARCELA RAMOS PALLARESNoch keine Bewertungen

- Construction Drawing Example - Sepctic TankDokument1 SeiteConstruction Drawing Example - Sepctic TanknzhazmiNoch keine Bewertungen

- Community Based SanitationDokument4 SeitenCommunity Based SanitationAnwar RosyidNoch keine Bewertungen

- PCO Accreditation Application FormDokument1 SeitePCO Accreditation Application FormJoyce TomaquinNoch keine Bewertungen

- Module 3 Presentation ScriptDokument55 SeitenModule 3 Presentation ScriptjakariaNoch keine Bewertungen

- Waste Water Treatment OptionsDokument4 SeitenWaste Water Treatment OptionsGreen Action Sustainable Technology GroupNoch keine Bewertungen

- Dewats - Chapter 01Dokument13 SeitenDewats - Chapter 01Sam PradhanNoch keine Bewertungen

- Case Study Hlt234 - FinalDokument32 SeitenCase Study Hlt234 - FinalNorazuree DramanNoch keine Bewertungen

- Lecture 123 Sludge Treatment and Disposal (Introduction)Dokument8 SeitenLecture 123 Sludge Treatment and Disposal (Introduction)Aqib KhalidNoch keine Bewertungen

- ADVANCE ENVIRONMENTAL ENINEERING Ques BankDokument2 SeitenADVANCE ENVIRONMENTAL ENINEERING Ques Bankabhishek5810Noch keine Bewertungen

- Restroom Cleaning ChecklistDokument1 SeiteRestroom Cleaning ChecklistTRISHULA INDIANoch keine Bewertungen

- Status of Solid Waste Management in DelhipdfDokument10 SeitenStatus of Solid Waste Management in DelhipdfShivang AgarwalNoch keine Bewertungen