Beruflich Dokumente

Kultur Dokumente

Internal Combustion Engine

Hochgeladen von

Anuj MauryaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Internal Combustion Engine

Hochgeladen von

Anuj MauryaCopyright:

Verfügbare Formate

PROJECT REPORT

BASI CS OF TRACTOR

Submitted by:

TANVIR CHAWLA

ID No. 38561

Under the guidance of

Mr. R.N. Pateriya

(Training Incharge)

Associate Professor

College of Technology

G.B. Pant University of

Agriculture & Technology,

Pantnagar.

Mr. Karanvir Singh

(Mentor)

and

Mr. Binu Thomas

(Coordinator)

Product Development

Department,

New Holland Tractors.

Greater Noida.

Department of Farm Machinery & Power Engineering

Agricultural Engineering

G.B. Pant University, PANTNAGAR.

1 JUNE 30 JUNE 2012

CONTENTS

About New Holland

Tractors

1. Internal Combustion Engine

-Internal Combustion Engine Cooling

-Fuel InjectionPump(FIP)

2. Clutch

Transmission

1. Differential

PTO(Power Take-Off)

Hydraulic System

Turbocharger

Three Point Hitch and Drawbars

Safety

Controls

1. Pedals

2. Levers and switches

By C.W. Hart and CG Parr of Charles City Iowa. Though, steam plows and tractor with IC engine

were in use simultaneously but during an exhibition in 1908 organised bu Winnipeg Industrial

Exhibition,farmers could compare the field performance of gasoline tractors with that of steam plow.

Although,solid rubber tires were being used on Industrial tractor in 1920s, they were not practical for

agricultural tractors due to little or no traction on grassy or muddy fields or on wet or icy pavement.

Ultimately, it was 1932 when some fire stone tire and rubber Co. brought suitable rubber tyres on

Allies-Chalmes tractor.

The introduction of tractors in India in organized sector could begin only in late 40s and early 50s

when Central Tractor Organisations(CTO) procured a number of World War II surplus machines for

Kans Eradication Programme in Central Province. However, one or two stray cases are known when

during 1920 a landlord of Maharashtra brought two gasoline tractor from Germany.Similarly,in1923

CTO produced 15-30 gasoline tractors.

Post independent ear has been a rapid growth in the import of tractors. During 2

nd

and 3

rd

Five year

Plan, import licence for 11000 and 30000 tractors respectively were issued by the Government.

During fourth Five Year Plan, increased use of improved variety of seeds, fertilizer and irrigation

facilities helped in creating a very bid market for tractors.As a result, Govt. issued licence for

manufacturing of tractors.However, the import was still continued. M/s Eicher Good Earth Ltd.

Faridabad was the first to start production with 18% indigeneous components in Sept. 1960.This was

followed by M/s TAFE Madras who launched the project of assembling tractors from CKD packs in

Aug. 1961. The production of indegeneous tractors which was 880 in 1961-62 reached to level of 2.5

lakh in 1998,which is the second highest in the world.Today, 12 tractor manufacturers are

manufacturingmore than 65 model in the range of15 to 60 HP and it is estimated thatmore than 20

lakh tractors are available on Indian farms.

Today, in India tractor technology has reached a reasonably advanced level. However,elsewhere in

world research and development is going on for computer operated tractor. It is expected that during

the first decade of the next century,such type of tractors may be available for agricultural works.

A tractor is an engineering vehicle specifically designed to deliver a high tractive effort (or torque)

at slow speeds, for the purposes of hauling a trailer or machinery used in agriculture or construction.

Most commonly, the term is used to describe a farm vehicle that provides the power and traction

to mechanize agricultural tasks, especially (and originally) tillage, but nowadays a great variety of

tasks. Agricultural implements may be towed behind or mounted on the tractor, and the tractor may

also provide a source of power if the implement is mechanised.

Drawbars

Until the 1950s, plows and other tillage equipment usually were connected to the tractor via

a drawbar, or a proprietary connecting system. The classic drawbar is simply a steel bar attached to

the tractor (or in some cases, as in the early Fordsons, cast as part of the rear transmission housing) to

which the hitch of the implement was attached with a pin or by a loop and clevis. The implement

could be readily attached and removed, allowing the tractor to be used for other purposes on a daily

basis. If the tractor was equipped with a swinging drawbar, the it could be set at the center or offset

from center to allow the tractor to run outside the path of the implement.

The drawbar system necessitated the implement having its own running gear (usually wheels) and in

the case of a plow, chisel cultivator or harrow, some sort of lift mechanism to raise it out of the

ground at turns or for transport. Drawbars necessarily posed a rollover risk depending on how the

tractive torque was applied. The Fordson tractors (of which more units were produced and placed in

service than any other farm tractor) was extremely prone to roll over backwards due to an excessively

short wheelbase. The linkage between the implement and the tractor usually had some slack which

could lead to jerky starts and greater wear and tear on the tractor and the equipment.

Drawbars were appropriate to the dawn of mechanization, because they were very simple in concept

and because as the tractor replaced the horse, existing horse-drawn implements usually already had

running gear. As the history of mechanization progressed, however, the advantages of other hitching

systems became apparent, leading to new developments (see below). Depending on the function for

which a tractor is used, though, the drawbar is still one of the usual means of attaching an implement

to a tractor .

Safety

Farm tractor rear turnover

The classic row crop tractor (an Allis-Chalmers WD) - note the absence of any rollover protection

system.

Agriculture in the United States is one of the most hazardous industries, only surpassed by mining and

construction. No other farm machine is so identified with the hazards of production agriculture as the

tractor. Tractor-related injuries account for approximately 32% of the fatalities and 6% of the nonfatal

injuries in agriculture. Over 50% is attributed to tractor overturns.

The roll-over protection structure (ROPS) and seat belt, when worn, are the most important safety

devices to protect operators from death during tractor overturns.

Modern tractors have a ROPS to prevent an operator from being crushed if the tractor turns over. The

ROPS does not prevent tractor overturns; rather, it prevents the operator from being crushed during an

overturn. This is especially important in open-air tractors, where the ROPS is a steel beam that

extends above the operator's seat. For tractors with operator cabs, the ROPS is part of the frame of the

cab. A ROPS with enclosed cab further reduces the likelihood of serious injury because the operator is

protected by the sides and windows of the cab.

These structures were first required by legislation in Sweden in 1959. Before they were required,

some farmers died when their tractors rolled on top of them. Row-crop tractors, before ROPS, were

particularly dangerous because of their 'tricycle' design with the two front wheels spaced close

together and angled inward toward the ground. Some farmers were killed by rollovers while operating

tractors along steep slopes. Others have been killed while attempting to tow or pull an excessive load

from above axle height, or when cold weather caused the tires to freeze to the ground, in both cases

causing the tractor to pivot around the rear axle.

For the ROPS to work as designed, the operator must stay within its protective frame. This means the

operator must wear the seat belt; not wearing it may defeat the primary purpose of the ROPS.

CONTROLS

Pedals

Modern farm tractors usually have four or five foot-pedals for the operator on the floor of the tractor.

The pedal on the left is the clutch. The operator presses on this pedal to disengage the transmission for

either shifting gears or stopping the tractor. Some modern tractors have (or as optional equipment) a

button on the gear stick for controlling the clutch, in addition to the standard pedal.

Two of the pedals on the right are the brakes. The left brake pedal stops the left rear wheel and the

right brake pedal does the same with the right side. This independent left and right wheel-braking

augments the steering of the tractor when only the two rear wheels are driven. This is usually done

when it is necessary to make a sharp turn. The split brake pedal is also used in mud or soft soil to

control a tire spinning due to loss of traction. The operator presses both pedals together to stop the

tractor. For tractors with additional front-wheel drive, this operation often engages the 4-

wheel locking differential (diff-lock) to help stop the tractor when traveling at road speeds.

The pedal furthest to the right is the foot throttle. Unlike in automobiles, it can also be controlled from

a hand-operated lever ("hand throttle"). This helps provide a constant speed in field work. It also helps

provide continuous power for stationary tractors that are operating an implement by shaft or belt. The

foot throttle gives the operator more automobile-like control over the speed of the tractor for road

work. This is a feature of more recent tractors; older tractors often did not have it

A fifth pedal is traditionally included just in front of the driver's seat to operate the rear differential

lock (diff-lock), which prevents wheel slip. The differential normally allows the outside wheel to

travel faster than the inside wheel during a turn. However, in low-traction conditions on a soft surface,

the same mechanism could allow one wheel to slip, further reducing traction. The diff-lock overrides

this, forcing both wheels to turn at the same speed, reducing wheel slip and improving traction. Care

must be taken to unlock the differential before turning, usually by hitting the pedal a second time,

since the tractor with good traction cannot perform a turn with the diff-lock engaged. In modern

tractors, this pedal is replaced with an electrical switch.

Levers and switches

Many functions once controlled with levers have been replaced with some model of electrical switch

with the rise of indirect computer controlling of functions in modern tractors.

Until the beginning of the 1960's, tractors had a single register of gears, hence one gear stick, often

with three to five forward gears and 1 reverse. Then, group gears were introduced, and another gear

stick was added. Later, control of the forward-reverse direction was moved to a special stick attached

at the side of the steering wheel, which allowed forward or reverse travel in any gear. Nowadays,

with CVTs or other clutch-free gear types, fewer sticks control the transmission, and some are

replaced with electrical switches or are totally computer-controlled.

The three-point hitch was controlled with a lever for adjusting the position, or as with the earliest

ones, just the function for raising or lowering the hitch. With modern electrical systems, it is often

replaced with a potentiometer for the lower bound position and another one for the upper bound, and a

switch allowing automatic adjustment of the hitch between these settings.

The external hydraulics also originally had levers, but now are often replaced with some form of

electrical switch; the same is true for the power take-off shaft.

A tractor consists of following major components:

TRACTOR

1.Internal Combustion Engine

-Internal Combustion Engine Cooling

-Fuel Injection Pump(FIP)

2. Clutch

Transmission

1. Differential

PTO(Power Take-Off)

Hydraulic System

Turbocharger

Three Point Hitch and Drawbars

Safety

Controls

1. Pedals

2. Levers and switches

Clutch

Clutch control refers to the act of controlling the speed of a vehicle with a manual transmission by

partially engaging the clutch plate, using the clutch pedal instead of (or in conjunction with) the

accelerator pedal. The purpose of a clutch is in part to allow such control; in particular, a clutch

provides transfer of torque between shafts spinning at different speeds. In the extreme, clutch control

is used in performance driving, such as starting from a dead stop with the engine producing maximum

torque at high RPM.

Benefits

There are benefits to the use of clutch control in specific circumstances:

Low gear and low speed

When a tractor is in first gear, small variations in engine speed translate to large changes in

acceleration and engine braking. However, with a combination of clutch control and careful use of

engine speed, a much smoother ride can be achieved: by allowing the clutch to slip, variations in

engine revs are not immediately translated into changes in drive shaft rotation speed, but rather the

friction on the clutch plate allows the drive shaft to gradually equalize with the speed of the engine.

Once the tractor reaches a suitable speed, the clutch can be fully engaged and speed can then be

controlled either by varying the engine speed or by partially disengaging the clutch again if necessary.

This particular use of clutch control is frequently taught to learner drivers as a way to control

acceleration when pulling away from a complete stop or when driving at very slow speeds while

minimizing the chance of stalling the engine.

Uphill start

When pulling away on an uphill slope the chance of stalling the engine is greater, and as a result it can

be beneficial to engage the clutch more slowly than normal while revving higher than normal.

Adverse road conditions

In adverse road conditions, notably snow or ice, it is recommended to pull away in as high a gear

as possible to minimize torque on the wheels and thereby maintain traction with the road. Pulling

away requires progressively slower engagement of the clutch as the gear increases, and in a high

gear it is necessary to engage the clutch slowly to avoid the increased risk of stalling the engine,

or, in the case of adverse weather conditions, spinning the wheels.

Changing from first to second gear under maximum power

As the clutch slips, engine speed is lost but torque is not lost except through the effect of the new

engine speed on the engine torque itself. So slipping the clutch actually gives more torque to the

wheels even though the fraction of power wasted in the clutch increases much faster.

It is not necessary to maintain high engine speed to properly operate a motor vehicle. Any vehicle

with a standard transmission can operate with an engine speed slightly above idle when following

the proper gear sequence. The clutch can be operated normally with no sacrifice in performance;

however, in certain off-road and racing conditions, to attain higher speed and better performance,

the practice of clutch control plays an integral part in doing so.

Balancing the clutch

Normally, when a vehicle is stationary on an uphill slope it is necessary to use the handbrake in

conjunction with clutch control to prevent the vehicle from rolling backwards when pulling away.

However, in situations where the vehicle must be stopped briefly, for example in slow moving traffic,

the clutch can be used to balance the uphill force from the engine with the downhill force of gravity.

The benefit of this is that there is no need for the hand- or foot-brake, and the driver can pull away

more quickly. Using this technique will, however, wear out the clutch faster.

Deceleration

Typically with motorcycles and in motor sport, the clutch is often used to facilitate the use of

resistance from the engine spinning at high speeds to decelerate the vehicle more quickly, often

accompanied with normal braking. This can be achieved by placing the vehicle in a gear that would

ordinarily be too low for the current speed and momentum of the vehicle and by partly engaging the

clutch. When this happens momentum energy from the inertia of the vehicle is taken away to spin the

engine as close as possible to its maximum capability. As the vehicle is decelerating the clutch can be

further released to transfer more energy to keep the engine spinning as quickly as possible. This

method causes excessive clutch wear however, and it could cause severe engine damage or wheel

lockup if the clutch were released suddenly.

A better method is to downshift to a higher gear that would spin the engine within it's RPM limit, and

use the throttle to "Reve match" the engine to the road speed before releasing the clutch fully.

Effective engine braking is still achieved with little or no excessive clutch wear.

Once the clutch is entirely released and the vehicle has decelerated some, this cycle proceeds

downwards through the gears to further assist deceleration. If the clutch is controlled improperly

while this is being attempted, damage or extra wear to the engine and gears is possible, as well as the

risk of wheels locking up and a subsequent loss of proper vehicle control.

Problems

Even normal use of clutch control increases the wear (and decreases the lifespan) of the clutch.

Excessive use of clutch control or riding the clutch will cause further damage.

Prolonged use

While the use of clutch control at low speed can be used to obtain greater control of acceleration and

engine braking, once a vehicle has picked up sufficient speed the clutch should be fully engaged

(pedal released).

Excessive engine revolutions

Excessively revving the engine while using clutch control, or keeping the clutch partially engaged

while accelerating with the gas pedal, can cause unnecessary damage to the clutch.

Slipping the clutch

Slipping the clutch (sometimes referred to as feathering the clutch) is a term used by automotive

enthusiasts to describe when the driver alternately applies and releases the clutch to achieve some

movement of the car. It's called slipping because the clutch plate will slip against the flywheel surface

when such an action is performed. Slipping the clutch is known to be hard on the clutch surface due to

the sliding friction created.

Drivers can frequently be observed slipping the clutch when they are trying to stay stationary on a hill

without using neutral and the brake. They apply the clutch to climb a bit, then release to roll back,

then apply again, etc. so that the car stays in about the same place. With enough practice, alternating

is no longer needed. Applying the correct amount of clutch pressure and throttle causes just enough

force from the engine to counter gravity and keep the vehicle stationary .The alternative to this

technique of staying stationary on a hill would be to put the vehicle in neutral and apply the brake.

Slipping the clutch is a popular term in drag racing culture and is done when launching a car, usually

in a drag race. Some contend that slipping the clutch is the best way to launch a front-wheel

drive (FWD) car as it prevents Torque steering that many FWD cars experience when too much

power is put to the front wheels.

Fuel Injection Pump(FIP)

An Injection Pump is the device that pumps fuel into the cylinders of a diesel engine. Traditionally,

the pump is driven indirectly from the crankshaft by gears, chains or a toothed belt (often the timing

belt) that also drives the camshaft. It rotates at half crankshaft speed in a conventional four-stroke

engine. Its timing is such that the fuel is injected only very slightly before top dead centre of that

cylinder's compression stroke. It is also common for the pump belt on gasoline engines to be driven

directly from the camshaft. In some systems injection pressures can be as high as 200 MPa.

Safety

Because of the need for positive injection into a very high-pressure environment, the pump develops

great pressuretypically 15,000 psi (100 MPa) or more on newer systems. This is a good reason to

take great care when working on diesel systems; escaping fuel at this sort of pressure can easily

penetrate skin and clothes, and be injected into body tissues with medical consequences serious

enough to warrant amputation.

Construction

Earlier diesel pumps used an in-line layout with a series of cam-operated injection cylinders in a line,

rather like a miniature inline engine. The pistons have a constant stroke volume, and injection volume

(i.e., throttling) is controlled by rotating the cylinders against a cut-off port that aligns with

a helicalslot in the cylinder. When all the cylinders are rotated at once, they simultaneously vary their

injection volume to produce more or less power from the engine. Inline pumps still find favour on

large multi-cylinder engines such as those on trucks, construction plant, static engines and agricultural

vehicles.

For use on cars and light trucks, the rotary pump or distributor pump was developed. It uses a single

injection cylinder driven from an axial cam plate, which injects into the individual fuel lines via a

rotary distribution valve. Later incarnations such as the Bosch VE pump vary the injection timing

with crank speed to allow greater power at high crank speeds, and smoother, more economical

running at slower revs. Some VE variants have a pressure-based system that allows the injection

volume to increase over normal to allow a turbocharger or supercharger equipped engine to develop

more power under boost conditions.

All injection pumps incorporate a governor to cut fuel supply if the crank speed endangers the engine

- the heavy moving parts of diesel engines do not tolerate overspeeding well, and catastrophic damage

can occur if they are over-revved.

New types

Mechanical pumps are gradually being phased out in order to comply with international emissions

directives, and to increase performance and economy. Alternatives include common rail

diesel systems and electronic unit direct injection systems. These allow for higher pressures to be

developed, and for much finer control of injection volumes compared to mechanical systems.

REFERENCES:

BOOKS

1. FARM TRACTOR (Maintenance and Repair)

By S.C. Jain and C.R. Rai

2. Elements of gricultural Engineering

By Dr. Jagdishwar Sahay

3. Textbook on Agricultural Engineering

By Er. Sanjay Kumar

OTHER SOURCES

Internet

Das könnte Ihnen auch gefallen

- Welding Missing On Y-Section Channel and Long Runner TubeDokument14 SeitenWelding Missing On Y-Section Channel and Long Runner TubeAnuj MauryaNoch keine Bewertungen

- One Can Use A Thumb Rule For ReferenceDokument13 SeitenOne Can Use A Thumb Rule For ReferenceAnuj MauryaNoch keine Bewertungen

- 68p01ysd HB PDFDokument1 Seite68p01ysd HB PDFAnuj MauryaNoch keine Bewertungen

- Scientifically: "Where Nature at Its Best"Dokument2 SeitenScientifically: "Where Nature at Its Best"Anuj MauryaNoch keine Bewertungen

- Ancient Egypt PPT Lecture 1Dokument19 SeitenAncient Egypt PPT Lecture 1Anuj MauryaNoch keine Bewertungen

- T Shirt & Shoes - GoodyearDokument2 SeitenT Shirt & Shoes - GoodyearAnuj MauryaNoch keine Bewertungen

- MIN 14 STD ElectricalDokument1 SeiteMIN 14 STD ElectricalAnuj MauryaNoch keine Bewertungen

- Underwater WindmillDokument49 SeitenUnderwater WindmillAnuj Maurya100% (1)

- Cause and Effect DiagramDokument6 SeitenCause and Effect DiagramAnuj MauryaNoch keine Bewertungen

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5795)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Chevrolet Camaro First GenerationDokument5 SeitenChevrolet Camaro First Generationapi-323099156Noch keine Bewertungen

- 245 Wiring Diagram For Left Front Door Control Unit (DCU)Dokument3 Seiten245 Wiring Diagram For Left Front Door Control Unit (DCU)McDimaD100% (1)

- Pilgrim 05 Jaguar Base ElectricalDokument6 SeitenPilgrim 05 Jaguar Base ElectricalnicehornetNoch keine Bewertungen

- Volkswagen Polo Clasic Fuse DescriptionDokument1 SeiteVolkswagen Polo Clasic Fuse Descriptiondragoszaman1Noch keine Bewertungen

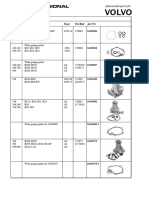

- 1734 VolvoDokument6 Seiten1734 VolvocarlosNoch keine Bewertungen

- Test Volvo V70 1.6d 2009Dokument8 SeitenTest Volvo V70 1.6d 2009turbobrikNoch keine Bewertungen

- FOODLANE-DATABASE (1) (Autosaved) - 1Dokument15 SeitenFOODLANE-DATABASE (1) (Autosaved) - 1Jennifer LegaspiNoch keine Bewertungen

- Texas Drive Magazine November1-14,2010Dokument24 SeitenTexas Drive Magazine November1-14,2010texasdriveNoch keine Bewertungen

- Peugeot 508 2.0 HDi RXH FR 176kmDokument6 SeitenPeugeot 508 2.0 HDi RXH FR 176kmMiha EllaNoch keine Bewertungen

- Brochure Scania Irizar I3Dokument10 SeitenBrochure Scania Irizar I3MioMaulenovoNoch keine Bewertungen

- FULL 1992 Service Manual Incl Turbo PDFDokument1.865 SeitenFULL 1992 Service Manual Incl Turbo PDFSebastian GomezNoch keine Bewertungen

- DBuild PSA TRNAVA C3Citroen 02032024Dokument32 SeitenDBuild PSA TRNAVA C3Citroen 02032024alaaaboalmagd434Noch keine Bewertungen

- Volkswagen Strategy ManagementDokument12 SeitenVolkswagen Strategy ManagementPrasad Kumar0% (1)

- Catalog With Price of TechtiumDokument1.603 SeitenCatalog With Price of TechtiumArmando Ortiz100% (1)

- Form 21: (See Rule 47 (A) and (D) ) Sale CertificateDokument1 SeiteForm 21: (See Rule 47 (A) and (D) ) Sale CertificateMagalakshme TafeNoch keine Bewertungen

- Polo Gti Brochure PDFDokument6 SeitenPolo Gti Brochure PDFMohd AkhirNoch keine Bewertungen

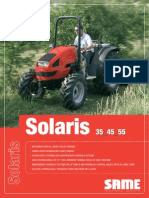

- 113 308.8151.3.1-2 Solaris 35-55 enDokument2 Seiten113 308.8151.3.1-2 Solaris 35-55 enDaniel TarlungaNoch keine Bewertungen

- Main Wiring For Hyundai I20 1St GEN F/L (2012-2014) 5DR 1.2L (PETROL) (15.03.2012-14.07.2014)Dokument2 SeitenMain Wiring For Hyundai I20 1St GEN F/L (2012-2014) 5DR 1.2L (PETROL) (15.03.2012-14.07.2014)بن علال عبد الحميدNoch keine Bewertungen

- Review - Lights, Reelight sl100Dokument1 SeiteReview - Lights, Reelight sl100velorutionNoch keine Bewertungen

- SPEAKERDokument1 SeiteSPEAKERبن علال عبد الحميدNoch keine Bewertungen

- 17MY L200 TechnicalspecDokument2 Seiten17MY L200 TechnicalspecsilvaNoch keine Bewertungen

- All About CarsDokument16 SeitenAll About Carsapi-255581071Noch keine Bewertungen

- My Favorite CarDokument2 SeitenMy Favorite CarEfistein Archymedes NagaNoch keine Bewertungen

- Motor Encendido Por Compresion Diesel Datos Recopilados Del Motor Hyundai I30 1.6 Crdi 136 (Man. 6) (2017)Dokument4 SeitenMotor Encendido Por Compresion Diesel Datos Recopilados Del Motor Hyundai I30 1.6 Crdi 136 (Man. 6) (2017)Osmar VallejosNoch keine Bewertungen

- Application For Driver'S LicenseDokument2 SeitenApplication For Driver'S LicenseShalom HernandezNoch keine Bewertungen

- Volvo Fh12 A Type Workshop Manual Group 37Dokument10 SeitenVolvo Fh12 A Type Workshop Manual Group 37kristin98% (41)

- 07 AutoDokument6 Seiten07 Auto2791957Noch keine Bewertungen

- B40 45 50X-5 - Sb1085e PDFDokument450 SeitenB40 45 50X-5 - Sb1085e PDFGORDNoch keine Bewertungen

- VW AG4 TransmissionDokument8 SeitenVW AG4 TransmissionIan Mcphee100% (3)