Beruflich Dokumente

Kultur Dokumente

Lesson 01 PDF

Hochgeladen von

Abuubakr Abdelwhab Hassan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

85 Ansichten12 SeitenAllignment

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAllignment

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

85 Ansichten12 SeitenLesson 01 PDF

Hochgeladen von

Abuubakr Abdelwhab HassanAllignment

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 12

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Lesson 1 Code: Sabic M22B 1

LESSON 1

INTRODUCTION TO SHAFT ALIGNMENT

Shaft alignment is a technical skill that is not common in the construction and maintenance

professions, but categorized more like a specialty. It requires unique and expensive

measurement instruments, some calculation capability, and relies heavily on experience for

successful results on heavy, high-speed, or high-temperature machines. This training

course will provide an integral training knowledge and experience of shaft alignment to

solve misalignment problems in rotating machinery. Emphasis shall be laid on ways to

analyze, identify and correct the root causes of misalignment, unbalancing and vibration to

achieve precise operation, and improving machinery performance.

Vibration monitoring and analysis are useful tools for predicting incipient mechanical,

electrical, and process-related problems within plant equipment, machinery, and

continuous-process systems. Therefore, they are the most often used predictive

maintenance technologies. Vibration analysis can provide the means to first schedule

maintenance and ultimately to eliminate the need for corrective maintenance tasks.

Vibration analysis can be used to evaluate all equipment within a plant. The monitoring of

the condition of machinery can significantly reduce the costs of maintenance. Firstly it can

allow the early detection of potentially catastrophic faults which could be extremely

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

2 Code: Sabic M22B Lesson 1

expensive to repair. Secondly it allows the implementation of condition based maintenance

rather than periodic or failure based maintenance. In these cases significant savings can be

made by delaying scheduled maintenance until convenient or necessary. This training

course is designed to expose the techniques of vibration analysis of machinery, with the

aim of improving machinery monitoring and diagnosis and to implement latest standard

systems and procedures as a tool for achieving precise operation, and improving machinery

performance. Emphasis shall be laid on topics relevant to basics of vibration, vibration

measurements, vibration analysis, international standard system and assess machinery

condition. It provides valuable information and knowledge of the principles and procedures

of condition based monitoring and machine condition monitoring, with focus placed upon a

range of topics, e.g. machinery vibration response, data acquisition procedures, transducer

selection & mounting, signal conditioning, data displays, machinery condition evaluating

and analysis and computer application in vibration analysis and condition monitoring. The

objective of this training course is to prepare attendees to be better analysts and gain

understanding of vibration principles and techniques and add to their practical knowledge of

machines.

Who Should Attend:

The training program is designed and targeted to engineers and technicians who are

dealing with the operation and maintenance of rotating equipment and totally new to shaft

alignment and who are running alignment and wish to improve their knowledge and skills.

And for all interested and using vibration and equipment condition monitoring for identifying

and correcting the machinery problems. And for maintenance engineers, maintenance

planners, supervisors and managers and senior technicians involved in machines condition

monitoring and vibration measurement and analysis.

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Lesson 1 Code: Sabic M22B 3

Introduction to Shaft Alignment

What is shaft alignment?

Shaft alignment is the positioning of the rotational centers of two or more shafts such that

they are co-linear when the machines are under normal operating conditions. The Process

of Adjusting a piece of machinery so that its shaft will be in line with the shaft of the

machine to which it coupled (The Stationary Machine). Alignment is a critical aspect of

operation and the techniques used should be properly understood. Misalignment is the

main cause of Machine Potential Failure Shaft alignment is a technical skill that is not

common in the construction and maintenance professions, but categorized more like a

specialty. It requires unique and expensive measurement instruments, some calculation

capability, and relies heavily on experience for successful results on heavy, high-speed, or

high-temperature machines.

Side Effect of Misalignment

Bearing failure

Coupling Failure, even in flexible types

Internal heating

Shaft Fatigue

Seal Leakage

High energy consumption

Bearing failure

Vibration

Misalignment causes excessive vibrations. It is, by far, the leading cause of machinery

malfunctions, downtime and maintenance (but often not identified as the root cause). There

is also no testing or certification of alignment craft people. With no common training, no

certification, and no common standards, it should come as no surprise that there is large

variability in the results. The guidelines for when to require alignment checks are:

1. All new shaft coupled equipment.

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

2. After repair work is done that disturbs shafts or bearings, and before energizing.

3. Whenever vibration indicates the need.

4. Periodically on critical equipment

Fig. 1-1.

The most important requirement for any shaft alignment system is repeatability of the

readings. This is evaluated with a 360 deg repeatability test. It is also a good way to

evaluate a fixture system when considering a purchase. Basically, measuring systems that

do not return to zero (within 0.002 inch) after a 360 deg rotation should be rejected. Be

suspicious of plastic straps or other flexible fixture components. The choice of measuring

systems and methods is up to the aligner. The two fundamental choices are dial indicators

or lasers. Dial-indicator systems are the most useful because they can be used to measure

shaft run out, bearing alignment, and soft foot directly. All of the above measurements are

required by the standard, and needed to assure a goo(l-running machine, but not attainable

with lasers. Lasers require batteries, are not intrinsically safe for use in explosive

environments, and cannot do face-and-rim measurements.

Correcting Common Problems

Time is spent on collecting vibration data on hundreds of machines, But not on actually

correcting the problems. Those involved with the PDM implementation do a lot of analysis

may not be involved in the correction of the problems they have identified.

4 Code: Sabic M22B Lesson 1

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Lesson 1 Code: Sabic M22B 5

How to utilize these data?

First step:

Determine which pieces of equipment are problems and which are not. The vibration limit of

0.3 ips ( 7.6 mm/s) is a good break point to use. All equipment 0.3 ips (7.6 mm/s) or higher

should be repaired if the number of equipment at or above 0.3 ips is too large to tackle, a

further prioritizing process may be necessary.

Next Step:

Breaking down the equipment over the limit by type..

Fig. 1-2. Categorized Equipment Failures.

Of the 109 machines over the limit pumps and fans seem to have the biggest problems.

Third step:

Looking into the work performed on pumps and fans can often reveal a facility-wide or

systemic problem. For example, the facility that reported this data further investigated pump

problems. The result indicated that there was little or no alignment of coupled machinery

being performed.

Fourth step:

Deeper investigation revealed that the plants only dial indicator (used in precision

alignment) was damaged and locked away in a machinists toolbox. The facility purchased

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

new indicators and trained every mechanic in proper alignment techniques. As stated

previously, the most common problems found in rotating machinery through vibration

analysis are (in approximate order) misalignment, imbalance, bearing damage, and

looseness. Grouping all problems together can start to reveal other systemic problems.

Investigations can help facility management focus on the top problems that can be solved,

with additional training, new methods, or new equipment.

Fig. 1-3.

Types of Misalignment

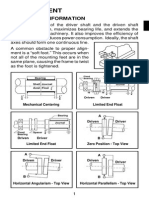

Explanation of offset and angularity

Fig. 1-4.

6 Code: Sabic M22B Lesson 1

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Lesson 1 Code: Sabic M22B 7

There are two components of misalignment-angular and offset.

Explanation of Vertical Angularity

i. Positive Vertical Angularity

Fig. 1-5.

ii. Negative Vertical Angularity

Fig. 1-6.

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Explanation of Horizontal Angularity

i-Positive Horizontal Angularity

Fig. 1-7.

ii-Negative Horizontal Angularity

Fig. 1-8.

8 Code: Sabic M22B Lesson 1

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Lesson 1 Code: Sabic M22B 9

Explanation of Offset

i. Positive Vertical Offset

Fig. 1-9

ii. Positive Horizontal Offset

Fig. 1-10.

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

iii. Negative Vertical Offset

Fig. 1-11.

iv. Negative Horizontal Offset

Fig. 1-12.

10 Code: Sabic M22B Lesson 1

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Lesson 1 Code: Sabic M22B 11

Angular misalignment:

This occurs when the shaft center-lines are out of parallel, although they may intersect at

the coupling. Angular misalignment sometimes referred to as gap or face, is the

difference in the slope of one shaft, usually the moveable machine, as compared to the

slope of the shaft of the other machine, usually the stationary machine. The units for this

measurement are comparable to the measurement of the slope of a roof (i.e., rise/run). In

this case the rise is measured in mils and the run (distance along the shaft) is measured in

inches. The units for angular misalignment are mils/1 in. As stated, there are two separate

alignment conditions that require correction. There are also two planes of potential

misalignment-the horizontal plane (side to side) and the vertical plane (up and down). Each

alignment plane has offset and angular components, so there are actually four alignment

parameters to be measured and corrected. They are horizontal angularity (HA), horizontal

offset (HO), vertical angularity (VA), and vertical offset (VO).

Fig. 1-13.

SHAFT ALIGNMENT

AND VIBRATION ANALYSIS

Fig. 1-13. Contd.

Parallel, Offset misalignment:

This occurs when the shaft center-lines remain parallel, but are offset Offset misalignment,

sometimes referred to as parallel misalignment, is the distance between the shaft centers of

rotation measured at the plane of power transmission. This is typically measured at the

coupling center. The units for this measurement are mils (where 1 mil = 0.001 in.).

Fig. 1-14.

Fig. 1-15.

12 Code: Sabic M22B Lesson 1

Das könnte Ihnen auch gefallen

- Vibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisVon EverandVibration Basics and Machine Reliability Simplified : A Practical Guide to Vibration AnalysisBewertung: 4 von 5 Sternen4/5 (2)

- Csi Ds TrainingandcertifDokument20 SeitenCsi Ds TrainingandcertifElvis Alberto Rodriguez BravoNoch keine Bewertungen

- Structural Health MonitoringVon EverandStructural Health MonitoringDaniel BalageasNoch keine Bewertungen

- Spike Energy (Deteccion Temprana para Muy Altas Frecuencias) PDFDokument22 SeitenSpike Energy (Deteccion Temprana para Muy Altas Frecuencias) PDFMarcos Manzano100% (1)

- Why Industrial Bearings Fail: Analysis, Maintenance, and PreventionVon EverandWhy Industrial Bearings Fail: Analysis, Maintenance, and PreventionNoch keine Bewertungen

- Don't Get Soft: Cover Series: Installation Best PracticesDokument6 SeitenDon't Get Soft: Cover Series: Installation Best PracticesHatem Abdelrahman100% (1)

- Motors:: The Past Is PresentDokument6 SeitenMotors:: The Past Is Presenteko bagus sunaryoNoch keine Bewertungen

- Gearmotor Sizing Guide PDFDokument5 SeitenGearmotor Sizing Guide PDFAnonymous Hy5Ir9QXNoch keine Bewertungen

- SPM HD Case StoryDokument34 SeitenSPM HD Case StorycatraioNoch keine Bewertungen

- Fan VibrationDokument6 SeitenFan VibrationRavi Deshmukh100% (2)

- Using PeakVue Plus Technology For Detecting Anti Friction Bearing FaultsDokument11 SeitenUsing PeakVue Plus Technology For Detecting Anti Friction Bearing Faultseko bagus sunaryo100% (1)

- Checking Bearing AlignmentDokument4 SeitenChecking Bearing AlignmentTheerayootNoch keine Bewertungen

- Vibration Signatures Reveal Gear Tooth DefectsDokument8 SeitenVibration Signatures Reveal Gear Tooth DefectsHURRYSTARNoch keine Bewertungen

- Standard and Measurement of Motor VibrationDokument2 SeitenStandard and Measurement of Motor VibrationNam Lê HữuNoch keine Bewertungen

- Time Waveform Analysis TechniquesDokument2 SeitenTime Waveform Analysis TechniquesManel Montesinos100% (1)

- Analysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisDokument6 SeitenAnalysis and Diagnosis of The Different Defects of The Bearings and Gearings by Vibration AnalysisJournal of Computer Science and EngineeringNoch keine Bewertungen

- Ch3 Balancing of Rigid - Flexible - Linked PDFDokument119 SeitenCh3 Balancing of Rigid - Flexible - Linked PDFAlexis CordovaNoch keine Bewertungen

- Vibrasyon Electrical ProblemsDokument4 SeitenVibrasyon Electrical ProblemsbbulutmmNoch keine Bewertungen

- Solving Motor Vibration Problems On Vertical PumpsDokument5 SeitenSolving Motor Vibration Problems On Vertical Pumpsjameel babooramNoch keine Bewertungen

- Article Balancing of Rotor Blades PDFDokument5 SeitenArticle Balancing of Rotor Blades PDFClaudio SalicioNoch keine Bewertungen

- Quick Guide To Vibration DiagnosticsDokument72 SeitenQuick Guide To Vibration DiagnosticsAbderrahim AbarayNoch keine Bewertungen

- EIT IDC Machinery Vibration Rev5Dokument26 SeitenEIT IDC Machinery Vibration Rev5nabil160874Noch keine Bewertungen

- Detecting Rolling Elements Bearings Faults: February 2020Dokument57 SeitenDetecting Rolling Elements Bearings Faults: February 2020Felipe Andres Figueroa VidelaNoch keine Bewertungen

- VVVF DrivesDokument16 SeitenVVVF DrivesIsradani MjNoch keine Bewertungen

- Diagnosis of Centrifugal Pump Faults Using Vibration MethodsDokument12 SeitenDiagnosis of Centrifugal Pump Faults Using Vibration MethodsHatem ShawkiNoch keine Bewertungen

- High Vibration at Main Gear Box of Gas TurbineDokument9 SeitenHigh Vibration at Main Gear Box of Gas TurbineJJNoch keine Bewertungen

- Order Analysis ToolkitDokument16 SeitenOrder Analysis ToolkitManuel Enrique Salas FernándezNoch keine Bewertungen

- Causes of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and ShaftsDokument6 SeitenCauses of Rotor Distortions and Applicable Common Straightening Methods For Turbine Rotors and Shaftsbigsteve9088Noch keine Bewertungen

- Pitfalls in The Analysis of Machinery Vibration MeasurementsDokument7 SeitenPitfalls in The Analysis of Machinery Vibration MeasurementsTheerayoot PoomchaiNoch keine Bewertungen

- Motor Bearing Failure Analysis by Vibration MonitoringDokument180 SeitenMotor Bearing Failure Analysis by Vibration MonitoringGeert Henk Wijnants100% (1)

- Introduction To Vibration: R.Narasimha Swamy Senior ConsultantDokument43 SeitenIntroduction To Vibration: R.Narasimha Swamy Senior Consultanthemanth45Noch keine Bewertungen

- Rolling Element Bearing Fault Detection With A Single Point Defect On PDFDokument8 SeitenRolling Element Bearing Fault Detection With A Single Point Defect On PDFsunil481Noch keine Bewertungen

- Extracto ISO 10816Dokument10 SeitenExtracto ISO 10816clroyo9475Noch keine Bewertungen

- Va Cat III - Velosi A4Dokument4 SeitenVa Cat III - Velosi A4shahbaz akramNoch keine Bewertungen

- Training, Class I, Testing, IIb, 1-10Dokument12 SeitenTraining, Class I, Testing, IIb, 1-10luis_hernandez_qNoch keine Bewertungen

- Solving Motor Vibration Problems On Vertical Pumps ResonanceDokument5 SeitenSolving Motor Vibration Problems On Vertical Pumps Resonancejameel babooramNoch keine Bewertungen

- Systematic Approach to Solving Vibration ProblemsDokument24 SeitenSystematic Approach to Solving Vibration Problemsantok09Noch keine Bewertungen

- Analysis of Fault Conditions in Permanent-Magnet In-Wheel MotorsDokument81 SeitenAnalysis of Fault Conditions in Permanent-Magnet In-Wheel MotorsSyed Qaseem AliNoch keine Bewertungen

- Chandra Gupt Porwal, CMD, NIMDC PVT LTD.Dokument13 SeitenChandra Gupt Porwal, CMD, NIMDC PVT LTD.CHANDRA GUPT PORWALNoch keine Bewertungen

- 2 - Slow Speed Vibration Signal AnalysisDokument9 Seiten2 - Slow Speed Vibration Signal AnalysisSasi NimmakayalaNoch keine Bewertungen

- Successful Solution: To The Challenge ofDokument2 SeitenSuccessful Solution: To The Challenge ofKenny RuizNoch keine Bewertungen

- Vibration Monitoring of VibrationsDokument18 SeitenVibration Monitoring of VibrationsManel MontesinosNoch keine Bewertungen

- Ultrasound For Slow Speed Bearing Monitoring - RonTangen PDFDokument67 SeitenUltrasound For Slow Speed Bearing Monitoring - RonTangen PDFaabejaroNoch keine Bewertungen

- Form - Wound - Repair - Specification Rewinding PDFDokument10 SeitenForm - Wound - Repair - Specification Rewinding PDFBenjie CallantaNoch keine Bewertungen

- Bearing Vibration AnalysisDokument11 SeitenBearing Vibration AnalysisAnh Tuan PhanNoch keine Bewertungen

- Acoustic Signatures of Gear Defects Using Time-Frequency Analyses and A Test RigDokument22 SeitenAcoustic Signatures of Gear Defects Using Time-Frequency Analyses and A Test RigKhalid F AbdulraheemNoch keine Bewertungen

- Gearbox FailureDokument18 SeitenGearbox FailureDhananjay B KNoch keine Bewertungen

- Dynamic Vibration AbsorbersDokument7 SeitenDynamic Vibration AbsorberstmacspamNoch keine Bewertungen

- MH pgs0700Dokument15 SeitenMH pgs0700Hamza Nouman100% (1)

- Vibration Analysis of Gear Box.5-MilosprokoDokument3 SeitenVibration Analysis of Gear Box.5-MilosprokoRavikiran Hegde100% (2)

- Vibration Analysis Including Stator Rotor Hou 2018 Journal of Electrical SDokument14 SeitenVibration Analysis Including Stator Rotor Hou 2018 Journal of Electrical SSathish KumarNoch keine Bewertungen

- ElectricMotorGreasing PDFDokument6 SeitenElectricMotorGreasing PDFHemraj Singh RautelaNoch keine Bewertungen

- TND6041-D DC Motor Driver FundamentalsDokument3 SeitenTND6041-D DC Motor Driver FundamentalsAlex CarmonaNoch keine Bewertungen

- Bearing damage classification ISO standardDokument6 SeitenBearing damage classification ISO standardPraveen PaviNoch keine Bewertungen

- Cutting Speed OptimizationDokument14 SeitenCutting Speed OptimizationCharles OndiekiNoch keine Bewertungen

- Grease Refill QtyDokument3 SeitenGrease Refill QtyParmasamy SubramaniNoch keine Bewertungen

- A I RS: David G. Dorrell, William ThomsonDokument11 SeitenA I RS: David G. Dorrell, William ThomsonEng Bagaragaza RomualdNoch keine Bewertungen

- Temperature Effects On DC Motor Performance 1Dokument10 SeitenTemperature Effects On DC Motor Performance 1BabuNoch keine Bewertungen

- A Practical Introduction To Condition Monitoring of RollingDokument14 SeitenA Practical Introduction To Condition Monitoring of Rollingsatya_chagantiNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument8 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument8 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument8 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument8 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument8 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Energies 08 08497 PDFDokument19 SeitenEnergies 08 08497 PDFAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument8 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Introduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabDokument4 SeitenIntroduction To Reliability Engineering: Technical Director Dr. Eng. Abuubakr I. Abdel WahabAbuubakr Abdelwhab HassanNoch keine Bewertungen

- 1 Gate Globe Ball Butterfly1Dokument40 Seiten1 Gate Globe Ball Butterfly1Abuubakr Abdelwhab HassanNoch keine Bewertungen

- Pre AssesmentDokument29 SeitenPre AssesmentAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Gear Box Ecoman 2a 1Dokument21 SeitenGear Box Ecoman 2a 1Abuubakr Abdelwhab HassanNoch keine Bewertungen

- Professional LadderDokument19 SeitenProfessional LadderAbuubakr Abdelwhab HassanNoch keine Bewertungen

- Standard 12t/192 Points: Argus AGS-4D 5 8Dokument1 SeiteStandard 12t/192 Points: Argus AGS-4D 5 8Angel Sanchez GonzalezNoch keine Bewertungen

- KX-MB271, KX-MB781 - SMDokument293 SeitenKX-MB271, KX-MB781 - SMAna Lorena SalvatierraNoch keine Bewertungen

- Guided vs unguided transmission mediaDokument7 SeitenGuided vs unguided transmission mediaMehwish SabirNoch keine Bewertungen

- Smartxide Punto Brochure ENG Rev 1.2 SINDokument6 SeitenSmartxide Punto Brochure ENG Rev 1.2 SINSulay Avila LlanosNoch keine Bewertungen

- Thermopiles ReportDokument33 SeitenThermopiles ReportDerrick EvangelistaNoch keine Bewertungen

- An177 PDFDokument34 SeitenAn177 PDFSam PandezNoch keine Bewertungen

- BL Thereja QA FULLDokument15 SeitenBL Thereja QA FULLAishaNoch keine Bewertungen

- Induction LightingDokument2 SeitenInduction Lightingnosyparker619Noch keine Bewertungen

- Space Based Solar PowerDokument26 SeitenSpace Based Solar PowerArun Gopinath0% (1)

- Service Manual: NAU-PG8400US4 QX-3624N-ADokument31 SeitenService Manual: NAU-PG8400US4 QX-3624N-Aboroda2410Noch keine Bewertungen

- Unit-1.0-Measurement Standards and Design of GaugesDokument40 SeitenUnit-1.0-Measurement Standards and Design of GaugesAbhijeet RandhirNoch keine Bewertungen

- Metall-Ceramic Framework Design Manual PDFDokument52 SeitenMetall-Ceramic Framework Design Manual PDFCucu Constantin100% (1)

- Light WaveDokument28 SeitenLight WaveKomalFatimaNoch keine Bewertungen

- Ch3000 At3552 Series Analog Externally Modulated Full Spectrum Transmitter Data SheetDokument4 SeitenCh3000 At3552 Series Analog Externally Modulated Full Spectrum Transmitter Data SheetGilmar Peterle PaganiniNoch keine Bewertungen

- Mwr10d6 DVD ManualDokument82 SeitenMwr10d6 DVD Manualeblackhorse2Noch keine Bewertungen

- Information Sheet BulbDokument9 SeitenInformation Sheet BulbRex Chambers LadaoNoch keine Bewertungen

- Physics Wave Properties Exam QuestionsDokument2 SeitenPhysics Wave Properties Exam QuestionsNaveed AhmedNoch keine Bewertungen

- Optical CommunicationDokument3 SeitenOptical CommunicationKrishan PandyaNoch keine Bewertungen

- BISPLATE ALLOY Technical-Guide-ArmourDokument16 SeitenBISPLATE ALLOY Technical-Guide-ArmourFery FebryantoNoch keine Bewertungen

- Nuclear Fusion PowerDokument11 SeitenNuclear Fusion PowerAndré RebelloNoch keine Bewertungen

- E-960-D90Q FeaturesDokument1 SeiteE-960-D90Q FeaturesaimatsuccessNoch keine Bewertungen

- Mitigation of Fretting Fatigue Damage in Blade and Disk Pressure Faces With Low Plasticity Burnishing PDFDokument9 SeitenMitigation of Fretting Fatigue Damage in Blade and Disk Pressure Faces With Low Plasticity Burnishing PDFhamidrezachamaniNoch keine Bewertungen

- E 986 - 04 (2010)Dokument3 SeitenE 986 - 04 (2010)ruben carcamoNoch keine Bewertungen

- Lab ActivitiesDokument14 SeitenLab ActivitiesAlbertNoch keine Bewertungen

- Food Chemistry: A B D D C ADokument6 SeitenFood Chemistry: A B D D C AMutiaRezaNoch keine Bewertungen

- Phoenix 9.7 ReferenceDokument268 SeitenPhoenix 9.7 ReferenceMarko OreškovičNoch keine Bewertungen

- Lecture 4Dokument11 SeitenLecture 4Yogesh SharmaNoch keine Bewertungen

- Optical MicrometerDokument2 SeitenOptical MicrometerrubensNoch keine Bewertungen

- Excise and Tax Stamps Products and VerificationDokument7 SeitenExcise and Tax Stamps Products and VerificationTobacco IndustryNoch keine Bewertungen

- Practice Dashboard - SAT - Khan AcademyDokument2 SeitenPractice Dashboard - SAT - Khan AcademyIssam0% (1)