Beruflich Dokumente

Kultur Dokumente

4021-6 Rimseal Foam Equipment

Hochgeladen von

oscarninan0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten2 SeitenAngus Rimseal foam Equipment

Copyright

© © All Rights Reserved

Verfügbare Formate

PDF, TXT oder online auf Scribd lesen

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenAngus Rimseal foam Equipment

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

0 Bewertungen0% fanden dieses Dokument nützlich (0 Abstimmungen)

24 Ansichten2 Seiten4021-6 Rimseal Foam Equipment

Hochgeladen von

oscarninanAngus Rimseal foam Equipment

Copyright:

© All Rights Reserved

Verfügbare Formate

Als PDF, TXT herunterladen oder online auf Scribd lesen

Sie sind auf Seite 1von 2

Angus Rimseal Foam Equipment is

used for the protection of vertical

open top floating roof (OTFR)

storage tanks and comprises two

elements - the Rimseal Foam

Generator (RFG) which produces

expanded foam when supplied with

foam solution and the Rimseal

Foam Pourer (RFP) which delivers

the foam gently into the rimseal

area.

Available in two basic body sizes

(the RFG 50 and RFG 80), with

capacities ranging from 54

litres/minute at 4 bar to 684

litres/minute at 10 bar, each unit is

factory-calibrated to deliver a

specified flow at a given pressure

within the limits shown below.

The RFP is a low-profile unit which

protects the foam from high winds

and guides it gently on to the tank

wall. The front shield allows fully

developed foam to emerge in a

cohesive blanket that flows intact

onto the inside wall of the tank.

The stainless steel mesh at the foam

exit helps to prevent blockage from

insects and nesting birds.

For new tanks, the new models can

make the most cost-effective use of

foam concentrate and water

resources by producing the

designed foam solution application

rate. For retrofit onto existing tanks

during refurbishment, the new

Angus RFG models can replace

existing units without the need for

expensive modification. Accurate

factory-calibration ensures full

compatibility with existing foam

concentrate induction systems.

To further simplify installation, a

fixing kit is now supplied as an

optional extra which facilitates

installation to the tank whilst still in

use and without the need for hot

work.

Angus Rimseal Foam Equipment is

suitable for use with Angus low

expansion foam concentrates. For

hydrocarbon fuels Angus FP70, FP70

Plus or Petroseal should be used;

but for polar solvent risks Angus

Alcoseal should be used.

ref: 4021/6/4.05 page: 1 of 2

Rimseal Foam Equipment

www.angusfire.co.uk

Rimseal Foam Equipment

ref: 4021/6/4.05 page: 2 of 2

THAME PARK ROAD, THAME, OXFORDSHIRE, OX9 3RT, ENGLAND

Tel: +44 (0)1844 265000 Fax: +44 (0)1844 265156

e-mail: general.enquiries@kiddeuk.co.uk

Angus Fire. Angus Fire reserves the right to modify any specification without prior notice.

SPECIFICATION DATA

RFG 50 RFG 80 RFP 50 RFP 80

Dimension A (mm) 159 236 - -

B(mm) - - 1000 1000

C(mm) - - 700 700

D(mm) - - 200 240

E(mm) - - 40 40

F(mm) - - 75 75

G(mm) - - 142 102

H (mm) 75 AF Hex. 105 AF Hex. - -

Inlet Connection 2 NPSC (f) 3 NPSC (f) 2 NPT (m) 3" NPT (m)

Outlet Connection 2 NPSC (f) 3 NPSC (f) - -

Materials Body Cast Iron to BS 2789 Grade 420/12 - -

Internal Fitting Stainless Steel to BS 970 316S31 - -

Deflector - - Carbon Steel

Internal Mesh - - Stainless Steel

Pipe - - Steel tube to BS 1387

Optional Clamps - - Clamp: Malleable iron, natural finish

Bolt: Steel, zinc plated

Finish Yellow Thermoplastic Powder Coated

Approx Weight (Kg) 3.5 6.5 37 41

To Install Fixing Holes - - 4 x 12mm dia. holes

Optional Clamps - - Min. 2 clamps per pourer

OPERATING DATA

Operating Pressure 3 bar to 10 bar

Typical Foam Expansion 4:1 to 8:1

Typical 25% Drainage Time 1.5 to 3 minutes using Angus FP70 Foam Concentrate

Das könnte Ihnen auch gefallen

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- Static Mixer Designing QuestionnairesDokument1 SeiteStatic Mixer Designing Questionnairesnazar750Noch keine Bewertungen

- Helical Static Mixer Data SheetDokument5 SeitenHelical Static Mixer Data Sheetnazar750Noch keine Bewertungen

- String: "String".title "String".upper : "String".lower F" Sring (String) (String) String"Dokument16 SeitenString: "String".title "String".upper : "String".lower F" Sring (String) (String) String"nazar750Noch keine Bewertungen

- SolidWorks Motion Tutorial 2013Dokument32 SeitenSolidWorks Motion Tutorial 2013bhumijayaNoch keine Bewertungen

- Static Mixer User ManualDokument9 SeitenStatic Mixer User Manualnazar750Noch keine Bewertungen

- Sewer AppDokument27 SeitenSewer AppEr Harsh MahajanNoch keine Bewertungen

- The Mathematics of Pumping Water PDFDokument9 SeitenThe Mathematics of Pumping Water PDFOualid LamraouiNoch keine Bewertungen

- 01-203 RW Mechanical DrawingsDokument6 Seiten01-203 RW Mechanical Drawingsnazar750Noch keine Bewertungen

- Horizontal ScrubberDokument8 SeitenHorizontal Scrubbernazar750Noch keine Bewertungen

- ElectricalDokument46 SeitenElectricalRobert Columbine100% (2)

- Jonshon ScreenDokument25 SeitenJonshon Screennazar750Noch keine Bewertungen

- 01-243 TW Mechanical DrawingsDokument4 Seiten01-243 TW Mechanical Drawingsnazar750Noch keine Bewertungen

- Basics of Control ComponentsDokument100 SeitenBasics of Control ComponentsImma DamalerioNoch keine Bewertungen

- Chlorine SiemensDokument3 SeitenChlorine Siemensnazar750Noch keine Bewertungen

- 01-203 RW Mechanical DrawingsDokument6 Seiten01-203 RW Mechanical Drawingsnazar750Noch keine Bewertungen

- Sluice Gate DenizDokument1 SeiteSluice Gate Deniznazar750Noch keine Bewertungen

- Blower DenizDokument1 SeiteBlower Deniznazar750Noch keine Bewertungen

- List of AbbreviationsDokument3 SeitenList of Abbreviationsnazar750Noch keine Bewertungen

- How To Model A Citrus Squeezer in SolidWorksDokument40 SeitenHow To Model A Citrus Squeezer in SolidWorksnazar750Noch keine Bewertungen

- Wire Length Calculator: Quick OverviewDokument2 SeitenWire Length Calculator: Quick Overviewnazar750Noch keine Bewertungen

- Toggle Clamp DrawingsDokument5 SeitenToggle Clamp Drawingsnazar750Noch keine Bewertungen

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Caja de Cambio RTLO-14913Dokument36 SeitenCaja de Cambio RTLO-14913Rodrigo SanhuezaNoch keine Bewertungen

- IDT Imageprospekt 2012 Web enDokument46 SeitenIDT Imageprospekt 2012 Web enjbharghavNoch keine Bewertungen

- SIF's For TrunnionDokument10 SeitenSIF's For TrunnionfileseekerNoch keine Bewertungen

- Neptune 7100 Series Brochure PDFDokument4 SeitenNeptune 7100 Series Brochure PDFKatherine MejíaNoch keine Bewertungen

- Canalizari ValsirDokument154 SeitenCanalizari Valsirbradu09Noch keine Bewertungen

- General Catalogue - Equipment PDFDokument6 SeitenGeneral Catalogue - Equipment PDFDiegoNoch keine Bewertungen

- Side Pocket Mandrels - American Completion ToolsDokument3 SeitenSide Pocket Mandrels - American Completion ToolsquirogasNoch keine Bewertungen

- Nuflo DP Cone MeterDokument8 SeitenNuflo DP Cone MeterAlvaro RodriguezNoch keine Bewertungen

- Water Supply & Sanitry DOMBOQDokument31 SeitenWater Supply & Sanitry DOMBOQajay_430Noch keine Bewertungen

- Pipe FlotationDokument5 SeitenPipe FlotationabhisheknharanghatNoch keine Bewertungen

- Shear Stress Though Tapered Pipe Thread - Eng-TipsDokument4 SeitenShear Stress Though Tapered Pipe Thread - Eng-TipsrodrigoperezsimoneNoch keine Bewertungen

- Client Guide To Steel Chimney InspectionDokument27 SeitenClient Guide To Steel Chimney InspectionAnkit BiswasNoch keine Bewertungen

- SC0901-MTO - Considering Hot Tapping or Subsea Tie-In - PDFDokument4 SeitenSC0901-MTO - Considering Hot Tapping or Subsea Tie-In - PDFankeshkatochNoch keine Bewertungen

- Jis g3462 Grade Stba 12 Tubes PDFDokument1 SeiteJis g3462 Grade Stba 12 Tubes PDFMitul MehtaNoch keine Bewertungen

- ISO 2531-2009 - SG CANALIZACAO - Bureau VeritasDokument1 SeiteISO 2531-2009 - SG CANALIZACAO - Bureau Veritasjonathan orosNoch keine Bewertungen

- Breech Lock InfoDokument5 SeitenBreech Lock InfoNenad TrkuljaNoch keine Bewertungen

- Tabla Asme b31.1Dokument1 SeiteTabla Asme b31.1agustin100% (1)

- Dep 30.10.02.16 - 2012Dokument11 SeitenDep 30.10.02.16 - 2012karthicbc2020Noch keine Bewertungen

- M&H Awwa C500 Standard Double Disc Gate Valves: Available Configurations / Figure NumbersDokument20 SeitenM&H Awwa C500 Standard Double Disc Gate Valves: Available Configurations / Figure NumbersGoutham KSNoch keine Bewertungen

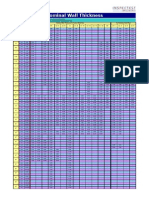

- 08A - Pipes Nominal Wall Thickness A4Dokument1 Seite08A - Pipes Nominal Wall Thickness A4umairasimpk100% (1)

- Macneil Pipe BrochureDokument2 SeitenMacneil Pipe BrochurecmakNoch keine Bewertungen

- FlatPlate Hydronic HeatExchanger UsaDokument28 SeitenFlatPlate Hydronic HeatExchanger Usasas999333100% (1)

- BPRV CatalogueDokument8 SeitenBPRV CataloguefkboulosNoch keine Bewertungen

- Mars5 Operation ManualDokument99 SeitenMars5 Operation Manualmj alvarezNoch keine Bewertungen

- Quality Assurance Plan: High Frequency Electric Resistance Welded PipeDokument15 SeitenQuality Assurance Plan: High Frequency Electric Resistance Welded PipeSachin KumarNoch keine Bewertungen

- CAT Hydraulic SystemsDokument4 SeitenCAT Hydraulic Systemsjimmy gomezNoch keine Bewertungen

- Pipe IndustryDokument18 SeitenPipe IndustryJamuna Nawani0% (1)

- Federal Signal Electraray Hazardous Location Strobe Warning LightDokument2 SeitenFederal Signal Electraray Hazardous Location Strobe Warning LightCésar AugustoNoch keine Bewertungen

- Filter DryerDokument20 SeitenFilter Dryermd_taheriNoch keine Bewertungen

- Ceramic Backing: Reduce Costs Using One-Sided WeldingDokument16 SeitenCeramic Backing: Reduce Costs Using One-Sided WeldingSamanthaPereraNoch keine Bewertungen