Beruflich Dokumente

Kultur Dokumente

Uec 3 & Uec3 MPC Manual440-12100

Hochgeladen von

Periyasamy Chellaiah50%(2)50% fanden dieses Dokument nützlich (2 Abstimmungen)

828 Ansichten40 SeitenThis manual is proprietary information of Limitorque Corporation furnished for customer use ONLY. It is intended to be a guide and should not be considered as a sole source of technical instruction. The choice of system components is the responsibility of the buyer, and the use of them cannot be Limitorque's liability.

Originalbeschreibung:

Originaltitel

Uec 3 & Uec3 Mpc Manual440-12100

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenThis manual is proprietary information of Limitorque Corporation furnished for customer use ONLY. It is intended to be a guide and should not be considered as a sole source of technical instruction. The choice of system components is the responsibility of the buyer, and the use of them cannot be Limitorque's liability.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

50%(2)50% fanden dieses Dokument nützlich (2 Abstimmungen)

828 Ansichten40 SeitenUec 3 & Uec3 MPC Manual440-12100

Hochgeladen von

Periyasamy ChellaiahThis manual is proprietary information of Limitorque Corporation furnished for customer use ONLY. It is intended to be a guide and should not be considered as a sole source of technical instruction. The choice of system components is the responsibility of the buyer, and the use of them cannot be Limitorque's liability.

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 40

UEC-3 &

UEC-3-MPC

Bulletin 440-12100 6/96

Installation & Commissioning Manual

Limitorque

UEC-3 & UEC-3-MPC Installation & Commissioning Manual

1996 Copyright Limitorque Corporation, All rights reserved.

Printed in the United States of America.

Disclaimer

All rights reserved. No part of this book shall be reproduced, stored in a retrieval

system, or transmitted by any means, electronic, mechanical, photocopying,

recording, or otherwise without the written permission from Limitorque. While

every precaution has been taken in the preparation of the book, the publisher

assumes no responsibility for errors or omissions. Neither is any liability

assumed for damages resulting from the use of the information contained

herein.

This document is proprietary information of Limitorque Corporation furnished

for customer use ONLY. No other uses are authorized without written permis-

sion of Limitorque Corporation.

Limitorque Corporation reserves the right to make changes, without notice, to

this document and the products it describes. Limitorque Corporation shall not

be liable for technical or editorial errors or omissions made herein; nor for inci-

dental or consequential damages resulting from the furnishing, performance

or use of this document.

This manual contains information that is correct to the best of Limitorques

knowledge. It is intended to be a guide and should not be considered as a sole

source of technical instruction, replacing good technical judgment, since all

possible situations cannot be anticipated. If there is any doubt as to exact

installation, configuration, and/or use, call Limitorque Corporation at (804)

528-4400.

The choice of system components is the responsibility of the buyer, and the

use to which they are put cannot be the liability of Limitorque Corporation.

However, Limitorques sales team and application engineers are always avail-

able to assist you in making your decision.

Acknowledgments

Sections of this document are edited and/or reprinted with the written per-

mission of A.E.G. Modicon Inc and Allen-Bradley a Rockwell International

Company.

LOGITORQUE and LIMITORQUE are registered trademarks of Limitorque Corporation

Modbus is a registered trademarks of A.E.G. Modicon, Inc

BITBUS is a registered trademark of Intel Corporation

MS-DOS is a registered trademark of Microsoft Corporation

IBM-PC is a registered trademark of International Business Machines Corporation

Belden is a registered trademark of Belden, a division of Cooper Industries, Inc.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

i

Contents

1. Introduction 1

1.1 Premise............................................................................................................................................1

1.2 Emphasis .........................................................................................................................................1

1.3 Audience ..........................................................................................................................................2

2. Product Description 3

2.1 UEC-3...............................................................................................................................................3

2.2 UEC-3-MPC.....................................................................................................................................3

3. General Information/Workmanship 5

3.1 Safety Information............................................................................................................................5

3.2 Electrostatic Discharge Awareness................................................................................................5

3.3 UEC-3 Label ....................................................................................................................................6

3.4 Dip Switch Location and Conventions ...........................................................................................7

3.5 EPROM Care and Installation ........................................................................................................9

3.5.1 Care and Storage...........................................................................................................9

3.5.2 Removal........................................................................................................................10

3.5.3 Installation.....................................................................................................................10

3.6 Supply Voltage...............................................................................................................................10

4. UEC-3/UEC-3-MPC Installation 13

4.1 Site preparation .............................................................................................................................13

4.2 Visual inspection ...........................................................................................................................13

4.3 Wire preparation............................................................................................................................13

4.4 Actuator Wiring..............................................................................................................................13

4.5 Grounding......................................................................................................................................14

5. UEC-3/UEC-3-MPC Commissioning 15

5.1 Initial inspection .............................................................................................................................15

5.2 Start-up procedure ........................................................................................................................15

5.2.1 Power LEDs .................................................................................................................17

5.2.2 Reset LEDs..................................................................................................................17

5.3 UEC-3-MPC Calibration Procedure.............................................................................................18

5.4 Troubleshooting..............................................................................................................................23

5.4.1 Troubleshooting Tools ..................................................................................................23

5.4.1.1 Universal Diagnostic Tool ...........................................................................23

5.4.1.2 Modsim Diagnostic Software.....................................................................23

5.4.2 Component Replacement ...........................................................................................24

5.4.2.1 Control Fuse Replacement........................................................................24

5.4.2.2 24VDC I/O Power Supply Fuse Replacement ........................................25

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

ii

5.4.2.3 Single Board Computer Replacement ......................................................26

5.4.2.4 Termination/Interconnect Board Replacement .........................................27

5.4.3 Complete Module Replacement .................................................................................28

6. Conversion of UEC-3 Basic Controller 31

6.1 Converting UEC-3 to UEC-3-MPC Position Controller ...............................................................31

6.1.1 Installation of PT20SD (optional) ................................................................................32

7. Parts 33

8. Customer Service 35

Figures

3-1 Model, Option, and Conguration Identication Label..................................................................6

3-2 Single Board Computer DIP Switch and Component Location...................................................7

3-3 DIP Switch Conventions .................................................................................................................8

3-4 Default DIP Switch Settings for UEC-3 and UEC-3-MPC............................................................9

3-5 Locating Power Supply Board .....................................................................................................11

3-6 Locating Power Supply Board Mounting Screw..........................................................................11

3-7 Locating Power Supply Bracket Retaining Screw.......................................................................12

3-8 Power Supply Board .....................................................................................................................12

5-1 UEC-3/UEC-3-MPC Start-up Procedure.....................................................................................16

5-2 UEC-3-MPC Calibration Procedure........................................................................................18-21

Tables

5-1 Table of Values for Proportional Band and Deadband................................................................22

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

iii

1. Introduction

1.1 Premise

These instructions are to aid in the installation and commissioning of the UEC-

3 family of control modules. Your safety and satisfaction are important to

Limitorque. Be sure to follow all instructions carefully. Pay special attention to

safety.

1.2 Emphasis

Please refer to the following methods used to emphasize text throughout this

manual:

Safety warnings, cautions, and notes present material that is important to

user safety. Be sure to read any safety notices you see as they could prevent

equipment damage, personal injury, or even death to you or a co-worker.

Warning refers to personal safety. They alert you to potential danger or

harm. Failure to follow warning notices could result in personal injury or death.

Caution directs attention to general precautions, which if not followed, could

result in personal injury and/or equipment damage.

Note highlights information critical to your understanding or use of these

products.

Bold text highlights other important information that is critical to system com-

ponents.

CAPITALIZED text stresses attention to the details of the procedure.

Underlined text emphasizes crucial words in sentences that could be mis-

understood if the word is not recognized.

The purpose of this section is to alert you to possible safety hazards associ-

ated with this equipment and the precautions you can take to reduce the risk

of personal injury and damage to the equipment.

Safety notices in this manual provide important information. Read and be famil-

iar with these instructions before attempting installation, operation, or

maintenance. Failure to observe these precautions could result in serious

bodily injury, damage to the equipment, or operational difculty.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

1

1.3 Audience

This Installation and Commissioning Manual is designed to help you to prop-

erly install and commission the UEC-3 Control Module and the UEC-3

Modulating Position Controller. You do not have to be an expert in electronics

or digital controls to utilize this manual. However, this manual assumes you

have a working understanding of basic electronics and a fundamental under-

standing of microprocessor concepts.

The material in this manual supplements the following Limitorque publication:

UEC-3 Operation Manual - Bulletin 440-12000 Rev. A.

It is recommended that you completely read all the general information and

all sections pertaining to the type of UEC-3 module for your application so that

you can promptly nd any information you need.

It is also recommended that you have a copy of the Operation Manual for your

UEC-3 module as well as the applicable actuator wiring diagram available

before attempting to install or commission a UEC-3 or UEC-3-MPC controlled

actuator.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

2

2. Product Description

The UEC-3 is a microprocessor based controller for the complete range of

Limitorque actuators. It provides many protection and control features which

are designed to be individually congured to t specic customer needs. This

conguration may be altered in the eld as process requirements change or

as the real needs of the actuator are realized.

2.1 UEC-3

(Universal Electronic Controller)

The basic UEC-3 model provides control, indication, alarm, and protection

features. It is intended for use with open/close or pushbutton throttling valves.

2.2 UEC-3-MPC

(Modulating Position Controller)

This model is designed to position valves in accordance with a 4-20mA

command signal, thereby controlling level, ow, pressure, etc. All the indica-

tion, alarm, and protection features of the basic UEC-3 are retained in this

model.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

3

This page is intentionally blank.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

4

3. General Information/Workmanship

Throughout this manual, the designation UEC-3 will refer to a basic Universal

Electronic Controller with a 4-wire conguration. UEC-3-MPC will refer to the

Universal Electronic Controller with positioning control.

The information in this section is applicable to all members of the UEC-3 family

of controllers.

3.1 Safety Information

Practice all plant and safety codes and standards. Failure to follow instructions

can result in personal injury and/or property damage.

To prevent the possible ignition of hazardous atmospheres, do NOT remove

the cover of Division 1 units with power applied.

All servicing should be performed by qualified technicians. Dangerous volt-

ages may be present on the circuit boards and terminations.

Use extreme caution when working around power-input cables. These cables

have potentially lethal voltages on them.

When fuse replacement is required, use only Limitorque specified parts for

continued safe operation.

Have qualied personnel verify all wiring and connections against vendor draw-

ings prior to energizing the equipment. Incorrect wiring and/or connections

can result in equipment damage.

3.2 Electrostatic Discharge Awareness

The circuit boards in the UEC products may contain components that are

subject to damage from electrostatic discharge (static electricity). The follow-

ing precautions and procedures are recommended when handling circuit

boards or components. Failure to observe these practices when handling and

shipping circuit board products may void your warranty.

Keep plastics and other materials prone to the buildup of electrostatic charges

(static electricity) away from boards, components, and work area.

Avoid synthetic or wool clothing and wear cotton or cotton blend materials.

Keep components and circuit boards away from clothing and hair.

Discharge static electricity on your body by touching and momentarily holding

a grounded metal object before handling electronic components. This is espe-

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

5

cially important after walking across carpeted areas.

Handle components in the eld as little as necessary.

Handle components only by the edges, and avoid contact with leads, circuits,

or connectors.

Do not touch the printed circuit board, the connectors, or the components with

conductive devices or with your hands.

Always place the component or board into an anti-static protective bag for

transportation or storage.

Transport all static-sensitive components only in static-shielding carriers or

packages. Place static awareness labels on all components to prevent removal

from static-shielding container during transit.

Handle all static-sensitive components at a static-safe work area including:

oor mat, wrist strap, air ionizer, ground cord, and conductive table mat.

Do not subject components to sliding movements over any surface, at any

time.

3.3 UEC-3 Labels

Labels are afxed to the housings of all UEC modules. The information included

on this label indicates: type of UEC-3 (basic, MPC or DDC), options, trans-

former voltage, module serial number and status of LK1 link. The label also

contains space for the user to record the settings of the configuration DIP

switches. See Figure 3-1

Figure 3-1 - Model, Option, and Conguration Identication Label

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

6

S2

S3

S1

1 2 3 4 5 6 7 8

1 2 3 4 5 6 7 8

1 2 3 4

ON

OFF

ON

OFF

ON

OFF

(DDC Only)

OUT IN LK1:

UEC-3 BASIC CONFIGURATION

SWITCH POSITIONS

Serial No.

Model Options

UEC-3 BASIC

UEC-3-MPC

Potentiometer

PT20S (R-1)

Logitorque UEC-3-DDC

Type A

Transformer Type/Tapping

Type B

4

6

0

V

4

1

5

V

3

8

0

V

2

2

0

V

5

7

5

V

5

2

5

V

2

2

0

V

1

1

5

V

3.4 DIP Switch Location and Conventions

The UEC-3 and UEC-3-MPC units are congured using DIP switches S1 and

S2 located on the Single Board Computer (SBC) as shown in

Figure 3-2

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

7

Figure 3-2 - Single Board Computer DIP Switch

and Component Location

RAM

34 Pin

Bus connector

for connection

to Diagnostic

Tools

EPROM

(program storage)

Microprocessor

with EEPROM

(permanent

variable storage)

Analog to

Digital (A/D)

Converter Chip

(Optional)

Analog Input

Connector

Reset LED Digital I/O

Isolation

34 Pin Power

and I/O

Connector

Switching

Pre-regulator

Linear 5V

Regulator

DIP Switch S1

(feature selection)

DIP Switch S2

(feature selection)

Figure 3-3 shows an example of a DIP switch and the conventions that are

used in describing the conguration of the DIP switches. An individual switch

position is said to be ON when the switch is in the CLOSED state. In the ON

position, the switch is towards the ON indication on the switch housing and

away from the number designation. All tables showing DIP switch congura-

tions indicate a 1 when the switch state is ON.

Conversely, the switch position is said to be OFF when the switch is in the

OPEN state. In the OFF position, the switch is towards the number designa-

tion and away from the ON indication on the switch housing. The tables indicate

a 0 when the switch is OFF or OPEN.

Care should be taken to assure that the each DIP switch is pushed rmly in

either the open or closed direction.

Figure 3-3 - DIP Switch Conventions

Caution

Always use a small non-metallic tool to move the DIP switches.

NEVER use a pencil because graphite lings may cause short

circuits on the printed circuit boards or in the switches.

Note

If changes to the DIP switches are made while power is present at

the actuator, it is important to turn the power off and on again in order

to initialize the changes.

To change DIP switch settings for a particular application, refer to the UEC-3

Operation Manual Bulletin# 440-12000 Rev. A.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

8

1 2 3 4 5 6 7 8

OFF

ON

Dip Swich

SX-7 Position 7

If sufcient information is provided at the time of order, the DIP switches will

be set according to the order. If the specic details are not provided at time of

order, the actuator will be provided with the default settings shown in

Figure 3-4.

ESD action - CLOSE - S1-1,-2 Remote control mode - 4 WIRE - S2-1,-2-3

Local inching - DISABLED - S1-3 Seating method at close - POSITION - S2-4

Modulating mode - DISABLED - S1-4 Autophase control - ENABLED - S2-5

Slow speed opening - DISABLED - S1-5 Slow speed closing - DISABLED - S2-6

Closing rotation - CLOCKWISE - S1-6

Thermostat bypass - DISABLED - S1-7 NOTE: FOR A STANDARD UEC-3

Interlock / Inhibit - DISABLED - S1-8 ALWAYS SELECT:

EEPROM - DISABLED - S2-7

Software Control - ENABLED - S2-8

Figure 3-4 - Default DIP Switch Settings for UEC-3 and UEC-3-MPC

3.5 EPROM Care and Installation

Normally you will not need to handle the EPROM. However, if you do

need to handle the EPROM, (for example, to install a rmware upgrade),

you should follow these instructions.

3.5.1 EPROM Care and Storage

The UEC-3 family of control modules are equipped with EPROM integrated

circuits (IC) which are fragile and static sensitive. Care should be taken in the

storage and handling of the EPROMs.

Do not ship or store EPROMs near strong electrostatic, electromagnetic, mag-

netic or radioactive elds.

Do not remove labels from EPROMs.

Store EPROMs away from direct sunlight at temperatures from -40C to

85C (-40F to 185F).

Store EPROMs in static free containers with care to prevent breakage from

shock or damage to pins.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

9

S1

ON

OFF

1 2 3 4 5 6 7 8

ON

OFF

KEY

S2

ON

OFF 1 2 3 4 5 6 7 8

3.5.2 EPROM Removal

It is recommended that an integrated circuit (IC) inserter/extractor tool be used

to remove EPROMs from the socket.

If an IC inserter/extractor is unavailable, use the following procedure:

Carefully insert a small flathead screwdriver into the space between the

EPROM and the socket. Slowly and gently pry the EPROM out of the socket

taking care not to bend or break the pins.

3.5.3 EPROM Installation

It is recommended that an IC inserter/extractor be used to hold the EPROM

for installation.

To insert a replacement EPROM, use the following procedure:

The notch at the top of the EPROM must be lined up with the notch at the top

of the socket. Failure to position properly will result in damage to the EPROM.

Gently place the pins of one side of the EPROM in the socket. Roll the EPROM

over until the pins on the other side are lined up. You may have to use some

back pressure to get the pins to line up. When you are sure all pins are lined

up with the socket holes, push down on the top of the EPROM rmly until the

pins are well seated in the socket.

3.6 Supply Voltage

The transformer voltage on the UEC module will be factory set to the supply

voltage specied at the time of order. This setting is recorded, at the factory,

on the label afxed to the side of the UEC housing.

The following procedure should be used to change the transformer voltage:

Tools required to change the transformer voltage:

Medium phillips head screwdriver

Flat blade screwdriver

Long-handled needle nose pliers

No additional parts are required to change the transformer voltage

1. Isolate power from actuator.

2. It is not necessary to remove wires from terminal strip to termination/inter-

connect board.

3. Remove the larger clear cover by pressing down with both thumbs on

indented areas on top edge of cover.

4. Unlatch and release the 34-pin ribbon cable connector on the SBC located

near the heat sink.

5. Remove the four screws securing the SBC and remove the SBC.

6. Remove the insulator sheet.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

10

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

11

Figure 3-5

Locating Power Supply Board

Figure 3-6

Locating Power Supply Board

Mounting Screw

7. Unlatch and release the 50 pin connector located on the Power Supply

Board between the fuse cartridge and the phase LEDs. Move this ribbon

cable over the edge of the enclosure to permit access to the metal plate.

8. Remove the four screws securing the metal plate. Insert a at blade screw-

driver under the plate and gently lift and set aside. This plate will be

connected to the assembly via a green ground wire. It is not necessary to

remove the ground wire from the plate.

9. Locate the Power Supply Board which is mounted on the wall of the enclo-

sure opposite the Termination/Interconnect board. See Figure 3-5.

10. Remove and retain the single screw from the outside of housing which

secures the power board from the bottom. See Figure 3-6.

11. Using a long phillips head screwdriver, partially unscrew the screw located

on the inside base of the UEC housing which holds the bracket to the

housing. See Figure 3-7. Unscrew only enough to separate the bracket

from the housing. DO NOT COMPLETELY REMOVE THIS SCREW.

12. Slide the power board slowly up and out of the housing being careful to

move wiring aside. Care should be taken to prevent damage to the wiring

insulation by coming into contact with the edges of the bracket. It is only

necessary that the power board be moved enough to locate and change

the transformer jumpers.

(continued on next page)

Termination/

Interconnect Board

Power Supply Board

Power Supply

Board Mounting Screw

13. Locate the transformer jumpers as shown in Figure 3-8.

14. Using pliers, carefully remove the jumper and reinsert into position for the

desired input voltage:

Std. Optional

LK1 for 460V 575V

LK2 for 415V 525V

LK3 for 380V 220V

LK4 for 220V 115

15. If the main power is single phase, set all three LK7 jumpers (located beside

the ribbon cable connector) to the 1 phase setting to disable phase detection.

16. Carefully slide the power board back into the housing.

17. Tighten the bracket screw at the base of the housing.

18. Replace and tighten the screw on the outside of the housing.

19. Replace the metal plate and secure with 4 screws.

20. Reconnect the 50-pin ribbon connector.

21. Replace the insulator sheet on top of the ribbon cable keeping the 34-pin

connector free.

22. Reconnect 34-pin connector into the SBC.

23. Replace the SBC and secure with 4 screws.

24. Replace the UEC clear cover.

25. It is recommended that the new voltage with date changed be recorded

and initialed on the label located on the side of the UEC housing.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

12

Figure 3-7 -

Locating Power Supply

Bracket Retaining Screw

Figure 3-8 -

Power Supply Board

Power Supply

Bracket

Retaining

Screw

Transformer

Jumpers

LK7 - Phase

Detector

Jumpers

4. UEC-3/UEC-3-MPC Installation

4.1 Site Preparation

Proper site preparation is essential to the successful operation of the UEC-3

controlled actuators.

1. A site map or detailed site plan should be available. This should include

location and tag numbers of all actuators, junction boxes and terminal

strips.

2. Free access to the control compartments of each actuator will be required

for set-up, conguration and troubleshooting.

3. All wires should be properly labeled or identied.

4. Control and power wiring for the actuator should both be installed in proper

conduit but never in the same conduit. Shielding is not enough to prevent

induction of stray voltages onto signal leads from power lines.

5. Power distribution grid should be available to identify the impact of power

isolation to a particular actuator or group of actuators.

4.2 Visual Inspection

The UEC module contained in your Limitorque actuator has been tested prior

to shipment. It is recommended that a visual check of the module take place

prior to applying power to the actuator.

Check for any physical damage to the UEC module

Verify that all ribbon cables are fully seated and that the clips are in a verti-

cal position.

Verify that all EPROMs are properly aligned and fully seated.

4.3 Wire Preparation

For connections to the Termination/Interconnect Board, an 18 gage, 380V wire

is recommended. All wires should be stripped 0.25 inch (6 mm) from the end

and tinned with resin core solder for best results.

4.4 Actuator Wiring

It is essential that all wiring is in accordance with the wiring diagram provided

with your actuators. Copies of the wiring diagram are mailed to purchasers of

Limitorque actuators and one copy is normally placed inside the actuators

control compartment before shipment. Becoming familiar with the wiring

diagram will ease setup.

Wiring Verication should be done with the actuator isolated from power.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

13

Note:

The transformer voltage on the UEC module will be factory set to suit

the supply voltage specied at the time of order. This setting is

recorded, at the factory, on the label afxed to the side of the UEC

housing.

1. Check to make sure that the transformer voltage on the UEC-3 label is

the same as the incoming supply. If not, refer to Section 2.6 -Supply

Voltage for the procedure to change the voltage.

2 Verify that actuator wiring is in accordance with the wiring diagram shipped

with the actuator.

3. If the external control voltage is above 90VAC or 90VDC, link LK1 must be

removed. Locate LK1 at the bottom of the Termination/Interconnect Board

near the SBC. To remove, grasp the black housing and pull straight up.

4. Verify that DIP switch settings on the SBC are correct to enable the desired

functionality. See Section 2-3 of this manual for DIP switch key and basic

settings.

The unit is now ready for commissioning. See Section 5 for instructions.

4.5 Grounding

The remote control inputs on the Termination/Interconnect Board are opto-iso-

lated to protect the internal logic circuits from high voltage transients and

ground loops. Additional grounding for these inputs is not required.

Please refer to the wiring diagram for your particular Limitorque actuator for

additional grounding requirements.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

14

5. UEC-3/UEC-3-MPC Commissioning

5.1 Initial Checkout

All UEC-3 and UEC-3-MPC modules and their corresponding actuators are

tested before shipment to ensure proper operation. After assembly, the actu-

ator is cycled through normal operation, thereby assuring that the motor, wiring,

and controller are all functioning properly.

Final setup is not complete until the actuator is installed. Field setup is required.

Please use the instruction and maintenance manual appropriate for your actu-

ator to adjust the limit and torque switches.

Verify that the connectors for the ribbon cables are properly seated and that

the clips are in closed position.

Verify that all socketed integrated circuits are properly aligned and fully seated.

Make sure that for MPC applications, the Analog to Digital Converter chip is

installed.

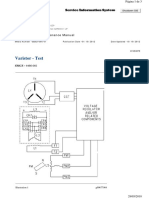

5.2 Start-up Procedure

The start-up procedure for the UEC-3 and UEC-3-MPC is given in the form of

a ow chart in Figure 5-1.

Note:

The settings of the DIP switches S1 and S2 on the SBC Board should

be recorded before beginning any procedure.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

15

Figure 5-1 - UEC-3/UEC-3-MPC Start-up Procedure

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

16

Do you want

phase correction?

SW2-5 on

Power off,

then on

Yes

Set position

limits

Center Pot

at 50% valve

position.

Selector switch

to Local

No

Power off

Swap incoming power leads

Power on

Yellow LED on?

(Phase Rotation OK)

SW2-5 off

Power off,

then on

Yes

No

Test

pushbuttons

Open PB=> Open dir

Close PB=> Close dir

Verify

Change position of SW1-6

(Direction to close)

No

Power off,

then on

Yes

Change other options

as required in std.

configuration

Power off,

then on

Wait 15 sec

SW93 LEDs on?

See Section 6.4

Troubleshooting

No Yes

UEC-3-MPC

go to

calibration

procedure

UEC-3 End of

Start-up

5.2.1 Power LEDs

During start-up check the LEDs on the power supply board. (See Figure 5-1

of Bulletin 440-12000 Rev. A. for the location of the LEDs.)

The Power Supply Boards on most versions of the UEC-3 and UEC-3 MPC

Modules have three LED indicators - red, yellow, and green. The state of these

indicators for various operating conditions are given below:

On units which have been congured for three phase power, both the red and

yellow LEDs should be illuminated when power is present to the actuator, and

the green indicator should not be illuminated

If the yellow LED is not illuminated, the unit is out of phase and incoming power

leads (L1 & L3) should be switched.

If the red LED is not illuminated, one of the phases is not present and incom-

ing power connections should be checked.

On units which have been congured for three phase power, all of the LEDs

should be illuminated when power is present to the actuator.

The green LED indicates that the phase detector circuit has been bypassed

and that there is no phase protection.

5.2.2 Reset LED

During Start-up, check the Reset LED on the Single Board Computer. (See

Figure 5-2 of Bulletin 440-12000 Rev. A. for the location of the RESET LED.)

On all UEC modules the Reset LED should be steadily illuminated when power

is present to the actuator.

If Reset LED blinks every 1.5 sec, check that EPROMs are properly seated

and that no pins are damaged or missing.

If Reset LED blinks every 11-12 seconds, check that module is not in extended

conguration mode.

See Bulletin 440-12000 Rev. A. for other faults which may cause this LED to

blink.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

17

5.3 UEC-3-MPC Calibration Procedure

The calibration procedure for the UEC-3-MPC is given in the form of a flow

chart in Figure 5-2. This procedure is also discussed in the Operation Manual.

*Note

Span and Zero reference must always be changed together

Figure 5-2 - UEC-3-MPC Calibration Procedure (Sheet 1 of 4)

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

18

SW2-1,2&3

on

SW2-5,6,7 off

Selector switch

to Local

Press Open button

Wait until actuator

stops at OPEN

Set SW2-5 ON

Press Close button

Wait until actuator

stops at Closed

Set command as

needed (20mA?)

Set command as

needed (4mA?)

Change position

of SW2-4

Change position of

SW2-4

Setting Span

and Zero*

Are

MPC parameters

stored?

No

Yes

Skip to section that

requires adjustment

Go to Test

(Sheet 3)

Note

The default level for proportional band was factory set at 14.0%

Note

Default level for deadband was factory set at 1.0%

Figure 5-2 - UEC-3-MPC Calibration Procedure (Sheet 2 of 4)

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

19

Set S1 to the desired

value as shown on

Table 5-1

Change the position

of SW2-4

Set SW2-1,2,3,6 & 8

ON

Set SW2- 5 & 7 OFF

Go to Test

(Sheet 3)

Set Proportional

Band

Set S1 to the desired

value as shown on

Table 5-1

Change the position

of SW2-4

Set SW2-1,2,3,5,6 &8

ON

Set SW2- 7 OFF

Go to Test

(Sheet 3)

Set Deadband

Figure 5-2 - UEC-3-MPC Calibration Procedure (Sheet 3 of 4)

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

20

Set S1 for desired

action.*

Change the position

of S2-4

Set S1-3,4,5,6,7,8

OFF

Set S2-1,2,3,7 & 8

ON

Set S2- 5 & 6

OFF

Go to Test

Set Action On

Loss of Signal

*S1-1 S1-2 Action

OFF OFF CLOSE

ON OFF STOP

ON ON OPEN

Figure 5-2 - UEC-3-MPC Calibration Procedure

(Sheet 4 of 4)

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

21

Set S2-1,2,3,5,

7 & 8 on

Change the position

of SW2-4

No

Actuator

movement properly

follows command

signal?

See Section 6.4

Troubleshooting

No

Control

satisfactory(response

time, overshoot,

accuracy?)

Yes

Yes

Apply external 4-

20mA command

signal

Selector Switch to

Remote

S2-1,2,3,5,6,7,8

ON

Change position of

S2-4

S2-2 off

Test Response

to Signal

Exit Extended

Configuration

SAVE TO EEPROM

Remove external

4-20mA

command signal

Loss of signal

action correct

?

Yes

No

See Section 5.4

Troubleshooting

Adjust proportional

band & deadband

See Sheet 2

End calibration

Set S1 &2 for desired features

Power OFF then ON

Set action on

loss of signal

Table 5-1 - Table of Values for Proportional Band and Deadband

% DIP S1 % DIP S1

12345678 123456 78

1 10000000 26 01011000

2 01000000 27 11011000

3 11000000 28 00111000

4 00100000 29 10111000

5 10100000 30 01111000

6 01100000 31 11111000

7 11100000 32 00000100

8 00010000 33 10000100

9 10010000 34 01000100

10 01010000 35 11000100

11 11010000 36 00100100

12 00110000 37 10100100

13 10110000 38 01100100

14 01110000 39 11100100

15 11110000 40 00010100

16 00001000 41 10010100

17 10001000 42 01010100

18 01001000 43 11010100

19 11001000 44 00110100

20 00101000 45 10110100

21 10101000 46 01110100

22 01101000 47 11110100

23 11101000 48 00001100

24 00011000 49 10001100

25 10011000 50 01001100

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

22

5.4 Troubleshooting

If no Pushbutton Station LEDs are illuminated, see the Troubleshooting Charts.

(See Figures 9-2, 9-3, and 9-4 of the Operation Manual.)

5.4.1 Troubleshooting Tools

Limitorque has developed diagnostic tools to aid in troubleshooting UEC-3

and UEC-3-MPC controlled actuators. The use of either of these tools will

assist in the quick diagnosis of actuator alarms and faults.

5.4.1.1 Universal Diagnostic Tool

The Universal Diagnostic Tool (UDT) is a hand held device that can determine

and diagnose the source of valve actuator alarms and faults on any UEC- 3

or UEC-3-MPC based actuator. It is designed as a rst-level diagnostic tool

providing preliminary troubleshooting information and is very easy to use.

Please refer to the UEC-3 and DDC-100 Diagnostic Interface Installation and

Operation Manual - Bulletin 437-10000 for instructions on using the UDT.

5.4.1.2 Modsim Diagnostic Software

A personal computer and Modsim diagnostic software can be used to trou-

bleshoot the UEC-3 controlled actuator. Modsim is designed to provide detailed

diagnostic information in addition to the information provided by the UDT.

Please refer to the UEC-3 and DDC-100 Diagnostic Interface Installation and

Operation Manual - Bulletin 437-10000 for UEC-3 to PC connectivity.

Please refer to the Modsim Modbus Simulation Software Operation Manual -

Bulletin 435-23001 for instructions for using Modsim.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

23

5.4.2 Component Replacement

Limitorque recommends the eld replacement of Control and I/O Power Supply

fuses, Single Board Computer, and Termination /Interconnect Board. If any

other components within the UEC-3 or UEC-3-MPC module require replace-

ment, it is recommended that the complete UEC-3 or UEC-3-MPC module be

replaced. See Section 5.4.3 for instructions on replacing the complete

UEC module.

5.4.2.1 Control Fuse Replacement

The following procedure should be used to replace the 120V control power

fuse (FS3) on the Power Supply Board:

Tools required:

Small athead screwdriver

Parts Required:

Control fuse: P/N: EF2-5X20MM-1A-250V

1. ISOLATE POWER FROM THE ACTUATOR.

2. Remove cover bolts and open control compartment cover.

3. Remove the larger clear cover of the UEC-3 by pressing down with both

thumbs on indented areas on top edge of cover.

4. Locate the fuse cartridge near the 50 pin IDC connector and the heat sink.

5. Insert screwdriver into slot on cap of fuse cartridge and turn 90in the

direction of the arrow.

6. Lift cap with fuse out of the cartridge.

7. Pull fuse out of cap and replace with Limitorque P/N: EF2-5X20MM-1A-

250V

8. Inspect replacement fuse to conrm that it is the correct size and undam-

aged.

9. Be sure to insert replacement fuse rmly in cap.

10. Align the brackets on the cap and fuse assembly with the notch in the car-

tridge and push straight in to insert.

11. Insert screwdriver into slot on cap of fuse cartridge and turn 90opposite

direction of ARROW.

12. Replace clear cover.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

24

5.4.2.2. 24 VDC I/O Power Supply Fuse Replacement

Tools required:

Small at head screwdriver

Parts required:

24VDC I/O Power Fuse P/N: EF2-5X20MM-1A-250V

1. ISOLATE POWER FROM ACTUATOR.

2. Remove cover bolts and open control compartment cover.

3. To gain access to the Termination/ Interconnect Board, remove the smaller

clear cover on the UEC-3 by inserting a at head screwdriver in the gap

at the front of the cover and lifting up and towards the base of the housing.

4. Locate the fuse near the pushbutton station IDC connector.

5. Remove the protective shroud from the fuse by inserting the screwdriver

blade under the shroud at each end and pry gently.

6. Remove fuse by inserting the screwdriver blade under one end of the fuse

and pry gently until it is free from the fuse holder.

7. Inspect the replacement fuse (Limitorque P/N: EF2-5X20MM-1A-250V)

to conrm that it is the correct size and undamaged.

8. Insert the replacement fuse by lining up the metal ends with the metal

brackets on the fuse holder and pushing the fuse straight down into the

fuse holder.

9. Replace protective shroud over the fuse and holder. To ease replacement,

squeeze the ends of the shroud gently to expand as you are replacing.

10. Replace clear plastic cover.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

25

5.4.2.3. Single Board Computer (SBC) Replacement

The following procedure should be used to replace the SBC:

Tools required:

Medium phillips head screwdriver

Small non-metallic tool for DIP Switch setting

Parts Required:

Single Board Computer: P/N: 61-825-0996-1

1. ISOLATE POWER FROM ACTUATOR.

2. Remove cover bolts and open control compartment cover.

3. Remove the larger clear cover of the UEC-3 by pressing down with both

thumbs on indented areas on top edge of cover.

4. Unlatch and release the 34-pin ribbon cable on the SBC located near the

heat sink.

5. Remove the four screws securing the SBC and remove the board.

6. It is not necessary to replace the insulator sheet with a new sheet unless

visible damage is present.

7. Inspect replacement SBC for obvious damage and verify that the Analog

to Digital Converter (ADC) chip (if required) is installed.

Note

Make sure that Analog to Digital Converter (ADC) chip is installed

for modulating applications.

8. Connect the 34-pin connector into the replacement SBC.

9. Position replacement SBC on top of the insulator sheet and secure with

four screws.

10. Set the DIP switch on the replacement SBC to match the one being

replaced.

11. Replace the UEC-3 clear cover.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

26

5.4.2.4. Termination/Interconnect Board Replacement

The following procedure should be used to replace the Termination

/Interconnect Board:

Tools required:

Medium phillips head screwdriver

Small at head screwdriver

Parts required:

Termination/Interconnect Board: P/N: TM74-743-0050

1. ISOLATE POWER FROM ACTUATOR.

2. Remove cover bolts and open control compartment cover.

3. Remove the larger clear cover of the UEC-3 by pressing down with both

thumbs on indented areas on top edge of cover.

4. Unlatch and remove the 50 pin ribbon connector located at the end of the

Termination/Interconnect Board adjacent to the SBC near the 34 pin con-

nector. Return the release latches to the closed position.

5. Remove smaller clear cover by inserting a at head screwdriver in the gap

at the bottom of the cover and lifting up and towards the base of the

housing.

6. Disconnect all incoming wires to the Termination/Interconnect Board. Make

sure all wires are labeled for easy reconnection.

7. Position latches for both IDC connectors on the Termination/ Interconnect

Board to the closed position before attempting to remove.

8. Remove and retain the 4 mounting screws on the Termination/Interconnect

Board. Pull the Termination/Interconnect Board away from the SBC to clear

the 50 pin connector to remove.

9. Inspect the replacement Termination/Interconnect Board for obvious

damage.

10. Position latches for both IDC connectors on the replacement Termination/

Interconnect Board to the closed position before attempting to install.

11. Install the replacement board by gently inserting the 50 pin connector into

the slot adjacent to SBC. The 40 pin connector will t in the slot provided.

Secure this board with 4 mounting screws.

12. Reconnect wires to the terminals on the replacement Termination/

Interconnect Board.

13. Replace small clear cover.

14. Reconnect the 50 pin ribbon cable to the Termination/Interconnect Board.

15. Replace larger clear cover.

16. Reconnect IDC connector (J6).

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

27

5.4.3 Complete UEC-3 or UEC-3-MPC Module Replacement

The procedure for the replacement of the complete UEC-3 or UEC-3-MPC

module is as follows:

Tools required to replace the complete UEC-3 or UEC-3-MPC Module:

Small at blade screwdriver

Medium at blade screwdriver

Small non-metallic DIP switch tool

Parts Required:

Replacement UEC-3 or UEC-3-MPC Module - contact your local distributor

or Limitorque Parts Department for correct P/N for your application.

1. ISOLATE POWER FROM THE ACTUATOR.

2. Remove cover bolts and open control compartment cover.

3. Disconnect leads from the UEC module at the terminal strip.

4. Disconnect ribbon cable connections to Pushbutton Station and geared

limit switch at Termination/Interconnect Board.

5. Disconnect remaining Termination/Interconnect Board wiring to other

devices such as an R/I converter.

6. Remove and save the 4 mounting screws on the base of the UEC module

and remove the assembly.

7. Set the DIP switches on the SBC of the replacement module to match

those of the module removed.

8. Check to make sure that the transformer voltage on the replacement

module is the same as on the module removed. If not, please refer to

Section 2.6 - Supply Voltage for the procedure to change the voltage.

Note

Replacement UEC-3 and UEC-3-MPC modules are shipped with 460V

transformer voltage as standard unless otherwise specied on parts

order.

9. Mount the new UEC-3 module on the mounting plate using 4 screws.

Note

For replacement in L-120 actuators, it is necessary that the module

be secured rst by the mounting screw closest to the input wires,

followed by the screw on the opposite side of the box. These should

hold the module secure while the remaining screws are put in.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

28

10. Reconnect wiring and ribbon cables to the Termination/Interconnect Board.

11. Connect wires from UEC-3 module to terminal strip according to wiring

diagram supplied with actuator.

12. Reapply power to the actuator.

13. Verify proper operation. See Section 5.2.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

29

This page is intentionally blank.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

30

6. Conversion of the UEC-3

Basic Controller

An installed UEC-3 control module can be modied in the eld to operate as

a UEC-3-MPC controller. These changes should be performed by a qualied

technician using genuine Limitorque parts and following the procedures in this

section. All tools and parts required are listed in each procedure.

6.1 Converting UEC-3 to

UEC-3-MPC Position Controller

The UEC-3-MPC is a 4-20 milliAmp controller which will change the position

of the valve in proportion to a current signal received from a set point con-

troller or similar device.

An actuator originally supplied with UEC-3 controls may be changed to UEC-

3-MPC controlled actuator.

The following procedures should be used to convert a UEC-3 actuator to a

UEC-3-MPC actuator:

Tools required:

Small non-metallic DIP switch tool

Small at blade screwdriver

Medium at blade screwdriver

Parts required:

Feedback potentiometer: Consult factory for part required

Analog Interface Board: P/N: 61-825-0962-2

A/D Converter Chip: P/N: 61-825-0733-1

Optional UEC-3-MPC parts:

PT20SD Position Transmitter: P/N: TM74-743-0066

1. ISOLATE POWER FROM THE ACTUATOR.

2. Remove actuator cover bolts and open control compartment cover.

3. Install potentiometer if not already installed in actuator. See actuator

Instruction and Maintenance manual for installation instructions or contact

your local Limitorque distributor for information.

4. Install Analog Interface Board. Analog board installation differs with type

and size of actuator. Consult factory or nearest service center for instal-

lation instructions.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

31

5. Remove the large clear cover on the UEC-3 module and connect ribbon

cable, J3A, from the Analog Interface Board to J3 connector on the Single

Board Computer (SBC). When the cover is replaced, the ribbon cable will

t through the cut-out in the cover.

6. Before replacing the cover, install the Analog to Digital Converter chip into

U18 on the Single Board Computer being careful to match notches and

avoid bending pins. The location of the Analog to Digital Converter (U18)

is shown in Figure 5-2 of the Operation Manual.

7. Calibrate the UEC-3-MPC (See UEC-3 Operation Manual - Bulletin 440-

12000 Rev. A., and Section 5.3 of this manual for calibration procedure).

6.1.1 Installation of the PT20SD (Optional)

The procedure and parts required for the installation of PT20SD differs accord-

ing to the type and size of Limitorque actuator. Please consult the nearest

Limitorque Blue Ribbon Service facility or Limitorques Service Department

for assistance.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

32

7. Parts

X indicates that parts are standard.

O indicates that parts are optional.

Item Part Number UEC MPC

Single Board Computer 61-825-0996-4 X X

Termination/Interconnect Board 61-825-1060-3 X X

3 Phase Power Supply Board 61-825-1235-4 X X

Single Phase & Special Power Supply Boards 61-825-1234-4 O O

Primary Fuses (FS1 & FS2) EF4-TDC11-250MA X X

Control Fuse (FS3) EF2-5X20MM-1A-250V X X

24VDC I/O Power Fuse (FS4) EF2-5X20MM-1A-250V X X

PT 20SD TM74-743-0066 O O

SBC Analog Board 61-825-0962-2 X

SW93 Pushbutton Station TM74-790-0033 X X

Customer Service Kit TM0700504 O O

Universal Diagnostic Tool 61-825-0950-3 O O

UDT Serial Interface Adapter 61-825-0951-3 O O

ADC Chip 61-825-0733-1 X

Note

Part Numbers are subject to change as product improvements are

introduced. Consult Limitorque for current part numbers.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

33

This page is intentionally blank.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

34

8. Customer Service

For parts or parts information, call your local Limitorque distributor or the Parts

Department in Lynchburg, VA, at 804-522-9833. For fastest response, please

have the order number and serial number from the actuator available when

contacting Limitorque for parts or parts information. This information can be

found on a Limitorque label afxed to the main housing of the actuator.

For service information, call your local Limitorque distributor, Blue Ribbon

Service Center or the Service Department in Lynchburg, VA, at 804-845-9366.

For fastest service, please have the order number and serial number from the

actuator available when contacting Limitorque with service questions. This

information can be found on a Limitorque label afxed to the main housing of

the actuator.

Limitorque Corporation UEC-3 & UEC-3-MPC Installation & Commissioning Manual

Bulletin 440-12100 6/96

35

Limitorque

Bulletin 440-12100 6/96

For further Limitorque service assistance call:

Limitorque Corporation

7615 Boeing Drive

Greensboro, NC 27409-8347

Phone (910) 668-0871

Fax (910) 605-5310

Limitorque Corporation

8901 Jameel Road Suite 180

Houston, TX 77040

Phone (713) 690-1960

Fax (713) 690-1277

or contact the Limitorque ofces listed below

Limitorque Corporation

5114 Woodall Road

P.O. Box 11318

Lynchburg, VA

24506-1318

Phone (804) 528-4400

Fax (804) 845-9736

Limitorque International

Trinity House

Kennet Side

Newbury

Berkshire, RG15 5EH England

Phone 44-1-635-46999

Fax 44-1-635-36034

Limitorque/Nippon Gear Co. Ltd.

Tennoz Central Tower 2-2-4,

Higashi-Shinagawa,

Shinagawa-Ku,

Tokyo 140, Japan

Phone 03-5460-7516

Fax 03-5460-8396

Limitorque of India, Ltd.

E-45/2 Okhla Industrial Area,

Phase-II

New Delhi 110 020, India

Phone 91-129-277135

Fax 91-11-683-9329

Limitorque Australia Ltd.

Division of Control Engineering

(Aust.) Pty., Ltd.

17 Scoresby Road

Bayswater, Victoria 3153,

Australia

Phone 613-729-0555

Fax 613-729-8225

Limitorque Asia Pte Ltd.

75 Bukit Timah Rd.

#05-01/02 Boon Siew Building

Singapore 229833

Phone 65-332-9100

Fax 65-332-9112

Das könnte Ihnen auch gefallen

- Field Terminations Manual, Tricon v9.0JLDokument268 SeitenField Terminations Manual, Tricon v9.0JLjesus lopezNoch keine Bewertungen

- SMB Series Catalogur PDFDokument106 SeitenSMB Series Catalogur PDFSatish KumarNoch keine Bewertungen

- Rotork E370E AWT Range Installation and Maintenance InstructionDokument36 SeitenRotork E370E AWT Range Installation and Maintenance Instructionahmedsalehawad100% (1)

- RE50214 Nivometer PDFDokument16 SeitenRE50214 Nivometer PDFCaspar Heerkens100% (1)

- 2VAA001623 en S Control SPDSO14 Digital Output ModuleDokument51 Seiten2VAA001623 en S Control SPDSO14 Digital Output ModuleanbarasanNoch keine Bewertungen

- Fieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Von EverandFieldbus Systems and Their Applications 2005: A Proceedings volume from the 6th IFAC International Conference, Puebla, Mexico 14-25 November 2005Miguel Leon ChavezNoch keine Bewertungen

- Arca Valve Manual - 830 POSITIONERDokument13 SeitenArca Valve Manual - 830 POSITIONERAtul bhabad0% (1)

- E Smartlink MRV I Complete Section 10 14Dokument88 SeitenE Smartlink MRV I Complete Section 10 14Anghelho CANoch keine Bewertungen

- Fuel Oil Meter ManualDokument89 SeitenFuel Oil Meter ManualbouguerraNoch keine Bewertungen

- PF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListDokument5 SeitenPF7000 A-FRAME and B-FRAME: Medium Voltage Drive Preventive Maintenance Check ListRaul quispe quispeNoch keine Bewertungen

- 57-606.9 Eclipse Model 706 Hart Io 1 PDFDokument108 Seiten57-606.9 Eclipse Model 706 Hart Io 1 PDFAbdul Shaharlal ENoch keine Bewertungen

- Atv31 (E)Dokument220 SeitenAtv31 (E)Santos Zosimo Ocas GoicocheaNoch keine Bewertungen

- Abb ActuatorDokument160 SeitenAbb ActuatorSayak GhoshNoch keine Bewertungen

- 3300-16 Dual Vibration Monitor PDFDokument7 Seiten3300-16 Dual Vibration Monitor PDFmohamedkhalifehNoch keine Bewertungen

- 04 Actuator EnglDokument14 Seiten04 Actuator Englsumantabal_uceNoch keine Bewertungen

- Installation Operation Manual 30HXC - 080 - 375 PDFDokument50 SeitenInstallation Operation Manual 30HXC - 080 - 375 PDFJohn SotoNoch keine Bewertungen

- User's Manual: AD/DA Conversion UnitDokument194 SeitenUser's Manual: AD/DA Conversion Unitmgkso706Noch keine Bewertungen

- Siemens VFD Manual 193Dokument328 SeitenSiemens VFD Manual 193nitinsomanathanNoch keine Bewertungen

- Eclipse 706 Pactware User Guide V3Dokument26 SeitenEclipse 706 Pactware User Guide V3Abdul Shaharlal ENoch keine Bewertungen

- Uec 3 ManualDokument2 SeitenUec 3 ManualabhijeetdhandaNoch keine Bewertungen

- 21h4e1b4 Annunciator KeyboardDokument12 Seiten21h4e1b4 Annunciator KeyboardCHRISTIANABGNoch keine Bewertungen

- DR290Dokument63 SeitenDR290DineshNoch keine Bewertungen

- Comfort ControllerDokument130 SeitenComfort ControllerCarlos TorresNoch keine Bewertungen

- Pressure & Temperature Switch RT SeriesDokument4 SeitenPressure & Temperature Switch RT SeriesVivek Vous AimeNoch keine Bewertungen

- Ns3100 50m Supplemental Instructions For Fta3100 Series Variable Speed ControllersDokument80 SeitenNs3100 50m Supplemental Instructions For Fta3100 Series Variable Speed ControllersTrung Thành VõNoch keine Bewertungen

- Autro Safe Bs310 Commissioning - Handbook - Key1c6Dokument52 SeitenAutro Safe Bs310 Commissioning - Handbook - Key1c6Mohamed MeeranNoch keine Bewertungen

- 3500/32 and 3500/34 4 Channel Relay Module and TMR Relay ModuleDokument66 Seiten3500/32 and 3500/34 4 Channel Relay Module and TMR Relay Modulenabil160874Noch keine Bewertungen

- Abb SwitchesDokument112 SeitenAbb SwitchestechtricNoch keine Bewertungen

- Binder 6Dokument208 SeitenBinder 6Sunil K100% (1)

- Data Sheet PTCDokument8 SeitenData Sheet PTCjjermanNoch keine Bewertungen

- Miura Steam Boiler Operation ManualDokument90 SeitenMiura Steam Boiler Operation ManualLuan NguyenNoch keine Bewertungen

- NW User ManualDokument51 SeitenNW User Manualscribdhas2006Noch keine Bewertungen

- Mil-Globe Control ValveDokument8 SeitenMil-Globe Control ValveGovarthanan GopalanNoch keine Bewertungen

- CCN StandardDokument66 SeitenCCN StandardGabriel LopezNoch keine Bewertungen

- Multi-Turn Actuators SA 07.2 - SA 16.2 SAR 07.2 - SAR 16.2 Control Unit: Electronic (MWG) With Actuator Controls AC 01.2 Non-IntrusiveDokument100 SeitenMulti-Turn Actuators SA 07.2 - SA 16.2 SAR 07.2 - SAR 16.2 Control Unit: Electronic (MWG) With Actuator Controls AC 01.2 Non-IntrusiveMatheus de AlmeidaNoch keine Bewertungen

- Samson PRV Mounting and Operating InstructionDokument20 SeitenSamson PRV Mounting and Operating InstructionRick CalaguiNoch keine Bewertungen

- Imsed01 & Imset01Dokument146 SeitenImsed01 & Imset01Dang Jinlong100% (1)

- Vortex FMDokument14 SeitenVortex FMtirutkkNoch keine Bewertungen

- HSB-H2 Manual 2010Dokument78 SeitenHSB-H2 Manual 2010Hasan SarfrazNoch keine Bewertungen

- Catalog Hyundai HGCDokument92 SeitenCatalog Hyundai HGCBảo ChâuNoch keine Bewertungen

- Altistart-48 Maintanance ManualDokument64 SeitenAltistart-48 Maintanance ManualKarthik SriramakavachamNoch keine Bewertungen

- 750 193levelmasterDokument50 Seiten750 193levelmasterJesus CovarrubiasNoch keine Bewertungen

- 5040 - MASIBUS CONTROLLER User - Manual PDFDokument53 Seiten5040 - MASIBUS CONTROLLER User - Manual PDFYUYWEGDYNoch keine Bewertungen

- Hamf 8 4Dokument15 SeitenHamf 8 4Mohd Fadzlee TokimanNoch keine Bewertungen

- Spare Part ListDokument1 SeiteSpare Part ListshantaNoch keine Bewertungen

- Abb Servi̇s Çanta Malzemeleri̇ 2021Dokument4 SeitenAbb Servi̇s Çanta Malzemeleri̇ 2021Hasan Yiğit Demir100% (1)

- Limitorque l120Dokument60 SeitenLimitorque l120ausumetNoch keine Bewertungen

- 574 914 PDFDokument1 Seite574 914 PDFDee RajaNoch keine Bewertungen

- Main Valve Adjustment Procedure of Mark VIDokument19 SeitenMain Valve Adjustment Procedure of Mark VImohamed abourayaNoch keine Bewertungen

- Controls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZDokument126 SeitenControls, Start-Up, Operation, Service and Troubleshooting: 30XA080-500 Air-Cooled Liquid Chillers 60 HZHasib Khan100% (1)

- Varistor - Test (GZP)Dokument3 SeitenVaristor - Test (GZP)Hugo CiprianiNoch keine Bewertungen

- Genius IO Modules PDFDokument284 SeitenGenius IO Modules PDFCharanNoch keine Bewertungen

- IMI Maxseal ICO3S 1-2, 2-Way, 174 Psi, Auto PDFDokument1 SeiteIMI Maxseal ICO3S 1-2, 2-Way, 174 Psi, Auto PDFawahidNoch keine Bewertungen

- Operator's Guide and Instruction Manual: Digital Bypass Solid State StarterDokument48 SeitenOperator's Guide and Instruction Manual: Digital Bypass Solid State StarterMatthew Keegan100% (1)

- Samwon Automatic Temperature Controller SU-105 User Manual 2Dokument3 SeitenSamwon Automatic Temperature Controller SU-105 User Manual 2vb corpNoch keine Bewertungen

- 160 54-PW2 1 PDFDokument18 Seiten160 54-PW2 1 PDFMersal AliraqiNoch keine Bewertungen

- Product Catalogue 2Dokument20 SeitenProduct Catalogue 2Varinder LoonaNoch keine Bewertungen

- Manuel Profibus Aertronic Aerzener G2 V107Dokument15 SeitenManuel Profibus Aertronic Aerzener G2 V107Diana ConsstantinNoch keine Bewertungen

- Icontrol AC Rel 3 4 42-02-2223 B5Dokument414 SeitenIcontrol AC Rel 3 4 42-02-2223 B5ElputoAmo XDNoch keine Bewertungen

- Course Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. RDokument25 SeitenCourse Title: Building Services (Electrical) : Prepared By: Olabode Oluwafemi. ROlawale AdebesinNoch keine Bewertungen

- Noise Part 2 of 5Dokument4 SeitenNoise Part 2 of 5nonotjenNoch keine Bewertungen

- BSCPH 202Dokument4 SeitenBSCPH 202pp1560078Noch keine Bewertungen

- Question Paper Code:: Reg. No.Dokument2 SeitenQuestion Paper Code:: Reg. No.senthil periakaruppanNoch keine Bewertungen

- Transformer Voltage RegulationDokument21 SeitenTransformer Voltage RegulationAbdelilahaliNoch keine Bewertungen

- Electrical Poles Trasverse Load Calculation (22.8.12)Dokument12 SeitenElectrical Poles Trasverse Load Calculation (22.8.12)Waleed Mohammed FekryNoch keine Bewertungen

- Component Id Certification Test: (DVD-64C)Dokument10 SeitenComponent Id Certification Test: (DVD-64C)Salih AnwarNoch keine Bewertungen

- 104 Servomotor Se BoschDokument76 Seiten104 Servomotor Se BoschelektronNoch keine Bewertungen

- OrbitDokument13 SeitenOrbitGeorgios PapakostasNoch keine Bewertungen

- Switching CircuitDokument2 SeitenSwitching CircuitSecure Energy FutureNoch keine Bewertungen

- Murata MA40 SERIESDokument2 SeitenMurata MA40 SERIESMiltonAlvaradoPonceNoch keine Bewertungen

- C3controls Understanding Trip Curves PDFDokument8 SeitenC3controls Understanding Trip Curves PDFAditya GizerNoch keine Bewertungen

- 01-CAP100 Single Line Diagram For Capacitor Bank of TLM PlantDokument11 Seiten01-CAP100 Single Line Diagram For Capacitor Bank of TLM PlantVidiya NovelinNoch keine Bewertungen

- 1 CM-2600 Series, 2.6" OD BLDC Hollow Shaft Servo Motor/encoder Servomotor/encoderDokument3 Seiten1 CM-2600 Series, 2.6" OD BLDC Hollow Shaft Servo Motor/encoder Servomotor/encoderChandru ChristurajNoch keine Bewertungen

- Manual Eco ENG PDFDokument230 SeitenManual Eco ENG PDFamcneela0% (1)

- S60SC4M Mxqwqqs PDFDokument11 SeitenS60SC4M Mxqwqqs PDFBaharak BaghiNoch keine Bewertungen

- Hitachi-HRL SeriesDokument13 SeitenHitachi-HRL SeriesJose LopezNoch keine Bewertungen

- Strong Cast: Test Full AmplifiersDokument8 SeitenStrong Cast: Test Full AmplifiersyanmaesNoch keine Bewertungen

- FisicaDokument5 SeitenFisicaMariaNoch keine Bewertungen

- BG5914 08 0 enDokument8 SeitenBG5914 08 0 endavidk8Noch keine Bewertungen

- Led TV: Service ManualDokument68 SeitenLed TV: Service ManualZigma FNoch keine Bewertungen

- LAB Experiement 2Dokument5 SeitenLAB Experiement 2lillyNoch keine Bewertungen

- Science5 ST3 Q3Dokument4 SeitenScience5 ST3 Q3ronaldNoch keine Bewertungen

- The Calculation of The Temperature Rise and Load Capability of Cable SystemsDokument13 SeitenThe Calculation of The Temperature Rise and Load Capability of Cable SystemsRogelio Revetti100% (1)

- OCN Unit 1,2Dokument23 SeitenOCN Unit 1,2M Madhu MaliniNoch keine Bewertungen

- 3926-Article Text-15001-1-10-20180918 PDFDokument20 Seiten3926-Article Text-15001-1-10-20180918 PDFDored AkareNoch keine Bewertungen

- ReportDokument55 SeitenReportArpitSemwalNoch keine Bewertungen

- Product Specification: LanguageDokument22 SeitenProduct Specification: LanguageCharles BernabéNoch keine Bewertungen

- Convention Paper: Simulation of An Analog Circuit of A Wah Pedal: A Port-Hamiltonian ApproachDokument9 SeitenConvention Paper: Simulation of An Analog Circuit of A Wah Pedal: A Port-Hamiltonian ApproachMafeCastro1998Noch keine Bewertungen

- ID 610C Carver Intro To Motor ControlDokument46 SeitenID 610C Carver Intro To Motor Control조용규Noch keine Bewertungen