Beruflich Dokumente

Kultur Dokumente

Kalrez Brochure

Hochgeladen von

adhityaCopyright

Verfügbare Formate

Dieses Dokument teilen

Dokument teilen oder einbetten

Stufen Sie dieses Dokument als nützlich ein?

Sind diese Inhalte unangemessen?

Dieses Dokument meldenCopyright:

Verfügbare Formate

Kalrez Brochure

Hochgeladen von

adhityaCopyright:

Verfügbare Formate

DuPont

Kalrez

PERFLUOROELASTOMER PARTS

RELIABLE, LONG-TERM SEALING IN EXTREME

CHEMICAL AND THERMAL ENVIRONMENTS

2

You Can Rely on DuPont

Kalrez

Sealing Solutions

in the Harshest Processing Environments

Engineered for optimum performance

For over 40 years, DuPont has been

relentless in pursuing improvement in the

manufacture of peruoro elastomer parts.

Elastomeric parts typically consist of

three components: a polymer chain (the

backbone of the elastomer), a crosslinking

system (which links the polymer chains

together and is the key to elasticity and

sealing performance), and a ller system

(used to enhance mechanical properties).

Based on our extensive experience,

DuPont adjusts these components to

optimize seal performance.

Reduce maintenance costs

DuPont

Kalrez

parts help stretch your

mean time between repair (MTBR)

and lower your maintenance costs.

Their durability minimizes unscheduled

downtime while letting you extend

time between routine inspections

and replacement cycles for critical

components.

Increase productivity

By reducing the frequency of seal

changes, repairs and inspections, you can

increase process and equipment uptime

for greater productivity and yield.

Increase safety

Lasting longer and performing better than

other elastomers, Kalrez

helps reduce

the risk of chemical exposure from

seal failure.

Reduce fugitive emissions

Kalrez

and Kalrez

Valve Stem Packing

Systems can help you reduce leaks

and fugitive emissions for improved

compliance with environmental

regulations. Because Kalrez

parts

maintain their sealing integrity, you

reduce your risk of environmental

non-conformance.

Maintain process purity

Kalrez

parts help prevent process

contamination by:

Resisting degradation in harsh

chemicals

Maintaining sealing force at high

temperatures to re duce leakage

Containing fewer ingredients that

extract into the pro cess

Providing lower outgassing in vacuum

sealing

Meeting stringent FDA regulations for

purity and cleanliness

ISO 9001 quality assured with full

traceability

Kalrez

parts are made only by DuPont, a

fully integrated manufacturer of Vespel

parts and shapes, Viton

uoro elastomers

and Neoprene rubber polymers, as well

as peruoroelastomer parts. Kalrez

parts

are manufactured in ISO 9001 quality

certied facilities and packaged in a bar-

coded bag for full traceability.

DuPont

Kalrez

Offers a Variety of Products to Meet Your Application Needs

The DuPont

Kalrez

product line has

been specically designed to deliver

outstanding performance in aggressive

process environments. Whether its

resistance to acids, amines, ultrapure

de-ionized water, strong bases or high

temperatures, by selecting the Kalrez

part that is best suited to a specic

application, manufacturers can improve

seal performance in their operating

environment.

Broad chemical and temperature

resistance in chemical/hydrocarbon

processing

Processing environments in chemical

and hydro carbon plants are running

hotter, longer and with more aggressive

chemicals. In order to increase meantime

between repair (MTBR) and improve

safety, Kalrez

has been the product

of choice. The industry standard has

long been DuPont

Kalrez

4079, but

increasing demands on production

have called for new products with even

greater performance capabilities. Today,

the DuPont

Kalrez

Spectrum

family of

products expands on the chemical and

thermal properties of Kalrez

4079 to

better meet the requirements of these

applications.

Purity in food and pharmaceuticals

The regulatory requirements of the

food and pharmaceuticals industries

require increased awareness and

stricter guidelines regarding product

safety. Kalrez

parts for pharmaceutical

applications offer cleanliness and

chemical inertness with the resilience of

a true elastomer. With its combination of

thermal and chemical performance and

rubber-like sealing ability, Kalrez

offers

the pharmaceutical industry a new level

of protection against conta mination and

seal failure.

Electronics

Kalrez

parts help reduce the total

operating cost of wafer processing,

photovoltaic manufacturing processes,

and at panel display equipment by

providing longer seal life and increasing

meantime between repair. Unplanned

maintenance due to incompatible sealing

materials can interfere with production

schedules, causing downtime. Kalrez

parts can help improve sealing reliability in

processes that use high heat, aggressive

chemicals and plasma.

Other demanding applications

Because of its exceptional chemical and

temperature resistance, Kalrez

was

rst used in aerospace and downhole

applications. Its outstanding resistance

to fuels, additives, lubricating oils and

corrosive chemicals has made Kalrez

the

product of choice in the most aggressive

environments where seal failure is

unacceptable.

3

4

DuPont

Kalrez

Delivers the Broadest Chemical Resistance

Across the Board

Superior chemical resistance to more

than 1800 chemicals

DuPont

Kalrez

peruoroelastomer

parts have virtually universal chemical

resistance. They withstand attack from

more than 1,800 chemicals, solvents

and plasmas. Standardizing on Kalrez

products for broad chemical resistance

reduces your need to keep multiple

materials on the shelf, thus lowering cost

of inventory.

Minimal swell

Chemically induced swelling can cause

O-rings and sealing components made of

other rubbers to expand out of retaining

grooves, resulting in seal failures. Kalrez

parts resist extreme volume swell when

exposed to a wide variety of chemicals

and solvents, including concentrated nitric

acid, sodium hydroxide, ethylene diamine

and steam.

Optimizing chemical resistance and

seal performance

In order to maximize seal performance in

specic applications, DuPont continually

develops new products as emerging

needs are discovered. In chemical

and hydrocarbon processing, a family

of products called DuPont

Kalrez

Spectrum

are available for better

overall chemical resistance and higher

thermal stability. This combination gives

processors a larger operating window

for additional chemical usage and higher

temperature excursions. For more

specic information about the chemical

compatibility of Kalrez

parts, consult the

DuPont Chemical Resistance Guide or

the Kalrez

Application Guide available on

our website or contact your Kalrez

parts

authorized distributor.

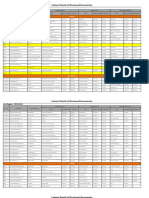

Temperature

Compression set

5 = best performance

Seal force

retention

Acids

Bases

Amines

Steam

Solvents

Kalrez

4079

Kalrez

Spectrum

6375

Kalrez

Spectrum

7075

Advancements in polymer technology have improved

chemical resistance of elastomers

DuPont

Kalrez

Performs in High Temperature Applications and Processes

Service temperature range up to 327 C

Even after long-term exposure

to temperatures up to 327 C

(620 F), DuPont

Kalrez

parts retain

their elasticity and recovery properties

better than other high-temperature

elastomers. Their high-temperature

properties, coupled with near universal

chemical resistance, enable Kalrez

parts

to withstand an extremely broad range of

process media.

Maintains sealing force to keep

seals tight

As proven in ISO 3384 tests, Kalrez

parts outperform other elastomers when

it comes to sealing force retention, a

measure of seal life. Even under harsh

and aggressive conditions, Kalrez

will

retain its sealing force longer. And thanks

to its true-rubber resiliency, Kalrez

prevents leaks caused by creep, a major

problem with PTFE.

Low compression set

Kalrez

parts exhibit low compression

set, maintaining their elastic recovery

to maintain tight seals over the long

haul. Because Kalrez

parts recover

better under compression than other

peruoroelastomer parts, they maintain

their shape better under prolonged stress.

Kalrez

4079

Kalrez

Spectrum

7075

Silicone

Fluoroelastomer

S

e

a

l

i

n

g

F

o

r

c

e

R

e

t

e

n

t

i

o

n

(

%

o

f

i

n

i

t

i

a

l

f

o

r

c

e

)

Test Duration (hours)

100

90

80

70

60

50

40

30

20

10

0

0 100 200 300 400 500 600 700

C

o

m

p

r

e

s

s

i

o

n

s

e

t

,

%

Kalrez

Spectrum

7075

45

35

25

15

5

0 200 400 600

Exposure, hr

Kalrez

4079

Sealing force retention at 204 C Compression set at 204 C

Test method: ISO 3384: 1991, method A, 214 O-ring Test method: D395B, 214 O-ring

5

DuPont

Kalrez

Increases Mean Time Between Repairs

in Tough Chemical and Hydrocarbon Processes

DuPont

Kalrez

KVSP

reduces

fugitive emissions and improves

process control

Kalrez

Vespel

Tested up to class 600 per ANSI/FCI 91-1-1994

Certifed according to TA Luft requirements

Meets requirements of Pressure Equipment

Directive PED97/23/EC

Kalrez

provides long seal life in

chemical and hydrocarbon processing

In pumps, valves, mechanical seals or

analytical equipment, DuPont

Kalrez

peruoroelastomer parts are proving their

value year in and year out. Their long-term

resistance to the harshest chemicals and

the highest temperatures makes them

resistant to swelling and embrittlement,

a leading cause of premature seal failure.

Whether its O-rings, custom shapes or

valve stem packing, Kalrez

parts can

improve your productivity, control fugitive

emissions and reduce costly seal failures.

Kalrez

KVSP

valve stem packing

system reduces friction

In either manual or automatic controls,

you can improve valve performance,

reduce maintenance costs and limit

fugitive emissions to less than 10 ppm

with DuPont

Kalrez

KVSP

. Kalrez

KVSP

is a combination of Kalrez

V-rings

and DuPont

Vespel

backup components

that can handle temperatures up to

288 C. They provide a self-adjusting,

maintenance-free alternative to graphite

and PTFE (polytetrauoroethylene)

packing systems.

Through reduced friction, Kalrez

KVSP

improves process control variability,

resulting in improve ments to both yield

and product quality. Friction data proves

that Kalrez

KVSP

performs at levels

comparable to PTFE packing sets. No

valve modications are necessary and

adjustments are rarely needed after

installation to make Kalrez

KVSP

an

important upgrade to valve performance.

6

7

DuPont

Kalrez

Delivers Integrity and Purity in Pharmaceutical Processes

T

O

C

(

p

p

m

)

600

550

500

450

400

350

300

250

200

150

100

50

0

EPDM Pt-Silicone FKM Kalrez

Kalrez

PTFE

6221 6230

Kalrez

6221 and 6230 have extractable levels comparable to PTFE

Kalrez

parts are much more

inert and cleaner than EPDM,

silicone and FKM, and very

similar to PTFE.

EPA method 415; TOC tests performed on 1 sanitary seals, immersed in 50 mL of sterile WFI at 100 C/24 hrs.

The solution was then diluted to 100 mL and analyzed.

FDA and USP compliancy

The U.S. Food and Drug Administration (FDA) confrmed the compliance of

DuPont

Kalrez

6221 and 6230 peruoroelastomer parts for repeated use

in contact with food by Food Contact Notifcation (FCN) 000101. FCN 000101

was established through the FDA Premarket Notifcation Process for food

contact substances as described in section 409(h) of the Federal Food, Drug,

and Cosmetic Act (21 U.S.C. 348(h)) and is the primary method by which the

FDA authorizes the use of food additives that are food contact substances.

FCN 000101 requires materials to have extractable levels less than 0.2 mg/in

2

.

Designated Kalrez

6221 and 6230 products have been tested in accordance

with United States Pharmacopeia Class VI (USP Class VI) and met those

requirements. In addition, designated Kalrez

products also comply with the

requirements in U.S. FDA regulation 21 CFR 177.2600.

Please see back cover of this brochure for additional information.

With its combination of thermal and

chemical performance, and its rubber-

like sealing ability, DuPont

Kalrez

parts offer the pharmaceutical industry

a new level of protection against

process contamination and seal failure.

Similar to PTFE in cleanliness, heat and

chemical resistance, Kalrez

has the

resilience and compressive strength of

frequently used sealing materials such

as ethylene propylene polymers (EPDM),

uoroelastomers (FKM) and silicone

rubber. Black and white Kalrez

parts

have been developed to meet the unique

sealing needs of todays pharmaceutical

and biopharmaceutical manufacturing

processes for increased purity and

sealing integrity.

Deliver Higher Yields in Electronics with DuPont

Kalrez

Parts

Seals in electronics manufacturing

are subject to process conditions that

challenge seal performance. Chemical

resistance that is nearly universal,

coupled with superior high-temperature

properties, enables DuPont

Kalrez

parts to withstand virtually any process

mediaincluding plasmasat elevated

temperatures.

In addition to providing superior chemical

resistance and thermal stability,

Field proven in electronics processes

Over 50,000 wafers processed in a high-energy oxygen

plasma asher without a slit valve seal change

Over 400 wafer batches (6 months) in a 250 C nitride

LPCVD tube furnace

4x improvement in seal life and reduced seal sticking

vs. silicone in a 300 C nitride process

Doubled seal life in a metal etch process compared to

other peruoroelastomers

Seal life improved 10x over silicone in a plasma asher

door seal at 130 C

Lower ionic extractables in a 100 C wet chemical

pump application

Over 6 months seal life in a large slit valve for Liquid

Crystal Display processing etcher

Over 3 months seal life in a 280 C diffusion furnace

application

8 months seal life (35% more than competitive custom slit

valve seal) for DuPont

Kalrez

TriLobe

in a TEOS PE-CVD

process

Doubled seal life with a Kalrez

seal in a plasma asher

8x to 14x improvement in seal life (over 3 months)

compared to a competitive peruoroelastomer in plasma

asher showerhead seals

Doubled seal life compared to a competitive

perfuoroelastomer in a PECVD slit valve application

Best overall performance in LPCVD using ClF

3

cleaning

gas (lower outgassing and particle generation)

DuPont

Kalrez

UltraPure

parts

offer lower contamination in reactive

plasmas and cleaning gases, improved

vacuum-sealing perfor mance and

lower outgassing. In addition, Kalrez

UltraPure

parts are manufactured

under clean-cell conditions and specially

cleaned and double packaged at Class

100 workstations. Kalrez

provides

long-term reliability in aggressive

plasmas, deposition, thermal and wet

processing applications, whether its

for wafer processing, photovoltaic

manufacturing processes, or at panel

display equipment.

Kalrez

parts are available in standard

AS568 O-ring sizes as well as metric and

JIS O-ring sizes. Sheet stock and custom

geometries are available for die-cut

gaskets or custom development.

8

9

DuPont

Kalrez

Parts Provide Superior Performance in Other Extreme Environments

Aircraft and aerospace

The ability to withstand extreme

temperatures makes DuPont

Kalrez

parts ideal for use in aircraft and

aerospace applications. Kalrez

parts also

withstand aggressive aerospace uids,

including jet fuels, engine lubricating oils,

hydraulic uids, rocket propellants and

oxidizers.

Kalrez

has proven its superior

performance for more than 40 years in

such applications as:

Aviation, marine and industrial gas

turbine engines

Auxiliary power units

Hydraulic actuators

Bleed air valves and fttings

In order to address the industrys need for

materials that withstand more aggressive

operating environments, the next

generation of aircraft/aerospace materials

were developed. These products, called

DuPont

Kalrez

AeroSeal

, deliver

outstanding thermal stability and

compression set resistance, and have

excellent seal force retention.

Oil and gas

Kalrez

parts stand up to severe

downhole conditionsfrom high

pressures and temperatures, to

aggressive sour gas and corrosive uids.

Blistering heat, corrosive uids and toxic

gases can destroy the physical properties

and sealing performance of other

materials.

Field-proven across the industry for over

40 years in applications such as:

Tubing-to-packer seals

Subsurface safety valves

Logging boots

Casing tie-back seals

Survey tool seals

Slip-joint seals

10

From Technical Assistance to Fast, Reliable Supply

You Get More than Just a Product

Latest updates

We provide our customers with

the latest information about

sealing performance.

Visit our website

www.dupontelastomers.com

and read or download the latest

product information. Check out

the DuPont Chemical Resistance

Guidean online tool that rates

the chemical resistance of all

elastomers, including DuPont

Kalrez

and DuPont

Viton

, in a

variety of chemi cals.

For more specic information

on Kalrez

including seal design,

contact us about the Kalrez

Application Guide, a unique

interactive software program.

Worldwide technical support and

testing facilities

We help you with the technical assistance

and support you might need to achieve

optimum results in the shortest possible

time. Our worldwide R&D expertise can

help you with:

Compound selection and seal design

Application testing and development

Failure analysis

On-site training

Fast delivery

Upon agreement and request, standard

O-rings and make-to-stock parts

can be delivered within 48 hours to

most European and North American

destinations. Ask our Sales and Customer

Service Representatives to nd out more.

In any shape you want

Standard O-rings in AS-568, metric

and JIS sizes

Customized O-rings in various

cross-sections and diameters

Valve seats, diaphragms, gaskets,

packer seals, T-seals, column

ttings, custom shapes

DuPont

Kalrez

KVSP

Valve Stem

Packing System

Customer-tailored solutions

Finite Element Analysis (FEA)

Advanced Finite Element Analysis offers

single-source analysis capability. From

designing new seal shapes with concurrent

analysis to groove geometry optimization,

FEA gives unequalled fexibility. It shortens

your product development lead times and

brings innovative solutions to the market.

Worldwide presence and network of

reliable distributors

Kalrez

parts are readily available through an

ex tensive network of worldwide-authorized

distributors. Our authorized distributors can

give you the technical assistance needed

to help solve your sealing problems. For

a complete list of authorized distributors,

please contact DuPont.

Visit the DuPont Chemical Resistance Guide at:

www.dupontelastomers.com

Technical support for achieving optimum results

Depend on DuPont elastomers for the support you need to achieve optimum results in the shortest possible time.

Our worldwide R&D and application expertise can help you with:

Process development Application testing New application development

The information set forth herein is furnished free of charge and is based on technical data that DuPont believes to be reliable and falls within the normal range of properties. It is intended for use by persons

having technical skill, at their own discretion and risk. This data should not be used to establish specication limits nor used alone as the basis of design. Handling precaution information is given with the

understanding that those using it will satisfy themselves that their particular conditions of use present no health or safety hazards. Since conditions of product use and disposal are outside our control, we

make no warranties, express or implied, and assume no liability in connection with any use of this information. As with any product, evaluation under end-use conditions prior to specication is essential.

Nothing herein is to be taken as a license to operate or a recommendation to infringe on patents.

Kalrez

peruoroelastomer parts are not routinely tested using the USP testing protocol. Cured samples made only from compounds 6221 and 6230 have been tested in accordance with USP protocols and meet

the requirements of a USP Class VI polymer. USP testing was done to support use of Kalrez

parts in pharmaceutical processing and food processing applications. While USP Class VI compliance materials are

not required for pharmaceutical and food processing applications, many pharmaceutical and food processing customers including customers seeking ISO 9000 certication, have requested compliance. Testing

of any nished article that incorporates Kalrez

peruoroelastomer parts is the responsibility of the manufacturer or seller of the nished article if certication that meets USP standards is required.

Caution: Do not use in medical applications involving permanent implantation in the human body. For other medical applications, discuss with your DuPont customer service representative and read

Medical Caution Statement H-50103-3.

Copyright 2010 DuPont. The DuPont Oval logo, DuPont

, The miracles of science

, Kalrez

, Kalrez

AeroSeal

, Kalrez

KVSP

, Kalrez

UltraPure

, Kalrez

Sahara

, Kalrez

Spectrum

, Kalrez

TriLobe

,

Vespel

, and Viton

are registered trademarks or trademarks of E.I. du Pont de Nemours and Company or its afliates. All rights reserved.

Reference Number KZS-A10105-00-A0710 Printed in the U.S.A.

Visit us at: kalrez.dupont.com or vespel.dupont.com

Contact DuPont at the following regional locations:

North America

800-222-8377

Greater China

+86-400-8851-888

Latin America

+0800 17 17 15

ASEAN

+65-6586-3688

Europe, Middle East, Africa

+41 22 717 51 11

Japan

+81-3-5521-8484

Das könnte Ihnen auch gefallen

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Von EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Bewertung: 4.5 von 5 Sternen4.5/5 (121)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryVon EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryBewertung: 3.5 von 5 Sternen3.5/5 (231)

- Grit: The Power of Passion and PerseveranceVon EverandGrit: The Power of Passion and PerseveranceBewertung: 4 von 5 Sternen4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaVon EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaBewertung: 4.5 von 5 Sternen4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItVon EverandNever Split the Difference: Negotiating As If Your Life Depended On ItBewertung: 4.5 von 5 Sternen4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerVon EverandThe Emperor of All Maladies: A Biography of CancerBewertung: 4.5 von 5 Sternen4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingVon EverandThe Little Book of Hygge: Danish Secrets to Happy LivingBewertung: 3.5 von 5 Sternen3.5/5 (400)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeVon EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeBewertung: 4 von 5 Sternen4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyVon EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyBewertung: 3.5 von 5 Sternen3.5/5 (2259)

- Shoe Dog: A Memoir by the Creator of NikeVon EverandShoe Dog: A Memoir by the Creator of NikeBewertung: 4.5 von 5 Sternen4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreVon EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreBewertung: 4 von 5 Sternen4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersVon EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersBewertung: 4.5 von 5 Sternen4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnVon EverandTeam of Rivals: The Political Genius of Abraham LincolnBewertung: 4.5 von 5 Sternen4.5/5 (234)

- Her Body and Other Parties: StoriesVon EverandHer Body and Other Parties: StoriesBewertung: 4 von 5 Sternen4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceVon EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceBewertung: 4 von 5 Sternen4/5 (895)

- The Unwinding: An Inner History of the New AmericaVon EverandThe Unwinding: An Inner History of the New AmericaBewertung: 4 von 5 Sternen4/5 (45)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureVon EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureBewertung: 4.5 von 5 Sternen4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealVon EverandOn Fire: The (Burning) Case for a Green New DealBewertung: 4 von 5 Sternen4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Von EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Bewertung: 4 von 5 Sternen4/5 (98)

- Learning Sanskrit in 30 DaysDokument110 SeitenLearning Sanskrit in 30 DaysJohn89% (28)

- Lululemon Sample Case AnalysisDokument49 SeitenLululemon Sample Case AnalysisMai Ngoc PhamNoch keine Bewertungen

- CompressDokument14 SeitenCompressAnonymous gfR3btyU0% (1)

- Google Cloud PlatformDokument17 SeitenGoogle Cloud PlatformAathithya MahendranathNoch keine Bewertungen

- BS 21-Pipe Thread PDFDokument22 SeitenBS 21-Pipe Thread PDFRaza AidanNoch keine Bewertungen

- Designing The Highway: Reported By: Juvy Ann Acabo Czarina AguilarDokument12 SeitenDesigning The Highway: Reported By: Juvy Ann Acabo Czarina AguilarCzarinaCanarAguilarNoch keine Bewertungen

- Donor's Tax Post QuizDokument12 SeitenDonor's Tax Post QuizMichael Aquino0% (1)

- Cracks Low Rise BuildingsDokument12 SeitenCracks Low Rise BuildingsHarilal Kishan100% (1)

- Iso 6164Dokument19 SeitenIso 6164adhityaNoch keine Bewertungen

- Leading With Emotional IntellegenceDokument10 SeitenLeading With Emotional IntellegencevvvasimmmNoch keine Bewertungen

- XC3000 Series Motion Control System of Laser Cutting Commissioning Manual TextDokument138 SeitenXC3000 Series Motion Control System of Laser Cutting Commissioning Manual Textgerardo.reynosoNoch keine Bewertungen

- ALEINDokument1 SeiteALEINadhityaNoch keine Bewertungen

- As 568Dokument15 SeitenAs 568adhityaNoch keine Bewertungen

- Sanskrit LearningDokument6 SeitenSanskrit LearningadhityaNoch keine Bewertungen

- Sanskrit IntroductoryDokument156 SeitenSanskrit IntroductoryHarish Bhavsar100% (2)

- SP42Dokument10 SeitenSP42Susavan MandalNoch keine Bewertungen

- Zwick 3103Dokument2 SeitenZwick 3103adhityaNoch keine Bewertungen

- Iso 3949Dokument15 SeitenIso 3949adhityaNoch keine Bewertungen

- 2015-16 Hose Tubes and Ducting SectionDokument98 Seiten2015-16 Hose Tubes and Ducting SectionadhityaNoch keine Bewertungen

- ASTM-D2000 How To Read PDFDokument3 SeitenASTM-D2000 How To Read PDFadhityaNoch keine Bewertungen

- A Rare Conversation Between Ramkrishna Paramahansa & Swami VivekanandDokument2 SeitenA Rare Conversation Between Ramkrishna Paramahansa & Swami Vivekanandadhitya100% (1)

- Front Matter PDFDokument2 SeitenFront Matter PDFadhityaNoch keine Bewertungen

- WILP BrochureDokument8 SeitenWILP Brochureshantanugulzar2452Noch keine Bewertungen

- Front Matter PDFDokument2 SeitenFront Matter PDFadhityaNoch keine Bewertungen

- Campbellcrimpnology Delivers The Only Comprehensive Package of Crimping Products in The IndustryDokument1 SeiteCampbellcrimpnology Delivers The Only Comprehensive Package of Crimping Products in The IndustryadhityaNoch keine Bewertungen

- Table of ContentsDokument4 SeitenTable of ContentsadhityaNoch keine Bewertungen

- Dendrite Adhesive Manufacturer Kolkata IndiaDokument1 SeiteDendrite Adhesive Manufacturer Kolkata IndiaadhityaNoch keine Bewertungen

- CAT Principal Bench OA No 1455 of 2013Dokument3 SeitenCAT Principal Bench OA No 1455 of 2013adhityaNoch keine Bewertungen

- Hydroblast WhitepaperDokument22 SeitenHydroblast WhitepaperadhityaNoch keine Bewertungen

- CAT Principal Bench OA No 1493 of 2014Dokument3 SeitenCAT Principal Bench OA No 1493 of 2014adhityaNoch keine Bewertungen

- Anamoly Committee of National JCM On 6th CPCDokument2 SeitenAnamoly Committee of National JCM On 6th CPCadhityaNoch keine Bewertungen

- Solar Backpack DesignDokument24 SeitenSolar Backpack DesignadhityaNoch keine Bewertungen

- CAT Principal Bench OA No 988 of 2014 Important For GopalaDokument7 SeitenCAT Principal Bench OA No 988 of 2014 Important For GopalaadhityaNoch keine Bewertungen

- ACP Issued On 4th October 2012Dokument2 SeitenACP Issued On 4th October 2012adhityaNoch keine Bewertungen

- Rigveda SandhyaavandanamDokument10 SeitenRigveda SandhyaavandanamShivprasad ShenoyNoch keine Bewertungen

- Narendra ModiDokument123 SeitenNarendra Modimrpradeep.eleNoch keine Bewertungen

- Gen. Coll.-2014fDokument8.152 SeitenGen. Coll.-2014fVeron Golocan Sowagen JovenNoch keine Bewertungen

- A Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Dokument10 SeitenA Thermoelectric Scanning Facility For The Study of Elemental Thermocouples Robin E Bentley - Meas. Sci. Technol. 11 (2000) 538-546Ver OnischNoch keine Bewertungen

- LC1D40008B7: Product Data SheetDokument4 SeitenLC1D40008B7: Product Data SheetLê Duy MinhNoch keine Bewertungen

- IELTS Speaking Forecast Tháng 1-4Dokument21 SeitenIELTS Speaking Forecast Tháng 1-4Toby ThomasNoch keine Bewertungen

- Release Notes Csi Bridge V 2020Dokument9 SeitenRelease Notes Csi Bridge V 2020Abdul KadirNoch keine Bewertungen

- Topic 7Dokument18 SeitenTopic 7Anonymous 0fCNL9T0Noch keine Bewertungen

- Pabon v. NLRCDokument4 SeitenPabon v. NLRCHaniyyah FtmNoch keine Bewertungen

- 12-24VDC Powered Ignition System: N N N N N N NDokument2 Seiten12-24VDC Powered Ignition System: N N N N N N NLeinner RamirezNoch keine Bewertungen

- BUSINESS PROPOSAL-dönüştürüldü-2Dokument15 SeitenBUSINESS PROPOSAL-dönüştürüldü-2Fatah Imdul UmasugiNoch keine Bewertungen

- Divisional Sec. Contact Details 2019-03-01-UpdateDokument14 SeitenDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Noch keine Bewertungen

- Course Outline of Lecturer Economics For Service Commissions TestDokument5 SeitenCourse Outline of Lecturer Economics For Service Commissions TestSheraz Ali KhanNoch keine Bewertungen

- Urban Jungle 8Dokument3 SeitenUrban Jungle 8Angel Medez GonzalezNoch keine Bewertungen

- 147380-1 Motoman XRC Controller Fieldbus (XFB01) Instruction ManualDokument102 Seiten147380-1 Motoman XRC Controller Fieldbus (XFB01) Instruction Manualrubi monNoch keine Bewertungen

- Improving The Passenger Experience: Monitoring Airport Quality of ServiceDokument6 SeitenImproving The Passenger Experience: Monitoring Airport Quality of ServiceParisa HadidianNoch keine Bewertungen

- SERVA 4-Axle Coiled Tubing Unit - Electric Over HydraulicDokument25 SeitenSERVA 4-Axle Coiled Tubing Unit - Electric Over HydraulicWilliamNoch keine Bewertungen

- Dorp Handbook and Plan EBCESDokument30 SeitenDorp Handbook and Plan EBCESJenelou delapenaNoch keine Bewertungen

- Psar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0Dokument183 SeitenPsar Techspec Autologicsoftwaretechspecfor Psarvehicles en PF v2.0PhatNoch keine Bewertungen

- Device Protocol - v2.2.4Dokument81 SeitenDevice Protocol - v2.2.4Aston MartinNoch keine Bewertungen

- Activity 3 Data SheetDokument9 SeitenActivity 3 Data SheetEli GabuatNoch keine Bewertungen

- Arbitrage Calculator 3Dokument4 SeitenArbitrage Calculator 3Eduardo MontanhaNoch keine Bewertungen

- DITS 2213 Final Exam OSDokument6 SeitenDITS 2213 Final Exam OSAmirul FaizNoch keine Bewertungen

- Writing Case StudyDokument2 SeitenWriting Case Studyerankit.sapNoch keine Bewertungen

- Toyota PDFDokument3 SeitenToyota PDFPushp ToshniwalNoch keine Bewertungen